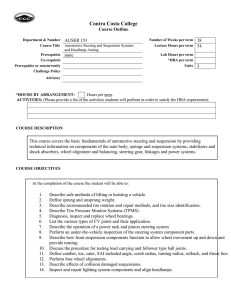

steering performance dependence on front suspension design

advertisement