Upstream Downstream Operations Data Appendix

advertisement

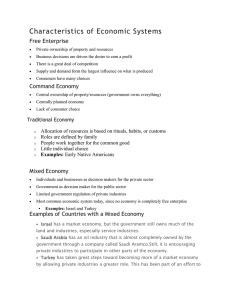

appendix 169 168 appendix Appendix Upstream Downstream Operations Data Top of reservoir dammam dome A 3-D reservoir model of the Dammam Dome from 2008 is aligned with the corresponding area from the first map of the Dammam Dome, drawn in 1934. Geological fault Reservoir porosity reflected in different colors reservoir quality The 3-D model illustrates the reservoir, roughly 1,500 meters below ground. Poor Good Excellent appendix 171 170 appendix Upstream The origins of hydrocarbons Upstream encompasses all the activities from the drill bit to the refinery: the Land Sea exploration for, and development, production and processing of, oil and gas. Water injection, oil stabilization, gas processing and pipelines are included within the scope of upstream operations. Upstream begins with earth scientists searching for oil and gas by examin- Tiny forms of sea life such as plankton die and accumulate on the ocean floor. ing rock outcrops on the surface to try to understand the subsurface strata. They integrate their interpretations with data collected from inside the well: from drill cuttings (bits of rock that rise to the surface as a well is drilled), core samples and wire-line logs (instruments that record electrical values, Layers of sediment form as the accumulation process continues over time. radioactivity, temperature and other rock properties). The integrated data are used to identify prospects—areas likely to contain petroleum. Once a prospect has been identified, geoscientists acquire and interpret seismic data to develop integrated geological and geophysical models that are used to select the best drilling locations. After a discovery is made, drilling to delineate and develop a field takes place, and reservoir engineers design production plans. Improvements in technology continue to increase recovery rates, enabling geoscientists and petroleum engineers to manage reservoirs efficiently and for the long term. Saudi Aramco also places significant emphasis on operations safety and environmental protection. The Origins of Oil and Gas Oil and gas originate almost entirely from the remains of ancient plants and animals as shown in the diagram on the facing page. The solar energy absorbed by Parts of the dead material change to hydrocarbons mixed with other sedimentary materials. Layers become more and more compresssed as further layers settle on top. these organisms and stored as carbon molecules in their bodies has been recycled into petroleum energy in the form of organic compounds composed mostly of hydrogen and carbon. These hydrocarbon compounds were created when microscopic marine organisms and plant matter were buried by layers of sediment and, over millions of years, transformed through bacteria, heat and pressure into oil and gas, which gradually seeped up through layers of rock, collecting in underground structures called traps. The fossilized remains of ancient marine organisms, seen in the core samples pulled up from wells thousands of meters deep and collected from rock outcrops on the surface, yield a wealth of clues to geologists searching for oil and gas. These specimens, as seen by a scanning electron microscope in EXPEC, are acritarchs, fossil marine organisms of unknown biological affinity, and date to the early Silurian age, about 430 million years ago. New material–depositing sediment forms an impervious layer called cap rock. Gas Oil Gas, oil and water Earth movements cause folds in the crust. appendix 173 172 appendix Stratigraphy of Eastern Saudi Arabia The rich oil and gas fields of Saudi Arabia, located mainly in the Eastern Province, are linked to the region’s long history of relative tectonic stability in its subsurface. The virtually flat platform of the Arabian Shelf, which underlies the middle and siberia eastern side of the Arabian Peninsula and its shallow eastern offshore area, enabled an almost uninterrupted accumulation of sediments, which provided both the source for oil and gas and the reservoirs in which these hydrocarbons accumulated. europe china turkey iran generalized cross section of saudi arabia tibet north america indochina southeast asia in millions of years africa sea level arabia south america –304.8m india The final 10 million years of the late Jurassic Period witnessed significant environmental changes, as shallow seas receded and advanced, leaving behind alternate layers of nonporous anhydrite and porous and permeable limestone. The latter layers formed the Arab Zone, which contains the world’s largest petroleum reserves. Over the course of millions of years, infrequent tectonic events led to the formation of structural traps, capped by anhydrite, which captured the hydrocarbons. e a r ly j u r a s s i c 1 9 5 m i l l i o n y e a r s a g o key The enormous hydrocarbon reservoirs in what became Saudi Arabia accumulated in carbonate sedimentary rocks deposited in the late Jurassic Period, around 150 million years ago. ancient Landmass –609.6m cretaceous period 67–140 million years ago australia a n ta r c t i c a limestone –914.4m 120 The Earth’s interior, composed of semi-molten rock, is in constant motion. The outer rigid layer, the lithosphere, consists of large plates Zubair Zone 130 Upper Ratawi Zone 135 Lower Ratawi Zone 140 Manifa Zone collide with each other in a process called plate tectonics, forming mountains, basins and the continents themselves. Arab B Member Arab C Member animals appeared in great numbers. About 100 million years later, in the early Devonian Period, the Paleozoic oceans began to close, and eventually the supercontinents of Gondwana and Euramerica collided to form Pangea. jurassic period which included the landmass of Arabia, stretched from the Equator to the South Pole, and it and the other continents were flooded by shallow seas. Algae were dominant, and hard-shell marine 140–204 million years ago Around 1.1 billion years ago in the Precambrian, the Earth’s landmasses formed one of Gondwana formed around 514 million years ago, in the late Cambrian Period. Gondwana, 150 In the last 20 million years, the Red Sea opened, rifting Arabia away from Africa. –2,133.6m –2,438.4m Hanifa Zone Hadriya Zone Fadhili Zone Jurassic Period, about 180 million years ago. This age was dominated by the giant dinosaurs, Jurassic Period, enormous layers of organic matter accumulated in what became Saudi Arabia. –1,524m Arab D Member Mid-Jubaila Zone Pangea began to break apart in three main episodes, with the first occurring in the middle the first appearance of birds and extensive inland seas where, 30 million years later, in the late porous limestone –1,219.2m –1,828.8m Arab A Member supercontinent, Rodinia, which, some 250 million years later, broke apart. The supercontinent sandstone Bahrain Zone that slide over the semi-molten layer. These plates pull apart from, slip past, dive under and anhydrite shale Modern Landmass seafloor spread ridge A Brief Geological Timeline of Saudi Arabia sand and mud 100 subduction zone (triangles point in the direction of subduction) key 165 –2,743.2m appendix 175 174 appendix Petroleum Traps Niyashin Rimthan As Sayd El Haba Reservoir rock and water Juraybi‘at Abu Hadriya Duhaynah Jaladi Bakr Faridah Manifa Kurayn Sharar Habari Watban Cap rock Maharah Ribyan Harqus Namlan Wari‘ah Gas Marjan Lawhah Hasbah Dibdibah Jauf Suban An anticline trap is an upward fold in the layers of rock shaped like an arch. Petroleum migrates into the highest part of the fold and is prevented from escaping by an overlying bed of impermeable cap rock. The great majority of oil reservoirs are found in anticline traps. Zuluf Safaniya Dhib Karan Jana Jurayd Rabib Berri Khursaniyah Fadhili Samin Hamur Arabiyah Abu Sa‘fah Qatif Oil bahrain Dammam Dhahran Fazran Jaham a Abqaiq r a b ia ‘Ain Dar n g ul f Shedgum Khurais Riyadh Gas Oil Reservoir rock and water Shiblah Hilwah Manjurah Farhah Awtad Warid Mazalij Sirayyan Sahba Dilam Arsan Abu Sanaman Shidad Raghib Wudayhi Midrikah Duayban Haradh Jufayn Dirwazah Niban Nujayman Halfa Nuayyim Muraiqib Abu Sidr Kassab Qamran Maghrib Sham‘ah ‘Amad Kahla Shaybah Shutfah North Ramlah Tukhman Waqr Ghinah Marzouk Jawb Zimlah Shaden Hawtah Lughfah Yabrin Abu Markhah Nisalah united arab e m i r at e s Tinat Mulayh Burmah Hazmiyah Harmaliyah Abu Rakiz Khuzama q ata r Ghawar Qirdi Hawiyah Abu Jifan Cap rock A fault is the result of horizontal layers of rock being folded or deformed, creating a fracture. When the rocks on the two sides of a fracture move in opposite directions, a fault is created. A fault trap occurs when formations on either side of a fault prevent further migration of petroleum. ‘Uthmaniyah Kidan Umm Jurf Usaylah South Layla Cap rock Gas Oil Stratigraphic traps occur when a reservoir layer, also called a bed, is sealed by other beds or by a change in porosity or permeability within the reservoir bed itself. Reservoir rock and water key Nearly all of Saudi Aramco’s oil and gas fields are located in the Eastern Province. Other fields are located in the Central Province, south of Riyadh, and in the Western Province, on the Red Sea coast. Total recoverable crude oil reserves are roughly 260 billion barrels—the largest in the world. Reserves of natural gas are roughly 279 trillion cubic feet, fourth largest in the world. Jalamid Towns C a p i ta l oil field Kahf gas field scale in kilometers 0 50 Sidr Midyan Barqan 100 scale in kilometers 100 200 se 0 d Oil and gas are formed in organic-rich layers of rock exposed to heat and Tabuk re Petroleum Traps oil and gas fields of saudi arabia a pressure, called source rock. The oil and gas will migrate upward through the rock layers where, Umluj Al Wajh if conditions are favorable, they will accumulate in reservoirs, layers of porous and permeable rock such as limestone or sandstone. The migration of hydrocarbons to the surface is stopped by an impermeable layer of rock that acts as a seal, or cap. Oil and gas accumulate only where the reservoir and cap rock form traps. Geologists classify petroleum traps into two basic types: structural traps, formed by Earth movements and rock folds, and stratigraphic traps, the result of the deposition of layers favorable to the formation and trapping of petroleum. Two common examples of structural traps are anticline and fault traps. e s t i m at e d w o r l d w i d e c r u d e o i l r e s e r v e s e s t i m at e d w o r l d w i d e g a s r e s e r v e s (billion barrels) as of january 1, 2010 (trillion cubic feet) as of january 1, 2010 260 saudi arabia 211 VENEZUELA 175 137 115 CANADA IRAN IRAQ 1,680 Russia 1,045 Iran 895 qatar 279 saudi arabia 265 TURKMENISTAN appendix 177 176 appendix Exploration The professionals in Saudi Aramco’s Exploration organization cover Saudi Arabia on a scale that extends from wide swaths of desert, basins and mountains to the micron level. They also consider a fourth dimension in their quest: time, which they measure in the hundreds of millions of years. A new road, cut through a hill, allows a young geologist to map rock layers near al-‘Ula, Saudi Arabia. The Fossil Record Core samples, drill cuttings, plugs (a kind of mini-core pulled from the Sedimentologists and carbonate geologists in Saudi Aramco’s Core Lab study the separate layers, or beds, within hydrocarbon reservoirs as revealed by core samples. Thin sections are cut from the core samples and examined by company micropaleontologists, who look for fossils of marine and land organisms, and by palynologists, who look for ancient pollens and spores. This short interval of a core sample, pulled from 1,468 meters deep in the Shaybah field, shows the contact between crude oil and gas. The light brown section of the core is filled with Arabian Super Light crude oil while the gray section is from the gas column of the reservoir, above the oil column. The limestone core is composed of fragments of an ancient bivalve, and the oil and gas are stored in the inter-particle pore spaces between the shell fragments. larger core) and thin sections mounted on slides are examined by geoscientists. The rock yields a wealth of knowledge about the reservoir: porosity and permeability, basic and structural geology, petroleum physics, stratigraphy, sedimentology and other data. Geoscientists are especially interested in microfossils such as pollens, spores, protists (one-celled organisms, including algae, dinoflagellates and others) and Foraminifera—organisms with calcium carbonate shells. The fossil record illustrates the historical environment of Arabia: from shallow, warm seas during the Jurassic Period to glaciers and ice sheets when Arabia, in its continental wandering, was located near the South Pole. Fossil remains of the single-celled aquatic organisms known as Foraminifera serve as excellent records of the environment and geologic age of the rock layers in which they are found. Foraminifera, with their hard exoskeletons, small size, short reproductive cycles, prolific numbers and wide distribution over marine environments, are especially valuable fossil clues. A hydrocarbon reservoir is similar to a sponge soaked with oil and gas. Two key factors in a reservoir’s potential productivity are how big the holes in the sponge are and how they connect, known as porosity and permeability. Using a scanning electron microscope, company scientists can examine the reservoir rock at the 2- to 5-micron level, close enough to see the individual pores in the stone, and better understand the porosity and permeability of the reservoir. The rock on the left reveals poor reservoir quality, while the sample on the right shows excellent porosity and good permeability. appendix 179 178 appendix Company earth scientists and petroleum engineers use the latest in 3-D reservoir simulation technology in the Upstream Professional Development Center in Dhahran. Such technology provides a better understanding of prospects before an exploratory drilling program begins, and in reservoir development, it helps delineate fields and place wells to optimize production. Seismic Imaging Seismic surveying is used in conjunction with structure drilling in the search for oil and gas. Sound waves, produced by mechanical vibrators mounted on the underside Reservoir Characterization Reservoir characterization plays a critical role throughout the productive life of an oil or gas field. Every producing reservoir has a reservoir simulation model that of large trucks, penetrate layers of rock thousands of meters beneath the Earth’s surface. The is continually updated with new drilling and production data and is used to develop and evaluate sound waves are reflected back to the surface where their altered waveforms are recorded as alternative reservoir management strategies. Because of the huge size and large well spacing of raw seismic data. This information is manipulated by powerful computers to produce an image Saudi Arabia’s hydrocarbon resources, Saudi Aramco has developed its own reservoir simulator, of the underground rock formations. POWERS (Parallel Oil Water and Gas Reservoir Simulator), to produce 3-D geo-cellular models, comprising billions of individual cells. These reservoir models are used in reserves estimation and reservoir simulation models, which are also used to evaluate proposed well locations. appendix 181 180 appendix Reservoir Nano-agents: Resbots™ One promising avenue of research in reservoir manage- ment is the development of nano-scale reservoir robots, called Resbots. Company researchers are studying the feasibility of deploying Resbots, 1/1,000th the size of a human hair, with the fluids injected into a hydrocarbon reservoir. Resbots would gather information about reservoir properties, including pressure, temperature and fluid type, in onboard memory. The Resbots would be retrieved through production wells and the data downloaded and analyzed, helping delineate the extent of the reservoir, map fractures and faults in the rock, define areas of higher permeability, identify bypassed oil, optimize well placement and help design even more precise A multilateral well extends multiple branches within the hydrocarbon reservoir. Multilateral wells improve well productivity and reduce field development costs by requiring fewer wells to produce a field. geological models of the reservoir. For the Resbots concept, the Exploration and Petroleum Engineering Center (EXPEC) Advanced Research Center won the prestigious New Horizons Idea Award at the 2008 World Oil Awards. Drilling and Reservoir Engineering Drilling is conducted for both exploration and production purposes. Structure drilling is used to determine key subsurface strata. Wildcat wells are drilled to test whether oil or gas is present in the structures that geologists have recommended. Once a new field has been discovered, a number of delineation wells are drilled some distance apart in order to outline the configuration and size of the field. Finally, the field is put into production by drilling development wells in a pattern recommended by petroleum engineers. Water injection wells inject treated seawater to maintain reservoir pressure. Drilling technology has come a long way since the early days of the industry. Directional drilling was first introduced in the 1920s, driven by the need to drill from difficult onshore sites Geologists direct well drilling from Saudi Aramco’s Geosteering Center in Dhahran as real-time information is transmitted from sensors near the drill bits. The center operates 24 hours a day, seven days a week. and, later, from offshore platforms. Horizontal wells became popular in the 1980s and were developed for deeper wells in the 1990s. A horizontal well penetrates a reservoir bed across the target zone, rather than down through it, improving recovery rates. More recent developments include multilateral wells, with multiple junctions like the branches of a tree. Drilling wells, whether for exploration, delineation, production or water injection, is at the heart of the petroleum industry. A maximum reservoir contact (MRC) well is a multilateral horizontal well with more than five kilometers of total contact with the reservoir rock. Such wells also employ “smart” well features that enable a reservoir management team to intervene remotely. For example, the team can shut off one lateral without disturbing the remaining laterals. Smart wells also include downhole sensors, which provide real-time monitoring of the well, helping optimize production and reservoir management. A further refinement of the MRC is the extreme reservoir contact (ERC) well, a smart multilateral well that does not require individual control lines from the wellhead on the surface to each lateral. This allows an unlimited number of smart laterals, which can be remotely controlled using real-time data. The Geosteering Operations Center (GOC) in Dhahran is staffed by teams of geologists and engineers who monitor drilling operations anywhere in the field. They analyze downhole data in real time to remotely guide drilling activities and ensure that each well is optimally placed. appendix 183 182 appendix Oil & Gas Production and Processing Gas Production and Processing Natural gas is processed to produce clean fuel (methane, or For a diagram of Saudi Aramco’s oil and gas production operations and a map of production sales gas) and feedstock (methane, ethane, propane, butane and natural gasoline). Sales gas and facilities, see the Operations Data section. ethane are consumed entirely by Saudi Arabia’s utilities and industry. Excess propane, butane and natural gasoline (collectively known as NGL) that are not used by the domestic petrochemicals Saudi Aramco’s oil and gas production operations encompass Saudi Arabia, including territorial waters in the Arabian Gulf and the Red Sea. Totaling more than 1.5 million square industry are exported to world markets. kilometers, this area is larger than the combined areas of Texas, California, Oklahoma and Utah, or of France, Spain and Germany. gas production Oil Production and Processing Most oil-producing wells are free-flowing with a typical oil Sales Gas NGL flow rate of 5,000 bpd. Once the oil is extracted, it is piped to a gas-oil separation plant (GOSP) Gas Plant where water and the majority of dissolved gases are extracted. The remaining oil is then sent to a stabilization facility, such as the Abqaiq Plants, for final gas separation and removal of hydrogen Sulfur sulfide. The extracted gas is sent to Gas Operations facilities for additional processing, while the water is injected back into the ground. This oil is now dry (no water), sweet (no hydrogen sulfide) Oil Gas GOSP Condensate and stabilized (no gas), and can be refined or exported. This gas-oil separation plant (GOSP) is one of four that perform the initial processing of oil from the Shaybah field. Gas Gas Oil Saudi Aramco’s Master Gas System (MGS) is fed with two types of gases: the gases associated with crude oil that are removed by the gas-oil separation plants (GOSPs), and the non-associated gases that come from gas wells that do not produce crude oil. Gas processing involves removing the hydrogen sulfide (H2S) and carbon dioxide (CO2) to produce sweet gas, and separating sales gas (methane) from the heavier components. The heavier products are liquefied and pumped to NGL plants for fractionation and final delivery to customers. The H2S is converted to elemental sulfur and sold to domestic and export markets. Water Water Associated Gas Non-Associated Gas Basic process of Gas Plants Condensate Sour Associated Gas Sour Non-Associated Gas Condensate Stripper Low Pressure Amine High Pressure Amine Acid Gas Sweet Gas Fluids produced from an oil well are typically under pressure and comprise oil, dissolved gas, salty water and some hydrogen sulfide. This mixture is sent to a gas-oil separation plant (GOSP) for initial processing. At the GOSP, a pressure step-down process releases most of the dissolved gas. A desalting process then removes the salt water. The resulting sour crude oil is then sent for stabilization. Inlet for oil/water/gas mixture Sulfur Recovery Unit Compression Gas outlet Water Gas Liquid Sulfur Dehydration Foam Oil Cooling Emulsion Water NGL Recovery Water outlet Oil outlet NGL Sales Gas In the gas plant, gas is received at slugcatchers, which separate condensate and water from gas and capture liquid ”slugs.“ These slugs, traveling at high velocity, may damage piping systems. Condensate liquids go to the stripping section, where H2S and water are removed. The separated sour gas feed goes to the gas treating modules, where, via contact with alkylamine, the H2S and CO2 are stripped away, creating sweet gas. The sweet gas is compressed and chilled to separate ethane and heavier gases. The H2Sand CO2-rich gas, now referred to as acid gas, is sent to the sulfur plants where H2S is converted to elemental sulfur, recovered and made into solid pellets for domestic and export sales. appendix 185 184 appendix Pipelines Saudi Aramco operates a pipeline network nearly 20,000 kilometers long—roughly equivalent to the flying distance between Rome and Sydney—including flow lines from oil and gas wells, water injection pipelines and systems for refined products distribution. Major crosscountry pipelines include the Saudi Arabia–Bahrain Pipeline and the East-West Crude Oil and NGL pipelines to Yanbu‘ on the Red Sea. The NGL pipeline linking Yanbu‘ and Shedgum is the longest and most advanced gas line ever built—1,170 kilometers long. Downstream Downstream encompasses all the activities that occur after crude oil and gas have been produced and initially processed. The fractionation of natural gas liquids (NGL), the refining of crude oil and the petrochemical industry are downstream activities. Shipping and distribution of crude oil and refined products are also included within this scope. OSPAS The Oil Supply Planning and Scheduling (OSPAS) organization is the nerve center for the movement of all of Saudi Aramco’s crude oil, natural gas and refined products. OSPAS plans, schedules, coordinates and monitors the quantity—and quality—of millions of barrels of crude oil every day of the year from the wellhead to company terminals. OSPAS also tracks refined product movements from seven refineries, 19 bulk plants, 18 air refueling sites, five strategic storage facilities and 1,600 kilometers of refined products pipeline. It also tracks gas and NGL from six gas plants, three fractionation centers and more than 5,000 kilometers of pipeline. Saudi Aramco also operates 44 export berths at five marine ports, loading millions of barrels of oil and refined products each day onto supertankers destined for ports in the world’s three major energy markets: Asia, North America and Europe. Within OSPAS, the “Big Board” of the Operations Coordination Center (OCC) tracks the movement of oil, gas, NGL and refined products, and also oversees terminal operations and electrical power distribution. Operators in the Operations Coordination Center can, at a glance, see the entire scope of the company’s hydrocarbon production and distribution operations. With the click of a mouse, operators can check the status of individual pipeline valves, the feed rate of a distillation column at a refinery, the volume of a storage tank or the loading status of a supertanker. Terminals Saudi Aramco’s enormous storage tank farms and shipping terminals supply crude oil, NGL and refined products to customers around the globe. Every year, more than 9,000 tankers call at company terminals at Ras Tanura and Ju‘aymah on the Arabian Gulf, and at Yanbu‘, Jiddah and Rabigh on the Red Sea. The Ras Tanura Terminal consists of the South Pier, the North Pier and the Sea Islands. The South Pier, currently abandoned, is where Saudi crude oil was first loaded onto the tanker D. G. Scofield in May 1939. The North Pier, connected to the mainland by a 1,200-meterlong causeway and trestle, operates six berths for the loading of crude oil, refined products and refined liquid petroleum gasses (RLPG). The Ras Tanura Sea Islands are a complex of man-made islands approximately 1½ kilometers northeast of the North Pier. The four Sea Islands (one of which is decommissioned) each feature a loading station for crude oil and bunker fuel (to power marine vessels) and two berths. Six supertankers of up to 500,000 deadweight tons can load simultaneously. In addition to linking wells to processing plants, Saudi Aramco’s pipeline system delivers crude oil, gas, NGL and refined products to domestic industries and utilities and to company export terminals. appendix 187 186 appendix Refining Crude oil is a mixture of hydrocarbon molecules, the simplest of which, methane, is one carbon atom linked with four hydrogen atoms. The three principal groups of hydrocarbon compounds that occur naturally in crude oil are paraffins, aromatics and naphthenes. The refining process begins with the distillation, or fractionation, of crude oil into separate hydrocarbon groups. Each hydrocarbon fraction has its own boiling point. The light fractions, CH4– Methane (Natural Gas) such as kerosene, have low boiling points while heavier fractions, such as fuel oil, have high boiling points. In the refining process, crude oil is heated in a distillation column, and the vapors resulting from the boiling are drawn off and condensed. The fractions produced by a distillation column are only the products that are in the crude oil to begin with—to produce more of a desired fraction, such as gasoline, refineries must add conversion processes. The earliest conversion process was thermal cracking, in which the heavy fractions of crude oil are heated to a high temperature and the hydrocarbon molecules “cracked” to release C 3H8– Propane the lighter fractions, gasoline, for example. In visbreaking, residual (heavy oils leftover from the distillation process) is heated, cooled with gas oil and rapidly burned or flashed. Visbreaking reduces the viscosity of heavy oils and produces tar. Coking involves heating residual, but at higher temperatures than visbreaking, until it cracks into heavy oil, gasoline and naphtha. The heavy, almost pure carbon residue left behind is called coke and is also a commercial product. Gas Naphtha* Reflux Crude Oil Distillation Column * For processing into gasoline or petrochemicals ** For further processing into jet fuel Kerosene** A crude oil loading line is lifted into place aboard a supertanker calling at the Ju‘aymah Offshore Terminal in the Arabian Gulf. The Ju‘aymah Offshore Terminal is a crude oil and bunker fuel loading facility designed Light Diesel Oil for loading and topping off deep-draft tankers. The loading facilities are roughly 29 kilometers north-northwest of Ras Tanura and 11 kilometers offshore. The largest supertankers afloat C16H34– Diesel take on cargo from six single-point moorings (SPM), each with a crude oil loading rate of up to 130,000 barrels per hour. There is also a two-berth RLPG loading facility at Ju‘aymah, accessible from the shore via a 10-kilometer trestle. Light fractions of crude oil, such as methane and butane, are drawn from the top of the distillation column, while heavier molecules, such as diesel, come from lower in the column. Heavy Diesel Oil The Yanbu‘ crude oil terminal consists of four loading berths, two of which can be used Furnace simultaneously for a combined loading rate of 300,000 barrels per hour. Ships taking on cargo at Yanbu‘ for Europe or North America can save about 7,400 kilometers (4,000 nautical miles) per round trip, compared with sailing around the Arabian Peninsula from Ras Tanura or Ju‘aymah. The Yanbu‘ NGL Plant has an associated two-berth RLPG terminal that can also handle natural gasoline tankers. The nearby Yanbu‘ Refinery also has its own terminal, consisting of four berths for loading fuel oil and marine diesel for cargo or bunker, motor diesel oil, regular and premium gasoline, jet fuel, kerosene, naphtha and RLPG. Fuel Oil The Jiddah Terminal imports crude oil for the Jiddah Refinery and exports finished and unfinished naphtha, kerosene, jet fuel, diesel, premium gasoline and fuel oil from four crude oil and refined product berths and five bunker loading berths. Steam Saudi Aramco also operates smaller bulk plant marine terminals at Jazan and Duba. Asphalt Crude Oil The fractional distillation of crude oil is the first step in the refining process, which yields a range of products, including petroleum gas (methane, ethane, propane and butane); naphtha; gasoline; kerosene; gas oil or diesel distillate, used to make diesel fuel and heating oil; lubricating oil; fuel oil; and residuals such as coke, asphalt, tar and waxes. appendix 189 188 appendix The Saudi Aramco Shell Refinery Co. (SASREF), a joint venture between Saudi Aramco and Shell, operates this refinery complex in Jubail. Catalytic cracking involves the use of a solid material, called a catalyst, mixed with the oil to help Company (SATORP), a venture with Total of France, will be located in Jubail, and the Red Sea Refining crack the heavier fractions. The process of hydrocracking adds high-pressure hydrogen gas to catalytic Co., a subsidiary of Saudi Aramco, will be located in Yanbu‘. The third project is a company-owned cracking, producing additional volumes of gasoline and other light fractions. Catalytic reforming uses refinery and terminal in the Jazan region of southwestern Saudi Arabia. Internationally, Saudi Aramco, a catalyst to combine low-weight naphtha into aromatics, which are used in blending gasoline and through subsidiary offices, is a joint or equity venture partner in refineries in the United States, the making chemicals. Republic of Korea, China and Japan. The various products from the distillation and cracking processes must be treated to remove The Ras Tanura Refinery is the most complex refinery in the company’s domestic portfolio. The undesirable compounds, such as sulfur, and to meet various performance and environmental specifica- refinery includes facilities for crude oil stabilization and distillation, NGL processing, gas condensate tions. distillation, hydrocracking, visbreaking and catalytic reforming. Saudi Aramco operates four domestic refineries, at Riyadh, Ras Tanura, Yanbu‘ and Jiddah, and owns 50 percent of two domestic joint-venture refineries, with ExxonMobil in Yanbu‘ (SAMREF) The Yanbu‘ Refinery is a hydroskimming plant, which is more complex than a topping refinery, and it produces liquefied petroleum gas, gasoline, jet fuel, diesel oil and fuel oil, mainly for the domestic and with Shell in Jubail (SASREF). Saudi Aramco also has a 37.5 percent stake in Petro Rabigh, with market. The Jiddah Refinery features catalytic cracking and a catalytic reformer, and is a key supplier Sumitomo Chemical Co. holding 37.5 percent and the Saudi public 25 percent. Work is also under of fuel to the Jiddah and Makkah areas, especially during peak demand periods such as Ramadan and way on three additional refining complexes. Two of the projects are 400,000-bpd full-conversion Hajj. The Riyadh Refinery, like the Jiddah facility, contains a vacuum column, which permits processing refineries integrated with petrochemical facilities: The Saudi Aramco Total Refining and Petroleum of the heavier crude fractions. The Riyadh plant also features a hydrocracker and a catalytic reformer. appendix 191 190 appendix Gas Fractionation Natural gas liquids recovered at the gas plants are sent to the NGL frac- Distribution In addition to the giant storage tank farms that feed shipping terminals with crude tionation plants at Yanbu‘, Ju‘aymah and Ras Tanura for further processing. Typically, NGL plants oil, NGL and refined products, Saudi Aramco operates a vast network of bulk plants and air fueling receive ethane plus NGL in a combined feed from the gas plants via pipelines. The NGL is then units strategically located throughout Saudi Arabia. Overall capacity of the company’s storage pumped to the de-ethanizer columns in the fractionation modules, where the ethane is separated facilities for all hydrocarbons is roughly 200 million barrels. Pipelines, marine crude oil tankers, overhead as a vapor product. The ethane is sent to consumers as petrochemical feedstock or product carriers and trucks are the principal delivery systems for the company’s petroleum and injected into the sales gas system. The heavier gas at the bottom of the de-ethanizer column is petroleum products. fractionated in additional steps, yielding propane, butane, natural gasoline, hexane and pentane. Through its 19 bulk plant operations, Saudi Aramco annually supplies around 375 million Natural gasoline and pentane are blended and sent to refining, while the hexane and heavier barrels of refined products to about 5,000 domestic bulk customers. Compliance reviews and components are used as feedstock for petrochemical plants. periodic spot checks are conducted to assist in maintaining product quality and to assure operations compliance with established safety and environmental policies and procedures. Approximately 2,000 trucks are used to transport refined products over the Kingdom’s 150,000 kilometers of highways. The use of these trucks, which are subject to strict safety and quality standards, is being minimized as Saudi Aramco replaces them with new pipeline systems. Shipping vessels account for almost all of Saudi Aramco exports of crude oil, NGL and refined products and are also used to transport hydrocarbons to supply and distribution facilities on the Red Sea. The company’s shipping subsidiary, Vela International Marine Limited, was established in 1984, when rights to Vela’s name and four existing tankers were acquired. Vela currently operates a fleet of 17 very large crude carriers (VLCCs), each capable of carrying 2.1 million barrels of crude oil. Vela also owns and operates five product tankers that perform coastal trade in the Red Sea and the Arabian Gulf. Overall, Vela ships make roughly 1,000 voyages per year—83 percent of which are international, with the remainder domestic—safely transporting roughly 2 million bpd. The Master Gas System, which handles more than 9 billion standard cubic feet per day of gas, provides fuel and feedstock to domestic industries, such as this plant in Jubail. The sales gas (methane) system is extensive, covering large areas of Saudi Arabia from coast to coast. Adding to its complexity is the integration and interdependence of the three main systems: oil, gas and NGL. The sales gas system depends greatly on oil production, since associated gas represents a significant part of the system feed. It is also fully integrated into the NGL system, since any NGL component recovered during processing causes a reduction in the sales gas supply. Sales gas is piped to more than 54 industrial customers, including power, desalination and petrochemical plants, throughout the Eastern, Central and Western provinces of Saudi Arabia. The Ju‘aymah and Yanbu‘ gas plants receive ethane (C2) plus NGL, and Ras Tanura receives propane (C3) plus NGL for fractionation and sweetening. The Ju‘aymah plant also receives C3 plus NGL streams from the Berri Gas Plant and the Qatif and Abqaiq crude stabilization facilities. The Ju‘aymah and Yanbu‘ gas plants produce ethane, propane, butane and natural gasoline products, while the Ras Tanura Refinery produces all but ethane. The Ju‘aymah facility also has a depentanizer column and associated facilities necessary for the delivery of a hexane (C6) stream to petrochemical customers in Jubail. Propane is primarily used as petrochemical feedstock in the industrial cities of Yanbu‘ and Jubail and the excess is exported. Butane is used as domestic petrochemical feedstock and is also exported as a liquid. NGL products are used to produce more than 50 petrochemical products and are sold to customers in more than 100 countries worldwide. The Saiph Star, a doublehull crude oil carrier, joined the Vela fleet in 2009. appendix 193 192 appendix Petrochemicals The petrochemical industry traces its roots to World War II, when the demand The next year, Saudi Aramco and The Dow Chemical Co. began exploring the possibility of for synthetic materials rose due to shortages of, and lack of access to, natural resources. Before building a petrochemical complex. The proposed joint venture, to be located in the Jubail industrial the war, petrochemicals were an experimental sector: synthetic rubbers were developed in the area, is perhaps the largest and most complex project in Saudi Aramco’s downstream portfolio. early 1900s; Bakelite, the first petrochemical-derived plastic, in 1907; and polystyrene in the The project proposal includes chemicals and plastics production units and an associated conversion 1930s. Today, petrochemicals are found in furniture, kitchen appliances, medical equipment, park for local and foreign private-sector companies to build industries to use the products. automobiles, airplanes and ships, soaps and detergents, solvents, drugs, fertilizers, pesticides, computers, paints, epoxies, clothing and shoes, flooring and insulating materials, cosmetics, luggage, and recording disks and tapes. The final destination of most crude oil is the fuel tank of a vehicle, whether a motorcycle, car, truck, airplane or train. Saudi Aramco exports of crude oil power the transportation industries in Europe, North America and Asia— in this case, China. Natural Gas Crude Oil NGL Methane Xylenes Benzene petrochemical products: olefins (mainly ethylene, propylene and the C4 derivatives, including butadiene) and aromatics (benzene, toluene, xylene and naphthalene). A significant proportion of the basic petrochemicals are converted into polymers: polyethylene, polyvinyl chloride and polystyrene, all derived from ethylene, and polypropylene, derived from propylene. Polymers are used in plastics, synthetic rubbers and synthetic fibers, such as polyester, nylon and acrylic. Beginning in the 1990s with a series of international joint and equity ventures in refining and marketing, Saudi Aramco has been transforming itself from a crude oil producing and exporting company into an integrated petroleum enterprise, with activities all along the value chain. The Ethane C4 box* Propylene Ethylene Olefins Xylenes Toluene Benzene Pygas C4 box* Propylene Ethylene Solvents, dyes, fibers and films used in products such as polyester fibers and plastics and in plasticizers, substances that make plastics more flexible and are used in medical tubing and blood bags, toys and footwear. Industrial chemicals used in coatings, sealants, adhesives, paints and the foam used in furniture, bedding, car seats and building insulation. Plastics used in boats, cars, computers, food containers and packaging, construction materials, nylon, toys, carpets, shampoo, cleaning products, emulsifiers and pharmaceuticals. Used for gasoline blending or as feedstock. Synthetic rubbers and plastics used in such products as automotive parts, tires, aviation gasoline and the gasoline additive MTBE. Resins, fibers and plastics used in such products as detergents, solvents, varnishes, super-absorbent materials, acrylic fibers, pharmaceuticals, cosmetics and food packaging. Plastics, polyesters and synthetic rubber used in products such as luggage, appliances, automotive parts, footwear, flooring and tires. most recent development in the company’s transformation is the petrochemical sector. The goal is to create more value from Saudi Arabia’s hydrocarbon resources, principally by bringing petrochemicals processing and manufacturing to the Kingdom rather than exporting commodity petrochemicals petrochemicals to foreign markets where they are used in associated industries. The petrochemical industry converts crude oil and natural gas into basic petrochemical building blocks that, in turn, are used to produce consumer goods ranging from heart valves to raincoats. Pygas LPG a r o m at i c s among others. These feedstocks are then further cracked to create the basic building blocks for Toluene Methane Petrochemical facilities receive their raw material, known as feedstocks, from refineries and NGL and gas plants. Feedstocks include ethane, naphtha, propane, butane and hexane, Associated Gases Naphtha In March 2006, Saudi Aramco and Sumitomo Chemical Co. of Japan broke ground on the Petro Rabigh joint venture, one of the world’s largest integrated refining and petrochemical facilities. The complex commenced operations in early 2009 and has the capacity to produce 18.4 million tons of high-value petroleum products and 2.4 million tons of ethylene- and propylene-based petrochemical derivatives per year. An associated industrial city will use the materials produced by Petro Rabigh to manufacture a wide range of products for local and international consumption. *Butylene, butadiene and derivatives appendix 195 194 appendix Safaniya Jubail Tanajib Nariya Ju‘aymah Ras Tanura Qatif Dammam Dhahran Khursaniyah Berri iraq Operations Data Domestic Operations Map ■ International Operations Map ■ Oil and Gas Operations ■ Production and Workforce History Shedgum Turaif Badanah jordan ■ Abqaiq al-Jawf al-Hasa Khurais Sakaka Dawmat al-Jandal kuwait Hafar al-Batin Qaisumah Tayma Duba ‘Udhailiyah ‘Uthmaniyah Rafha Tabuk al-Wajh Qurayyah Safaniya Tanajib Hayil Haradh al-Khafji Jubail Nariya al-‘Ula Buraydah Ras Tanura Qatif Dammam Abqaiq Dhahran Hofuf al-Zilfi ‘Unayzah Khaybar al-Hasa Yanbu‘ il pi pel ine Riyadh crude o east-west al-Dawadimi ine al-Kharj ngl pipel east-west Madinah Khurais Hawiyah Salwah Haradh saudi arabia united arab e m i r at e s Rabigh Layla Jiddah Makkah Tayif oman al-Sulayyil al-Bahah Bishah Tathlith Abha Khamis Mushayt Najran ash-Sharawrah Jazan yemen d o m e s t i c o p e r at i o n s key Towns d o m e s t i c r e f i n e ry major crude oil pipeline C a p i ta l j o i n t / e q u i t y v e n t u r e r e f i n e ry major ngl pipeline s e a w at e r t r e at m e n t p l a n t crude oil terminal trans-Arabian pipeline gas processing plant refined products terminal S h ay b a h - a b q a i q p i p e l i n e I n t e g r at e d r e f i n e r y a n d petrochemical plant domestic refined products terminal major oil processing complex domestic refined products d i s t r i b u t i o n fa c i l i t y ngl terminal oil field gas field scale in kilometers 0 200 appendix 197 196 appendix >S-Oil Corporation Seoul republic of korea >Saudi Petroleum Overseas Ltd. >Aramco Overseas Company B.V. London Toyko >Saudi Petroleum Ltd. >Aramco Overseas Company B.V. >Showa Shell Sekiyu K.K. j a pa n The Hague | Aramco Overseas Company B.V. Rotterdam >Texaco Esso AOC Maatschap >TEAM Terminal B.V. at l a n t i c O c e a n Saudi Petroleum Ltd. Beijing > Aramco Overseas Company B.V. New Delhi Aramco Overseas Company B.V. Shanghai > Fujian Refining and Petrochemical Co. Ltd. Pa c i f i c O c e a n > Sinopec SenMei (Fujian) Petroleum Co. Ltd. Fujian Okinawa Hong Kong > Aramco Overseas Company B.V. > Saudi Aramco Sino Co. Ltd. New York City Saudi Petroleum International Ltd. Washington, D.C. Aramco Services Company Singapore Saudi Petroleum Ltd. indian Ocean u n i t e d s tat e s > Aramco Services Company > Saudi Refining Inc. > Motiva Enterprises LLC Sidi Kerir Houston Ain Sukhna SUMED Arab Petroleum Pipelines Co. LOOP Aramco Gulf Operations Co. Ltd. al-Khafji > Luberef > Saudi Aramco Mobil Refinery Co. Ltd. (SAMREF) > MARAFIQ Yanbu‘ > MARAFIQ Jubail | > Saudi Aramco Shell Refinery Co. (sasref) Dhahran Ju‘aymah Ras Tanura Rabigh | Petro Rabigh Thuwal saudi arabia Jiddah > Luberef > Jiddah Oil Refinery Co. i n t e r n at i o n a l o p e r at i o n s key Towns Saudi Aramco Headquarters a f f i l i at e , s u b s i d i a r y o r joint/equity venture long-term storage and t e r m i n a l fa c i l i t i e s m a r a f i q : E l e c t r i c i t y a n d W at e r U t i l i t y f o r J u b a i l a n d Ya n b u ‘ Luberef: Saudi Aramco L u b r i c at i n g O i l R e f i n e r y C o . loop: Louisiana offshore oil port lightering areas ports p r i n c i pa l e x p o r t r o u t e s v e l a s h i pp i n g r o u t e s Dubai Vela International Marine Limited appendix 199 198 appendix Abu Hadriya Zuluf Qatif Shaybah Khursaniyah Ghawar Berri Marjan Abu Sa‘fah Safaniya Berri Abqaiq Khursaniyah Haradh Hawiyah Harmaliyah Qatif Qatif ‘Uthmaniyah Shedgum Ras Tanura Abqaiq Hawiyah Yanbu‘ Jubail Abqaiq Tapline MARAFIQ Dhahran Tanks Jubail*** Ras Tanura Khurais Bahrain* Ras Tanura Ju‘aymah Yanbu‘ Ras Tanura Ju‘aymah Yanbu‘ Central Arabian Fields Yanbu‘ Ras Tanura Ju‘aymah Riyadh Yanbu‘** Petro Rabigh Jiddah SWCC MARAFIQ key g a s o p e r at i o n s o i l o p e r at i o n s The crude oil produced by Saudi Aramco from both onshore and offshore fields first goes to gas-oil separation plants for removal of gases, water and salt, after which it is sent for further processing at stabilizers or refineries. Most of the crude oil is delivered to tankers at Ras Tanura, Ju‘aymah or Yanbu‘. key oil Field r e f i n e ry gosp: gas-oil s e pa r at i o n p l a n t i n t e g r at e d r e f i n e r y a n d petrochemical plant s ta b i l i z e r plant terminal Local customer *The refinery in Bahrain is not a Saudi Aramco facility. **Two Yanbu‘ refineries (one joint venture) *** Joint venture Gas produced with crude oil is collected from gas-oil separation plants and fed to gas processing plants. There, impurities are removed, hydrogen sulfide is recovered for conversion into elemental sulfur, and sweet, dry gas is extracted for use as an industrial fuel or feedstock. From gas processing centers at Shedgum, Hawiyah, Khursaniyah and ‘Uthmaniyah, NGL (natural gas liquids) and ethane are piped to plants at Yanbu‘ and Ju‘aymah for fractionation. After removal of the ethane, the NGL is further fractionated into LPG (propane and butane) and natural gasoline. Gas produced independently of crude oil (non-associated gas) is processed at the Haradh and Hawiyah gas plants for delivery into the sales gas system. The Hawiyah NGL Plant processes sweet gas from the Hawiyah and Haradh gas plants. NGL from the Berri Gas Plant goes to Ju‘aymah or Ras Tanura for fractionation. LPG is exported from Yanbu‘ and Ju‘aymah. From the fractionation plants, ethane is delivered to the industrial complexes at Yanbu‘ and Jubail for use as a petrochemical feedstock. n o n - a s s o c i at e d gas wells gosp: gas-oil s e pa r at i o n p l a n t Gas Plant marafiq: electricity a n d w at e r u t i l i t y for jubail and ya n b u ‘ N G L : n at u r a l g a s liquids plant swcc: saline w at e r c o n v e r s i o n c o r p o r at i o n industrial complex terminal f r a c t i o n at i o n p l a n t o t h e r i n d u s t ry saudi electric c o m pa n y Average daily production of crude oil and NGL s a u d i a r a m c o p r o d u c t i o n h i s t o ry 1 9 3 8 – 2 0 1 0 (thousands of barrels) key crude oil N at u r a l G a s L i q u i d s 2010 2009 2008 2007 2006 2005 2004 2003 2002 2001 2000 1999 1998 1997 1996 1995 1994 1993 1992 1991 1990 1989 1988 1987 1986 1985 1984 1983 1982 1981 1980 1979 1978 1977 1976 1975 1974 1973 1972 1971 1970 1969 1968 1967 1966 1965 1964 1963 1962 1961 1960 1959 1958 1957 1956 1955 1954 1953 1952 1951 1950 1949 1948 1947 1946 1945 1944 1943 1942 1941 1940 1939 1938 6,826.94 141.42 8,343.95 184.78 9,016.95 219.45 8,066.11 253.11 9,251.08 309.26 9,631.37 369.23 9,623.83 448.17 6,327.22 429.50 4374.30 330.10 3,922.08 355.07 3,041.10 316.31 4,689.80 304.18 3,991.00 344.92 4,928.10 416.21 4,863.53 420.95 6,257.56 533.23 8,053.40 586.74 8,156.57 622.06 7,854.74 639.76 7,833.28 687.93 7,807.63 731.85 7,864.83 756.15 7,751.93 767.45 8,006.24 764.83 7,274.05 737.35 7,800.07 778.71 7,570.64 801.05 6,792.32 868.32 8,103.45 945.43 8,610.58 1,058.14 9,064.62 1,096.94 8,912.17 1,093.24 8,531.91 1,081.00 8,924.14 1,098.92 7,912.56 1,123.96 7,910.20 1,219.30 1,520.70 2.90 1,629.02 5.80 1,716.11 11.01 2,024.87 13.87 2,392.74 15.56 2,597.56 20.40 2,829.98 38.47 2,992.66 46.17 3,548.87 52.12 4,497.58 52.07 5,733.40 54.07 7,334.65 97.12 8,209.71 137.63 1,392.52 1,247.14 1,095.40 1,015.03 992.11 986.13 965.04 953.00 844.64 824.76 761.54 546.70 476.74 390.31 246.17 164.23 58.39 21.30 13.34 12.41 11.81 13.87 10.78 1.36 200 appendix appendix 201 key saudi e x pat r i at e t o ta l w o r k f o r c e s a u d i a r a m c o w o r k f o r c e h i s t o ry 1 9 3 5 – 2 0 1 0 ( at y e a r - e n d ) 2010 2009 2008 2007 2006 2005 2004 2003 2002 2001 2000 1999 1998 1997 1996 1995 1994 1993 1992 1991 1990 1989 1988 1987 1986 1985 1984 1983 1982 1981 1980 1979 1978 1977 1976 1975 1974 1973 1972 1971 1970 1969 1968 1967 1966 1965 1964 1963 1962 1961 1960 1959 1958 1957 1956 1955 1954 1953 1952 1951 1950 1949 1948 1947 1946 1945 1944 1943 1942 1941 1940 1939 1938 1937 1936 1935 48,053 7,013 47,741 7,057 10,636 3,334 12,432 4,390 14,931 5,451 15,187 6,543 16,740 8,787 17,894 16,755 21,839 20,413 26,321 24,260 29,753 27,885 33,067 28,165 34,226 24,736 34,882 23,273 33,382 18,209 31,906 13,958 31,623 12,555 32,085 12,399 31,712 12,216 32,106 11,582 32,900 12,948 33,847 13,008 34,615 14,107 44,938 12,548 46,180 11,596 12,216 5,408 46,133 10,347 46,172 9,360 45,586 8,490 46,315 8,186 45,869 8,208 46,496 7,991 46,365 7,589 45,505 7,015 44,991 6,852 44,702 6,654 45,464 6,629 47,502 6,939 115 26 1,076 62 548 54 2,745 340 3,178 463 2,668 382 1,647 193 1,654 171 2,692 190 7,585 1,475 8,087 3,379 7,297 2,684 12,018 4,879 12,226 7,379 10,026 6,099 10,767 6,734 13,786 8,852 14,819 10,273 14,051 9,393 14,665 8,782 13,844 8,091 13,671 7,535 13,222 6,635 12,572 6,076 12,216 5,408 11,660 4,296 11,442 3,558 11,341 3,124 10,892 2,998 10,805 2,999 10,793 2,958 10,761 2,848 10,294 2,678 9,894 2,483 9,438 2,213 9,133 2,099 9,109 2,225 9,590 2,575 54,798 55,066 54,441 52,093 51,356 51,843 52,520 53,954 54,487 54,077 54,501 54,076 55,532 56,345 56,480 57,776 57,486 48,722 46,855 45,848 43,688 43,928 44,484 44,178 45,864 51,591 58,155 58,962 61,232 57,638 50,581 42,252 34,649 25,527 21,730 20,382 16,822 13,970 12,165 11,334 11,232 11,651 12,377 12,972 13,609 13,751 13,804 13,890 14,465 15,000 15,956 17,624 18,648 19,857 21,206 21,935 23,447 23,444 25,092 22,638 17,501 16,125 19,605 16,897 9,981 11,466 9,060 2,882 1,825 1,840 3,050 3,641 3,085 602 1,138 141 202 appendix appendix 203