CL-F0016(AP) Mild Facial Cleanser: Soap-Based

advertisement

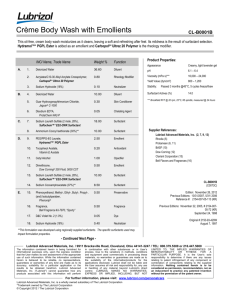

Mild Facial Cleanser: Soap-Based CL-F0016(AP) Carbopol®* Aqua SF-1 Polymer provides stabilization and enhanced pearlescence to this facial cleanser formula, which contains a high level of free fatty acid. Hydramol™* PGDS Ester serves as a light conditioner and also enhances viscosity. A. INCI Name, Trade Name Weight % Function Lauric Acid, POFAC-1299 5.33 Fatty Acid Soap Myristic Acid, Edenor® C14 98/100 4.00 3. Stearic Acid, 1801 10.67 Fatty Acid Soap 4. Cetearyl Alcohol (and) Ceteareth-20, Promulgen™* D Emulsifier 2.00 Emulsifier 5. Methylparaben 0.20 Preservative 6. Deionized Water 5.53 Diluent 7. Potassium Hydroxide (91.5 %) 4.12 Neutralizer 8. Glycerin 15.00 Humectant 9. Propylene Glycol 5.00 Humectant 10. Sodium Lauroyl Sarcosinate (30 %)** 25.00 Surfactant 11. Cocamidopropyl Betaine (30 %)** 5.00 Surfactant 12. PEG-90 Diisostearate, Hydramol™* PGDS Ester 1.00 Conditioner 13. Disodium EDTA 0.05 Chelating Agent 14. Deionized Water 2.00 Diluent 15. Acrylates Copolymer (30 %), Carbopol®* Aqua SF-1 Polymer 5.00 Rheology Modifier 16. Deionized Water 10.00 Diluent 17. Fragrance, Fragrance Youhuo 173 0.10 Fragrance 1. 2. : B. C. D. E. F. Fatty Acid Soap Product Properties: Appearance Pearlized viscous white cream pH (10% aqueous dilution) 8.8 – 9.2 Viscosity (mPa·s)*** 45,000 – 55,000 Yield Value (dyn/cm²) 2,000 – 2,500 Stability Passed 3 months @ 45°C Passed 5 freeze/thaw cycles Carbopol®* Aqua SF-1 Polymer Actives (wt.%) 1.5 Soap (wt.%) 24.0 Surfactant Actives (wt. %) 9.0 *** Brookfield DV-II @ 20 rpm, @ 25°C #7 spindle, after 24 hours Supplier References: Southern Acid (1, 3) Cognis (2) Lubrizol Advanced Materials, Inc. (4, 12, 15) UENO (5) Sinopharm (8, 9) Givaudan (17) CL-F0016(AP) (CLF-004) Edition: November 14, 2012 Reference # SHPWR05173 Book #: APPC-006-03-78 (RS) Previous Editions: 11/2/2007, 6/8/2006 **This formulation was developed using regionally supplied surfactants. The specific surfactants used may impact formulation properties. Original Edition: Jan. 2006 - Continued Next Page - Lubrizol Advanced Materials, Inc. / 9911 Brecksville Road, Cleveland, Ohio 44141-3247 / TEL: 800.379.5389 or 216.447.5000 The information contained herein is being furnished for informational purposes only, upon the express condition that the User makes its own assessment of the appropriate use of such information. While the information contained herein is believed to be reliable, no representations, guarantees or warranties of any kind are made as to its accuracy, suitability for a particular application or the results to be obtained herefrom. Lubrizol Advanced Materials, Inc. ("Lubrizol") cannot guarantee how any products associated with this information will perform in combination with other substances or in User’s process. Due to the variations in methods, conditions and equipment used commercially in processing these materials, no warranties or guarantees are made as to the suitability of the information/products for the applications disclosed. Lubrizol shall not be liable and the User assumes all risk and responsibility for, any use or handling of any material beyond Lubrizol's direct control. LUBRIZOL MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. It is the User’s sole responsibility to determine if there are any issues relating to patent infringement of any component or combination of components relating to the supplied information. Nothing contained herein is to be considered as permission, recommendation, nor as an inducement to practice any patented invention without the permission of the patent owner. For further information, please visit: www.lubrizol.com/personalcare Lubrizol Advanced Materials, Inc. is a wholly owned subsidiary of The Lubrizol Corporation *Trademark owned by The Lubrizol Corporation © Copyright 2012 / The Lubrizol Corporation Mild Facial Cleanser: Soap-Based Procedure: 1. PART A: Melt ingredients maintaining the temperature at 75°C. 2. PART B: Add Potassium Hydroxide to water, and heat to 75°C with agitation. Mix until dissolved. Add Glycerin & Propylene Glycol. Mix well for a minimum of 15 minutes. 3. Add PART B quickly to PART A with high speed agitation. Keep the temperature at 80-85°C and maintain moderate mixing for 60 minutes. 4. After saponification is complete, add PART C (Ingredients 10, 11, 12) with agitation. Mix until the batch is homogenous. 5. PART D: In a separate vessel, disperse Disodium EDTA into deionized water. 6. PART E: In a separate vessel, disperse Carbopol®* Aqua SF-1 Polymer into deionized water with gentle agitation. 7. Cool main batch (PARTS A, B, C) to 55-60°C. Add PARTS D & E. Mix until uniform. 8. Maintain a temperature of the batch at 45-50°C for 20 minutes. Then begin cooling. 9. When temperature is at 35°C, add PART F ingredient to batch. Mix until uniform. Mix for 15-30 minutes until the formula is uniform. CL-F0016(AP)