CO-0012(IN) Coconut Enriched Hair Color Cream (Natural Black)

advertisement

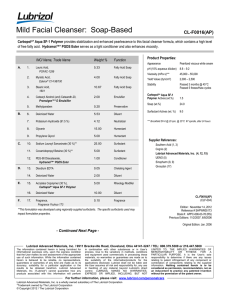

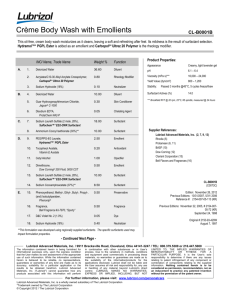

Coconut Enriched Hair Color Cream (Natural Black) CO-0012(IN) In today’s fast-moving fashionable world, where covering grey hair and using different hair colors is in the trend, the Indian consumer continues to trust in gentle care from ancient days by using coconut oil on hair, believed to give nutrition and nourishment. Introducing for the first time hair color enriched with coconut oil to balance fashion with care, Chromapol™* 5 polymer in hair color allows products such as cream format with cold process which encourages customers to do-it-yourself, whereas Merquat™* 2003PR polymer in the formulation leaves conditioned hair post coloring along with coconut oil. This formulation is for natural black hair color; it is a color base to be mixed with a developer. INCI Name, Trade Name Weight % Function Appearance Off-white thick viscous cream pH 9.0 – 9.5 Viscosity (mPa·s)** 45,000 – 50,000 1. Distilled Water 2. Propylene Glycol 5.00 Humectant 3. p-Phenylenediamine, Para Phenylenediamine 1.28 Oxidative Colorant 4. Resorcinol, Resorcinol 0.80 Oxidative Colorant 5. m-Aminophenol, Meta Aminophenol 0.12 Oxidative Colorant Chromapol™* 5 Polymer (% TS): 1.5 Merquat™* 2003PR Polymer (% TS): 0.2 6. 2,4-Diaminophenoxyethanol HCL, 2,4-Diaminophenoxyethanol HCL (DPE 2 HCL) 0.20 Oxidative Colorant **Brookfield Programmable DV-III+ Rheometer spindle #6 @ 20 rpm, 25 °C @ 24 hours 7. N,N-Bis(2-Hydroxyethyl)-p-Phenylenediamine Sulfate, N,N-Bis(2-Hydroxyethyl)-p-Phenylenediamine Sulphate (HED) 0.16 Oxidative Colorant 8. Sodium Sulfite, Sodium Sulphite 0.30 Stabilizer 9. Ascorbic Acid, Ascorbic Acid / Vitamin C 0.30 Stabilizer 10. Sodium Hydrosulfite, Sodium Dithionite 0.10 Stabilizer 11. Distilled Water C. 12. Ethanolamine, Monoethanolamine 3.00 Neutralizer D. 13. Acrylates/Beheneth-25 Methacrylate Copolymer (30% TS), Chromapol™* 5 Polymer 5.00 Rheology Modifier 14. Distilled Water 26.94 Carrier / Vehicle 15. Coconut Oil 20.00 Oil Phase 16. Polyquaternium-53 (21% TS), Merquat™* 2003PR Polymer 1.00 Conditioning Agent 17. Distilled Water 5.00 Carrier / Vehicle 18. PEG-40 Hydrogenated Castor Oil, Cremophor® RH 40 0.60 Perfume Solubilizer 19. Perfume, Perfume Cool Smiles D 1308603 0.20 Perfume A. :B. E. F. 20.00 10.00 Carrier / Vehicle Product Properties: Carrier / Vehicle Stability: Passed 3 months @ RT, 45 °C and 50 °C, passed 5 cycles freeze/thaw Supplier References: Chemstar India (3, 4, 5, 6, 7) Lubrizol Advanced Materials, Inc. (13, 16) BASF (18) Mane India (19) CO-0012(IN) Based on CO-0009A(IN) Edition: February 9, 2015 Reference #: NP0100 006-12, #80 (SAKG) Original Edition: January 5, 2015 - Continued Next Page Lubrizol Advanced Materials, Inc. / 9911 Brecksville Road, Cleveland, Ohio 44141-3247 / TEL: 800.379.5389 or 216.447.5000 The information contained herein is being furnished for informational purposes only, upon the express condition that the User makes its own assessment of the appropriate use of such information. While the information contained herein is believed to be reliable, no representations, guarantees or warranties of any kind are made as to its accuracy, suitability for a particular application or the results to be obtained herefrom. Lubrizol Advanced Materials, Inc. ("Lubrizol") cannot guarantee how any products associated with this information will perform in combination with other substances or in User’s process. Due to the variations in methods, conditions and equipment used commercially in processing these materials, no warranties or guarantees are made as to the suitability of the information/products for the applications disclosed. Lubrizol shall not be liable and the User assumes all risk and responsibility for, any use or handling of any material beyond Lubrizol's direct control. LUBRIZOL MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. It is the User’s sole responsibility to determine if there are any issues relating to patent infringement of any component or combination of components relating to the supplied information. Nothing contained herein is to be considered as permission, recommendation, nor as an inducement to practice any patented invention without the permission of the patent owner. For further information, please visit: www.lubrizol.com/personalcare Lubrizol Advanced Materials, Inc. is a wholly owned subsidiary of The Lubrizol Corporation *Trademark owned by The Lubrizol Corporation or its affiliates © Copyright 2015 / The Lubrizol Corporation Coconut Enriched Hair Color Cream (Natural Black) Procedure: 1. Add distilled water and propylene glycol in PART A to a main mixing vessel. Mix until uniform. 2. In a separate vessel, add PART B ingredients (dyes, stabilizers and distilled water). Mix until uniformly dispersed. 3. Add premix PART B ingredients to main mixing vessel. Mix until uniformly dispersed. 4. Add PART C ingredient (neutralizer – monoethanolamine) into main mixing vessel. Mix until uniform. 5. In a separate vessel, mix PART D ingredients (Chromapol™* 5 polymer and distilled water). Then add coconut oil and mix until uniform. Then add premix PART D ingredients to main mixing vessel. Mix until uniform. 6. In a separate vessel, mix PART E ingredients (Merquat™* 2003PR polymer and distilled water). Then add premix PART E ingredients to main mixing vessel and mix until uniform. 7. In a separate vessel, mix PART F ingredients – perfume solubilizer and perfume. Mix until uniform. 8. Add premix PART F ingredients to main mixing vessel. Mix until uniform. NOTE: In the presence of sulfated dyes being used in the formulation, it is recommended to neutralize them before the addition of Chromapol™* 5 polymer. This will avoid the precipitation of dyes in the formulation. CO-0012(IN)