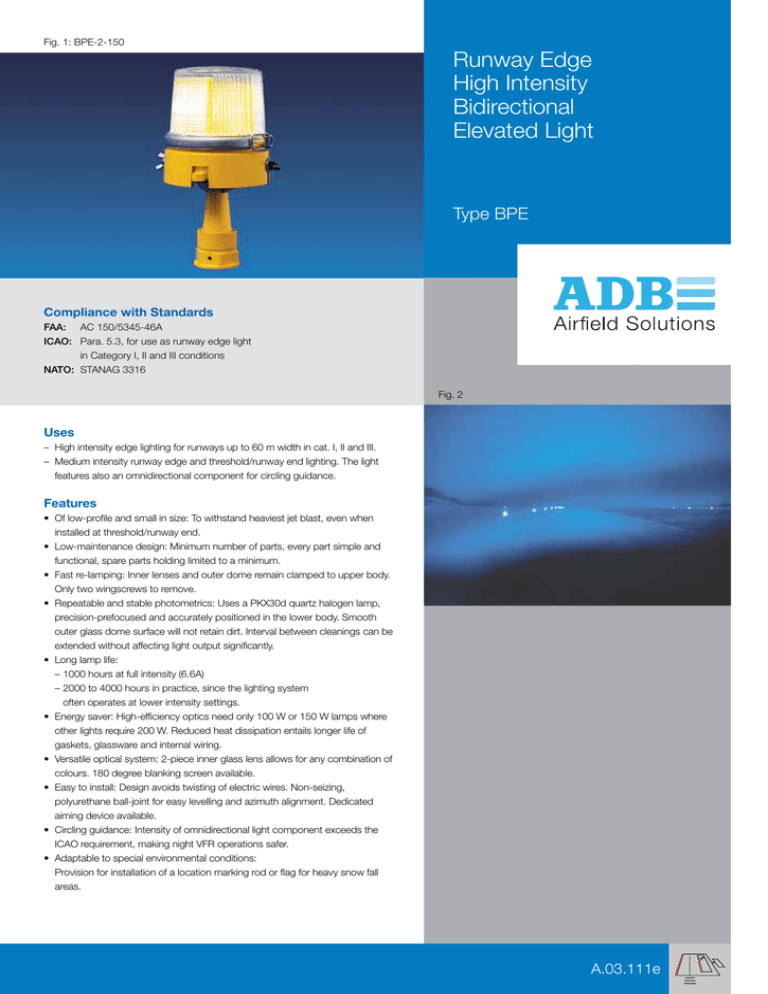

Fig. 1: BPE-2-150

Runway Edge

High Intensity

Bidirectional Elevated Light

Type BPE

Compliance with Standards

FAA: AC 150/5345-46A

ICAO: Para. 5.3, for use as runway edge light

in Category I, II and III conditions

NATO: STANAG 3316

Fig. 2

Uses

– High intensity edge lighting for runways up to 60 m width in cat. I, II and III.

– Medium intensity runway edge and threshold/runway end lighting. The light

features also an omnidirectional component for circling guidance.

Features

• Of low-profile and small in size: To withstand heaviest jet blast, even when

installed at threshold/runway end.

• Low-maintenance design: Minimum number of parts, every part simple and

functional, spare parts holding limited to a minimum.

• Fast re-lamping: Inner lenses and outer dome remain clamped to upper body.

Only two wingscrews to remove.

• Repeatable and stable photometrics: Uses a PKX30d quartz halogen lamp,

precision-prefocused and accurately positioned in the lower body. Smooth

outer glass dome surface will not retain dirt. Interval between cleanings can be

extended without affecting light output significantly.

• Long lamp life:

–1000 hours at full intensity (6.6A)

–2000 to 4000 hours in practice, since the lighting system often operates at lower intensity settings.

• Energy saver: High-efficiency optics need only 100 W or 150 W lamps where

other lights require 200 W. Reduced heat dissipation entails longer life of

gaskets, glassware and internal wiring.

• Versatile optical system: 2-piece inner glass lens allows for any combination of

colours. 180 degree blanking screen available.

• Easy to install: Design avoids twisting of electric wires. Non-seizing,

polyurethane ball-joint for easy levelling and azimuth alignment. Dedicated

aiming device available.

• Circling guidance: Intensity of omnidirectional light component exceeds the

ICAO requirement, making night VFR operations safer.

• Adaptable to special environmental conditions:

Provision for installation of a location marking rod or flag for heavy snow fall

areas.

A.03.111e

Construction (Fig. 3)

Fig. 3

1.Outer dome, glass, externally smooth.

2.Positioning ring for inner lenses.

3.180° Inner prismatic lenses, glass, through-coloured or clear.

4.O-ring gasket – Heat resistant.

5.Clamping ring – Stainless steel.

6.Upper body, die-cast aluminium alloy.

7.Lamp, quartz halogen, prefocus PKX30d.

8.Lower body, die-cast aluminium alloy.

9.Wire strain reliever

10.Ball joint, polyurethane

11.Frangible stem, die-cast aluminium alloy.

12.2-pole plug to FAA L-823 with heat resistant wires.

1

2

7

3

4

8

9

10

5

6

Finish

11

Phosphating and baked polyester electrostatic powder coating.

Colour: aviation yellow

Stainless steel hardware.

12

Electrical Supply

6.6 A, through a 100, 150 or 200 W isolating transformer.

See catalogue leaflet A.06.110.

Fig. 4

Photometric Performances

Vert.

Degr.

Lamp: 100, 150 or 200 W – 6.6 A prefocus halogen lamp –

PKX30d 1000 hours rated life at full intensity.

White Light – 150 W lamp – Toe-in 3.5 °

500CD

20

BPE-2-150

Colour

Lamp

(W)

Aver.

Intens.

Cd.

Beam spread

Horiz.

Vert.

Runway edge

ICAO 45m

White

150

13326

-2 to 9°

0 to 7°

ICAO 45m

White

200

14505

-2 to 9°

0 to 7°

ICAO 60m

White

150

11413

-2 to 11°

0 to 7°

ICAO 60m

White

200

13586

-2 to 11°

0 to 7°

ICAO 60 m

Yellow

150

6016

-2 to 11°

0 to 7°

FAA L-862

White

150

13700

-2 to 9°

0 to 7°

White

200

14900 -2 to 9°

0 to 7°

Runway edge M.I.

White

100

8463

-2 to 9°

0 to 7°

Threshold M.I.

Green

100

1711

-2 to 7.5°

2 to 7°

Green

100

1777

-1.5 to 1.5°

3.5 to 5.5°

Red

100

1365

-4.5 to 4.5°

0.2 to 1°

Runway edge

Threshold M.I.

FAA L-861

Runway End M.I.

Runway end

ICAO

Red

150

3203

-6 to + 6° 0.25 to 4.75°

ICAO

Red

200

4160

-6 to + 6° 0.25 to 4.75°

Notes:1)45 W – 6.6 A – lamp available for solving specific cases.

Contact factory for performance figures.

2)Outside main beams, intensity in white light never falls below 50 cd from 0 to 15 degrees vertical. This meets ICAO and FAA requirements for circling guidance purposes.

3)Omnidirectional blue dome available on request.

16

1000CD

500CD

1000CD

12

8

5000CD

5000CD

4

0

-20 16

12

8

4

0

4

8

12 +16

Hor.

degr.

Installation

Installation

– On conduit elbow TC2. (Fig. 5) or anchor stake PA 2

(see cat. leaflet A.05.111).

– On mounting plate T300/3 (see cat. leaflet A.05.111).

– On L-867 steel base. (Fig. 6 – see cat. leaflet A.05.120).

The stability has to be ensured through appropriate means (e.g. concrete).

Levelling and aiming in azimuth of the light are easily performed with the

dedicated aiming device supplied on request.

Ordering Code

BPE 2 150 C/Y S

Lamp rating

Fig. 5

Fig. 6

100W

Fig. 7: Outline Dimensions (mm)

= 100

150W

= 150

200W

= 200

Colour

Clear

Yellow

Red Green

Blank

165

=C

= Y =R

= G = N left beam*

right beam*

*see Fig. 8

Accessories and options

– Aiming device.

– Snow flag.

300

280

Special requirements to be specified in full text

Complete, delete or modify as necessary

Packing Data

2” GAS

11 TPI

BPE-2-150, without inner lenses nor lamp; net weight: 2.7 kg

4 each In cardboard box 70 x 40 x 24 cm;

gross weight: 11.5 kg.

N.B. Inner lenses and lamps are packed separately.

Fig. 8: Colour Coding

Yellow on left-hand as side seen from here

C/C

C

Y

R

G

N

Y/C

Y/C

Runway Centre line

C/Y

C/Y

C/C

Yellow on right-hand side as seen from here

Clear

Yellow

Red

Green

blank

Arrow on

outer dome

Suggested Specification

The light shall be suitable for direct installation

on any standard mounting system with 2“ 11 TPI tapped hole. The optical system

shall consist of a double lens. Its outer

component shall have an externally smooth

surface to prevent accumulation of dirt. The

inner lens shall be in two halves, throughcoloured when required. The light shall resist

jet blast from the heaviest present day aircraft

and shall be frangible in case of impact.

Registered Office:

ADB

Airfield Solutions

Leuvensesteenweg 585

B-1930 Zaventem

Belgium

Phone: +32 (2) 7221711

Fax: +32 (2) 7221764

info.adb@adb-air.com

www.adb-air.com

© ADB

all rights reserved

order number DOCA03111EV2

subject to modifications

www.comith.be

The Runway Edge Light shall be high intensity,

elevated, in full compliance with FAA L-862

specification (AC 150/5345-46A) and with

ICAO Annex 14, Vol. I, para. 5.3. for use

in Category I, II and III systems and with

STANAG 3316. The prefocus halogen lamp

shall be 150 W, 6.6 A, rated life not less than

1000 hours at full intensity. The lamp shall be

fitted with lamp retaining clips and fool proof

positioning device. Overall height of the light,

when installed, shall not exceed 300 mm and

its total weight shall be 3 kg or less. The light

shall consist of alu­-minium alloy castings, heat

resistant glass optical parts and plain stainless

hardware. Gaskets and electrical wiring shall

be high temperature resistant. It shall be

possible to level and aim the light without need

for special tools.