CCS Ready Policy: Considerations and Recommended Practices for

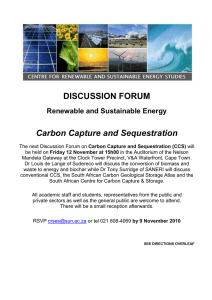

advertisement