Oil & Gas

Application Note

Inlet-Residue-NGL Solutions

for Natural Gas Processing Applications

To optimize the efficiency and profitability of your natural gas

processing plant you must account for the changing composition of

the inlet gas as well as adjust the natural gas liguid (NGL) extraction

efficiency to account for marketing conditions. The Inlet-ResidueNGL application for the 700XA gas chromatograph (GC) analyzes

the inlet gas and the two product streams in a single field-mounted

analyzer to provide real-time feedback to the control system

and the operators. Using the live compositions from a single gas

chromatograph enables tight control of product specifications

thereby maximizing the economic return of the facility.

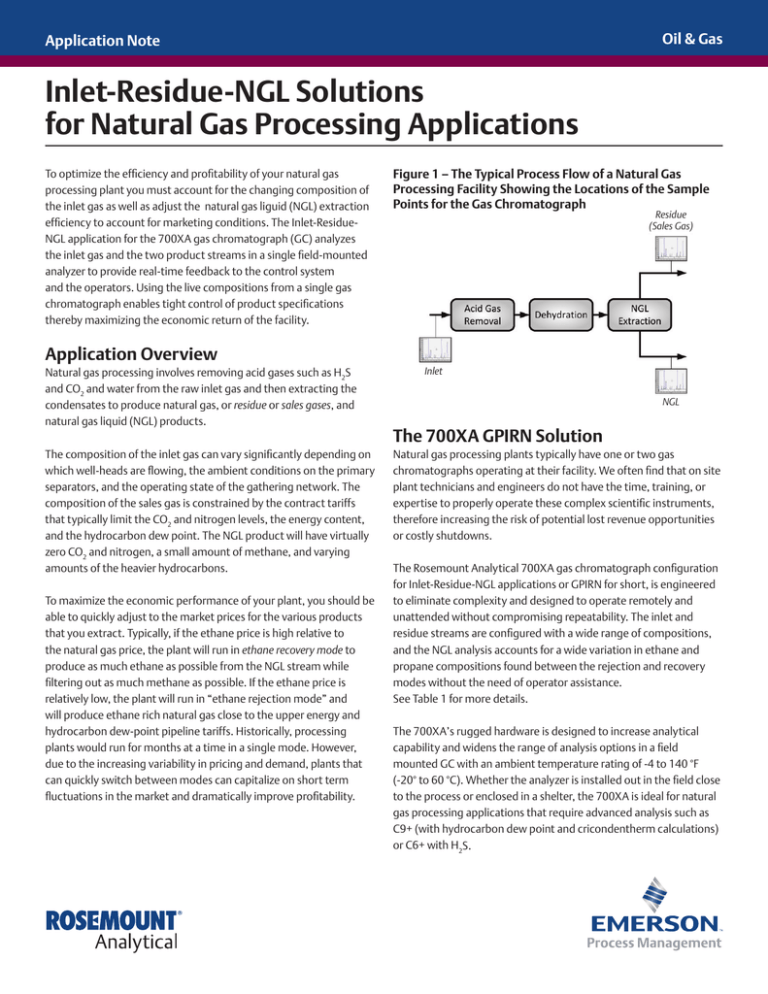

Figure 1 – The Typical Process Flow of a Natural Gas

Processing Facility Showing the Locations of the Sample

Points for the Gas Chromatograph

Residue

(Sales Gas)

Application Overview

Natural gas processing involves removing acid gases such as H2S

and CO2 and water from the raw inlet gas and then extracting the

condensates to produce natural gas, or residue or sales gases, and

natural gas liquid (NGL) products.

The composition of the inlet gas can vary significantly depending on

which well-heads are flowing, the ambient conditions on the primary

separators, and the operating state of the gathering network. The

composition of the sales gas is constrained by the contract tariffs

that typically limit the CO2 and nitrogen levels, the energy content,

and the hydrocarbon dew point. The NGL product will have virtually

zero CO2 and nitrogen, a small amount of methane, and varying

amounts of the heavier hydrocarbons.

To maximize the economic performance of your plant, you should be

able to quickly adjust to the market prices for the various products

that you extract. Typically, if the ethane price is high relative to

the natural gas price, the plant will run in ethane recovery mode to

produce as much ethane as possible from the NGL stream while

filtering out as much methane as possible. If the ethane price is

relatively low, the plant will run in “ethane rejection mode” and

will produce ethane rich natural gas close to the upper energy and

hydrocarbon dew-point pipeline tariffs. Historically, processing

plants would run for months at a time in a single mode. However,

due to the increasing variability in pricing and demand, plants that

can quickly switch between modes can capitalize on short term

fluctuations in the market and dramatically improve profitability.

Inlet

NGL

The 700XA GPIRN Solution

Natural gas processing plants typically have one or two gas

chromatographs operating at their facility. We often find that on site

plant technicians and engineers do not have the time, training, or

expertise to properly operate these complex scientific instruments,

therefore increasing the risk of potential lost revenue opportunities

or costly shutdowns.

The Rosemount Analytical 700XA gas chromatograph configuration

for Inlet-Residue-NGL applications or GPIRN for short, is engineered

to eliminate complexity and designed to operate remotely and

unattended without compromising repeatability. The inlet and

residue streams are configured with a wide range of compositions,

and the NGL analysis accounts for a wide variation in ethane and

propane compositions found between the rejection and recovery

modes without the need of operator assistance.

See Table 1 for more details.

The 700XA’s rugged hardware is designed to increase analytical

capability and widens the range of analysis options in a field

mounted GC with an ambient temperature rating of -4 to 140 °F

(-20° to 60 °C). Whether the analyzer is installed out in the field close

to the process or enclosed in a shelter, the 700XA is ideal for natural

gas processing applications that require advanced analysis such as

C9+ (with hydrocarbon dew point and cricondentherm calculations)

or C6+ with H2S.

Oil & Gas

Table 1 - Composition Ranges for the 700XA Inlet-ResidueNGL recommended application.

Inlet

Sales/Gas Residue

NGL Product

Nitrogen

0–10

0–10

–

Methane

75–100

75–100

0–5

Carbon Dioxide

0–10

0–10

0–1

Ethane

0–20

0–20

0–60

Propane

0–10

0–10

0–70

Isobutane

0–5

0–5

0–20

n-Butane

0–5

0–5

0–20

Isopentane

0–1

0–1

0–10

n-Pentane

0–1

0–1

0–10

0–0.7

0–0.7

0–10

Hexanes Plus (C6+)

Figure 2– A 700XA Configured for the GPIRN Application

that is Suitable for Mounting in a Three-sided Shelter, a GC

Cabinet, or an Analyzer House.

System Design

The sample system design is critical to the performance of any

analyzer system and is an integral component of the Inlet-ResidueNGL application (see Table 1). Particulate filters, liquid filters,

check-valves, and bypass flow rotameters are provided for the two

vapor streams. Flow switches in the bypass flow can be included as

an option. To ensure there is no contamination between the inlet

gas and the residue gas sample streams, double-block-and-bleed

solenoids are used to select between the calibration and vapor

streams.

The liquid sample initially is conditioned through a liquid particulate

filter with fast bypass loop and armored rotameter mounted

externally to the main SHS enclosure. A very low volume side stream

is passed into the vaporizing regulator mounted inside the SHS

enclosure. The vaporized sample then passes through a manual ball

valve that allows for the manual calibration of the liquid analysis.

The vaporized liquid sample is injected into the GC oven through a

dedicated sample injection valve that is separate from the sample

injection valve used for the inlet and residue streams.

Both of the sample injection valves vent through dedicated

atmospheric referencing valves to enable the purging samples

to be routed to a safe sample vent (such as to the flare or vapor

recovery system) while enabling the sample loop to be referenced to

atmospheric pressure prior to injection into the analytical flow path

to ensure accurate and repeatable measurements.

All of the vapor state sample handling components are mounted

inside a stainless steel heated cabinet that can optionally include

a viewing window for easy system checks and can be incorporated

into the 700XA gas chromatograph, or mounted remotely.

Page 2

Figure 3 – GPIRN Sample System

Oil & Gas

700XA Specifications and Drawings

Please consult Rosemount Analytical if your requirements are outside the specifications listed below. Improved performance, other products

and material offerings may be available depending on the application.

Construction

Environmental temperature: -20° to 60 °C (-4° to 140 °F)

Environmental temperature without safety certification:

40° to 60 °C (-40° to 140 °F)

Detector: Thermal conductivity detector (TCD), flame ionization detector (FID), TCD/TCD or TCD/FID dual detector configurations possible; flame photometric detector (FPD) available.

Enclosure Protection Rating: IP66

Gating Options: Fixed-time, slope sensing gating of peaks

• Dimensions (without sample system):

Streams: Up to 20 externally controlled streams or up to 8 internal

(includes calibration stream)

• Wall-mount: 711 mm H x 445 mm W x 498 mm D

Chromatograms stored/archived internally: Stores over 80 days of

analysis report data and up to 2500 individual chromatograms.

(28'' H x 17.5'' W x 19.6'' D)

• Pipe-mount: 711 mm H x 445 mm W x 671 mm D

Standard: 24V DC (21–30V DC)

(60.3'' H x 17.5'' W x 24.1'' D)

Optional: 90–264V AC, 47–63 Hz

Corrosion Protection:

Typical Power Consumption at 22 °C (72 °F):

Startup: 105 Watts DC (125 Watts AC)

Steady State: 35 Watts DC (40 Watts AC)

• GC Enclosure Material: Copper free aluminum coated with industrial grade powder coat suitable for high humidity and salt-

laden environments.

Note: Add 15.5 Watts DC (18 Watts AC) for LOI

• Electronics: All electronic circuit boards are tropicalized with a clear conformal coating.

Communications (Standard)

• Process Wetted Materials: Stainless steel. Where the function of an item excludes the use of stainless steel (e.g. glass rotameter tubes), materials that are resistant to corrosion are used.

Mounting: Floor-standing (standard), wall- or pipe-mount (optional)

Approximate Weight (without sample system): 50 kg (110 lbs.)

Area Safety Certification Options:*

CSA:

–– USA and Canada

• Class I, Division 1, Groups B, C, and D

ATEX / IECEx

–– Ex II 2G

–– Ex d IIC Gb T6

(Ta = -20 °C to 60 °C)

Ethernet: Two ports – one RJ-45 and one four-wire with 10/100 mbps

Analog inputs: Two standard isolated inputs filtered with transient

protection, 4–20 mA (user scalable and assignable)

Analog outputs: Six isolated outputs, 4–20 mA

Digital inputs: Five inputs, user assignable, optically isolated, rated to 30V DC @ 0.5 A

Digital outputs: Five user-assignable outputs, Form C and

electromechanically isolated, 24V DC

Serial: Three termination blocks, configurable as RS-232, RS-422 or

RS-485 and one RS-232 D-sub (9-pin) Modbus/PC Connection

Communications (Optional)

Two expansion slots available for additional communications.

Each slot has the capacity to add one of the following:

Four analog inputs (isolated) card

*Stated T-ratings can vary based on applications.

Performance Capabilities

Four analog outputs (isolated) card

Eight digital inputs (isolated) card

Five digital outputs (isolated) card

One RS-232, RS-422 or RS-485 serial connection card

One modem card, 300-19.2k baud

Additionally, a FOUNDATION™ fieldbus module is available.

Memory Capacity: 1 GB of flash memory for data storage; 128 MB of SDRAM system memory with 2 MB static RAM (battery-backed)

Carrier Gas: Application-dependent. Typically zero-grade helium, nitrogen, or hydrogen

Carrier Gas Input Pressure Range (recommended):

6.2052–6.8947 bar (90–100 psig)

Power:

• Floor-mount: 1532 mm H x 445 mm W x 612 mm D

Sample & Calibration Gas Input Pressure Range:

0.2068–2.0684 bar: 1.0342 bar (recommended) or 15 psig

Electronics

(28'' H x 17.5'' W x 26.4'' D)

Oven: Airless, maximum 150 °C (302 °F)

Valves: Six-port and ten-port diaphragm chromatograph valves. Other types of valves, such as liquid injection or rotary valves, may be used depending on the application

Touch Key Local Operator Interface (Optional)

The 700XA local operator interface (LOI) allows for maintenance and

operation of a 700XA without a laptop or PC. The LOI is a state-of-the-art

high resolution color display that is touch key infrared activated and supports

all core GC operations.

Page 3

Oil & Gas

Option Selection

Use the matrix below to choose the options for your application and build up the model string to order.

700XA GPSCS -

1

-

2

700XA

700XA Process Gas Chromatograph

Level 1

Hazardous Area Approval

Level 2

Level 3

Level 4

Level 5

A

ATEX/IEC-Ex

C

CSA rated

3

-

4

F

Floor-mount

P

Pipe-mount

W

Power

AC

Wall-mount

Universal 85 to 240V AC

DC

24V DC

Front Panel

EN

Extended switch panel - 18 streams switches and FID ignite

button (ignitor not used inless option XX-YY are chosen on

level 12)

SK

Local Operator Interface (LCD)

SN

Standard switch panel - eight stream switches - not available

when an FID option is selected on Level 12

Additional* I/O and Serial/Modem Communications - Slot A

5D

5M

5N

5P

5R

5S

5T

Additional I/O Port - Four Additional Channels of Analog Inputs

(Isolated)

Additional I/O Port - Eight Additional Channels of Digital Inputs

(Isolated)

Modem

None

Additional I/O Port - Four Additional Channels of Analog Outputs

(Isolated)

Additional Serial Port - (1) RS422 or 485 (Factory/Field

configurable)

Additional Serial Port - (1) RS232

Additional I/O Port - Five Additional Channels of Digital Outputs

(Isolated)

Additional* I/O and Serial/Modem Communications - Slot B

6A

Additional I/O Port - Four Additional Channels of Analog Inputs

(Isolated)

6D

Additional I/O Port - Eight Additional Channels of Digital Inputs

(Isolated)

6M

Modem

6N

None

6P

Additional I/O Port - Four Additional Channels of Analog Outputs

(Isolated)

6R

Additional Serial Port - (1) RS422 or 485 (Factory/Field

configurable)

6S

Additional Serial Port - (1) RS232

6T

Additional I/O Port - Five Additional Channels of Digital Outputs

(Isolated)

Level 7

FOUNDATION™ Fieldbus Interface

Level 8

Sample System Mounting Location

L

Local Sample System - Sample System mounted under GC, with

tubing and signaling connections by RAI

R

Remote Sample Handling System - Includes an external junction

box for SHS signal wiring, attached to the 700XA. Signal Wiring

and tubing connections are others.

Level 9

Gas Processing Application

1F

Page 4

-

5

GPSCS

Level 1

Mounting

5A

Level 6

-

Interface Module

GPIRN

Gas Processing - Inlet Residue NGL (three streams)

GPDET

GPEPS

DeEthanizer Tower Overheads and Bottoms (two streams)

Ethane Purity

GPPPS

Propane Purity

GPPPX

Propane Purity Extended (with Propylene)

Level 2

Level 3

Level 4

Level 5

Level 6

Level 7

Level 8

-

6

-

7

-

8

- GPIRN

- GPIRN

9

Sample Conditioning System for 700XA

- Gas Processing Applications

Gas Processing Application SHS type

GPIRN

Inlet/Residue/NGL

GPDET DeEthanizer Tower

GPEPS

Ethan Purity

GPPPS

Propane Purity

GPPPX

Propane Purity Extended (with Propylene)

Hazardous Area

A

Local Sample System

C

CSA rated components - Class I, Division 1, Groups B, C, D

Mounting

LS1

Local Sample System - Sample System mounted under GC, with

tubing and signaling connections by RAI

RS1

Remote Sample Handling Sysem - Includes external junction

box, with signal wiring and tubing connection by others.

Power

A1

110V AC

A2

220V AC

Window

PL

Plexiglass - Lexan

Vapor Flow Switches

V1

Single Vapor Flow Switch

V2

Two Vapor Flow Switches

V3

Three Vapor Flow Switches

V4

Four Vapor Flow Switches

Vapor Sample Entry

H1

Single Vapor Heat Trace Boot

H2

Two Vapor Heat Trace Boots

H3

Three Vapor Heat Boots

H4

Four Vapor Heat Trace Boots

B

⅛ Bulkhead Fittings

Liquid Flow Switches

L1

Single Liquid Flow Switch

L2

Two Liquid Flow Switch

L3

Three Liquid Flow Switches

L4

Four Liquid Flow Switches

(*) Standard Communications - 5 Di/ 5 DO/2 AI/ 6 AO (All Isolated and (3) RS422, RS422 or RS485 (Factory/Field configurable) serial ports.

Optional Accessories

Vapor Sample Probe

Vapor Sample

Probe/Regulator

Vaporizing Regulator

Heating Sample Probe

Liquid Sample Probe

Heat Traced

Sample Line

Provide line size, process connection details, process

pressure and temperature.

Provide line size, process connection details, process

pressure and temperature.

For remote mount at the sample point

For vapor samples. To be mounted at the sample point.

Provide line size and process connection details.

⅛th Stainless steel heat traced sample tubing including

termination kit. Specify length required.

Oil & Gas

Recommended Installation

The drawings below represent the minimum recommended installation guidelines for the 700XA Gas Chromatograph.

Please consult Rosemount Analytical for detailed installation recommendations for your application.

Figure 4 – GPIRN OD Local

Figure 5 – GPIRN OD Remote

Page 5

Oil & Gas

www.RosemountAnalytical.com

www.Danalyzer.com

www.analyticexpert.com

www.twitter.com/RAIhome

www.youtube.com/user/RosemountAnalytical

www.facebook.com/EmersonRosemountAnalytical

AMERICAS

Emerson Process Management

Rosemount Analytical

Analytical Center of Excellence

10241 West Little York, Suite 200

Houston, TX 77040 USA

Toll Free 866 422 3683

T +1 713 396 8880 (North America)

T +1 713 396 8759 (Latin America)

F +1 713 466 8175

gc.csc@emerson.com

EUROPE

Emerson Process Management

Bond Street, Dumyat Business Park

Tullibody FK10 2PB UK

T +44 1259 727220

F +44 1259 727727

sales.gcema@emersonprocess.com

Scan the QR code with your

smartphone to go to our website.

MIDDLE EAST AND AFRICA

Emerson Process Management

Emerson FZE

Jebel Ali Free Zone

Dubai, United Arab Emirates, P.O. Box 17033

T +971 4 811 8100

F +971 4 886 5465

gc.csc@emerson.com

©2014 Emerson Process Management. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Rosemount

Analytical is a mark of one of the Emerson Process Management family of companies. All other

marks are the property of their respective owners.

The contents of this publication are presented for information purposes only, and while

effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their

use or applicability. All sales are governed by our terms and conditions, which are available

on request. We reserve the right to modify or improve the designs or specifications of our

products at any time without notice.

NGC_ANO_OilGas_700XA_GPIRN

ASIA-PACIFIC

Emerson Process Management

Asia Pacific Private Limited

1 Pandan Crescent

Singapore 128461

Republic of Singapore

T +65 6 777 8211

F +65 6 777 0947

analytical@ap.emersonprocess.com