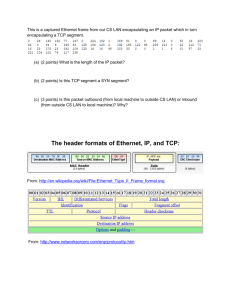

Automation and control Ethernet TCP/IP and Web technologies

advertisement