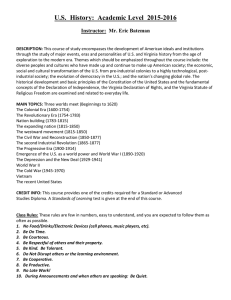

Advanced Technologies for Mineral Processing

advertisement

Advanced Technologies for Mineral Processing Unlock Potential, Create Value Tenova Mining & Minerals is a total integrated solutions provider to the global mining, bulk materials handling and minerals beneficiation and processing sectors, offering innovative technological solutions and full process and commodity knowledge across the mining industry value chain. Tenova Bateman Technologies offers differentiated, project-specific process technology solutions based on decades of establishing processing facilities. Advanced hydrometallurgical solutions include solvent extraction, electrowinning and leaching, supported by expertise in complementary processes from sulphuric and phosphoric acid plants, ion exchange circuits, water and wastewater treatment plants through to beneficiation processes for phosphate rock, base and precious metals, iron ore, coal and uranium. Pioneering the concept in the 1960s, Modular Plants offer competitive mineral processing packages while reducing risk in difficult project locations. Tenova Bateman Technologies has offices in Australia, Chile, Israel, and South Africa in addition to the world-wide network provided by Tenova offices located on five continents. This network of qualified and competent people provides knowledge about local business practices and language and enables real time service to customers. TECHNOLOGICAL INNOVATION Technological innovation is the foundation of Tenova Bateman Technologies competitiveness. Tenova Bateman Technologies is fully committed to research and development (R&D) to effectively meet the most pressing requirements of the minerals industry, both today and in the future. Developing flexible, individual and effective design concepts is the key to finding the ideal solution for each customer and may in some cases, differ from prevailing design concepts. By embracing innovation, Tenova Bateman Technologies is able to offer customers cutting-edge solutions they expect and maintain its position at the forefront of industry developments. A FOCUS ON PEOPLE People are vital to sustainable success and growth at Tenova Bateman Technologies, with our highly qualified and experienced staff recognised as the lifeblood of the company. Outstanding engineering and management expertise in every area of activity, a strong focus on the customer, a passion for innovation and fexibility: these are the features that distinguish and differentiate Tenova professionals. Tenova Bateman Technologies enhances and optimises the talents of the individual for the good of the team and to the optimal benefit of the customer. By supervising every stage of professional growth and providing on-going knowledge and skills training, Tenova Bateman Technologies guarantees the expertise of its people. heritage Tenova Bateman Technologies resulted from the acquisition of Bateman Engineering and Bateman Advanced Technologies, bringing with them leading expertise in process technologies, process and engineering design, fabrication, construction and the supply of complete turnkey process facilities. Established in Johannesburg, South Africa in 1919, Bateman evolved into a leading project house to the global natural-resources industry, responsible for projects in over 70 countries. Several technologies such as the Bateman Pulsed Column℗ Bateman Mixer Settler℗ and Bateman Modular plants, are well known in the industry and have set the benchmark for operational performance, reliability and customer satisfaction. Tenova Bateman Technologies has in-depth knowledge and understanding of the processing requirements for a wide range of minerals and commodities including phosphate rock, base and precious metals, diamonds, iron ore, coal and uranium, allowing the tailored application of our technology to a wide range of customer solutions. The Company has an extensive reference list of successful projects and applies this experience to the benefit of customers world-wide. QUALITY To meet and exceed our customer expectations with everything we do, quality and continuous improvement of service in line with best industry practices and standards are priorities at Tenova Bateman Technologies. Tenova Bateman Technologies quality management system is certified to ISO 9001:2008, which directs attention to customer focus, meeting customer needs and continuous improvement. HEALTH, SAFETY AND THE ENVIRONMENT Employees’ health and safety, in addition to environmental protection, are a top priority of Tenova Bateman Technologies. With the principle of Zero Harm as an integral part of its culture, Tenova Bateman Technologies is committed to a safe working environment and to minimising environmental impact across its operations and project sites. Tenova Bateman Technologies adheres to the Tenova Health, Safety and Environmental Policy that promotes the development of its activities in harmony with industry leading Health, Safety and Environmental standards. GENERAL OFFERING • • • • • • Process development Basic and detailed engineering Equipment supply Mineral processing plants Commissioning and training Aftersales spares and support This is further enhanced by our comprehensive process and equipment guarantees, global Tenova presence on five continents and project financing facilitation through the Tenova Project Finance Group. Various contracting models can be ultilised. include, but are not limited to: • Engineering and procurement • Engineering, procurement and construction • Engineering, supply and supervision • Cost plus These CALGARY – CANADA VANCOUVER – CANA DENVER – UNITED S MEXICO CITY – MEX TENOVA MINING & MINERALS WORLDWIDE With some 2,500 employees and operating companies on five continents, Tenova Mining & Minerals is close to its customers with technological support and real-time service. BELO HORIZ SÃO PAULO SANTIAGO – LIMA – PERU MODULAR PLANTS Modular plants are self contained or are integrated into conventional plants. They are used for prospecting, exploration, research and testing, mining and mineral processing on land or sea. The process design is robust and makes use of best available components from reputable suppliers that support their products worldwide. Modular plants are easy to erect on site since they are trial erected and pre-commissioned at the factory, where they are marked, stripped and packed into containers, prior to dispatch to site. Modular plants are used in the beneficiation and recovery of a wide range of commodities, including diamonds, coal, graphite, copper, magnesite, andalusite, chromite, iron ore, platinum and gold. BRISTOL – UNITED KINGDOM LEIPZIG – GERMANY LAUCHHAMMER – GERMANY GENOA – ITALY TARGU JIU – ROMANIA SOFIA – BULGARIA MOSCOW — RUSSIA ALMATY – KAZAKHSTAN ASTANA – KAZAKHSTAN TASCHKENT – UZBEKISTAN A ADA STATES XICO BEIJING — CHINA KOLKATA – INDIA CHENNAI — INDIA BANGALORE — INDIA BANGKOK – THAILAND YOKNEAM – ISRAEL JOHANNESBURG – SOUTH AFRICA ZONTE – BRAZIL – BRAZIL – CHILE U WATER TREATMENT Innovative but proven solutions for domestic and industrial water and wastewater treatment, ranging from low-cost rural facilities to zero discharge and integrated industrial systems. BRISBANE — AUSTRALIA PERTH — AUSTRALIA SYDNEY — AUSTRALIA SX and EW Innovative SX and EW solutions and technologies: • Bateman Pulsed Columns: a high-efficiency, cost effective, continuous contactor for solvent extraction, stripping and scrub applications in metal recovery systems. • Bateman Settlers™ provide substantial operational and performance benefits, enabling side-by-side orientation of pump mixers, thereby reducing capital costs and providing improved access for operators. • Turbulent Technologies Mixing System: a new mixing technology enabling significant reduction of entrainment without changing the process flow and can be retro-fitted easily to most existing mixer settlers or installed in new SX plants. • Tank houses of all sizes, from those for small operations to large-scale, manual and automated systems. Bateman Cross Flow electrolytic cells provide an improved electrolyte distribution flow pattern around each cathode, resulting in improved cathode quality. Applications include: • Conventional water treatment – Potable water treatment – Sewage water treatment – Sludge dewatering • Industrial water treatment – Effluent treatment – Ion exchange – Membrane desalination – Process water treatment – Acid mine drainage water treatment – Boiler feedwater preparation ION EXCHANGE Advanced processes for recovering, upgrading, separating and purifying metals and minerals using resins. Along with conventional fixed bed ion exchange and NIMCIX fluidised bed technologies, Tenova Bateman Technologies offers solutions based on the proprietary MetRIX™ Resin-in-Pulp technology, which offers both continuous adsorption and elution. The RIP (Resin in Pulp) process recovers metals directly from slurries, which: • Eliminates the need for a solid-liquid separation step • Offers significant capital and operating cost savings • Offers the potential of increased metal recovery RIP has found application in the gold and uranium industries and has been evaluated for the recovery of platinum group metals (PGMs), cobalt, copper, nickel, zinc, rare earth elements and vanadium from leached slurry or residue streams. BIO SX Process and technology development services including lab and pilot plant studies for the downstream separation of bio-based chemicals and pharmaceutical industries, including environmental projects, with special emphasis on separation by solvent extraction (SX). Bio-based chemicals and bio-fuels are fundamental components of future sustainable chemical production. Selective recovery and purification of bio-based chemicals are critical stages that impact both the feasibility of the process as well as the value and cost of its products. Tenova Bateman Technologies, with its vast experience and proprietary technologies in the field of solvent extraction, offers robust, low maintenance, small footprint solutions with high yields. SULPHURIC ACID PLANTS Comprehensive process design and project management skills to establish sulphuric acid facilities including the associated gas cleaning operations, utilising metallurgical processing off-gas, sulphur burning or pyrite roasting. Our extensive in-house processing technologies, in addition to technology marketing agreements with leading technology suppliers, gives Tenova Bateman Technologies access to the full range of proprietary technology and equipment for the execution of sulphuric acid plant design and construction projects. PURIFIED PHOSPHORIC ACID Tenova Bateman Technologies provides the full suite of technologies required for the production of phosphoric acid, including the solvent extraction stages, acid purification and concentration, and excess chloride removal to produce high quality food or agricultural grade phosphoric acid. The data acquisition during the process development stage is continuously monitored and improved in order to ensure reliable plant design information. • Pre-treatment – impurity removal such as sulphates, cadmium, fluorides and arsenic • Purification – using proprietary solvent extraction processes and selection of the optimal solvent for the purification stage • Post-treatment – bringing the product to its final specification through concentration, solvent recovery and the reduction of total organic carbon RESEARCH AND DEVELOPMENT Tenova Bateman Technologies has in-house laboratory and pilot plant facilities for solvent extraction, purified phosphoric acid and mineral beneficiation test work. Pilot scale modular SX and RIP plants can be supplied based on client requirements for process verification and scaling up test work. Tenova Bateman Technologies has agreements in place with research institutions such as Mintek in South Africa for the development of various technologies and actively co-operates with centres of higher learning around the world on projects of mutual interest to us and our clients. PHOSPHATE BENEFICIATION Tenova Bateman Technologies provides the full suite of technologies for the beneficiation of phosphate rock through to the production of phosphate salts. Project services ranging from process development through feasibility studies to turnkey projects are provided for: • Rock-phosphate beneficiation • Agricultural (wet) phosphoric acid • Technical (white) phosphoric acid • Food-grade phosphoric acid • Downstream phosphate salts Tenova Bateman Technologies services and technologies: • Ensure optimal utilisation of phosphate ores in conventional processes • Upgrade wet process acid to technical- and foodgrade acid and downstream products Our team of specialists can offer beneficiation process development for a range of minerals such as base metals, industrial and heavy minerals. Tenova BATEMAN TECHNOLOGIES Tenova MINING & MINERALS Tenova Minerals (Pty) Ltd 58 Emerald Parkway Road Greenstone Hill Johannesburg 1609 PO Box 7737 Johannesburg 2000 South Africa phone +27 11 899 9111 enquiries.TMM@tenova.com Tenova Mining & Minerals (Pty) Ltd 58 Emerald Parkway Road Greenstone Hill, Ext 21 1609 PO Box 7737 Johannesburg 2000 South Africa phone +27 11 899 9111 enquiries.TMM@tenova.com Bateman Advanced Technologies Ltd 13 Hatnufa St. P.O. Box 501 Hi-Tech Park Yokneam 2069206 Israel phone +972 4 957 9100 enquiries.TMM@tenova.com Bateman Chile SpA. Edificio Titanium Isidora Goyenechea N° 2800, 36th Floor Las Condes Santiago 7550647 Chile phone +56 2 (2)498 1100 enquiries.TMM@tenova.com Tenova Mining & Minerals Australia (Pty) Ltd Suite 2, 93 Francisco Street Belmont WA 6104 Australia phone +61-8-9365-9400 enquiries.TMM@tenova.com www.tenova.com TECHINT GROUP Edition 1 August 2013