Instrumentation, Controls & Electrical

Perfectly trained personnel

for Niederaussem thanks to

KRAFTWERKSSCHULE E.V. Simulator

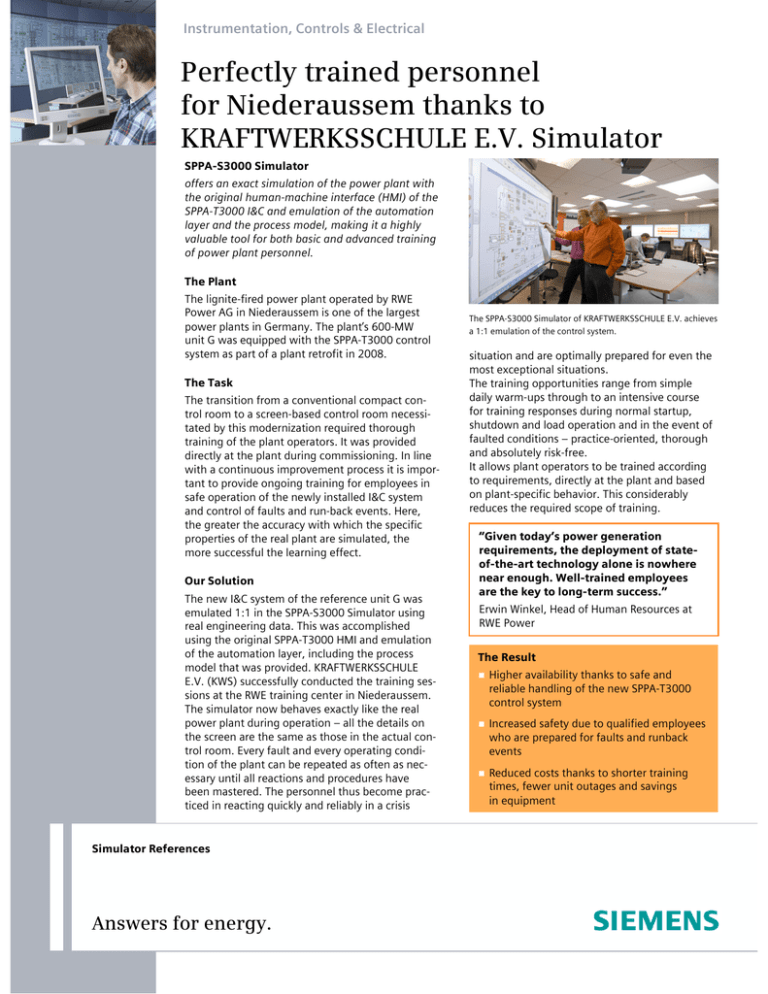

SPPA-S3000 Simulator

offers an exact simulation of the power plant with

the original human-machine interface (HMI) of the

SPPA-T3000 I&C and emulation of the automation

layer and the process model, making it a highly

valuable tool for both basic and advanced training

of power plant personnel.

The Plant

The lignite-fired power plant operated by RWE

Power AG in Niederaussem is one of the largest

power plants in Germany. The plant’s 600-MW

unit G was equipped with the SPPA-T3000 control

system as part of a plant retrofit in 2008.

The Task

The transition from a conventional compact control room to a screen-based control room necessitated by this modernization required thorough

training of the plant operators. It was provided

directly at the plant during commissioning. In line

with a continuous improvement process it is important to provide ongoing training for employees in

safe operation of the newly installed I&C system

and control of faults and run-back events. Here,

the greater the accuracy with which the specific

properties of the real plant are simulated, the

more successful the learning effect.

Our Solution

The new I&C system of the reference unit G was

emulated 1:1 in the SPPA-S3000 Simulator using

real engineering data. This was accomplished

using the original SPPA-T3000 HMI and emulation

of the automation layer, including the process

model that was provided. KRAFTWERKSSCHULE

E.V. (KWS) successfully conducted the training sessions at the RWE training center in Niederaussem.

The simulator now behaves exactly like the real

power plant during operation – all the details on

the screen are the same as those in the actual control room. Every fault and every operating condition of the plant can be repeated as often as necessary until all reactions and procedures have

been mastered. The personnel thus become practiced in reacting quickly and reliably in a crisis

Simulator References

Answers for energy.

The SPPA-S3000 Simulator of KRAFTWERKSSCHULE E.V. achieves

a 1:1 emulation of the control system.

situation and are optimally prepared for even the

most exceptional situations.

The training opportunities range from simple

daily warm-ups through to an intensive course

for training responses during normal startup,

shutdown and load operation and in the event of

faulted conditions – practice-oriented, thorough

and absolutely risk-free.

It allows plant operators to be trained according

to requirements, directly at the plant and based

on plant-specific behavior. This considerably

reduces the required scope of training.

“Given today’s power generation

requirements, the deployment of stateof-the-art technology alone is nowhere

near enough. Well-trained employees

are the key to long-term success.”

Erwin Winkel, Head of Human Resources at

RWE Power

The Result

Higher availability thanks to safe and

reliable handling of the new SPPA-T3000

control system

Increased safety due to qualified employees

who are prepared for faults and runback

events

Reduced costs thanks to shorter training

times, fewer unit outages and savings

in equipment

Published by and copyright © 2010:

Siemens AG, Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Power Generation, Inc.

Instrumentation & Controls

1345 Ridgeland Parkway, Suite 116

Alpharetta, GA 30004, USA

sppa-s3000.energy@siemens.com

www.siemens.com/sppa-s3000

For more information, contact our

Customer Support Center.

Phone: +49 180 524 70 00

Fax:

+49 180 524 24 71

(Charges depending on provider)

E-mail: support.energy@siemens.com

Fossil Power Generation Division

Instrumentation, Controls & Electrical

S3_FR_Niederaussem_e_V1-0

Order No. E50001-G230-A265-X-4A00

Printed in Germany

Dispo 05401, c4b: 7465

Printed on elementary chlorine-free

bleached paper.

All rights reserved.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or

their respective owners.

Subject to change without prior notice.

The information in this document contains general

descriptions of the technical options available,

which may not apply in all cases.

The required technical options should therefore be

specified in the contract.