Performance of a Horizontally Mounted Venturi in Low

advertisement

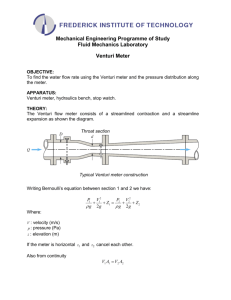

Chinese Journal of Chemical Engineering, 16(2) 320—324 (2008) RESEARCH NOTES Performance of a Horizontally Mounted Venturi in Low-pressure Wet Gas Flow* FANG Lide (方立德)** and ZHANG Tao (张涛) Key Laboratory for Process Measurement and Control, School of Electrical Engineering and Automation, Tianjin University, Tianjin 300072, China Abstract The performance of a Venturi tube used in wet gas flow have been explored mainly under higher-pressure condition, but very often, low-pressure test exists in some oil and gas fields in Tianjin Dagang Oil and Gas Field in China. In this study, the performance of horizontally mounted Venturi meters in low-pressure wet gas flow is discussed. Three 50 mm Venturi meters were tested systematically, with β values of 0.4048, 0.55 and 0.70, the operation pressure of 0.15 MPa, 0.20 MPa, 0.25 MPa, the gas densiometric Froude number from 0.6 to 2.0, the modified Lockhart-Maretinelli parameter from 0.0022 to 0.06, and the ratio of the gas liquid mass flow rate from 0.5 to 0.99. The effects of modified Lockhart-Maretinelli parameter, pressure, gas densiometric Froude number, diameter ratio, and gas-liquid mass flow rate ratio to the Venturi tube are analyzed with new independent data. Furthermore, low-pressure performance was compared with that under high pressure. Keywords gas-liquid two phase flow, wet gas metering, Venturi meter, over-reading 1 INTRODUCTION Wet gas has been defined as 90% gas, 95% gas and even 98% gas by different technical papers [1]. Normally, two ways are employed to meter wet gas, one is to use a multiphase flow meter in wet gas, while the other is to use a standard dry gas meter and apply corrections to the measurements [2]. As a mature single-phase flow measurement device, the Venturi meter (or tube) is easily to be considered for two-phase flow measurement [3]. Some tests have been done under high-pressure wet gas loop with high Lockhart-Maretinelli (LM) parameter to study the over-reading of Venturi meters in wet gas condition. In Steven’s paper [4], a 6˝ Venturi meter with diameter ratio (β) of 0.55 was installed in NEL (National Engineering Laboratory,UK) with pressure 2 to 6 MPa and Lockhart-Martinelli parameter 0 to 0.3. After that, NEL engineers Stewart and Boam presented two reports and a paper [5-7], three 4˝ meters were chosen with different β values (0.4, 0.60, 0.75) and tested over a range of pressure (1.5-6.0 MPa), gas velocity [gas densiometric Froude number (Frg) 0.5-5.5] and liquid fraction (Lockhart-Martinelli parameter X=0-0.4). Furthermore, Britton et al. [8], Kegel [9] did some tests in Colorado Engineering Experiment Station with pressure under 1.4-7.6 MPa, and Lockhart-Martinelli parameter between 0 and 0.25. However, very few full tests were done under low-pressure wet gas condition, so the authors implemented a full test program at Tianjin University (TJU) multiphase flow loop to cover this range. The results add to the experimental database, and provide necessary reference for the application of Venturi meters in low-pressure wet gas metering. 2 OVER-READING THEORY Defined over-reading as Eq. (1): OR = mg = m'g = m'g mg = ΔPtp ΔPg Cε AT 2 ρg ΔPg 1− β 4 Cε AT 2 ρg ΔPtp 1− β 4 the real gas mass flow rate can be corrected to m'g mg = OR (1) (2) (3) (4) Generally, the over-reading caused by two factors: one is the liquid presence in gas, which caused a blockage effect; the other is gas-accelerating effect to liquid, which caused a drag pressure drop. 3 EXPERIMENTAL APPARATUS Each Venturi meter was calibrated in dry gas at each test pressure prior to the respective wet gas tests, to establish a dry gas baseline performance against which the wet gas results could be compared. Both the Venturi calibrated test and wet gas test were conducted on TJU multiphase flow loop at pressure from 0.15 MPa to 0.25 MPa across a range of gas velocity. TJU’s low-pressure wet gas test facility is a complete system with full automatic control and multiple functions, which is not only a multiphase flow experiment system, but also a multiphase flow meter calibration system. As an experiment system, the test can be conducted in horizontal pipe, vertical pipe and 0-90° inclined pipe. As a calibration system, the test meter can be calibrated in standard meter method. Fig. 1 shows schematic of TJU multiphase flow loop. Received 2007-05-08, accepted 2008-02-12. * Supported by the National High Technology Research and Development Program of China (2006AA04Z167, 2007AA04Z180). ** To whom correspondence should be addressed. E-mail: leed_amy@yahoo.com.cn 321 Chin. J. Chem. Eng., Vol. 16, No. 2, April 2008 According to ISO5167-1, 4 (2003), a classical Venturi tube with a machined convergent section must have its straight length and diameter ratio according with Table 1. In this test, three Venturi tubes with β value equal to 0.4048, 0.55 and 0.70 were fabricated, the length of Venturi tubes is 388 mm, diameter is 50 mm, the length of cylindrical throat is 20 mm, conical convergent angle is a constant of 21°, conical divergent angle is 12°, the pipe wall roughness is 0.06 mm, and stainless steel flanges used in connection [10, 11]. Type 1151 differential pressure transducers from Rosemont were used, and the uncertainty of pressure transducers is 2.5‰。 The experimental parameters are listed in Table 1. Table 1 Diameter ratio β Pressure/ MPa 0.4048 Figure 1 Schematic of TJU multiphase flow loop 1—liquid tank; 2—air inlet; 3—compressor; 4—cooler system; 5—gas tank; 6—liquid pump; 7-9—Alicat mass flow controllers; 10—vortex flow meter; 11,13—roots flow meter; 12,15,16— turbine flow meter; 14—electrical flow meter; 17—horizontal experimental pipe; 18—vertical experimental pipe; 19—water tower; 20—gas liquid separator; 21—gas liquid mixer The facility makes up of six components, which are medium source, single phase flow pipe and standard meters, horizontal pipe, vertical pipe, 0-90° inclined pipe and computer control system. Gas is compressed air provided by two compressors, and it passes through cooling and drying units to access to two 12 m3 tanks. With these tanks, the pressure-regulating valve can hold a stable pressure 0-0.5 MPa for the test. The liquid used is water (oil or oil and water mixture also can be used) and a water pump pushes the water to a 30 m high water tower, which can hold a stable pressure for driving liquid flow. The uncertainty of the liquid standard meters is 5‰, and the gas standard meters is 1%. Gas and liquid whose flow rates have been measured through standard meters enter the mixer which makes the liquid become 100-1000 μm mist, and then go through the 50 mm experimental pipe (Fig. 2). The ball valve installed 14D upstream of the meter is used when maintaining the metering system. Generally, the valve remains full open not to perturb the flow. An ball valve which adjusts the test pressure is installed at the outlet of the experimental pipe. The ball valve has a hole on the ball with the same diameter as upstream pipe. Figure 2 0.55 0.7 4 4.1 Experimental parameters Lockhart-Martinelli parameter Frg 0.15 0.8-1.5 0.0022-0.0338 0.20 1.0-1.88 0.0022-0.0472 0.25 0.67-1.81 0.0022-0.0495 0.15 1.04-1.78 0.0022-0.0572 0.20 1.09-1.85 0.0022-0.0431 0.25 0.92-1.73 0.0022-0.0514 0.15 1.04-2.0 0.0024-0.0480 0.20 1.08-2.0 0.0025-0.0525 0.25 0.87-1.66 0.0027-0.0576 RESULTS AND ANALYSIS Effect of influencing parameters It has been showed that under high-pressure the over-reading of a Venturi was dependent on the gas Froude number Frg, Lockhart-Martinelli parameter X, gas density ρg (or pressure P) and the Venturi β value. Lockhart-Martinelli parameter is defined as X= ρl ρg ΔPl m = l ΔPg mg (5) The gas densiometric Froude number (Frg) is: Frg = υg gD ρg ρl − ρ g (6) Besides these parameters, the slip ratio also has significant effect to the over-reading. Based on the momentum balance and separated flow theory [12-14], the over-reading can be expressed theoretically as Horizontal experiment pipe 322 Chin. J. Chem. Eng., Vol. 16, No. 2, April 2008 ⎛1 ρg ⎞ ρl ⎟X + X2 OR = 1 + ⎜ ⋅ (7) +S⋅ ⎜ S ρg ⎟ ρ l ⎠ ⎝ Equation (7) shows that slip ratio S is also a factor influencing OR, but the slip ratio is hard to be determined accurately, so it needs to find another parameter to substitute it. de Leeuw used the gas densiometric Froude number to reflect gas liquid velocity ratio [15], but Eq. (6) can only reflect superficial gas velocity, not including liquid velocity. The parameter reflecting gas liquid velocity ratio is gas-liquid mass flow rate ratio, which can be shown as mg ml = ρg α x = ⋅ ⋅S 1 − x ρl 1 − α (8) Equation (8) shows that gas-liquid mass flow rate ratio are related with gas-liquid density ratio, gas cross-section fraction and slip ratio, and it can be acquired with the ratio of the gas to total mass flow rate. Next, the effects of the gas Froude number Frg, Lockhart-Martinelli parameter X, pressure P, the Venturi β value and gas-liquid mass flow rate ratio x /(1 − x) to over-reading will be analyzed. 4.2 Effect of Lockhart-Maretinelli parameter As expected, over-reading increases with increasing Lockhart-Martinelli parameter X, in agreement with almost all previous work under middle and high-pressure on this subject (Fig. 3). It is mostly due to the liquid, which reduces the gas passing area and brings about a blockage effect to the gas and an accelerating effect to the liquid. high-pressure, so over-reading is affected obviously by the gas Froude number. Figure 4 show the over-reading is less than 1 under low gas Froude number and low LM parameter as observed in many investigations. The over-reading less than 1 means that the differential pressure under two phase flow is less than it under signal gas phase flow when the gas velocity is small. The presence of a small amount of liquid may block the gas flow channel, increasing the friction pressure drop, but, liquid has a lubrication action at the pipe wall, which decreases the friction pressure drop. Under low gas Froude number and low LM parameter The over-reading less than 1 suggests simply that the blockage effect is weaker than the lubrication action. Figure 4 Venturi over-reading in different Frg for β=0.55 at 0.15 MPa Frg: ● 0.7; ■ 1.1; ▲ 2.0 4.4 Pressure effect Pressure also affects over-reading under lowpressure and low Lockhart- Martinelli parameter by affecting the gas liquid density ratio directly as shown in Fig. 5. It suggests clearly that the over-reading decreases with increasing pressure. make the gas density decreasing, From Eq. (6), under the same gas Froude number, the low gas density under lower pressure means higher gas superficial velocity and thus the larger friction. So the over-reading under low pressure is higher than that under high pressure. Figure 3 Venturi over-reading for all diameter ratio and pressure β value: ○ 0.4048; ■ 0.55; ▲ 0.7 4.3 Gas Froude number NEL (National Engineering Laboratory, UK) reported that some of the data seemed to tend to a value slightly above unity particularly at low X values [5-7]. But this prediction was not the case under low-pressure and low Lockhart Martinelli parameter with X less than 0.05. It is found that OR differs for different gas Froude number (in Fig. 4), mainly because that the gas liquid density ratio is lower under low-pressure. According to Eq. (6), for given Lockhart Martinelli parameter and gas Froude number, the gas velocity under low-pressure is higher than those under Figure 5 Venturi over-reading in different pressure for β=0.55 under low-pressure (Frg=2.0) ▲ 0.15 MPa; ● 0.20 MPa 4.5 Effect of Venturi diameter ratio Figure 6 show over-reading data from 3 Veturis for Frg=1.7 at 0.20 MPa. It is clear from Fig. 6 that the β value shows definite effect on over-reading under low-pressure. In some condition, the over-reading decreases with increasing β value with the exception of 0.70. The decrease of Venturi diameter ratio brings about the decrease of gas passing area in the Venturi Chin. J. Chem. Eng., Vol. 16, No. 2, April 2008 Figure 6 Venturi over-reading in different diameter ratio under 0.2 MPa (Frg=1.7) ■ 0.4; ● 0.55; ▲ 0.7 throat, the increase of gas velocity and gas liquid velocity ratio, and finally results in the increasing of over-reading. The over-reading of β = 0.70 is higher than 0.4048 and 0.55 because of differential pressure of 0.7 lower largely than the other β, it can be acquired from Eq. (2), mg ⎛ ΔPg = ⎜ ⎜ Cε A0 2 ρg ⎝ ΔPg = K ⋅ 2 ⎞ 1− β 4 ⎟ ⋅ ⎟ β4 ⎠ 1− β 4 β4 (9) (10) For different β, the differential pressure, which varies curvedly only with β under the same pressure and gas Froude number, decreases rapidly with the increasing value of β (Fig. 7). When the liquid exists in gas, the pressure drop is higher than gas flowing alone, for β=0.70, small liquid fraction will make a large over-reading. 323 Figure 8 Over-reading plots on gas liquid quality ratio for Frg=1.7 at 0.20 MPa ■ 0.4; ▲ 0.55; ● 0.7 ACKNOWLEDGEMENTS The author would like to thank National Engineering Laboratory of UK for providing the reports and professional advice on the web. NOMENCLATURE OR ΔPg ΔPl ΔPtp gas occupied cross-sectional area of pipe, m2 liquid occupied cross-sectional area of pipe, m2 area of the Venturi throat, m2 discharge coefficient inner diameter of upstream line pipe, m gas densiometric Froude number defined by Eq. (6) - gravitational acceleration, 9.81 m·s 2 -1 modified gas mass flow rate, kg·s - apparent gas mass flow rate, kg·s 1 over-reading superficial gas differential pressure, kPa superficial liquid differential pressure, kPa actual two-phase differential pressure, kPa S ug ul υg X x α β ε ρg ρl slip ratio ( S = ug / ul ) - real gas velocity, m·s 1 - real liquid velocity, m·s 1 - superficial gas velocity, m·s 1 Lockhart-Martinelli parameter defined by Eq. (5) ratio of gas to total mass flow rate [ x = mg /(mg + ml )] void fraction [α = Ag /( Ag + Al )] diameter ratio ( β = d / D ) expansibility factor - gas density, kg·m 3 - liquid density, kg·m 3 Ag Al AT C D Frg g mg m'g Subscripts Figure 7 Differential pressure varied with diameter ratio in the same pressure and gas Froude number 4.6 Effect of gas liquid quality ratio Figure 8 shows over-reading versus gas liquid quality ratio for Frg=1.7 at 0.20 MPa. At the same diameter ratio, the over-reading decreased with the increasing gas liquid quality ratio, the curves appeared exponential for all diameter ratio, and the over-reading decreased with the increasing diameter ratio. It is noticed that OR at β=0.55 was the smallest than other diameter ratio. Fig. 6 shows the same phenomenon as that in Fig. 8. The reason of this behavior needs further investigation. g l tp gas phase liquid phase gas-liquid two phase REFERENCES 1 2 3 4 Agar, J., Farchy, D., “Wet gas metering using dissimilar flow sensors: Theory and field trial results”, In: SPE Annual Technical Conference and Exhibition, San Antonio, Texas, 1-6 (2002). Lupeau, A., Platet, B., Gajan, P., Strzelecki, A., Escande, J., Couput, J.P., “Influence of the presence of an upstream annular liquid film on the wet gas flow measured by a Venturi in a downward vertical configuration”, Flow Meas. Instrum., 18, 1-11 (2007). Geng, Y.F., Zheng, J.W., Shi, T.M., “Study on the metering characteristics of a slotted orifice for wet gas flow”, Flow Meas. Instrum., 17, 123-128 (2006). Steven, R.N., “Wet gas metering with a horizontally mounted venturi 324 5 6 7 8 9 10 Chin. J. Chem. Eng., Vol. 16, No. 2, April 2008 meter”, Flow Meas. Instrum., 12, 361-372 (2002). National Engineering Laboratory of UK, “Effects of two-phase flow on single phase flowmeters”, Flow Measurement Guidance Note, (3), 6, 1-3 (1997). http://www.flowprogramme.co.uk/docs/reports.asp?rtype=6 Stewart, D.G., “The evaluation of dry gas meters in wet gas condition”, National Engineering Laboratory, London, 33-58 (2002). http://www.flowprogramme.co.uk/docs/reports.asp?rtype=1 National Engineering Laboratory of UK, “The evaluation of wet gas metering technologies for offshore application (1) Differential pressure meters”, Flow Measurement Guidance Note No.40.2 (2003). http://www.flowprogramme.co.uk/docs/reports.asp?rtype=6 Britton, C., Seidl, W., Kinney, J., “Experimental, wet gas data for a Herschel style Venturi”, In: 5th International Symposium on Fluid Flow Measurement, Arlington, VA (2002). Kegel, T., “Wet gas measurement”, Colorado Engineering Experiment Station, Inc. (CEESI) Publications, USA, 1-7 (2003). http:/www.ceesi.com/pubs_wetgas.aspx. ISO5167-1, “Measurement of fluid flow by mean of pressure differ- 11 12 13 14 15 ential deices inserted in circular cross-section conduits running full, part 1 General principles and requirements” (2003). ISO5167-4, “Measurement of fluid flow by mean of pressure differential deices inserted in circular cross-section conduits running full, part 4 Venturi tubes” (2003). Chisholm, D., “The influence of mass velocity on frictional pressure gradients during steam-water flow”, Inst. Mech. Eng., Thermodynam. Fluid Mech. Conv. Bristol, Paper No.35 (1968). Chen, Z.H., Cao, B.L., Zhao, Z.S., Gas-Liquid Two Phase Flow and Heat Transfer, Mechanical Industry Press, Beijing, 46-51 (1983). (in Chinese) Lin, Z.H., Wang, S.Z., Wang, D., Gas-Liquid Two Phase Flow and Boiling Heat Transfer, Xi’an Jiaotong University Press, China, 167-186 (2003). (in Chinese) de Leeuw, R., “Wet gas flow measurement using a combination of Venturi meter and a tracer technique”, North Sea Flow Measurement Workshop, Scotland (1994).