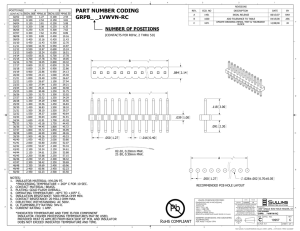

091 : 2000 CEB STANDARD MEDIUM VOLTAGE INSULATOR

advertisement

091 : 2000 CEB STANDARD MEDIUM VOLTAGE INSULATOR STRINGS AND HARDWARE FOR COASTAL APPLICATION (12KV & 36KV) CEYLON ELECTRICITY BOARD SRI LANKA Specification for MEDIUM VOLTAGE INSULATOR STRINGS AND HARDWARE FOR COASTAL APPLICATION (12KV & 36KV) CEB Standard 091 : 2000 CEYLON ELECTRICITY BOARD No. 50, Sir Chittampalam A. Gardener Mawatha, Colombo 2. Sri Lanka Telephone: 94-1-430471, 421720 Facsimile: 94-1-430473 E-mail : cebdp@mega.lk CEB STANDARD 091 : 2000 CONTENTS Page 1. Scope 2 2. System Psrsmeters 2 3. Service Conditions 2 4. Applicable Standards 2 5. Technical Requirements 3 6. Basic Features 4 7. Quality Assurance 7 8. Additional Requirements 7 9. Information to be Supplied with the Offer 8 10. Sample 9 11. Inspection and Testing 9 12. Annex. 10 1 CEB STANDARD 091 : 2000 SPECIFICATION FOR MEDIUM VOLTAGE INSULATOR STRINGS AND HARDWARE FOR COASTAL APPLICATION (12 kV and 36 kV) 1.0 SCOPE This Specification covers the general requirements of design, manufacture, testing, supply and delivery of Tension and Suspension Insulator Sets complete with Anti-Fog type Profile Disc insulators with hardware fittings for 33kV and 11kV coastal overhead distribution systems. 2.0 SYSTEM PARAMETERS a) b) c) d) e) 3.0 - 11kV 33kV 12kV 36kV 50Hz 50Hz Effective Non effective 13.1 kA 13.1 kA - 30 deg. C 40 deg. C 90% Humid tropical climate with polluted atmosphere. From M.S.L. to 1900 M above M.S.L. 90 days. SERVICE CONDITIONS a) b) c) d) 4.0 Nominal Voltage System Highest Voltage System Frequency Type of earthing System Fault Current (Sym.) e) Annual average ambient temperature Maximum ambient temperature Maximum Relative Humidity Environmental condition Condition Operational Altitude - f) Isokeraunic (Thunder day) level - APPLICABLE STANDARDS The equipment and components supplied shall be in accordance with the latest editions of the Standards specified below and amendments thereof. However the CEB Specification shall supersede these Standards in the event there is a discrepancy. a) IEC 60120 (1984) - Dimensions of Ball and Socket Couplings of String Insulator Units b) IEC 60305 (1995) - Characteristics of String Insulator Units of Cap & Pin Type. c) IEC 60372 (1984) - Locking device for ball and socket couplings of string insulator units: Dimensions and tests d) IEC 60383 (1993) Part 1 & Part 2 - Insulator for Overhead Line with Nominal Voltage above 1000V. 2 CEB STANDARD 091 : 2000 5.0 e) IECTR 61211 (1994) - Insulators of ceramic material and Steep wave front impulse test on high voltage insulators. f) IEC 60575 (1977) - Thermal - mechanical performance test and mechanical performance test on String Insulator Units. g) IEC 60797 (1984) - Residual strength of string insulator unit of glass or ceramic material for overhead lines after mechanical damage of dielectric. h) IEC 60507 (1991) - Artificial pollution tests on high-voltage insulators to be used on a.c. systems i) IEC/TR 60815 (1986) - Guide for the selection of insulators in respect of polluted conditions j) ASTM C 151-84 ANSI C29-2 (1992) - Standard test method for Autoclave expansion of Portland cement k) BSENISO 1461 (1999) - Hot dip galvanised coating on iron and steel articles. TECHNICAL REQUIREMENTS a) String Insulator unit ( Disc ) i) ii) iii) iv) v) vi) Type designation Profile type Porcelain diameter Insulator spacing Total Creepage distance Protected creepage distance - U70 BLP / U120 BP Anti - Fog type Profile 280mm 146mm 440mm 280mm b) Radio Interference - IEC60437-1997 (30dB) c) Data of Conductors to be used - Refer ANNEX B d) Insulator fixing cross-arm size mm - 100 x 50 x 6 channel e) Rated Voltage kV - 12 36 f) Minimum Failing Load of the insulator string; - 70 --- 70 120 70 i) ii) iii) Tension set for pole lines Tension set for tower lines Suspension set for tower lines 3 kN kN kN CEB STANDARD 091 : 2000 g) Insulation withstand Voltage i) ii) h) kV kV - 75 28 170 70 - 2 --- 4 4 4 No. of Disc Insulator units in a string i) ii) iii) 6.0 Dry Impulse(1.2/50 μs) peak Wet power frequency (1 min.) Tension set for pole lines Tension set for tower lines Suspension set for tower lines BASIC FEATURE 6.1 Design The insulators will be in service in a damp tropical saliferous climate having higher salinity level where intense lightning storms at certain periods of the year are expected. The design shall take this into account as well as to minimise the effect of local corona formation and discharge likely to cause radio interference. The design shall be such as to facilitate inspections, cleaning, repairs, and hot line maintenance. All corresponding parts to be made to gauge and be interchangeable. The conductor fittings shall be designed for a short circuit current of 10 KA for a duration of one second. The Disc Insulator Set shall withstand such a short circuit current without damage to component parts or welding between them. 6.2 Manufacture 6.2.1 String Insulator Units (Disc Insulators) 6.2.1.1 Insulators The Insulators shall be made of good commercial grade wet process porcelain and shall be `Type B' as per IEC 60383 (1993). The insulator shall be of the Anti–Fog type profile design and cylindrically head type. The entire surface of the porcelain insulator that will expose after (hardware) assembly shall be a smooth uniform brown colour glazed surface. The insulators shall have the correct shed formation to satisfy the specified flash- over characteristics stipulated in the relevant standards and shall be of the type “U 70 BLP / U120BP“ designation as per IEC60305' 6.2.1.2 Hardware The hardware of the disc insulators shall be of the Cap and Pin Type with `16A' Ball and Socket Couplings as per IEC 60120. The Caps of string insulator units shall be made of malleable cast iron and the Pins shall be made of steel. 4 CEB STANDARD 091 : 2000 The steel pin shall be provided with a Zinc (sacrificial) anti-corrosion sleeve at the interface between pin and internal cement, The thickness of the zinc sleeve shall not be less than 5mm and it shall protrude not less than 10mm from the lower surface of the cement. To withstand the damp tropical saliferous climate having higher salinity level, the cap shall be hot dip galvanized and the thickness of galvanising coating shall not be less than 100 micron The insulator head and cap shall be so designed to minimise the mechanical stresses developed due to thermal expansion and to minimise electrical stress distribution. 6.2.1.3 Locking Device The locking devices for the insulator units shall be made of Stainless Steel / Phosphor Bronze Split Pin or Security (W) Clip and shall comply with IEC 60372 (1984). The locking device shall prevent rotation of the disc insulators when the string is tensioned. The design shall be such as to allow (hot line maintenance ) easy removal for replacing of insulator units or fittings without the necessity to remove the insulator string from the cross arms. 6.3 Tension (Insulator) Sets 6.3.1 For Pole Line application The 12kV tension Insulator sets for pole line application shall have two (2) numbers of U70 BLP disc insulator units as per Drawing No. CEB/DS&S/2000/91A The 36kV tension Insulator sets for pole line application shall have four (4) numbers of U70 BLP disc insulator units as per Drawing No. CEB/DS&S/2000/91A 6.3.2 For Tower line application The 36kV tension Insulator sets for tower line application shall consists of four (4) numbers. of U120 BP disc insulator units complete with necessary hardware fittings including compression type conductor tension clamps, adjustable type arcing horns etc. as shown in the Drawing No. CEB/DS&S/2000/91B. 6.4 Suspension (Insulator) Sets The 36 kV Suspension Insulator sets for tower line application shall consist of four (4) numbers of Disc Insulator Units complete with necessary hardware including conductor suspension clamps, fixed type arcing horns etc. as per Drawing No. CEB/DS&S/2000/91C. 6.5 Insulator set fittings (Hardware) for Tension / Suspension sets The Hardware fittings for tension and suspension set shall conform to BS 3288 (1997). and the manufacturer shall furnish Type Test Certificate for all the hardware fitting used in the tension/suspension sets. 5 CEB STANDARD 091 : 2000 6.5.1 Fitting for Tension Set The tension insulator sets shall be complete with Ball Eye, Socket Eye, Anchor Shackle, Cotter Pins, bolted / compression type Conductor Tension Clamps, Arcing Horns etc. as per Drawing Nos. CEB/DS&S/2000/91A and CEB/DS&S/2000/91B. The bolted type conductor tension clamp (Dead End Clamp) shall be made of aluminium alloy with minimum three U bolts for attaching conductor as stipulated in Annex – B and as referred to in the schedule of prices. The compression type conductor tension clamp (Dead End Clamp) with jumper terminal shall be made of aluminium alloy/steel and the jumper lug made of aluminium alloy shall be fixed to the jumper terminal with two bolts. They shall be suitable to be used with the conductor as stipulated in the schedule of prices and the conductor type, size and Across Flat Dimension of the Die to be used is as per Annex B-1. The Ball Eye (Horn holder), Socket Eye (Horn holder) and Anchor Shackle shall be made of forged steel and their ultimate breaking load shall not be less that that of the insulator. Arcing Horns (Adjustable type) and the Cotter Pins shall be made of Steel. 6.5.2 Fitting for Suspension Set The suspension insulator sets shall be complete with Anchor Shackle/U Bolt, Ball Eye (Horn Holder), Socket Eye (Horn Holder), Cotter Pin, Arcing Horn, Conductor Suspension Clamp etc. as per Drawing Nos. CEB/DS&S/2000/91C. Conductor Suspension Clamp shall be made of aluminium alloy with 2 U bolts for attaching conductors as stipulated in the Annex B-1 and as referred to in the Schedule of Prices. The Anchor Shackle/U Bolt, Ball Eye and Socket Eye shall be made of forged steel. 6.6 Prevention of Radio Interference The design of all Insulator Hardware fittings and Accessories shall avoid sharp corners or projections, which would produce high electrical stress in normal working. The design of adjacent metal parts and mating surfaces shall be such as to prevent corrosion of the contact surface and to maintain good electrical contact under service conditions. 6.7 Galvanizing All insulator set hardware shall be galvanised after subjecting to the processes such as sawing, shearing, drilling, punching, filing, bending and machining. Galvanizing shall be applied by hot dip process to comply with the BSEN ISO 1461 (1999) specified. The thickness of zinc coating shall not be less than 100 microns in plain surface. To prevent the formation of white rust, all items shall be treated with sodium dichromate after galvanizing and stored under well ventilated conditions. 6 CEB STANDARD 091 : 2000 6.8 Finish The porcelain shall be sound, thoroughly vitrified and free from defects and blemishes which might adversely affect the life of the insulator. The exposed parts of the porcelain shall be smoothly glazed without any form of depression /defects. Galvanized coating on all hardware components of the string insulator unit and insulator set shall be smooth, continuous, uniform and free from flux stains and nodules of spelter. 7.0 QUALITY ASSURANCE The manufacturer of insulators and hardware components shall posses ISO 9002 Quality Assurance Certification for the manufacture of Porcelain Insulators and the hardware components for the plants where the manufacture of Porcelain Insulators and the hardware components is done. The Bidder shall furnish a copy of the ISO Certificate certified as true copy of the original by the manufacturer, along with the offer. 8.0 ADDITIONAL REQUIREMENTS 8.1 Identification The manufacturer's identification mark, minimum failing load ( kN ) and the year of manufacture shall be permanently marked on the insulators as per IEC60383. All the hardware fittings of the string insulator set shall also have the above marking except the year of manufacture . 8.2 Routine Tests The following routine tests as per BSEN/ IEC 60383 shall be carried out on all the items and the routine test reports shall be made available for the observation of the CEB Inspector at the time of inspection. a) b) c) 8.3 Visual Inspection Routine mechanical test Routine electrical test Packing The string Insulators and Hardware Fittings & Accessories shall be packed separately in non returnable palletised boxes suitable for overseas shipment to a tropical country. The packing shall also be suitable to withstand rough handling without sustaining damages. In packing cases where timber is used for reinforcement, the thickness of such timber parts shall not be less than 25mm. The Name of item, Voltage rating, Quantity and Weight shall be marked clearly on the outside of all packages. 7 CEB STANDARD 091 : 2000 8.4 Manufacturing Experience The manufacturer shall have at least 20 years of experience of manufacturing medium voltage insulators (of same rating offered) to IEC/BS Standards. He shall furnish sufficient documentary evidence in the Bid to prove his manufacturing experience 9.0 INFORMATION TO BE SUPPLIED WITH THE OFFER 9.1 The following shall be furnished with the Offer. a) b) c) d) e) f) g) h) 9.2 Catalogues describing all the item/components offered and indicating Model Nos, Constructional features, materials used for components. Complete dimensional drawings of all item. ISO 9002-Quality Assurance Certification as per Clause 7.0 . List of purchasers Duly completed schedule of guaranteed technical particulars Place of carrying out the Acceptance/Sample Tests as per Clause 11.2 Document to prove the manufacturing experience The Bidder shall furnish a chart indicating their recommended Arc Horn Gap settings for 11KV and 33Kv systems with Basic Insulation Levels as stipulated in Clause 5.0 and the applicable altitudes from MSl up to1900m above MSL for various pollution levels. Type Test Certificate i) The following Type test Certificate as per BSEN/IEC60383 from a recognized independent testing authority acceptable to CEB, shall be furnished with the offer. The Test Certificates shall be given for string insulator unit (disc) as well as for complete Suspension and Tension Insulator sets. a) b) c) d) e) ii) Verification of the dimensions Dry lightning impulse withstand voltage test Wet- power frequency withstand voltage test Electro-mechanical failing load test Mechanical failing load test The following Test Reports as per Standard specified for the string (disc) insulator units shall also be furnished; a) b) c) d) e) Artificial pollution tests as per IEC60507 (1991) and IEC 815 (1986) for disc insulator of Anti Fog profile type, the Salinity level to be 80 kg/m3 Thermal mechanical performance test as per IEC60575 -1977 Residual strength test as per IEC 60797:1984 Cement Auto Clave Expansion test as per ANSI C29-2:1992 & ASTM C151.84 Power Arc test as per IEC 61467 1997 Offers of Bidders who failed to furnish the above particulars/certificates and the sample as per Clause 10.0 shall be rejected. 8 CEB STANDARD 091 : 2000 10.0 SAMPLE One complete sample of the each item / rating quoted (complete with specified hardware) shall be supplied with the offer by the Bidder to facilitate analysis and evaluation of tender. 11.0 INSPECTION AND TESTING 11.1 Inspection The selected Bidder shall make necessary arrangements for inspection by an Engineer of the CEB and also to carryout in his presence Acceptance / Sample tests of the item offered. The report of routine tests performed on the items shall be made available for the observation of the Inspector 11.2 Acceptance/Sample Tests The following acceptance/sample test as per BSEN 60383-1:1998 shall be witnessed by the Engineer nominated by the CEB and cost of tests shall be born by the Bidder. The Bidder shall clearly indicate the place of testing. a) b) c) d) e) f) g) h) i) j) Verification of dimensionsVerification of displacements Verification of the locking system Temperature cycle test Electro-mechanical failing load test Mechanical failing load test Puncture withstand test – As per IEC601211 (1994) Porosity Test Galvanizing Test Steep Wave Front Test The steep wave front test shall be performed on 10 disc insulators selected at random. Each insulator shall be subjected to 10 (Ten) successive positive and negative impulse flash-over with a wave having an effective rate of rise of 2500KV/μs. Then rated dry or wet power frequency withstand voltage shall be applied to each disc insulator. If there is no electric puncture, the insulators are considered to be successfully passed the test. Failure of any one unit either in the steep front-of-wave test or subsequent power frequency withstand voltage test shall cause for testing another 20 units. Failure of more than one unit from the total so tested shall constitute failure to meet the requirements of this specification. 9 CEB STANDARD 091 : 2000 12.0 ANNEX Drawings A-1 CEB/DS&S/2000/91A 12kV &36 kV Tension Insulator string & Hardware for pole line application A-2 CEB/DS&S/2000/91B 36kV Tension Insulator string & Hardware for tower line application A-3 CEB/DS&S/2000/91C 36kV Suspension Insulator string & Hardware for tower line application B Conductor and Die details for compression type tension clamps C-1 Schedule of particulars - Properties of material used for insulator C-2 Schedule of guaranteed technical particulars for Tension and suspension insulator strings & Hardware. 10 CEB STANDARD 091 : 2000 11 CEB STANDARD 091 : 2000 12 CEB STANDARD 091 : 2000 13 CEB STANDARD 091 : 2000 ANNEX B DIE DETAILS FOR COMPRESSION TYPE TENSION CLAMPS (DEAD END CLAMPS) CONDUCTOR Code Name No. of Strand/Wire diameter (mm) O.D. of the Conductor (mm) ACROSS FLAT DIMENSION OF THE DIE TO BE USED (mm) DATA Actual Area of the Conductor (mm²) Breaking Load Single Part Fittings Two Part Fittings (kN) Lady Bird (AAC) 7/2.79 8.38 43 7.4 17.3 Fly (AAC) 7/3.40 10.2 64 10.5 17.3 Wasp (AAC) 7/4.39 13.2 106 16.8 21.0 Weasel (ACSR) 7/2.59 7.77 37 11.4 14.0 12.0 (Alu.) 5.4 (Steel) Racoon (ACSR) 7/4.09 12.3 92 27.4 21.0 17.3 (Alu.) 9.25 (Steel) Lynx (ACSR) 37/2.79 19.53 226 82.7 - 29.0 (Alu.) 13.5 (Steel) AAAC 7/2.67 8.02 39 12.7 12.0 AAAC 7/4.25 12.74 100 30.8 17.3 AAAC 19/3.66 18.30 200 60.33 26.0 * The Tension Clamp (Dead End Clamp) shall not permit slipping or cause damage to or failure at a load less than 95% of ultimate strength of the Conductor. 14 CEB STANDARD 091 : 2000 ANNEX C - 1 SCHEDULE OF PARTICULARS (This schedule shall be duly filled by the Manufacturer for each type of insulator offered) Properties of Material used for Insulators a) Type : b) Chemical Composition : c) Porosity d) Bulk density g/cm3 e) Fatigue strength N/mm2 : f) Tensile strength N/mm2 : g) Impact strength h) Modules of elasticity Gpa i) Mean Coefficient of linear thermal expansion 10-6K-1 : j) Resistance to thermal shock K k) Breakdown voltage kV/mm : l) Dielectric constant tan δ : m) Resistivity Ω : Volume % : : N/mm2 : : : I/We certify that the above data are true and correct. ------------------------------------------------------------------------------------------------------------- SEAL AND SIGNATURE OF THE MANUFACTURER / DATE 15 CEB STANDARD 091 : 2000 ANNEX C - 2 SCHEDULE OF GUARANTEED TCHNICAL PARTICULARS To be filled by the Manufacturer for each type and voltage rating offered ) TENSION 1. 2. Name of manufacturer & country of origin Insulator i) Type designation ii) Catalogue No iii) Profile type iv) Porcelain diameter v) Insulator spacing vi) Total Creepage distance : vii) Protected Cteepage distance : : : : : 3. Type of insulator material : 4. Complete insulator set i) Rated Voltage ii) Rated Frequency iii) Rated withstand Voltages : kV Hz : : kV kV : : kV kV : : kV kV : : kN : a) Lightning Impulse 1) 2) Positive Peak Negative Peak b) 1 Minute Power Frequency 1) 2) Wet Dry c) Power frequency flashover voltages i) ii) Wet Dry d) Minimum failing load e) Number of disc insulator Units in the set Nos f) Distance between centres of disc insulator units 5. mm : kV mm. mm. kN : mm. : % % : : : : For insulator Disc unit a) b) c) d) e) f) g) h) i) 6. : Power frequency Puncture Voltage Total Creepage Distance Protected Creeping distance Minimum Failing load Size of ball and socket coupling Out side diameter of disc Thickness of zinc sleeve mm Purity of zinc sleeve Zinc sleeve fused area Applicable Size of conductors (indicate the range of sizes of conductors) : : : : 16 SUSPENSION CEB STANDARD 091 : 2000 7. Radio Interference noise level at Standard test voltage 8. Dry Arcing Distance of the Complete Units 9. Material and Type of i) ii) : mm Tension Clamp Suspension Clamp : : 10. Overall Length of the complete Unit 11. Whether the following type test certificates as per IEC 60383 are furnished a) b) c) d) 12. 14. 15. 16. mm Verification of the dimensions Wet- power frequency withstand voltage test Electro-mechanical failing load test Mechanical failing load test : Yes/No : Yes/No : Yes/No : Yes/N : Whether the following Type Test Certificates As per Standard specified for the disc Insulator units are furnished; a) Thermal mechanical performance test as per IEC60575 Yes/No ; b) Residual strength test as per IEC 60797;1984 Yes/no : Cement Auto Clave Expansion test as per ANSI C29-2 Yes/No : c) 13. : Artificial pollution test IEC 60507 Salinity level as per Yes/No : g/m3 Whether the type test certificates as per BS 3288 for insulator set fitting (Hardware) furnished) : Yes/No : Whether the ISO 9002 Quality assurance certificates for the following are furnished a) Insulator Yes/No ; b) Insulator set Fitting Yes/No ; Whether the chart indicating the Arc Horn Gap settings as per Clause 9.1 h) furnished. Yes/.No : 17 CEB STANDARD 091 : 2000 17. Whether the following acceptance test as per Clause 10 will be carried out during the inspection and whether the place of testing is indicated a) b) c) d) e) f) g) h) i) Verification of dimensions Yes/No Place of testing Verification of displacements Yes/No Place of testing Verification of the locking system (Ball & Socket Couplings) Yes/No Place of testing Temperature cycle test Yes/No Place of testing Mechanical performance test followed by Electro-mechanical failing load test Yes/No ; Place of testing Puncture withstand test Yes/No : Place of testing Porosity test Yes/No Place of testing Galvanizing Test Yes/No Place of testing Steep wave front tests Yes/No Place of testing : : : : : : ; : : : : : : : : : I/We certify that the above data are true and correct --------------------------------------------------------------------------------------------------------------- SEAL AND SIGNATURE OF THE MANUFACTURER / DATE 18