Copper-Clad Aluminum as an alternative to Copper

advertisement

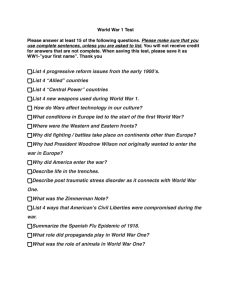

Copper-Clad Aluminum as an alternative to Copper flexible conductors for electric power cables: opportunities and challenges presented by Franco Peruzzotti • Jicable’15, 21 - 25 June 2015 - Versailles - France 19 June 2015 3,4 Copper vs Aluminum, historical trend price • Jicable’15, 21 - 25 June 2015 - Versailles - France Copper price pressure, consequences • Jicable’15, 21 - 25 June 2015 - Versailles - France Base Metals Total Prysmian Volume 2014 Copper 476 ktons/year Aluminium 155 ktons/year Lead 23 ktons/year TOTAL 654 ktons/year Total base metals by region in ktons (act.2014) SA 62 NA 85 APAC 70 EMEA 423 • Jicable’15, 21 - 25 June 2015 - Versailles - France Rod 383 ktons/year Rod 148 ktons/year Cu/Al usage ratio Prysmian applications, 2014 HV&Submarine Power Distribution Infrastructure Renewable Energy Special&OEM Oil&Gas Trade&Installer Heavy Industry Transportation Automotive Aerospace Elevator Military&Defence Telecom Solution Multimedia • Jicable’15, 21 - 25 June 2015 - Versailles - France Conductors, properties comparison key features quality conductivity IACS Specific Gravity, kg/dm3 weight per km, R equivalent diameter, R equivalent mechanical, Tensile kg/mm2-hard mechanical, Tensile kg/mm2-soft Elongation, % fine wire drawing fine wire flexibility installation handling moisture resistant connectors/terminations ease of recovery (end-of-life/or earlier for theft) • Copper Aluminum CCA-10% ETP 1350 Copperlite™ 100 8,91 1 1 45 35 25 *** *** *** *** *** *** Jicable’15, 21 - 25 June 2015 - Versailles - France 61 2,71 0,6 1,28 27 17 15 * * ** * *** 63 3,32 0,6 1,26 30 17 15 *** ** *** ** ** * Copper-Clad-Aluminum, a possible solution to replace Copper Copper-clad aluminum (CCA) conductors: • A core of aluminum clad in a concentric layer of copper • Copper by volume, 10% or 15% • Conductivity 63% - 67% IACS • Processed with conventional copper drawing lines • Skin effect, suitable for high-frequency applications • Lightweight • Approximately 40% lighter than Cu at same DC Resistivity • Cost saving • Lower in cost vs Cu with comparable performance • Anti-theft • Cladding forms a permanent metallurgical bond, making separation practically impossible • Fully recyclable • CCA can be recovered, i.e. as a particular aluminum alloy, to solve the issue of industrial scrap, as well as end-of-life product management • Jicable’15, 21 - 25 June 2015 - Versailles - France Copperlite™ CCA process • Jicable’15, 21 - 25 June 2015 - Versailles - France Cladding vs plating technology Plating: electrochemical process • Cu thickness limitation and diameter – the higher the diameter the lower the output, • Cu layer has weak consistency due to high porosity structure, difficult drawing, Cladding: metallurgical process • Copper being applied is solid, compact tape, so theoretically no limitation to Cu thickness, • Strong Cu/Al metallurgical bond allows easy drawing, • Environmentally friendly • High environmental impact • Jicable’15, 21 - 25 June 2015 - Versailles - France Telecom aerial Copper cable To counter theft, a new twisted-pair aerial TLC cable made from Copperlite™ CCA has been already introduced and is being currently used by Telecom Italia according to its Spec. CT 948, September 2011. Larger diameter conductor: 0.75 vs 0.6 mm or 1.14 vs 0.9 mm (to account for CCA’s higher resistivity) Larger cable diameter (+10%) Lower cable weight (–20%) Same electrical and transmission performances • Jicable’15, 21 - 25 June 2015 - Versailles - France OPEN ACCESS LV/MV power cables Utility, Low Voltage multi-polar cable, concentric neutral conductor of CCA as an alternative to Copper, ENEL Spec. DC 4126, August 2010 ARG7(E4*)OCR-0,6/1 kV – AUG7(E4*)OCR-0,6/1 kV 3 central core conductors in Aluminum and CCA10% concentric neutral conductor Cu vs CCA wires • Jicable’15, 21 - 25 June 2015 - Versailles - France LV 4x25mm2 CCA FG7OR 0.6/1.0kV, class 5 • Jicable’15, 21 - 25 June 2015 - Versailles - France Cable prototypes: building wire 450/750V Conductor (flexible or class 5) cross sections: – Copper 1,5mm2 (reference) – CCA 2,5 mm2 – Tinned CCA 2,5 mm2 – Aluminum 2,5mm2 Final multicore cables - FROR 3 x cores Cable production flow Insulated core stranding Insulation Extruded PVC (different colors to indentify the phase) • Jicable’15, 21 - 25 June 2015 - Versailles - France Outer Sheath Extruded PVC (double layer: filler +outer sheath) Cable prototypes: industrial wire 0.6/1.0 kV Conductor (flexible or class 5) cross sections: – Copper 16 mm² (reference) – CCA 25 mm² – Aluminum 25 mm² Final singlecore cables - FG7R 1kV 1 x core Cable production flow Insulation Extruded silane cross linked PE • Outer Sheath Extruded PVC (double layer) Jicable’15, 21 - 25 June 2015 - Versailles - France Wire Integrity Test 1. Pr En 3475-514, acid test Cleaned 1 m wire samples are helically wound and immersed in concentrated (∼ ∼18%) HCl solution for 1 minute at 25° °C. If the Cu layer is continuous nothing visible happens. Should an holiday be present H2 gas evolution becomes visible with the naked eye Al CORRODED 2Al → 2Al+++ + 6 e- Cu PROTECTED Dissolves in the acid potential ∼ -1,3 VSHE 6H+ + 6e- → 3H2↑ Hydrogen bubbles potential ∼ 0 VSHE • Jicable’15, 21 - 25 June 2015 - Versailles - France Wire Integrity Test, acid test Test performed on high quality CCA clad 0.12 mm wire with no bubbles visible after 1 minute test (left) and on low quality CCA plated 0.25 mm wire after some second of test (right) CCA Cladded (metallurgical process) CCA plated (electrochemical process) • Jicable’15, 21 - 25 June 2015 - Versailles - France Wire Integrity Test, basic test 2. Basic conditions Cleaned 1 m wire samples are helically wound and immersed in concentrated (∼ ∼ 4%) NaOH solution for 4 hours at 70° °C. Should an holiday be present Al will be etched locally, the damage being better seen in low power after-test microscope examination. Al CORRODED 2Al + 4H20 → 2AlO2- + 8H++6e- Cu PROTECTED 2AlO2- + 2NaOH + 2H+ → 2AlO2Na + 2H2O 6H+ + 6e- → 3H2↑ Hydrogen bubbles scarcely visible potential ∼ -0,9 VSHE Forms a gel in the solution potential ∼ -2,5 VSHE • Jicable’15, 21 - 25 June 2015 - Versailles - France Wire Integrity Test Results Test in acid conditions Test in basic conditions Material Wire o.d. (mm) Taken from stranded conductor (mm2) Ten 1 m wire samples average rating for no H2 (minutes) CCA 0,4 25,0 1,02 CCA 0,2 2,5 0,98 Sn CCA 0,2 2,5 2,47 Material Wire o.d. (mm) CCA CCA Sn CCA 0,4 0,2 0,2 • Taken from stranded conductor (mm2) 25,0 2,5 2,5 Jicable’15, 21 - 25 June 2015 - Versailles - France Five 1 m wire samples 5 5 5 Outdoor life test scheme 0,5 Ω, 300W Variac 1 kVA ∼ 24 Vac 15 A A mV A • 9 feed through terminals • 8 loops of different conductor wires • 16 wire terminations in series • Jicable’15, 21 - 25 June 2015 - Versailles - France 2,0 0,5 hours Outdoor life test infrastructure • Jicable’15, 21 - 25 June 2015 - Versailles - France Results, Cu1.5 mm2 vs CCA, SnCCA, Al 2.5mm2 650 600 ac potential drop (mV) 550 Cu 500 CCA 450 400 CCA Sn crimped Al burn-out & substitution ↓ 350 Al 300 250 200 150 0 200 400 600 800 1000 1200 Time (hour) • Jicable’15, 21 - 25 June 2015 - Versailles - France 1400 Al 2.5mm2 samples failed after 500, 1600h • Jicable’15, 21 - 25 June 2015 - Versailles - France Water exposure test set up Single wire and stranded conductors helical samples after 500 hour test in tap water. The Calomel reference electrode used for electrode potential monitoring also visible. • Jicable’15, 21 - 25 June 2015 - Versailles - France Water exposure test results time (h) to visible wire ext. from stranded conductor Al corrosion spots diam, conductor, material on 2 wire samples, mm mm2 1m length CCA 0,4 25 50-100 CCA 0,2 2,5 50-100 Sn CCA 0,2 2,5 500 • Jicable’15, 21 - 25 June 2015 - Versailles - France Salty water test of end cut CCA samples • Jicable’15, 21 - 25 June 2015 - Versailles - France Conclusions CCA is an attractive alternative to Copper Lightweight, low cost, anti-theft, critical issue CCA quality raw material quality (Cu, Al), good metallurgical bonding; 2 methods are proposed to test CCA integrity; Outdoor life test was defined to understand conductors behavior in realistic installation and sever conditions Results so far achieved demonstrate the potentiality of application of CCA as flexible conductor for electric LV power cables. • Jicable’15, 21 - 25 June 2015 - Versailles - France contact • Prysmian SPA, Milan, ITALY – Alberto BAREGGI, Flavio CASIRAGHI, Luca DE RAI, Silvio FRIGERIO, Davide MARTELLI; – – – – – • alberto.bareggi@prysmiangroup.com, flavio.casiraghi@prysmiangroup.com, luca.derai@prysmiangroup.com, silvio.frigerio@prysmiangroup.com, davide.martelli@prysmiangroup.com Prysmian Cavi e Sistemi Italia Srl, Milan, ITALY – Alessandro MAZZUCATO – alessandro.mazzucato@prysmiangroup.com • Dynext Srl, Legnano (Milan), ITALY – Franco PERUZZOTTI, Antonio PEZZONI; – franco.peruzzotti@dynext.eu, – antonio.pezzoni@dynext.eu • G.B. Studio Sas, Milan, ITALY – Pietro ANELLI, anellibonvini@tin.it • Copperweld, Nashville, Tennessee, USA – Dustin FOX, Syarif YANCE; – dfox@copperweld.com, – YSyarif@copperweld.com • Jicable’15, 21 - 25 June 2015 - Versailles - France