Nemko´s FREE NEBS-seminar in Stockholm June

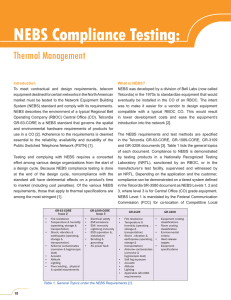

advertisement

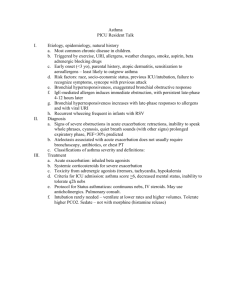

“Successful Market Access for your Telecom Network Equipment in North America: • Knowledge about NEBS requirements • Preparation of products for NEBS compliance • Perform efficient NEBS testing projects” Welcome to Nemko´s FREE NEBS-seminar in Stockholm June 8th! Programme Date: Time: Place: Adress: Booking: e-mail: phone: Tuesday, June 8th 09.15-12.30 (Nemko offers lunch from 12.30) Scandic Täby Hotel Näsbyvägen 4 in Täby (approx. 15 minutes by car from Stockholm city center) Latest Friday MAY 28th! to peter.hansson.ardbo@nemko.com or +46-(0)709-52 16 70 Mr Ravi Subramaniam from MET Laboratories in the US will give a presentation about NEBS requirements (GR-487-CORE, GR-63-CORE, Verizon Energy, GR-1089-CORE) and answer your questions. Nemko and MET will present how an efficient NEBS-project is performed with local support from Nemko´s Nordic organization. Nemko provides a one-stop-shop (testing & certification) offer for Telecom manufacturers in the Nordic region including NEBS services in collaboration with our US partner MET Laboratories. MET Laboratories is a pioneer in NEBS testing. MET performs all required NEBS testing at one fully equipped facility on either coasts. MET’s extensive capabilities include complete, Verizon-certified NEBS testing facilities, in Baltimore - MD, Santa Clara - CA and Union City - CA. Four in-house US based labs at each MET NEBS facility afford flexible scheduling and complete testing to all NEBS ANEBSprojectwithNemko/METasyourpartner requirements. A NEBS project with Nemko/MET as your partner The Nordic Region offers limited local NEBS support to manufacturers. Nemko/MET offers a unique NEBS service package (figure below) for the Nordic The Nordic Region offers limited local NEBS support to manufacturers. Telecom industry, where we provide local support during the whole project. Nemko/MET offers a unique NEBS service package (figure below) for the Nordic Telecom industry, where we provide local support during the whole project. Welcome! Peter Hansson Ardbo Country Manager Sweden Nemko Sweden What is NEBS? NEBS is a set of technical requirements and objectives that were originally developed by AT&T’s Bell Labs under the title of Technical Publications with the purpose of making network switches robust and reliable. After the 1984 divestiture of AT&T, NEBS ownership passed on to Bellcore (currently Telcordia), the research arm of Regional Bell Operating Companies (RBOC), for maintenance and upgrades. Since then Telcordia has renamed the publications Generic Requirements (GR) and published many new ones. The NEBS requirements and test methods are specified in the Telcordia GR-63-CORE, GR-1089-CORE, GR3109 and GR-3208 documents. The table below lists the general topics of each document. Compliance to NEBS is demonstrated by testing products in a Nationally Recognized Testing Laboratory (NRTL) sanctioned by RBOCs or in the manufacturer’s test facility, supervised and witnessed by an NRTL. Depending on the application and the customer, compliance can be demonstrated on a tiered system defined in the Telcordia SR-3580 document as NEBS levels 1, 2 and 3, where level 3 is for Central Office (CO) grade equipment. NEBS level 1 is mandated by the Federal Communication Commission (FCC) for co-location of Competitive Local Exchange Carrier (CLEC) equipment in the Incumbent Local Exchange Carrier (ILEC) spaces. Other standards bodies, such as the European Telecommunication Standards Institute (ETSI) and American National Standards Institute (ANSI), have NEBS-like standards. Compliance to ETSI is a requirement for the majority of the EU countries. ANSI’s requirements do not cover all the subjects that NEBS does and are still in progress. Some ANSI standards, such as fire testing, have gained wide acceptance in the industry and NEBS refers to them. A few companies also have developed their own standards, such as Verizon’s NEBS, SBC’s TP-76200 and AT&T NEBS. These are usually a collection of references to the NEBS with additional company specific requirements. Why NEBS? The answer lies in the network reliability and longevity requirements. The PSTN (Public Switched Telephone Network) was designed and is being operated by phone companies, which are considered utilities and are regulated by the FCC. The FCC requires certain network reliability and, at the same time, regulates the profit margins of the RBOCs and the phone rates. To keep the phone rate low, RBOCS are required to write off their capital expenditure in 20 to 25 years. This in turn compels RBOCs to hold onto most of their network equipment for a long duration and to update them only when the business requires it. Thus, to fulfill FCC requirements and to protect their investments, RBOCs have been enforcing NEBS as a mean of increasing the reliability and quality of products in the network. An indicator of the achieved reliability is the downtime of telecom switches, which is measured in minutes per year. In comparison, most information technology or enterprise equipment has regularly scheduled maintenance and downtimes. Many of these telecom switches have been in the field for more than 20 years, still operating reliably and demonstrating the effectiveness of NEBS. To verify NEBS compliance of a new product, RBOCs go through an approval process before deploying the product in their network. This is done by requiring the Telecommunications Carrier Group (TCG) NEBS Checklist to be completed for each product and to be backed by test reports. This checklist was created by a consortium of telecom operators (Bell South, Qwest, SBC and Verizon) in 2004 to examine various aspects of NEBS compliance and to obtain information regarding power requirements, power dissipations and physical dimensions. NEBS Testing NEBS testing is the last step in the design cycle. This is where the hardware and software have to be ready and integrated for the first time in a fully configured system. Since initial integrations are always a challenging process, enough time should be allocated for this step. A comprehensive test strategy and test plan should always be the first step in any NEBS testing. The test strategy should decide on matters such as tests to be carried out, number of EUTs (equipment under test), test location and other relevant information that affect the planning and budget. The test plan should contain the description of the EUT, set ups, logistics and pass and fail criteria among other necessary information. TCG provides a test plan and test report template in the required format for some RBOCS. Tests must always be sequenced to address equipment availability, marketing needs and the designer’s priorities. For example, if there is only a single system available, then the fire test is the last. However, if NEBS level 1 is required initially for marketing reasons (some RBOCs require NEBS level 1 for lab deployment), the fire test would have to be moved up in the schedule. A full set of NEBS testing with a single system can take anywhere from three to six months. To reduce the test period it is always recommended to allocate multiple systems for NEBS testing. This will get the product to the market faster, reduce the wear and tear on the EUT and increase the probability of success. Thermal and humidity tests are the longest NEBS tests and in total take about a month to complete. Even though not required, it is always a good practice to monitor internal system temperatures and, when dealing with marginal systems, to make sure the chamber fans are not interfering with the system fans in a negative way. Except for fire and airborne contaminates tests, NEBS testing should not be destructive. However, systems coming out of NEBS testing are not suitable for future testing. Reuse of the previously tested components increases the chance of failure and erroneous results.