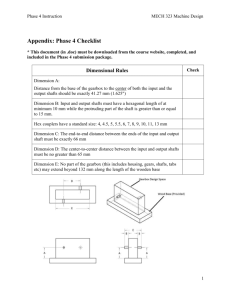

Linear Bushings and Shafts

advertisement