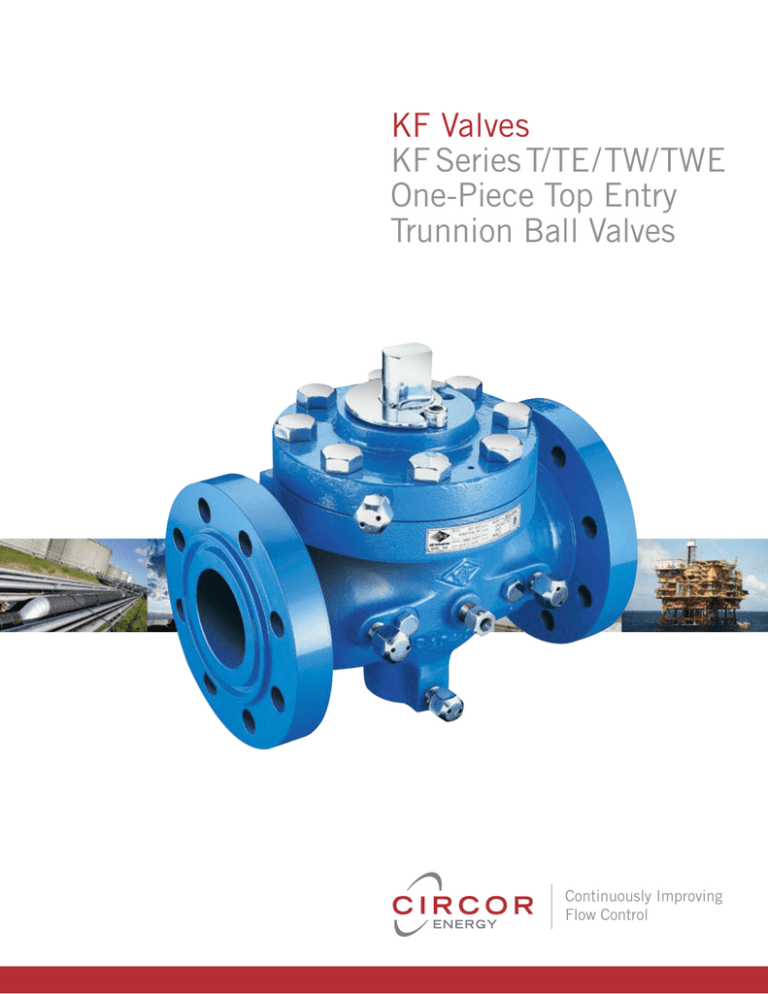

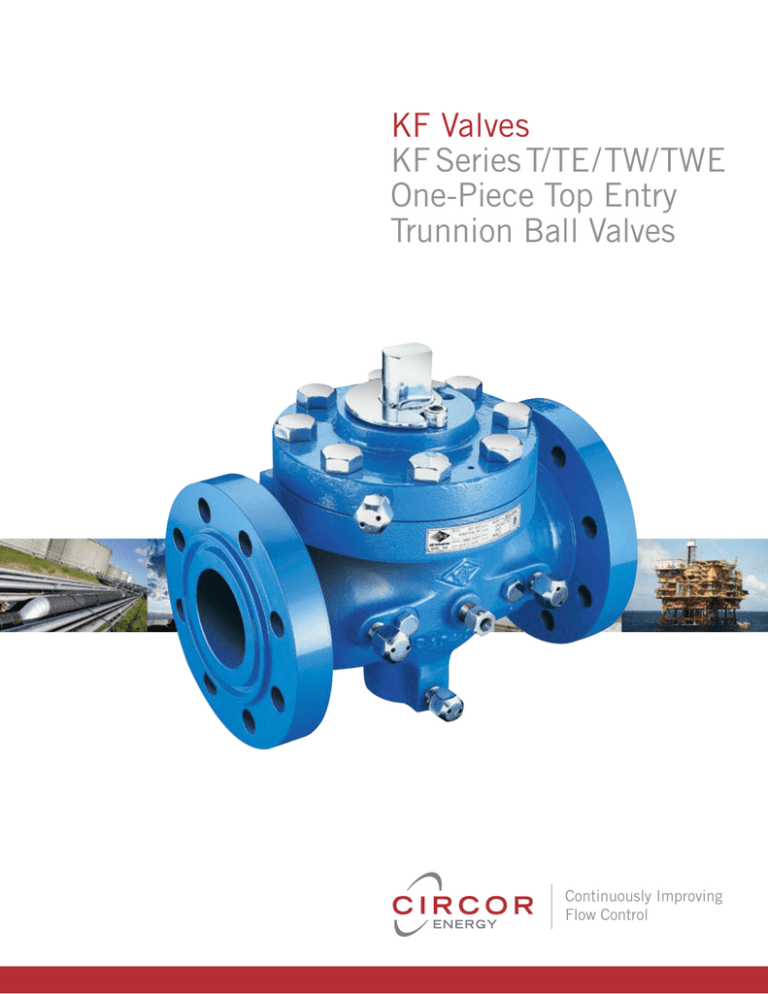

KF Valves

KF Series T/TE/ TW/TWE

One-Piece Top Entry

Trunnion Ball Valves

Continuously Improving

Flow Control

KF Series T/TE Ball Valves

Features

One-piece flanged top entry

trunnion design

Double block and bleed

Self relieving seat

One-piece ball and stem assures

precise positioning

This top entry valve with a one-piece

trunnion supported ball conforms

to API specifications 6A, 6D and

ANSI B16.34. All seats are retained

in metal holders which are springloaded against the ball for low

pressure, firesafe sealing.

Series T valves are offered in:

2" thru 12" class 600, 900,

1500 & 2500,

2" thru 7 1/16" API 6A class 2000,

3000 & 5000.

Anti-blowout one-piece

ball /stem design

O-rings plus firesafe packing

prevents leakage

Corrosion resistant low

friction bearings

Inconel® wave springs provide

upstream and downstream sealing

Stainless steel sealant injection

fittings for emergency stem or

seat sealing

Inline repairable due to patented

seat retainer design

Minimized torque required to

open and close valve

Antistatic device for grounding of

the ball, stem and body

Integral topworks direct

mounting pad

8" & larger valves are equipped

with lifting lugs

CE Marked

(P.E.D. 97/23/EC, Cat. 3)

Firesafe Function

In case of fire and seat construction

damage, firesafe requirements are

accomplished with automatic

metal-to-metal positive sealing.

Before

Contents

After

Series T / TE & TW/ TWE Valve Assembly Part Number Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 4

Design Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Technical Seating Features & Product Availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Applicable Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Component Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Series T / TE Dimensional Data, API 6D & ASME B 16.34, Class 600, 900, 1500 & 2500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 -12

Series T / TE Dimensional Data, API 6A, 2000, 3000 & 5000 RTJ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 -14

Series T W/ TWE Dimensional Data, API 6D & ASME B 16.34, Class 600 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Topworks & Stem Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 -17

Weights & Ring Grooves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 -19

Engineering Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Optional Accessories & Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

KF Valves

2

KF Series T/ TE Valve Assembly Part Number Codes

Ø • Domestic

E • Global

Base Number

See Chart Below

Body / Bolting Material

1 • CS Body-Standard

2 • SS / CS (Xylan®)

8 • LTCS / LTCS

E • 316SS / 660SS

H • CA -15M / 660SS

Trim Material

1 • CS (1 mil ENP) Standard on ANSI Cl. 1500, 2500 & 6A

2 • 316SS

3 • 410SS or CA -15M

6 • CS (3 mil ENP) Standard on ANSI Cl. 600 & 900

7 • LTCS (3 mil ENP) (LT Ball / Stem, CS Seats & SS Ftgs)

8 • LTCS (1 mil ENP) (LT Ball / Stem, CS Seats & SS Ftgs)

Seat Insert

5 • PEEK™

9 • Devlon® V

O-Ring / Backup Ring Material

2 • Viton® A

4 • EPDM / PEEK™

5 • Aflas® / PEEK™

8 • Low Temp Buna N

A • James Walker® Viton®

F • Elast-O-Lion® 985 (JW)

G • HNBR

Note: All Class 2500 assemblies

include PEEK™ backup rings.

Specifications

4 • NACE Cl. III Bolting

6 • NACE Cl. II Bolting

Options

9 • Standard

Actuation

1 • Handle

3 • Gear Operator

4 • Handle w/Locking Device

6 • Gear Operator w/Locking Device

9 • Bare Stem

A • For Actuation

Process Codes

(Last two digits used ONLY when process codes are required).

Ø 2487- 1 6 9 G 4 9 1 XX

Assembly Base Numbers, API

Example

Class

Asterisk ( * ) in lieu of dash ( - ) in Assembly Part Number

indicates customer requires source inspection.

(i.e. ØXXXX * XXXXXXXXX)

2000

3000

5000

(i.e. ØXXXX-XXXXXXXXX) - Domestic

(i.e. EXXXX-XXXXXXXXX) - Global

2 FP

3314

3324

3432

3 RP

3315

3325

3433

3 FP

3316

3326

3434

Size (in.)

4 RP

3317

3327

3435

4 FP

3318

3328

3436

6 RP

3319

—

3437

6 FP

3320

3330

3438

Assembly Base Numbers, RF & RTJ

Class / End

Connection

600 RF

600RTJ

900RF

900RTJ

1500RF

1500RTJ

2500 RF

2500 RTJ

2 FP

2486

2506

2734

2773

2860

2876

3087

3110

3 RP

2487

2507

2735

2774

2861

2877

—

—

3 FP

2488

2508

2736

2775

2862

2878

3089

3112

4 RP

2489

2509

2737

2776

2863

2879

3090

3113

4 FP

2490

2510

2738

2777

2864

2880

3091

3114

6 RP

2491

2511

2739

2778

2865

2881

3092

3115

Size (in.)

6FP

2492

2512

2740

2779

2866

2882

3093

3116

8RP

2493

2513

2741

2780

2867

2883

3094

3117

8 FP

2494

2514

2742

2781

2868

2884

3095

3118

10 RP

2495

2515

2743

2782

2869

2885

3096

3119

10 FP

2496

2516

2744

2783

2870

2886

3097

3120

12RP

2497

2517

2745

2784

2871

2887

—

—

12 FP

2498

2518

2746

2785

2872

2888

—

—

KF Valves

3

KF Series TW/ TWE Valve Assembly Part Number Codes

Ø • Domestic

E • Global

Base Number

See Chart Below

End Connection

3 • WE x WE

4 • RF x WE

5 • RTJ x WE

Weld End Wall Thickness

See Weld Chart Below

NACE II Conformance Body / Cl. II Bolting Material

N • A216 (CS) B7M

P • SS / B7M (Xylan®)

S • A352 LCC / L7M

T • SS / 660SS

Trim

2 • 316SS

6 • CS (3 mil ENP)

7 • LCC (3 mil ENP)

Seat Insert / FS

C • PEEK™ / FS

E • Devlon® / FS

Seal Material

2 • Viton® A

4 • EPDM

5 • Aflas®

8 • Low Temp Buna N

Actuation

1 • Handle

3 • Gear Operator

4 • Handle w /Locking Device

A • James Walker® Viton®

F • Elast-O-Lion® 985 (JW)

G • HNBR

6 • Gear Operator w/Locking Device

9 • Bare Stem

A • For Actuator

Process Codes

(Last two digits used ONLY when process codes are required).

Ø 6208-3 17 N 6 E G 1 XX

Example

Asterisk ( * ) in lieu of dash ( - ) in Assembly Part Number indicates customer requires source inspection. (i.e. XXXXX * XXXXXXXXX)

(i.e. ØXXXX- XXXXXXXXX) - Domestic • (i.e. EXXXX-XXXXXXXXX) - Global

Assembly Base Numbers

Class

600

900

2 FP

6177

6206

3 RP

6178

6207

3 FP

6179

6208

4 RP

6180

6209

4 FP

6181

6210

6 RP

6182

6211

Size (in.)

6 FP

6183

6212

8RP

6184

6213

8 FP

6185

6214

10 RP

6186

6215

10 FP

6187

6216

12 RP

6188

6217

12 FP

6189

6218

Note: Consult factory for sizes and psi classes not shown.

KF Series TW Buttweld End Schedule Code

Pipe

Description

Outside Diameter (in.)

(STD) Standard

Schedule 40

Schedule 60

XS

Schedule 80

Schedule 120

Schedule 160

XXS

2

Code

2.375

—

—

.154

08

—

—

.218

15

.218

15

—

—

.343

31

.436

37

3

Code

3.500

—

—

.216

14

—

—

.300

24

.300

24

—

—

.438

38

.600

44

Nominal Pipe Size (in.) / KF Schedule Code

Code

6

Code

8

Code

4.500

6.625

8.625

.237

17

.280

22

.322

28

.237

17

.280

22

.322

28

—

—

—

—

.406

35

.337

30

.432

36

.500

39

.337

30

.432

36

.500

39

.438

38

.562

42

.718

49

.531

40

.718

49

.906

55

.674

47

.864

53

.875

54

4

10

Code

10.750

.365

32

.365

32

.500

39

.500

39

.593

43

.843

52

1.125

62

1.000

58

12

Code

12.750

.375

33

.406

35

.562

42

.500

39

.687

48

1.000

58

1.312

68

1.000

58

Consult factory for other wall thicknesses.

KF Valves

4

KF Series T/ TE & TW/ TWE Design Features

1 Firesafe Standard Seal

a

a

a

b

b

b

d

d

c

c

1A

c

1B

A 2" - 6" class 600 -1500

All sizes class 2500

a

a Weather seal

b

b Stem seal braided carbon rope

c Primary stem seal

B 8" - 12" class 600 -1500

c

a Weather seal

b Stem seal braided carbon rope

c Primary stem seal

d Secondary stem seal

Note: Details for lower stem

configuration on page 8.

2 Lubricant / Emergency Seat Seal

Special sealants may be injected

into fittings that are located on the

body to restore sealing integrity if

seat sealing surface is damaged.

A second internal check valve

provides backup to the fitting.

3 Emergency Sealant

Injection System

2

3

The sealant injection system

located on the body can be utilized

in case of emergencies, o-ring

damage or if stem leakage occurs.

4 Double Sealed

Envelope Connections

Double o-rings or an o-ring and

firesafe gasket on body/bonnet

connections ensure positive sealing,

making the series T suitable for

above or below ground service.

5 Antistatic Device

A spring between the bonnet and

ball permits electrical continuity.

4

5

6 Heavy Duty Bearings

Heavy duty PTFE lined bearings

eliminate the need to lubricate stem

and trunnion journals, resulting in

smooth and easy operation. Upper

stem/lower trunnion bearings

balance the pressure load on the

ball by reducing friction between

ball and seat. A garfil epoxy bearing

with PTFE filler is standard in 2" - 6"

class 600, 900 & 1500 and 8", 10"

& 12" class 600 & 900.

A garloc DU bearing with PTFE liner

is standard in 8", 10" & 12" class

1500 and 2"-10" class 2500.

6

KF Valves

5

KF Series T/ TE & TW/ TWE Technical Seating Features

Double Block and Bleed

The double block and bleed

condition is available in all

seat design configurations.

When the ball is in the closed

position the body cavity

pressure may be drained

down to ‘zero’ by opening

the bleed valve and draining

the fluid by removing the

drain plug. Each seat works

independently assuring

tight shut off seal against

ball on the upstream and

downstream side.

Self Relieving Seat Design

Upstream Seat

The difference in the area

(D1) times the line pressure

forces the seat against the

ball surface. Also the springs

behind the seat adds the

force to the seat which keeps

the seat in contact with the

ball surface by providing the

tight seal.

Downstream Seat

When the body cavity pressure

exceeds the spring pressure,

automatic pressure relief

will occur by relieving the

body cavity pressure past

the downstream seat. This

eliminates the need for the

body relief valve.

Open Vent (Bleed Valve) to Atmosphere

for Seat Sealing Confirmation

PB=Body Cavity Pressure Is Atmosphere

CLOSED

BALL

FLOW LINE

Double Block and Bleed

Upstream Seat

Downstream Seat

PD -Line Pressure

PB=Body Cavity Pressure is Atmosphere

A2

D1

A1

PL-Line

Pressure

D1=A1-A2

A1

D1

A2

CLOSED

BALL

FLOW LINE

Self Relieving Seat Design

Product Availability, ANSI B16.34, API 6A & API 6D

Class /

End Connection

600 RF/RTJ

900 RF/RTJ

1500 RF/RTJ

2500RF/RTJ

2000RTJ

3000RTJ

5000 RTJ

Standard

ANSI B 16.34 &

API 6D

API 6A

2FP

X

X

X

X

X

X

X

3RP

X

X

X

—

X

X

X

3 FP

X

X

X

X

X

X

X

4RP/FP

X

X

X

X

X

X

X

Size (in.)

6RP

X

X

X

X

X

—

X

6FP

X

X

X

X

X

X

X

8RP/FP

X

X

X

X

—

—

—

10RP/FP

X

X

X

X

—

—

—

12RP/FP

X

X

X

—

—

—

—

Consult factory for sizes not shown.

KF Valves

6

KF Series T/ TE & TW/ TWE Applicable Standards

The following list contains the most important applicable standards for ball valves. KF valves may be designed,

manufactured and tested in accordance with other international standards on request.

API-American Petroleum Institute

Spec. Q1

Spec. 6A

Specification for wellhead and Christmas

tree equipment.

Spec. 6D

Specification for pipeline valves.

Std. 607

Fire test for soft seated

quarter-turn valves.

Spec. 6FA

Specification for fire testing of valves.

Std. 598

Valve inspection and test.

Std. 605

Large diameter carbon steel flanges.

ASME/ANSI-American National

Standard Institute

B 16.5

Steel pipe flanges and flanged fittings.

B 16.10

Face-to-face and end-to-end dimensions

of ferrous valves.

B 16.25

Butt welding ends.

B 16.34

Steel valves -flanged and butt welding

ends (pressure & temperature ratings).

B 31.3

Chemical plant and petroleum

refinery piping.

ASTM- American Society

for Testing Materials

Consult factory for details.

British Standards

BS 1503

Specification for steel forgings for

pressure purposes.

BS 1504

Specification for steel castings for

pressure purposes.

BS 2080

Face-to-face, center-to-face, end-to-end,

and center-to-end dimensions of

flanged and butt welding end steel

valves or the petroleum, petrochemical

and allied industries.

EC-European Community

CE Marked

(P.E.D. 97/23/EC, Cat. 3)

ISO- International Organization

for Standardization

ISO 9001: 2000

Quality systems- Model for quality

assurance in design /development,

production, installation and servicing.

MSS - Manufacturers

Standardization Society

SP 6

Standard finishes for contact

faces of pipe flanges and

connecting-end flanges of valves

and fittings.

SP 25

Standard marking system for

valves, fittings, flanges and unions.

SP 45

Bypass and drain

connection standard.

SP 55

Quality standard for steel

castings -visual method.

Hydrogen Sulfide

(H2S Environments)

NACE MR0175

ISO 15156

General principles for cracking

resistant materials in H2S

containing environments

in oil & gas production.

ISO 15156

For use in H2S containing environments

in oil and gas production.

B 31.4

Liquid petroleum transportation

piping systems.

B 31.8

Gas transmission and distribution

piping systems.

KF Valves

7

Series T/ TE & TW/ TWE Component Parts

8"FP & Larger

Sizes Only

5

17

36

16

6

15

5

12

13

3

29

2

20

5

24

6

36

14

4

35

10

4

11

8

9

7

7

22

9

8

11

10

18

19

20

40

21

1

41

Trunnion Cover O-Ring

Available for 11/2 " thru 6"

Bore Only

30

Lower Stem Detail

8" thru 12"

34

32

33

24

8"FP and

Larger Sizes Only

31

Primary Seal

Secondary Seal

Stem Packing

KF Valves

8

11/2" thru 8"RP Only

23

Note: Weld End Configuration

Not Shown (Series TW)

Parts List

Part No.

Description

1

Body

2

Bonnet

3*

Ball / Stem

4

Trunnion Bearing

5*

Stem Seal ††

6*

Stem Backup Ring ††

7*

Seat

8*

Seat O-Ring

9*

Seat Backup Ring

10*

Seat Sub Seal/Braided Carbon Rope

11*

Wave Spring

12

Bonnet Cap Screw

13 †

Stop Screw

14*

Bonnet Gasket / Seal

15*†

Stem Bearing

16 †

Stop Plate

17* †

Retainer

18

Retract. Port Screw

19*

Retract. Port Seal

20

Injection Fitting

21

Bleed Valve

22

Bonnet Alignment Pin

Grounding Plunger

23 †

24

Grounding Spring

29

Key, 8" & Larger Sizes Only

30

Thrust Plate

31

Thrust Adjustment Screw

32

Jam Nut

33

Thrust Plate Bolt

34

Lock Washer

35*

Bonnet Primary Seal

36*

Stem Packing / Braided Carbon Rope

40

Internal Ball Check

41*

Trunnion Cover O-Ring

*Recommended spare parts where applicable.

† Not used in 8"FP and larger assemblies.

†† 8" and larger use double stem seals.

KF Series T/ TE Dimensional Data

G

Z

H

F

E

U

D

A

BB

AA

F

V • No. of Holes

W • Hole Dia.

X • Bolt Circle

C

ANSI B16.5

Flanges

B

Y

Dimensional Data (in. / mm), 2"FP-12"FP, Class 600, API 6D & ANSI B16.34

Dimension (in.)

Size

(in.)

2x2

3x2

3x3

4x3

4x4

6x4

6x6

8x6

8x8

10 x 8

10 x 10

12 x 10

12 x 12

F

A

2.06

2.06

3.13

3.13

4.06

4.06

6.00

6.00

8.00

8.00

10.00

10.00

12.00

B

RF

11.5

14.0

14.0

17.0

17.0

22.0

22.0

26.0

26.0

31.0

31.0

33.0

33.0

C

RTJ

11.63

14.13

14.13

17.13

17.13

22.13

22.13

26.13

26.13

31.13

31.13

33.13

33.13

RF

5.75

7.00

7.00

8.50

8.50

11.00

11.00

13.00

13.00

15.50

15.50

16.50

16.50

D

RTJ

5.81

7.06

7.06

8.56

8.56

11.06

11.06

13.06

13.06

15.56

15.56

16.56

16.56

E

Top of

CL of

G

H

U

V

W

X

Y

Z

AA

BB

22

22

30

30

48

48

48

48

—

—

—

—

—

1.19

1.19

1.69

1.69

1.97

1.97

2.41

2.41

3.13

3.13

3.69

3.69

4.25

4.88

4.88

5.50

5.50

7.09

7.09

8.56

8.56

11.25

11.25

12.94

12.94

15.13

8

8

8

8

8

12

12

12

12

16

16

20

20

0.75

0.88

0.88

1.00

1.00

1.13

1.13

1.25

1.25

1.38

1.38

1.38

1.38

5.00

6.63

6.63

8.50

8.50

11.50

11.50

13.75

13.75

17.00

17.00

19.25

19.25

8

8

10

10

12

12

18

18

24

24

30

30

20

1.75

1.75

2.50

2.50

2.50

2.50

3.50

3.50

4.63

4.63

4.63

4.63

6.25

4.88

4.88

5.75

5.75

6.50

6.50

8.31

8.31

10.13

10.13

11.88

11.88

14.50

7.19

7.19

7.50

7.50

9.25

9.25

11.94

11.94

14.63

14.63

17.19

17.19

18.38

Handle H/Whl.

6.50

8.25

8.25

10.75

10.75

14.00

14.00

16.50

16.50

20.00

20.00

22.00

22.00

6.50

6.50

7.63

7.63

9.50

9.50

11.44

11.44

14.38

14.38

16.63

16.63

19.38

7.59

7.59

8.59

8.59

10.59

10.59

12.44

12.44

—

—

—

—

—

6.00

6.00

6.88

6.88

8.47

8.47

10.44

10.44

13.38

13.38

16.06

16.06

21.50

Dimension (mm)

Size

(in.)

2x2

3x2

3x3

4x3

4x4

6x4

6x6

8x6

8x8

10 x 8

10 x 10

12 x 10

12 x 12

F

A

52.39

52.39

79.38

79.38

103.19

103.19

152.4

152.4

203.2

203.2

254.0

254.0

304.8

B

RF

292.1

355.6

355.6

431.8

431.8

558.8

558.8

660.4

660.4

787.4

787.4

838.2

838.2

RTJ

295.28

358.78

358.78

435.0

435.0

561.98

561.98

663.6

663.6

790.6

790.6

841.4

841.4

C

RF

RTJ

146.05 147.64

177.8 179.39

177.8 179.39

215.9 217.49

215.9 217.49

279.4 280.99

279.4 280.99

330.2 331.79

330.2 331.79

393.7 395.3

393.7 395.3

419.1 420.7

419.1 420.7

D

E

Top of

CL of

G

H

U

V

W

X

Y

Z

AA

BB

558.8

558.8

762

762

1219.2

1219.2

1219.2

1219.2

—

—

—

—

—

30.16

30.16

42.86

42.86

50.00

50.00

61.12

61.12

79.4

79.4

93.7

93.7

108.0

123.8

123.8

139.7

139.7

180.2

180.2

217.5

217.5

285.8

285.8

328.6

328.6

384.2

8

8

8

8

8

12

12

12

12

16

16

20

20

19.1

22.2

22.2

25.4

25.4

28.6

28.6

31.8

31.8

34.9

34.9

34.9

34.9

127

168.3

168.3

215.9

215.9

292.1

292.1

349.3

349.3

431.8

431.8

489.0

489.0

203.2

203.2

254

254

457.2

457.2

457.2

457.2

609.6

609.6

762

762

508

44.5

44.5

63.5

63.5

63.5

63.5

88.9

88.9

117.5

117.5

117.5

117.5

158.8

123.8

123.8

146.1

146.1

165.1

165.1

211.1

211.1

257.2

257.2

301.6

301.6

368.3

182.6

182.6

190.5

190.5

235.0

235.0

303.2

303.2

371.5

371.5

436.6

436.6

466.7

Handle H/Whl.

165.1

209.55

209.55

273.05

273.05

355.6

355.6

419.1

419.1

508.0

508.0

558.8

558.8

165.1

165.1

193.68

193.68

241.3

241.3

290.51

290.51

365.1

365.1

422.3

422.3

492.1

192.88

192.88

218.28

218.28

269.08

269.08

315.91

315.91

—

—

—

—

—

152.4

152.4

174.63

174.63

215.11

215.11

265.11

265.11

339.7

339.7

408.0

408.0

546.1

KF Valves

9

KF Series T/ TE Dimensional Data

G

Z

H

F

E

U

D

A

BB

AA

F

V • No. of Holes

W • Hole Dia.

X • Bolt Circle

C

ANSI B16.5

Flanges

B

Y

Dimensional Data (in. /mm), 2"FP-12"FP, Class 900, API 6D & ANSI B16.34

Dimension (in.)

Size

(in.)

2x2

3x2

3x3

4x3

4x4

6x4

6x6

8x6

8x8

10 x 8

10 x 10

12 x 10

12 x 12

F

A

B

RF

2.06 14.50

2.06 15.00

3.13 15.00

3.13 18.00

4.06 18.00

4.06 24.00

6.00 24.00

6.00 29.00

8.00 29.00

8.00 33.00

10.00 33.00

10.00 38.00

12.00 38.00

C

RTJ

14.63

15.13

15.13

18.13

18.13

24.13

24.13

29.13

29.13

33.13

33.13

38.13

38.13

RF

7.25

7.50

7.50

9.00

9.00

12.00

12.00

14.50

14.50

16.50

16.50

19.00

19.00

D

RTJ

7.31

7.56

7.56

9.06

9.06

12.06

12.06

14.56

14.56

16.56

16.56

19.06

19.06

E

Top of

CL of

G

H

U

V

W

X

Y

Z

AA

BB

22

22

30

30

48

48

48

48

—

—

—

—

—

1.19

1.19

1.50

1.50

1.97

1.97

2.16

2.16

3.13

3.13

3.69

3.69

4.25

4.88

4.88

5.69

5.69

7.09

7.09

8.81

8.81

11.25

11.25

12.94

12.94

15.13

8

8

8

8

8

12

12

12

12

16

16

20

20

1.00

1.00

1.00

1.25

1.25

1.25

1.25

1.50

1.50

1.50

1.50

1.50

1.50

6.50

7.50

7.50

9.25

9.25

12.50

12.50

15.50

15.50

18.50

18.50

21.00

21.00

8

8

10

10

12

12

18

18

18

18

30

30

36

1.75

1.75

2.50

2.50

2.50

2.50

3.50

3.50

4.63

4.63

6.25

6.25

6.25

5.00

5.00

5.81

5.81

6.75

6.75

8.63

8.63

10.09

10.09

11.88

11.88

14.50

7.19

7.19

7.50

7.50

9.25

9.25

11.94

11.94

15.88

15.88

18.38

18.38

20.63

Handle H/Whl.

8.50

9.50

9.50

11.50

11.50

15.00

15.00

18.50

18.50

21.50

21.50

24.00

24.00

6.50

6.50

7.63

7.63

9.50

9.50

11.44

11.44

14.38

14.38

16.63

16.63

19.38

7.59

7.59

8.78

8.78

10.59

10.59

12.69

12.69

—

—

—

—

—

6.00

6.00

7.06

7.06

8.47

8.47

10.44

10.44

13.38

13.38

20.06

20.06

21.50

Dimension (mm)

Size

(in.)

2x2

3x2

3x3

4x3

4x4

6x4

6x6

8x6

8x8

10 x 8

10 x 10

12 x 10

12 x 12

F

A

52.39

52.39

79.38

79.38

103.19

103.19

152.4

152.4

203.2

203.2

254.0

254.0

304.8

B

RF

368.3

381

381

457.2

457.2

609.6

609.6

736.6

736.6

838.2

838.2

965.2

965.2

C

RTJ

371.5

384.2

384.2

460.4

460.4

612.8

612.8

739.8

739.8

841.4

841.4

968.4

968.4

RF

184.2

190.5

190.5

228.6

228.6

304.8

304.8

368.3

368.3

419.1

419.1

482.6

482.6

KF Valves

10

D

RTJ

185.7

192.1

192.1

230.2

230.2

306.4

306.4

369.9

369.9

420.7

420.7

484.2

484.2

E

Top of

CL of

G

H

U

V

W

X

Y

Z

AA

BB

558.8

558.8

762

762

1219.2

1219.2

1219.2

1219.2

—

—

—

—

—

30.16

30.16

38.1

38.1

50.00

50.00

54.8

54.8

79.4

79.4

93.7

93.7

108.0

123.8

123.8

144.5

144.5

180.2

180.2

223.8

223.8

285.8

285.8

328.6

328.6

384.2

8

8

8

8

8

12

12

12

12

16

16

20

20

25.4

25.4

25.4

31.8

31.8

31.8

31.8

38.1

38.1

38.1

38.1

38.1

38.1

165.1

190.5

190.5

235.0

235.0

317.5

317.5

393.7

393.7

469.9

469.9

533.4

533.4

203.2

203.2

254

254

304.8

304.8

457.2

457.2

457.2

457.2

762

762

914.4

44.5

44.5

63.5

63.5

63.5

63.5

88.9

88.9

117.5

117.5

158.8

158.8

158.8

127

127

147.6

147.6

171.5

171.5

219.1

219.1

256.4

256.4

301.6

301.6

368.3

182.6

182.6

190.5

190.5

235.0

235.0

303.2

303.2

403.2

403.2

466.7

466.7

523.9

Handle H/Whl.

215.9

241.3

241.3

292.1

292.1

381

381

469.9

469.9

546.1

546.1

609.6

609.6

165.1

165.1

193.68

193.68

241.3

241.3

290.51

290.51

365.1

365.1

422.3

422.3

492.1

192.88

192.88

223.0

223.0

269.08

269.08

322.3

322.3

—

—

—

—

—

152.4

152.4

179.4

179.4

215.11

215.11

265.11

265.11

339.7

339.7

509.6

509.6

546.1

KF Series T/ TE Dimensional Data

G

Z

H

F

E

U

D

A

BB

AA

F

V • No. of Holes

W • Hole Dia.

X • Bolt Circle

C

ANSI B16.5

Flanges

B

Y

Dimensional Data (in. /mm), 2"FP-12"FP, Class 1500, API 6D & ANSI B16.34

Dimension (in.)

Size

(in.)

2x2

3x2

3x3

4x3

4x4

6x4

6x6

8x6

8x8

10 x 8

10 x 10

12 x 10

12 x 12

F

A

B

RF

2.06 14.50

2.06 18.50

3.13 18.50

3.13 21.50

4.06 21.50

4.06 27.75

6.00 27.75

6.00 32.75

7.63 32.75

7.63 39.00

9.50 39.00

9.50 44.50

11.38 44.50

C

RTJ

14.63

18.63

18.63

21.63

21.63

28.00

28.00

33.13

33.13

39.38

39.38

45.13

45.13

RF

7.25

9.25

9.25

10.75

10.75

13.88

13.88

16.38

16.38

19.50

19.50

22.25

22.25

D

RTJ

7.31

9.31

9.31

10.81

10.81

14.00

14.00

16.56

16.56

19.69

19.69

22.56

22.56

E

Top of

CL of

G

H

U

V

W

X

Y

Z

AA

BB

22

22

30

30

48

48

—

—

—

—

—

—

—

1.19

1.19

1.63

1.63

1.97

1.97

3.63

3.63

3.38

3.38

3.69

3.69

4.25

4.88

4.88

6.88

6.88

7.94

7.94

11.31

11.31

11.25

11.25

16.94

16.94

19.88

8

8

8

8

8

12

12

12

12

12

12

16

16

1.00

1.25

1.25

1.38

1.38

1.50

1.50

1.75

1.75

2.00

2.00

2.13

2.13

6.50

8.00

8.00

9.50

9.50

12.50

12.50

15.50

15.50

19.00

19.00

22.50

22.50

8

8

10

10

12

12

18

18

18

18

30

30

36

1.75

1.75

2.50

2.50

2.50

2.50

4.63

4.63

4.63

4.63

6.25

6.25

6.25

5.13

5.13

6.13

6.13

7.00

7.00

8.38

8.38

11.56

11.56

12.63

12.63

14.50

7.19

7.19

7.50

7.50

9.25

9.25

17.63

17.63

17.75

17.75

20.63

20.63

20.63

Handle H/Whl.

8.50

10.50

10.50

12.25

12.25

15.50

15.50

19.00

19.00

23.00

23.00

26.50

26.50

6.50 7.59 6.00

6.50 7.59 6.00

8.94 9.97 8.25

8.94 9.97 8.25

10.41 11.50 9.31

10.41 11.50 9.31

14.94

—

13.31

14.94

—

13.31

14.63

—

13.38

14.63

—

13.38

20.63

—

23.31

20.63

—

23.31

24.13

—

21.50

Dimension (mm)

Size

(in.)

2x2

3x2

3x3

4x3

4x4

6x4

6x6

8x6

8x8

10 x 8

10 x 10

12 x 10

12 x 12

F

A

52.39

52.39

79.38

79.38

103.19

103.19

152.4

152.4

193.7

193.7

241.3

241.3

288.9

B

RF

368.3

469.9

469.9

546.1

546.1

704.9

704.9

831.9

831.9

990.6

990.6

1130.3

1130.3

RTJ

371.5

473.1

473.1

549.3

549.3

711.2

711.2

841.4

841.4

1000.1

1000.1

1146.2

1146.2

C

RF

184.2

235.0

235.0

273.1

273.1

352.4

352.4

415.9

415.9

495.3

495.3

565.2

565.2

D

RTJ

185.7

236.5

236.5

274.6

274.6

355.6

355.6

420.7

420.7

500.1

500.1

573.1

573.1

E

Top of

CL of

G

H

U

V

W

X

Y

Z

AA

BB

558.8

558.8

762

762

1219.2

1219.2

—

—

—

—

—

—

—

30.2

30.2

41.3

41.3

50.0

50.0

92.1

92.1

85.7

85.7

93.7

93.7

108.0

123.8

123.8

174.6

174.6

201.6

201.6

287.3

287.3

285.8

285.8

430.2

430.2

504.8

8

8

8

8

8

12

12

12

12

12

12

16

16

25.4

31.8

31.8

34.9

34.9

38.1

38.1

44.5

44.5

50.8

50.8

54.0

54.0

165.1

203.2

203.2

241.3

241.3

317.5

317.5

393.7

393.7

482.6

482.6

571.5

571.5

203.2

203.2

254

254

304.8

304.8

457.2

457.2

457.2

457.2

762

762

914.4

44.5

44.5

63.5

63.5

63.5

63.5

117.5

117.5

117.5

117.5

158.8

158.8

158.8

130.2

130.2

155.6

155.6

177.8

177.8

212.7

212.7

293.7

293.7

320.7

320.7

368.3

182.6

182.6

190.5

190.5

235.0

235.0

447.7

447.7

450.9

450.9

523.9

523.9

523.9

Handle H/Whl.

215.9

266.7

266.7

311.2

311.2

393.7

393.7

482.6

482.6

584.2

584.2

673.1

673.1

165.1

165.1

227.0

227.0

264.3

264.3

379.4

379.4

371.5

371.5

523.9

523.9

612.8

192.9

192.9

253.2

253.2

292.1

292.1

—

—

—

—

—

—

—

152.4

152.4

209.6

209.6

236.5

236.5

338.1

338.1

339.7

339.7

592.1

592.1

546.1

KF Valves

11

KF Series T/ TE Dimensional Data

G

Z

H

F

E

U

D

A

BB

AA

F

V • No. of Holes

W • Hole Dia.

X • Bolt Circle

C

ANSI B16.5

Flanges

B

Y

Dimensional Data (in. /mm), 2"FP-10"FP, Class 2500, API 6D & ANSI B16.34

Dimension (in.)

Size

(in.)

2x2

3x3

4x3

4x4

6x4

6x6

8x6

8x8

10 x 8

10 x 10

F

A

1.75

2.50

2.50

3.50

3.50

5.25

5.25

7.13

7.13

8.88

B

RF

17.75

22.75

26.50

26.50

36.00

36.00

40.25

40.25

50.00

50.00

C

RTJ

17.88

23.00

26.88

26.88

36.50

36.50

40.88

40.88

50.88

50.88

RF

8.88

11.38

13.25

13.25

18.00

18.00

20.13

20.13

25.00

25.00

D

RTJ

8.94

11.50

13.44

13.44

18.25

18.25

20.44

20.44

25.44

25.44

E

Top of

CL of

G

H

U

V

W

X

Y

Z

AA

BB

30

48

48

—

—

—

—

—

—

—

1.19

1.63

1.63

2.34

2.34

3.66

3.66

3.69

3.69

4.25

5.88

7.75

7.75

8.84

8.84

12.38

12.38

16.25

16.25

20.56

8

8

8

8

8

8

12

12

12

12

1.13

1.38

1.63

1.63

2.13

2.13

2.13

2.13

2.63

2.63

6.75

9.00

10.75

10.75

14.50

14.50

17.25

17.25

21.25

21.25

10

12

12

24

24

18

18

30

30

30

1.75

2.50

2.50

3.50

3.50

4.63

4.63

6.25

6.25

6.25

4.50

5.56

5.56

6.69

6.69

8.44

8.44

11.13

11.13

13.63

7.50

7.88

7.88

13.38

13.38

17.63

17.63

20.63

20.63

20.63

U

V

W

X

Y

Z

AA

BB

149.2

196.9

196.9

224.6

224.6

314.3

314.3

412.8

412.8

522.3

8

8

8

8

8

8

12

12

12

12

28.6

34.9

41.3

41.3

54.0

54.0

54.0

54.0

66.7

66.7

171.5

228.6

273.1

273.1

368.3

368.3

438.2

438.2

539.8

539.8

254

304.8

304.8

609.6

609.6

457.2

457.2

762

762

762

44.5

63.5

63.5

88.9

88.9

117.5

117.5

158.8

158.8

158.8

114.3

141.3

141.3

169.9

169.9

214.3

214.3

282.6

282.6

346.1

190.5

200.0

200.0

339.7

339.7

447.7

447.7

523.9

523.9

523.9

Handle H/Whl.

9.25

12.00

14.00

14.00

19.00

19.00

21.75

21.75

26.50

26.50

7.50 8.59 7.00

9.81 10.84 10.00

9.81 10.84 10.00

11.34

—

9.91

11.34

—

9.91

16.03

—

18.56

16.03

—

18.56

19.94

—

22.63

19.94

—

22.63

24.81

—

26.38

Dimension (mm)

Size

(in.)

2x2

3x3

4x3

4x4

6x4

6x6

8x6

8x8

10 x 8

10 x 10

F

A

44.5

63.5

63.5

88.9

88.9

133.4

133.4

181.0

181.0

225.4

B

RF

450.9

577.9

673.1

673.1

914.4

914.4

1022.4

1022.4

1270

1270

RTJ

454.0

584.2

682.6

682.6

927.1

927.1

1038.2

1038.2

1292.2

1292.2

C

RF

223.0

288.9

336.6

336.6

457.2

457.2

511.2

511.2

635

635

KF Valves

12

D

RTJ

227.0

292.1

341.3

341.3

463.6

463.6

519.1

519.1

646.1

646.1

E

Top of

CL of

G

H

Handle H/Whl.

235.0

304.8

355.6

355.6

482.6

482.6

552.5

552.5

673.1

673.1

190.5 218.3 177.8 762 30.2

249.2 275.4 254 1219.2 41.3

249.2 275.4 254 1219.2 41.3

288.1

—

251.6

—

59.5

288.1

—

251.6

—

59.5

407.2

—

471.5

—

92.9

407.2

—

471.5

—

92.9

506.4

—

574.7

—

93.7

506.4

—

574.7

—

93.7

630.2

—

669.9

— 108.0

KF Series T/ TE Dimensional Data

G

Z

H

F

E

U

D

A

BB

AA

F

V • No. of Holes

W • Hole Dia.

X • Bolt Circle

C

ANSI B16.5

Flanges

B

Y

Dimensional Data (in. ), 2"FP- 6"FP, Class 2000 RTJ, API 6A

Dimension (in.)

Size

(in.)

F

A

B

C

D

E

Top of

CL of

G

H

U

V

W

X

Y

Z

AA

BB

22

22

30

30

48

48

48

1.19

1.19

1.69

1.69

1.97

1.97

2.41

4.88

4.88

5.50

5.50

7.09

7.09

8.56

8

8

8

8

8

12

12

0.75

0.88

0.88

1.00

1.00

1.13

1.13

5.00

6.63

6.63

8.50

8.50

11.50

11.50

8

8

10

10

12

12

24

1.75

1.75

2.50

2.50

2.50

2.50

3.50

4.88

4.88

5.75

5.75

6.50

6.50

8.31

7.19

7.19

7.50

7.50

9.25

9.25

11.94

Handle H/Whl.

2 1/16 x 2 1/16

3 1/8 x 2 1/16

3 1/8 x 3 1/8

4 1/16 x 3 1/8

4 1/16 x 4 1/16

7 1/16 x 4 1/16

7 1/16 x 6

2.06

2.06

3.13

3.13

4.06

4.06

6.00

11.63

14.13

14.13

17.13

17.13

22.13

22.13

5.81

7.06

7.06

8.56

8.56

11.06

11.06

6.50

8.25

8.25

10.75

10.75

14.00

14.00

6.50

6.50

7.63

7.63

9.50

9.50

11.44

7.59

7.59

8.59

8.59

10.59

10.59

12.44

6.00

6.00

6.88

6.88

8.47

8.47

10.44

Dimensional Data (in. ), 2"FP- 6"FP, Class 3000 RTJ, API 6A

Dimension (in.)

Size

(in.)

F

A

B

C

D

E

Top of

CL of

G

H

U

V

W

X

Y

Z

AA

BB

22

22

30

30

48

48

1.19

1.19

1.50

1.50

1.97

2.16

4.88

4.88

5.69

5.69

7.09

8.81

8

8

8

8

8

12

1.00

1.00

1.00

1.25

1.25

1.25

6.50

7.50

7.50

9.25

9.25

12.50

8

8

10

10

12

24

1.75

1.75

2.50

2.50

2.50

3.50

5.00

5.00

5.81

5.81

6.75

8.63

7.19

7.19

7.50

7.50

9.25

11.94

Handle H/Whl.

2 1/16 x 2 1/16

3 1/8 x 2 1/16

3 1/8 x 3 1/8

4 1/16 x 3 1/8

4 1/16 x 4 1/16

7 1/16 x 6

2.06

2.06

3.13

3.13

4.06

6.00

14.63

15.13

15.13

18.13

18.13

24.13

7.31 8.50

7.56 9.50

7.56 9.50

9.06 11.50

9.06 11.50

12.06 15.00

6.50

6.50

7.63

7.63

9.50

11.44

7.59

7.59

8.78

8.78

10.59

12.69

6.00

6.00

7.06

7.06

8.47

10.44

Dimensional Data (in. ), 2"FP- 6"FP, Class 5000 RTJ, API 6A

Dimension (in.)

Size

(in.)

F

A

B

C

D

E

Top of

CL of

G

H

U

V

W

X

Y

Z

AA

BB

22

22

30

30

48

48

—

1.19

1.19

1.63

1.63

1.97

1.97

3.63

4.88

4.88

6.88

6.88

7.94

7.94

11.31

8

8

8

8

8

12

12

1.00

1.25

1.25

1.38

1.38

1.50

1.50

6.50

8.00

8.00

9.50

9.50

12.50

12.50

8

8

10

10

12

12

24

1.75

1.75

2.50

2.50

2.50

2.50

3.50

4.38

4.38

5.38

5.38

6.25

6.25

7.63

7.19

7.19

7.50

7.50

9.25

9.25

11.94

Handle H/Whl.

2 1/16 x 2 1/16

3 1/8 x 2 1/16

3 1/8 x 3 1/8

4 1/16 x 3 1/8

4 1/16 x 4 1/16

7 1/16 x 4 1/16

7 1/16 x 6

2.06

2.06

3.13

3.13

4.06

4.06

6.00

14.63

18.63

18.63

21.63

21.63

28.00

28.00

7.31

9.31

9.31

10.81

10.81

14.00

14.00

8.50

10.50

10.50

12.25

12.25

15.50

15.50

6.50

6.50

8.94

8.94

10.41

10.41

14.94

7.59

7.59

9.97

9.97

11.50

11.50

—

6.00

6.00

8.25

8.25

9.31

9.31

12.94

KF Valves

13

KF Series T/ TE Dimensional Data

G

Z

H

F

E

U

D

A

BB

AA

F

V • No. of Holes

W • Hole Dia.

X • Bolt Circle

C

ANSI B16.5

Flanges

B

Y

Dimensional Data (mm), 2"FP- 6"FP, Class 2000 RTJ, API 6A

Dimension (mm)

Size

(in.)

F

A

B

C

D

E

Top of

G

H

U

V

W

X

Y

Z

AA

BB

558.8

558.8

762

762

1219.2

1219.2

1219.2

30.16

30.16

42.86

42.86

50.00

50.00

61.12

123.8

123.8

139.7

139.7

180.2

180.2

217.5

8

8

8

8

8

12

12

19.1

22.2

22.2

25.4

25.4

28.6

28.6

127

168.3

168.3

215.9

215.9

292.1

292.1

203.2

203.2

254

254

304.8

304.8

609.6

44.5

44.5

63.5

63.5

63.5

63.5

88.9

123.8

123.8

146.1

146.1

165.1

165.1

211.1

182.6

182.6

190.5

190.5

235.0

235.0

303.2

CL of

Handle H/Whl.

2 1/16 x 2 1/16

3 1/8 x 2 1/16

3 1/8 x 3 1/8

4 1/16 x 3 1/8

4 1/16 x 4 1/16

7 1/16 x 4 1/16

7 1/16 x 6

52.39

52.39

79.38

79.38

103.19

103.19

152.4

295.28

358.78

358.78

435.0

435.0

561.98

561.98

147.64

179.39

179.39

217.49

217.49

280.99

280.99

165.1

209.55

209.55

273.05

273.05

355.6

355.6

165.1

165.1

193.68

193.68

241.3

241.3

290.51

192.88

192.88

218.28

218.28

269.08

269.08

315.91

152.4

152.4

174.63

174.63

215.11

215.11

265.11

Dimensional Data (mm), 2"FP- 6"FP, Class 3000 RTJ, API 6A

Dimension (mm)

Size

(in.)

F

A

B

C

D

E

Top of

G

CL of

H

U

V

W

X

Y

Z

AA

BB

30.16

30.16

38.1

38.1

50.00

50.00

123.8

123.8

144.5

144.5

180.2

223.8

8

8

8

8

8

12

25.4

25.4

25.4

31.8

31.8

31.8

165.1

190.5

190.5

235.0

235.0

317.5

203.2

203.2

254

254

304.8

609.6

44.5

44.5

63.5

63.5

63.5

88.9

127

127

147.6

147.6

171.5

219.1

182.6

182.6

190.5

190.5

235.0

303.2

Handle H/Whl.

2 1/16 x 2 1/16

3 1/8 x 2 1/16

3 1/8 x 3 1/8

4 1/16 x 3 1/8

4 1/16 x 4 1/16

7 1/16 x 6

52.39

52.39

79.38

79.38

103.19

152.4

371.5

384.2

384.2

460.4

460.4

612.8

185.7

192.1

192.1

230.2

230.2

306.4

215.9 165.1 192.88 152.4 558.8

241.3 165.1 192.88 152.4 558.8

241.3 193.68 223.0 179.4 762

292.1 193.68 223.0 179.4 762

292.1 241.3 269.08 215.11 1219.2

381 290.51 322.3 265.11 1219.2

Dimensional Data (mm), 2"FP- 6"FP, Class 5000 RTJ, API 6A

Dimension (mm)

Size

(in.)

F

A

B

C

D

E

Top of

CL of

G

H

U

V

W

X

Y

Z

AA

BB

558.8

558.8

762

762

1219.2

1219.2

—

30.2

30.2

41.3

41.3

50.0

50.0

92.1

123.8

123.8

174.6

174.6

201.6

201.6

287.3

8

8

8

8

8

12

12

25.4

31.8

31.8

34.9

34.9

38.1

38.1

165.1

203.2

203.2

241.3

241.3

317.5

317.5

203.2

203.2

254

254

304.8

304.8

609.6

44.5

44.5

63.5

63.5

63.5

63.5

88.9

111.1

111.1

136.5

136.5

158.8

158.8

193.7

182.6

182.6

190.5

190.5

235.0

235.0

303.2

Handle H/Whl.

2 1/16 x 2 1/16

3 1/8 x 2 1/16

3 1/8 x 3 1/8

4 1/16 x 3 1/8

4 1/16 x 4 1/16

7 1/16 x 4 1/16

7 1/16 x 6

52.39

52.39

79.38

79.38

103.19

103.19

152.4

371.5

473.1

473.1

549.3

549.3

711.2

711.2

185.7

236.5

236.5

274.6

274.6

355.6

355.6

KF Valves

14

215.9

266.7

266.7

311.2

311.2

393.7

393.7

165.1

165.1

227.0

227.0

264.3

264.3

379.4

192.9

192.9

253.2

253.2

292.1

292.1

—

152.4

152.4

209.6

209.6

236.5

236.5

328.6

KF Series TW/ TWE Dimensional Data

G

Z

H

F

E

U

D

A

BB

AA

F

V • No. of Holes

W • Hole Dia.

X • Bolt Circle

C

ANSI B16.5

Flanges

B

Y

Dimensional Data (in. /mm), 2"FP-12"FP, Class 600, API 6D & ANSI B16.34

Dimension (in.)

Size

(in.)

2x2

3x2

3x3

4x3

4x4

6x4

6x6

8x6

8x8

10 x 8

10 x 10

12 x 10

12 x 12

B

C

D

WExWE

RTJ

WExWE

RTJ

FLG

RFxWE

x WE

RFxWE

x WE

x WE

11.50

14.00

14.00

17.00

17.00

22.00

22.00

26.00

26.00

31.00

31.00

33.00

33.00

11.56

14.06

14.06

17.06

17.06

22.06

22.06

26.06

26.06

31.06

31.06

33.06

33.06

5.75

7.00

7.00

8.50

8.50

11.00

11.00

13.00

13.00

15.50

15.50

16.50

16.50

5.78

7.03

7.03

8.53

8.53

11.03

11.03

13.03

13.06

15.56

15.56

16.56

16.56

6.50

8.25

8.25

10.75

10.75

14.00

14.00

16.50

16.50

20.00

20.00

22.00

22.00

F

E

6.50

6.50

7.63

7.63

9.50

9.50

11.44

11.44

14.38

14.38

16.63

16.63

19.38

Top of

CL of

Handle

H/Whl.

7.59

7.59

8.59

8.59

10.59

10.59

12.44

12.44

—

—

—

—

—

6.00

6.00

6.88

6.88

8.47

8.47

10.44

10.44

13.38

13.38

16.06

16.06

21.50

G

22

22

30

30

48

48

48

48

—

—

—

—

—

H

1.19

1.19

1.69

1.69

1.97

1.97

2.41

2.41

3.13

3.13

3.69

3.69

4.25

V

W

X

FLG

FLG

FLG

x WE

x WE

x WE

4.88

4.88

5.50

5.50

7.09

7.09

8.56

8.56

11.25

11.25

12.94

12.94

15.13

8

8

8

8

8

12

12

12

12

16

16

20

20

0.75

0.88

0.88

1.00

1.00

1.13

1.13

1.25

1.25

1.38

1.38

1.38

1.38

5.00

6.63

6.63

8.50

8.50

11.50

11.50

13.75

13.75

17.00

17.00

19.25

19.25

V

W

X

U

FLG

FLG

FLG

x WE

x WE

x WE

8

8

8

8

8

12

12

12

12

16

16

20

20

19.1

22.2

22.2

25.4

25.4

28.6

28.6

31.8

31.8

34.9

34.9

34.9

34.9

127

168.3

168.3

215.9

215.9

292.1

292.1

349.3

349.3

431.8

431.8

489.0

489.0

U

Y

Z

AA

BB

8

8

10

10

12

12

24

24

24

24

30

30

20

1.75

1.75

2.50

2.50

2.50

2.50

3.50

3.50

4.63

4.63

4.63

4.63

6.25

4.88

4.88

5.75

5.75

6.50

6.50

8.31

8.31

10.13

10.13

11.88

11.88

14.50

7.19

7.19

7.50

7.50

9.25

9.25

11.94

11.94

14.63

14.63

17.19

17.19

18.38

Y

Z

AA

BB

203.2

203.2

254

254

304.8

304.8

609.6

609.6

609.6

609.6

762

762

508

44.5

44.5

63.5

63.5

63.5

63.5

88.9

88.9

117.5

117.5

117.5

117.5

158.8

123.8

123.8

146.1

146.1

165.1

165.1

211.1

211.1

257.2

257.2

301.6

301.6

368.3

182.6

182.6

190.5

190.5

235.0

235.0

303.2

303.2

371.5

371.5

436.6

436.6

466.7

Dimension (mm)

Size

(in.)

2x2

3x2

3x3

4x3

4x4

6x4

6x6

8x6

8x8

10 x 8

10 x 10

12 x 10

12 x 12

B

C

D

WExWE

RTJ

WExWE

RTJ

FLG

RFxWE

x WE

RFxWE

x WE

x WE

292.1

355.6

355.6

431.8

431.8

558.8

558.8

660.4

660.4

787.4

787.4

838.2

838.2

293.7

357.2

357.2

433.4

433.4

560.4

560.4

662.0

662.0

789.0

789.0

839.8

839.8

146.1

177.8

177.8

215.9

215.9

279.4

279.4

330.2

330.2

393.7

393.7

419.1

419.1

146.8

178.6

178.6

216.7

216.7

280.2

280.2

331.0

331.8

395.3

395.3

420.7

420.7

165.1

209.6

209.6

273.1

273.1

355.6

355.6

419.1

419.1

508.0

508.0

558.8

558.8

F

E

165.1

165.1

193.7

193.7

241.3

241.3

290.5

290.5

365.1

365.1

422.3

422.3

492.1

Top of

CL of

Handle

H/Whl.

192.88

192.88

218.28

218.28

269.08

269.08

315.91

315.91

—

—

—

—

—

152.4

152.4

174.63

174.63

215.11

215.11

265.11

265.11

339.7

339.7

408.0

408.0

546.1

G

558.8

558.8

762

762

1219.2

1219.2

1219.2

1219.2

—

—

—

—

—

H

30.16

30.16

42.86

42.86

50.00

50.00

61.12

61.12

79.4

79.4

93.7

93.7

108.0

123.8

123.8

139.7

139.7

180.2

180.2

217.5

217.5

285.8

285.8

328.6

328.6

384.2

Note: Dimension A per pipe wall schedule on page 4.

KF Valves

15

Topworks & Stem Data

Flatted Stem 2"FP-8"RP

JD

K

CLOSED

OPEN

K

Round Stem Sq. Key 8"FP-12"FP

K

*DD dim. applicable to keyed stem only.

Top of stem to top

of mounting pad

H

JD

R

P • Hole Depth

S • Threaded Hole

T • No. of Holes

DD

Q CCD

R & Q typical

Dimension (in.)

Valve

Size

(in.)

2

2

2

2

2

2

2

3

3

3

3

3

3

3

4

4

4

4

4

4

4

6

6

6

6

6

6

6

8

8

8

8

10

10

10

10

12

12

12

API

Pressure

Class

6D 600

6D 900

6D 1500

6D 2500

6A 2000

6A 3000

6A 5000

6D 600

6D 900

6D 1500

6D 2500

6A 2000

6A 3000

6A 5000

6D 600

6D 900

6D 1500

6D 2500

6A 2000

6A 3000

6A 5000

6D 600

6D 900

6D 1500

6D 2500

6A 2000

6A 3000

6A 5000

6D 600

6D 900

6D 1500

6D 2500

6D 600

6D 900

6D 1500

6D 2500

6D 600

6D 900

6D 1500

H

1.63

1.63

1.63

1.63

1.63

1.63

1.63

2.13

1.94

2.06

2.06

2.13

1.94

2.06

2.41

2.41

2.47

2.50

2.41

2.41

2.47

2.88

2.63

2.63

3.66

2.88

2.63

2.63

3.13

3.13

3.13

3.69

3.69

3.69

3.69

4.25

4.25

4.25

4.25

JD

Stem

Dia.

1.124/ 1.120

1.124/ 1.120

1.124/ 1.120

1.372/1.368

1.124 / 1.120

1.124 / 1.120

1.124 / 1.120

1.499 / 1.495

1.499 / 1.495

1.499 / 1.495

1.747/ 1.743

1.499 / 1.495

1.499 / 1.495

1.499 / 1.495

1.999 /1.995

1.999 /1.995

1.999 /1.995

1.997/1.993

1.999 /1.995

1.999 /1.995

1.999 /1.995

2.499 / 2.495

2.499 / 2.495

2.868 / 2.872

2.872 / 2.868

2.499 / 2.495

2.499 / 2.495

2.875 / 2.871

2.874 / 2.871

2.874 / 2.871

2.874 / 2.871

3.497/ 3.495

3.249 / 3.246

3.249 / 3.246

3.249 / 3.246

3.989/ 3.987

3.999/ 3.997

3.997/ 3.994

3.997/ 3.994

*DD dimension is applicable to keyed stem only.

KF Valves

16

K

.749 / .744

.749 / .744

.749 / .744

.872/.868

.749 / .744

.749 / .744

.749 / .744

.999 / .994

.999 / .994

.999 / .994

1.247/ 1.243

.999 / .994

.999 / .994

.999 / .994

1.249 / 1.245

1.249 / 1.245

1.249 / 1.245

1/2 Sq.

1.249 / 1.245

1.249 / 1.245

1.249 / 1.245

1.749/ 1.745

1.749/ 1.745

3/4 Sq.

3/4 Sq.

1.749/ 1.745

1.749/ 1.745

3/4 Sq.

3/4 Sq.

3/4 Sq.

3/4 Sq.

7/8 Sq.

7/8 Sq.

7/8 Sq.

7/8 Sq.

1 Sq.

1 Sq.

1 Sq.

1 Sq.

P

Hole

Depth

.50

.50

.50

.50

.50

.50

.50

.88

.88

.88

.88

.88

.88

.88

.88

.88

.75

.75

.88

.88

.75

1.00

1.00

1.13

1.13

1.00

1.00

1.13

1.13

1.13

1.13

1.25

1.25

1.25

1.25

1.50

1.25

1.50

1.50

Q

R

2.69 BC

2.69 BC

2.69 BC

2.69 BC

2.69 BC

2.69 BC

2.69 BC

3.38

3.38

3.38

3.38

3.38

3.38

3.38

3.38

3.38

4.50

4.50

3.38

3.38

4.50

4.63

4.63

6.00

6.00

4.63

4.63

6.00

6.00

6.00

6.00

8.00

8.00

8.00

8.00

8.00

8.00

8.00

8.00

—

—

—

—

—

—

—

1.75

1.75

1.75

1.75

1.75

1.75

1.75

2.00

2.00

2.38

2.38

2.00

2.00

2.38

2.88

2.88

3.50

3.50

2.88

2.88

3.50

3.50

3.50

3.50

3.50

3.50

3.50

3.50

4.00

3.50

4.00

4.00

S

Threaded

Hole

5/16 -18

5/16 -18

5/16 -18

5/16 -18

5/16 -18

5/16 -18

5/16 -18

3/8 -16

3/8 -16

3/8 -16

3/8 -16

3/8 -16

3/8 -16

3/8 -16

3/8 -16

3/8 -16

1/ 2 -13

1/ 2 -13

3/8 -16

3/8 -16

1/ 2 -13

1/ 2 -13

1/ 2 -13

5/8 -11

5/8 -11

1/ 2 -13

1/ 2 -13

5/8 -11

5/8 -11

5/8 -11

5/8 -11

3/4 -10

3/4 -10

3/4 -10

3/4 -10

7/8 -9

3/4 -10

7/8 -9

7/8 -9

T

No. Of

Holes

4 on CL

4 on CL

4 on CL

4 on CL

4 on CL

4 on CL

4 on CL

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

CC D

DD*

3.19

3.25

3.25

3.25

3.19

3.25

3.25

4.50

4.50

4.75

4.75

4.50

4.50

4.75

5.50

5.50

5.94

5.94

5.50

5.50

5.94

6.50

7.50

8.25

8.25

6.50

7.50

8.25

8.25

8.25

8.25

10.50

10.25

10.25

10.25

10.63

10.25

10.63

10.63

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

3.200 / 3.186

3.200 / 3.186

—

—

3.200 / 3.180

3.200 / 3.180

3.200 / 3.180

3.200 / 3.180

3.885 / 3.865

3.630 / 3.610

3.630 / 3.610

3.630 / 3.610

4.440 / 4.420

4.440 / 4.420

4.440 / 4.420

4.440 / 4.420

Topworks & Stem Data

Flatted Stem 2"FP-8"RP

JD

K

CLOSED

OPEN

K

Round Stem Sq. Key 8"FP-12"FP

K

*DD dim. applicable to keyed stem only.

Top of stem to top

of mounting pad

H

JD

R

P • Hole Depth

S • Threaded Hole

T • No. of Holes

DD

Q CCD

R & Q typical

Dimension (mm)

Valve

Size

(in.)

2

2

2

2

2

2

2

3

3

3

3

3

3

3

4

4

4

4

4

4

4

6

6

6

6

6

6

6

8

8

8

8

10

10

10

10

12

12

12

API

Pressure

Class

6D 600

6D 900

6D 1500

6D 2500

6A 2000

6A 3000

6A 5000

6D 600

6D 900

6D 1500

6D 2500

6A 2000

6A 3000

6A 5000

6D 600

6D 900

6D 1500

6D 2500

6A 2000

6A 3000

6A 5000

6D 600

6D 900

6D 1500

6D 2500

6A 2000

6A 3000

6A 5000

6D 600

6D 900

6D 1500

6D 2500

6D 600

6D 900

6D 1500

6D 2500

6D 600

6D 900

6D 1500

H

41.3

41.3

41.3

41.3

41.3

41.3

41.3

54.0

49.2

52.4

52.4

54.0

49.2

52.4

61.1

61.1

62.7

63.5

61.1

61.1

62.7

73.0

66.7

66.7

92.9

73.0

66.7

66.7

79.4

79.4

79.4

93.7

93.7

93.7

93.7

108.0

108.0

108.0

108.0

JD

Stem

Dia.

28.55/ 28.45

28.55/ 28.45

28.55/ 28.45

34.85 / 34.75

28.55/ 28.45

28.55/ 28.45

28.55/ 28.45

38.07 / 37.97

38.07 / 37.97

38.07 / 37.97

44.37 / 44.27

38.07 / 37.97

38.07 / 37.97

38.07 / 37.97

50.77 / 50.67

50.77 / 50.67

50.77 / 50.67

50.72 / 50.62

50.77 / 50.67

50.77 / 50.67

50.77 / 50.67

63.47 / 63.37

63.47 / 63.37

72.85 / 72.95

72.95 / 72.85

63.47 / 63.37

63.47 / 63.37

73.03 / 72.92

73.00 / 72.92

73.00 / 72.92

73.00 / 72.92

88.82 / 88.77

82.52 / 82.45

82.52 / 82.45

82.52 / 82.45

101.32 / 101.27

101.57/101.52

101.52/101.45

101.52/101.45

K

19.02 / 18.90

19.02 / 18.90

19.02 / 18.90

22.15 / 22.05

19.02 / 18.90

19.02 / 18.90

19.02 / 18.90

25.37 / 25.25

25.37 / 25.25

25.37 / 25.25

31.67/ 31.57

25.37/ 25.25

25.37/ 25.25

25.37/ 25.25

31.72 / 31.62

31.72 / 31.62

31.72 / 31.62

12.7 Sq.

31.72 / 31.62

31.72 / 31.62

31.72 / 31.62

44.42 / 44.32

44.42 / 44.32

19.1 Sq.

19.1 Sq.

44.42/ 44.32

44.42/ 44.32

19.1 Sq.

19.1 Sq.

19.1 Sq.

19.1 Sq.

22.2 Sq.

22.2 Sq.

22.2 Sq.

22.2 Sq.

25.4 Sq.

25.4 Sq.

25.4 Sq.

25.4 Sq.

P

Hole

Depth

12.7

12.7

12.7

12.7

12.7

12.7

12.7

22.23

22.23

22.23

22.23

22.23

22.23

22.23

22.23

22.23

19.05

19.05

22.23

22.23

19.05

25.4

25.4

28.58

28.58

25.4

25.4

28.58

28.58

28.58

28.58

31.75

31.75

31.75

31.75

38.1

31.75

38.1

38.1

Q

R

68.3 BC

68.3 BC

68.3 BC

68.3 BC

68.3 BC

68.3 BC

68.3 BC

85.7

85.7

85.7

85.7

85.7

85.7

85.7

85.7

85.7

114.3

114.3

85.7

85.7

114.3

117.5

117.5

152.4

152.4

117.5

117.5

152.4

152.4

152.4

152.4

203.2

203.2

203.2

203.2

203.2

203.2

203.2

203.2

—

—

—

—

—

—

—

44.5

44.5

44.5

44.5

44.5

44.5

44.5

50.8

50.8

60.3

60.3

50.8

50.8

60.3

73.0

73.0

88.9

88.9

73.0

73.0

88.9

88.9

88.9

88.9

88.9

88.9

88.9

88.9

101.6

88.9

101.6

101.6

S

Threaded

Hole

5/16 -18

5/16 -18

5/16 -18

5/16 -18

5/16 -18

5/16 -18

5/16 -18

3/8 -16

3/8 -16

3/8 -16

3/8 -16

3/8 -16

3/8 -16

3/8 -16

3/8 -16

3/8 -16

1/2 -13

1/2 -13

3/8 -16

3/8 -16

1/2 -13

1/2 -13

1/2 -13

5/8 -11

5/8 -11

1/2 -13

1/2 -13

5/8 -11

5/8 -11

5/8 -11

5/8 -11

3/4 -10

3/4 -10

3/4 -10

3/4 -10

7/8 -9

3/4 -10

7/8 -9

7/8 -9

T

No. Of

Holes

4 on CL

4 on CL

4 on CL

4 on CL

4 on CL

4 on CL

4 on CL

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

CC D

DD*

81.0

82.6

82.6

82.6

81.0

82.6

82.6

114.3

114.3

120.7

120.7

114.3

114.3

120.7

139.7

139.7

150.8

150.8

139.7

139.7

150.8

165.1

190.5

209.6

209.6

165.1

190.5

209.6

209.6