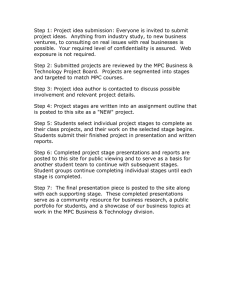

LG Load Management

advertisement

Load Management Ripple Control Technical Data Controller Enermet MPC/MSC Summary of the most important advantages Compact controller for all ripple control codes Multiple use for tariff, load and lighting management Well-structured operating concept for fast access Process control according to industrial standard Adaptive load regulator for reduction of demand peaks Possibility of network integration Supervisor software for remote control via a communication channel Two Hardware Parts User friendly Controller The Enermet MPC and MSC controller types support ripple control codes generally applied. Ripple control applications, such as tariff control, lighting management aswell as online load management, are integrated in a compact system. Due to its advanced operating concept the everyday use of the system can be mastered fast and easily. The modular concept of the MPC allows for easy field extension. In the MPC/MSC the various applications are defined as objects to which logical names can be given. Objects are either controlled manually or depending on time or events. Protocol files can be evaluated during operation. The MPC/MSC consists of a process controller PS and a personal computer PC. The process controller is designed for a rugged environment and performs the actual ripple control functions. The PC acts as an intelligent user interface. All relevant data is clearly structured and displayed on the monitor. Text appears in the language chosen. The use of the mouse guarantees manual operation without any delay. Print-out of all activities is possible. As an option the MPC/ MSC can be remotely controlled with supervisor software via a PC interface, or be integrated into another system. Adaptive Load Regulator Demand peaks can be reduced with the integrated, adaptive load regulator. The online regulator uses a performance target as reference for load distribution. The performance target can be controlled by a time or event program. The daily demand curve is displayed on a monitor and saved. For the graphic comparison with the current daily demand curve it is possible to superimpose a daily demand curve of any other previous days. Technical Data Controller Enermet MPC/MSC System overview Technical Data PC Radio Clock DCF 77 External inputs General Alarm PC MPC Process Controller PS Signal outputs Supervisor serial interface Demand measurement Start of measurement period windows 2000 1 serial interface RS-232 printer: laser, etc. Process Controller PS VME bus system Applications up to 200 objets up to 20 object groups up to 70 signals Substations MPC: up to 32 MSC: 1 External inputs MPC: up to 40 MSC: 7 General alarm Relay output Tracks DECABIT DECABIT/K22 mixed DECABIT/LG 50-110 mixed Impulse interval tracks without Substations External inputs General Alarm MPC Process Controller PS Demand measurement with CD drive operating system starting at Start of measurement period adressing Impulse interval tracks with addressing Options Load regulator up to 16 controlled objects Outputs for signals MPC: up to 16 Object overview Radio clock DCF 77, GPS Landis+Gyr AG Undermülistrasse 28 8320 Fehraltorf Switzerland Phone +41 44 954 8111 Fax +41 44 954 8101 info@landisgyr.ch www.landisgyr.com/europe Subject to change without notice Serial interface for remote control with supervisor software or via a computer ECH-FS-0707-000e Transmitter