Suitability of Analytical Methods for Stability Testing

advertisement

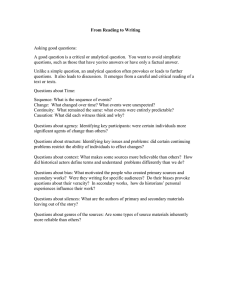

Suitability of Analytical Methods for Stability Testing – Is There Room for Improvement? By David R. Rudd, Ph.D. Glaxo Wellcome Research and Development ❖ O f all the topic areas which excellent position to have achieved. have been addressed by the With unambiguous guidance avail❝...the general praiseworthy International able, we can be confident that, by philosophy of Conference on Harmonization (ICH) following this internationally-agreed initiative in recent years, arguably we will gain the approval of analytical method path, that of analytical method validation our benefactors and reviewers (espeis the one which has progressed with cially the regulatory agencies) when validation the least difficulty and in a reasonour work is presented. employed able time frame. That is not to say But is everything as straightforthat there were not problems or areas ward as we might expect? Like internationally of disagreement within the topic most aspects of life, is the validation group – or that other topic groups of analytical methods more comseemed fairly were any less efficient or industrious plex than it seems? – but rather that the general philosoIn an attempt to answer these consistent at phy of analytical method validation questions, let me allude to two feathe outset. . .❞ employed internationally seemed tures of the available ICH guidance fairly consistent at the outset, allowdocuments which are frequently ing the harmonization process to become more an exer- raised during discussions. The first is one which was cise of unification of the description of this approach quite deliberately introduced by the members of the and not a modification of the approach itself. topic group during the development of the guidance As a result, the analytical method validation topic documents (particularly the “Methodology” text) group was able to produce two documents which and is that of flexibility. assisted in standardizing the terminology used durSome users have been critical of the guidance ing method validation exercises1 and which provide documents in this respect, pointing out that even the some guidance in the practical aspects of conducting “Methodology” text does not give clear, specific, these studies.2 These documents are now being ref- step-wise instructions concerning the practical erenced extensively, both within the pharmaceutical aspects of analytical method validation – and this is industry and by regulatory agencies, and therefore quite true. However, this is also quite deliberate, represent the definitive philosophy which is since the members of the topic group felt strongly expected to be employed by those engaged in ana- that the guidance documents should allow harmolytical method validation programs. nization of the philosophy of analytical method valClearly, as an exercise in harmonization, this is an idation, while recognizing that the practicalities 30 Analytical Method Validation David R. Rudd, Ph.D. would depend very much on the circumstances attempted to do is convey the idea of an analytical under which the analytical method might be used. method validation philosophy which will be acceptThese circumstances might encompass aspects such able internationally if based on the contents of the as analyte concentration range, sample size, sample ICH texts, but whose practical implementation will matrix etc., each of which might influence the pracdepend heavily on the sound scientific judgement tical aspect of the analytical method validation pro- and rationale provided by the analytical chemist. gram. In short, it was felt that to attempt to describe This, in fact, is the price that (quite rightly) must be a single, explicit, step-by-step procedure which paid if flexibility and the absence of prescriptive could be followed in all (or, at least, in the majority acceptance criteria are to be preserved in the guidof) cases was not only naive, but also potentially ance documents. The analytical chemist must be misleading to the inexperienced analytical chemist. prepared to exercise his or her scientific judgement We live in a complex environment and need to adapt in order to establish the specific practical steps to changes, however minor, at all times. Over-simwhich need to be made during the validation proplification can result in a lack of appreciation of subgram, and the appropriate scientific rationale must tlety and an inability to react, both intellectually and be provided to justify the approach taken. In short, practically, to new circumstances. the analytical method validation philosophy must be Thus, just as we may choose to furnish a house in based on good science – nothing more, nothing less. a “harmonized” way (carpets, drapes, chairs, tables, This is the harmonized philosophy which ICH beds, etc.), we reserve the right to exercise individpreaches. ual style or preferences (colors, sizes, etc.) if this Under these terms, and recognizing the extent to still enables us to achieve the required outcome. With ana❝We live in a complex environment lytical method validation, we are seeking to demonstrate and need to adapt to changes, the suitability of the method for its intended purpose and, however minor, at all times.❞ notwithstanding the available guidance from ICH or any other reputable source, exactly how this might be which the ICH guidance has become ingrained into done remains the prerogative and responsibility of everyday culture within the pharmaceutical industhe analytical chemist. try’s analytical community, it is worth considering The second feature which is often highlighted as whether the process is now complete for the topic of a shortcoming of the presently available guidance analytical method validation. Are there major areas documents is the absence of any acceptance criteria which would benefit from further development, or is for results generated during the analytical method this topic no longer one which needs to occupy our validation program. Again, the topic group largely attention? sought to avoid being overly prescriptive in this area In order to address these questions, it would be for exactly the reasons described earlier – that is, the useful to consider the application of analytical level of performance deemed acceptable for any par- methodology to formal, long-term stability studies – ticular analytical method depends heavily on the cirthis area being one in which issues of method percumstances under which it is expected to be used, formance frequently arise. and this can only realistically be assessed by the anaIn any application area, there is an important lytical chemist. point for the analytical chemist to appreciate – that So where does this leave us? Can we simply refer the responsibility for demonstration of suitability of to the available ICH texts on analytical method valithe method for its intended use is a major feature of dation, following the guidance when it suits, but the development and validation of the analytical prolargely “doing our own thing” when it doesn’t? Well, cedure. of course not. What these introductory remarks have It is this point which forms the basis of this artiSpecial Edition 31 David R. Rudd, Ph.D. cle – the importance of considering the implications of method performance data generated during method validation experiments. So, to revert to the chosen application, what are the particular issues associated with analytical methodology used for stability assessment of pharmaceutical materials? There is probably no single answer to this question which would satisfy everybody, but the following three aspects would usually be expected to feature somewhere in most replies: • Specificity (or “selectivity” as many practicing analytical chemists still prefer to call the level of discrimination of the method). • Precision associated with stability data generated (or, more exactly, the confidence interval of a particular data point). • The long-term consistency (or robustness) of the performance of the method. Let us look at each of these aspects in an attempt to identify areas which, the author believes, could still benefit from improvement (albeit to various degrees). The suggestion here is that if it is agreed that there is scope for improvement within our current practices, let us try to establish a process which allows those improvements to be introduced, ideally in a fully harmonized fashion. ICH has fulfilled an important role so far. Let us see if we can extend that process to the common good (i.e., for the benefit of industry, the regulatory Agency, and especially the patient). Specificity For any analytical method intended to be used to monitor changes in product quality throughout the proposed life-to-expiry, it is clearly crucial that this method has the ability either to detect and quantify loss of active potency or the increase in levels of drug-related impurities (degradation products). This capability reflects the level of discrimination of the method and is termed within ICH as “specificity.” It may often prove difficult to achieve all the desired characteristics of detection, discrimination, and quantification of the active drug substance and the drug-related impurities (degradation products) in a single analytical method. For this reason, ICH (and 32 Analytical Method Validation good scientific practice) allows the analytical chemist to arrive at this outcome using a combination of methods. Thus, a long-term stability study may often be undertaken using an assay method for the active drug substance where drug-related impurities (perhaps synthetic impurities and/or degradation products) are known not to interfere with the quantification of the analyte, supported by one or more additional methods which allow quantification of the appropriate drug-related impurities (degradation products). Now, no one would seriously question this practice. The rationale is scientifically sound, and ICH has rightly highlighted within its guidance texts this flexibility of approach as being entirely appropriate. However, the performance requirements of assay methods and impurity methods are different. In the former case, the analyte level is relatively high (compared to levels of drug-related impurities) and, provided that sufficient specificity is demonstrated to ensure lack of interference from drug-related impurities and any other components within the sample, then that is generally regarded as adequate discrimination for methods of this type. The fact that such a method may be unable to detect (for example, due to inappropriate choice of detection conditions) certain drug-related impurities (degradation products) is of no consequence as the main purpose of the method is simply to quantify the level of active drug substance. Contrast this with the level of performance required for drug-related impurity methods. Such methods, by definition, must be capable of detecting and quantifying all relevant drug-related impurities – a requirement made especially more difficult in view of the wide diversity of chemical structure and spectroscopic, chromatographic, and physical properties’ variations which are likely to be encountered with such molecules. And yet, for most long-term stability studies conducted on pharmaceutical materials, and despite this extensive range of method performance requirements, both assay and impurity methods are generally developed around a single “core” analytical technology – that of high performance liquid chromatography (HPLC). Of course, other approaches are used – and even the term “HPLC” encompasses a wide range of vari- David R. Rudd, Ph.D. ations in separation mode and detection capability. Nevertheless, reverse-phase HPLC with ultraviolet (UV) detection (frequently using a single wavelength) accounts for a huge percentage of the stability methodology used in the pharmaceutical industry today. Now, this position would be entirely tenable if such methodology were truly capable of providing the level of performance we need in all of the aspects discussed earlier, but can HPLC routinely deliver this? Frequently “Yes,” but often “No” is the conclusion – and the implications of this will become apparent later in this article. Precision What level of precision is needed in an assay method used in a long-term stability study? This question is best answered by reconsidering the problem. During most stability studies, we are looking to detect and quantify any long-term change in drug content using our assay method. So what level of change needs to be detected? Well, this is clearly product dependent and will be based on the manufacturing and life-to-expiry specifications, but let us take a simple, yet typical case. If a three-year study was being conducted, for example, on a typical tablet product, it would be important to have confidence that a change in assay of two to three percent, for example, could be detected over this period. (More exactly, it would be of great concern if the assay method was unable to detect such a change.) Figure 1 shows a simulated data set (derived statistically using Microsoft Excel® and representing a population with a specified mean value and a specified standard deviation) which may be regarded as typical in form of that generated using an HPLC assay method during a long-term stability study. By universal acclaim, and opinions have been sought from a large number of experienced people within the pharmaceutical industry and from regulatory agencies, this data set is regarded as being far too variable or irreproducible to allow meaningful conclusions to be drawn. Nevertheless, this data set is nothing more than a series of individual values drawn from two normally distributed populations with defined characteristics. Each of the individual data points represents an estimate of the true population mean, with the variation in results indicative of the level of precision of the measurement method rather than any inhomogeneity in the tablet batch. The data points assigned to the 25ºC/60%RH storage condition come from a population of mean = 100 and with a standard deviation = 2.0, whereas those from the 40ºC/75%RH storage condition have the same standard deviation (2.0), but a mean = 98.0. In stability terms, this equates to a batch of product losing 2.0% of its active content instantly (rather than gradually over the full duration of the stability study) and being monitored using an assay method with a level of reproducibility of 2.0% (a typical relative standard deviation for HPLC). And yet, by universal agreement, such a change (arguably even more distinct than if the 2.0% loss occurred gradually over the full duration of the stability study) cannot reliably be detected using methodology with a level of precision typical for HPLC. The startling, and somewhat ominous, conclusion is that many HPLC assay methods used during stability studies within the pharmaceutical industry are unlikely to be capable of detecting significant levels of change of active content in pharmaceutical products. Such methods are clearly inadequate for their intended purpose, and it is this situation which, the author believes, must be rectified with immediate effect. By taking this simulation work further, we have established that assay precision levels of 1.0% RSD (or Figure 1 Simulation of Assay Data Obtained at Two Storage Conditions During a 12-Month Stability Program Storage Period (Months) 25ºC / 60% RH 40ºC / 75% RH 0 100.0 100.0 1 99.2 94.6 3 99.9 100.3 6 97.9 97.3 9 104.7 97.5 Special Edition 12 99.1 99.4 33 David R. Rudd, Ph.D. better) are necessary to achieve the level of performance required in the chosen example and, realistically, this is beyond the capabilities of most HPLC methods currently applied routinely to long-term stability studies. So, does this mean that HPLC is wholly inappropriate as a principal assay technique for long-term stability studies involving pharmaceutical materials? Obviously, this conclusion would be an over-reaction to the shortcomings discussed previously, but it does indicate that either highly precise, yet equally selective, assay methods are required in order to achieve the level of “change detection” necessary in stability studies or that emphasis must be placed on quantification of degradation products as more subtle indicators of changes in product quality. Interestingly, Figure 2 (representing a hypothetical impurity data set such as might be obtained using an HPLC impurity method during a stability study) reveals unequivocally that changes in product stability have occurred – even though the relative accuracy and precision associated with the impurity data (compared to that obtainable using an HPLC assay method) is quite poor. (As an example, an accuracy of +/- 10% and a relative standard deviation of 5% to 10% is generally regarded as an acceptable level of performance for an HPLC impurity method). This is indeed a fortuitous situation and suggests how valuable impurity assessment can be as the principal indicator of change, while not imposing excessive demands on method performance (such as would be required if reliance were placed mainly on the use of assay data as we have seen earlier). So, the conclusion seems to be that in the absence of a highly precise, highly selective assay technique (at least, better than most HPLC approaches used at present), the assessment of product quality during stability studies is best carried out using estimates of increase in levels of drug-related impurities (degradation products). Modern methodology (even based on HPLC) seems to render this approach feasible – with one important caveat. That is, if emphasis is to be placed primarily on monitoring changes in impurity levels, we need to be confident that all impurities are being detected. This is another major stumbling block for HPLC-based impurity methods using single wavelength UV detection: First, not all impurities have identical spectroscopic characteristics; second, not all impurities exhibit a UV chromophore; and, third, not all impurities elute from an HPLC column. Each of these features could contribute to an underestimation of total impurity content by HPLC and, hence, lead to erroneous assessment of product quality and stability. The solution? Either alternative methodology which fails to exhibit these shortcomings (and many practicing analytical chemists believe that the combination of capillary electrophoresis with mass spectroscopic detection currently offers the best hope of high selectivity, adequate precision, and something approaching “universal” detection capability) or a method validation program which addresses the performance issues raised. Clearly it is in this latter area, at least until viable alternative methodology becomes routinely available, that the author believes that progress, in an internationallyharmonized fashion, should and must be made. Figure 2 Simulation of Impurity Data Obtained at Two Storage Conditions During a 12-Month Stability Program Storage Period (Months) 25ºC 40ºC 34 Principal Impurity 0 0.5 1 0.5 3 0.5 6 0.4 9 0.6 12 0.6 Secondary Impurity 0.2 0.3 0.2 0.2 0.2 0.3 Total Principal Impurity 1.3 0.5 1.4 0.5 1.5 0.5 1.2 0.7 1.5 0.8 1.6 0.9 Secondary Impurity 0.2 0.3 0.2 0.5 0.6 0.8 Total 1.3 1.5 1.5 2.0 2.1 2.4 Analytical Method Validation David R. Rudd, Ph.D. Consistency of Performance This final aspect is considered largely on the basis that long-term stability studies can typically last for periods of three years or longer. During this time, consistent method performance must be assured if relatively subtle changes in product stability are not to be overshadowed by (larger) variations in the quantitative aspects of the measurement method. How can this be ensured? There are two ways: First, by designing robustness (consistency of performance by virtue of insensitivity to typical variations in operating conditions) into the analytical method during its development; and, second, by providing appropriate system suitability tests which will allow confirmation of method performance each time the method is used. Both of these aspects of “method quality assurance” may be studied and then implemented using an appropriate validation program and, hence, provide (in the author’s opinion) another opportunity for rational, harmonized development of suitable strategies and philosophies. ble of quantifying all relevant drug-related impurities (degradation products) – and that no relevant impurities are lost, either through inappropriate sample treatment or through on-column retention (for example) in the case of HPLC. • Development of meaningful system suitability tests, based on carefully designed method robustness studies, with appropriate acceptance criteria for key aspects of method performance, to ensure that a consistent level of operation is achieved throughout the duration of the stability study. While there may be other aspects of method performance which merit equal consideration, the author believes that substantial advances may be made in improving data quality (and, hence, knowledge of product quality) by addressing the issues raised. In keeping with the ICH philosophy, however, the plea is not for prescriptive, inflexible guidance documents, but rather for an appreciation of the issues raised (and, hence, the shortcomings in our current practice) and a concerted, internationally harmonized approach to establishing ways in which these points may be addressed. ❏ Conclusion The ICH process has substantially advanced the harmonization of method validation philosophy within the pharmaceutical industry. Adoption of the principles expounded in available guidance, combined with sound, scientific judgement will generally allow the practicing analytical chemist to address most of the issues likely to be encountered under normal circumstances. When it comes to applying such methods to longterm stability studies, however, the author believes there are a number of aspects of method performance which remain to be addressed and which, therefore, offer the opportunity for further development of suitable validation strategies and philosophies. Such aspects include: • Suitability of assay methods (or assay techniques, in general) with respect to the level of precision required in order to detect defined levels of change during the life-to-expiry of the pharmaceutical material. • Demonstration that impurity methods are capa- About the Author David R. Rudd, Ph.D. heads the Process Improvement and Automation Group within Pharmaceutical Development (Europe) at Glaxo Wellcome Research and Development in the U.K. He has been actively involved in all aspects of pharmaceutical development for over 20 years and was a key member of the ICH working group which produced the definitive guidance texts on analytical method validation. David can be reached by phone at 44-1920882367, by fax at 44-1920-882295, and by e-mail at drr1605@glaxowellcome.co.uk Please note that the opinions expressed in this article are those of the author and do not necessarily reflect those of Glaxo Wellcome Research and Development Ltd. References 1. ICH harmonized tripartite guideline for Q2A: Validation of Analytical Procedures: Definitions and Terminology – available at http://www.fda.gov/cder/guidance/index.htm. 2. ICH harmonized tripartite guideline for Q2B: Validation of Analytical Procedures: Methodology – available at http://www.fda.gov/cder/guidance/index.htm. Special Edition 35