Pilkington Confidential Anti-condensation project.

Anti-condensation project.

External condensation is becoming an increasing problem as legislation drives towards more insulating window units, including triple-glazed, low-emissivity windows.

To combat this problem, coatings can be applied to the external surface of the window unit which delay or even prevent the onset of external condensation.

Pilkington have been working with Uppsala University to develop technology to analyse the conditions in which external condensation will occur and coating materials to alleviate the problem.

Since September 2008, internal work at Pilkington has involved deposition and characterisation of coatings, installation of test equipment purchased from Uppsala

University and collection and analysis of the data produced by the test equipment.

A technician/student spent 50% of his time, September to December 2008, depositing the coatings from small scale bench equipment to lab-prototype scale. September

2008 to February 2009 has involved characterisation of the coatings. The coatings have been characterised by XRD, AFM, SEM and XPS by the Pilkington Science

Support Group as well as contact angle measurements by the technician.

The performance of the coatings has been assessed since September 2008 using a test box purchased from Uppsala University.

Technical results summary.

Coatings of TiO

2

on various conducting (SnO

2

:F) substrates were prepared on the bench scale and prototype scale.

It was found that a TCO substrate with at least 70 ohms/sq sheet resistance was sufficient in reducing the occurrence of condensation, when coated with ~40 nm of

TiO

2

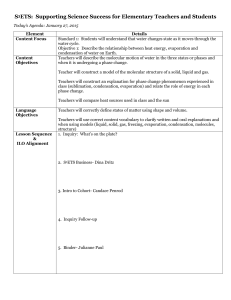

. A cross-sectional SEM of such a coating is shown in Figure 1.

The TiO

2

acts in a number of ways to combat the appearance of condensation on the window. Firstly the hydrophilic properties of TiO

2

disguise the appearance of condensation by causing the droplets to coalesce and sheet over the window. The

TiO

2

also smoothes the SnO

2

:F coating giving less nucleation points for water droplet to form.

Pilkington Confidential

Pilkington Technical Centre - Europe, Lathom, Ormskirk, Lancashire, England, L40 5UF

a b

Figure 1. SEM image of (a) titania coated TEC 70 sample, with an estimated titania layer thickness of 39nm (b) titania coated TEC 250 sample, with an estimated titania layer thickness of

74 nm.

Initial observations of TiO

2

on TEC substrates (TEC x where x = sheet resistance) indicate the following coating configurations are effective against external condensation:

TEC 7 – it was found that a titania coating of around 50nm – 60nm proved effective to combat external condensation.

TEC 15 – it was found that a titania coating of around 70nm – 90nm proved effective to combat external condensation.

TEC 70 – it was found that a titania coating of around 60nm – 80nm proved effective to combat external condensation.

TEC 250 – it was found that a titania coating of around 50nm – 60nm proved effective to combat external condensation.

TEC 1000 – it was found that a titania coating of around 25nm – 40nm proved effective to combat external condensation.

Pilkington Confidential

Pilkington Technical Centre - Europe, Lathom, Ormskirk, Lancashire, England, L40 5UF

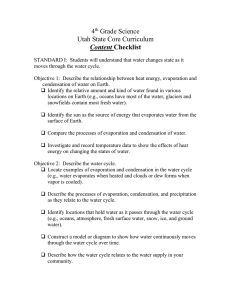

Table 1. Table showing a selection of sample ‘thicknesses’ of the titania layer, compared to the contact angle performance before and after UV radiation

Reference

Top Layer Thickness (Å)

Expected Average

TiO

2

Thickness (Å)

"Expected" "Average" c

Haze

Mean (%)

Standard

Deviation

Before UV

Irradiation

(mm)

Contact Angle

(°)

After 30mins

UV Irradiation

(mm)

Contact

Angle

(°)

TEC 70 3.2mm a, b

#2 01/11/2008

#3 01/11/2008

#9 07/11/2008

#14 12/11/2008

TEC 8 3mm

#1 12/11/2008

#3 12/11/2008

#6 14/11/2008

TEC 15 5mm

#11 20/11/2008

#12 20/11/2008

#15 21/11/2008

TEC 70 4mm

#1 22/11/2008

#7 26/11/2008

#8 26/11/2008

TEC 250 4mm

#2 04/12/2008

#7 06/12/2008

#14 10/12/2008

6385

8015

7680

8070

3633

4045

4495

4590

1790

1985

2570

2490

1400

2220

1670

2330

1790

2570

1865

2450

2260

6400

8015

7680

8070

3400

4045

4495

4590

1600

1985

2570

2490

1600

2220

1670

2330

1600

2570

1865

2450

2260

-

1630

1295

1685

-

195

780

700

-

412

862

957

-

820

270

930

-

780

75

660

470

-

1615

1280

1670

-

645

1095

1190

-

385

970

890

-

620

70

730

-

970

265

850

660

-

-

28.4313

72.9168

72.9168

-

87.3023

105.5303

99.8033

-

66.1032

95.0528

87.3023

-

123.1576

87.3023

72.9168

-

38.9542

41.0994

80.0235

-

1.60

1.40

1.45

-

1.90

1.50

1.60

-

1.30

1.60

1.80

-

2.40

2.35

1.70

-

-

2.70

1.80

1.80

-

1.57

1.36

1.51

-

0.75

0.46

0.29

-

0.06

0.31

0.14

-

0.02

0.05

0.16

-

-

0.21

0.29

0.29

0.5

0.47

1.11

1.26

0.7

1.44

0.91

2.00

12

14.8

17.3

20.7

≤ 0.74

2.27

1.97

1.82

0.5

-

1.46

1.76

1.17

-

3.80

2.30

1.70

-

2.20

3.30

5.10

-

1.90

4.30

2.60

-

4.00

3.10

2.75

-

-

4.60

2.05

2.70

-

-

5.9849

56.6471

28.4313

-

10.5754

43.3686

80.0235

-

48.2910

16.0279

4.3953

-

66.1032

7.3204

31.5257

-

9.0807

19.2223

27.0204

Pilkington Confidential

Pilkington Technical Centre - Europe, Lathom, Ormskirk, Lancashire, England, L40 5UF

A breakdown of the costs involved in this are presented below:

Man-hours

Activity Hours

Deposition of coatings

Characterisation

(XRD, SEM, XPS,

AFM, contact angle)

Technician 320

Scientist 80

Technician 50

Scientist 110

Installation of test equipment

Analysis and interpretation of test data

Instrumental cost

Scientist 8

Technician 12

Scientist 8

Technician 40

Scientist 10

Analysis (not incl. instrument depreciation) 530

Purchase of test boxes 10755

Name

BainesM

Location

UK / Lathom

FarmerJ UK / Lathom

FarnworthM UK / Lathom

JonesC

KaniukaJ

UK / Lathom

UK / Lathom

7.50

11.25

11.25

7.50

26.25

Manning T UK / Lathom 11.25 18.75

7.50

11.25

33.75

3.75

11.25 3.75

PhillipsI UK / Lathom 15.00

SheridanR

WeekesC

UK / Lathom

UK / Lathom

7.50

7.50

Wilson

Jackie

WoodsJ

UK / Lathom

UK / Lathom 11.25

7.50

7.50

15.00

26.25

7.50

11.25

11.25

7.50

22.50

15.00

22.50

161.25

15.00

7.50

7.50

15.00

26.25

Total 11.25 86.25

37.50

11.25 11.25

0.00

37.50

15.00

22.50

296.25

TR/0/

Pilkington Confidential page 1

Energieffektiva fönster utan utvändig kondens – utopi eller verklighet

Arne Roos

Uppsala universitet

Fönstrets termiska ledningsförmåga

U-värde i enheten W/m 2 K

• Single glazed

• Double glazed

• Triple glazed

• Double glazed + low-e

• Triple glazed + low-e

• Triple glazed + 2 low-e

• Triple glazed + 2 low-e + Krypton

• Insulated wall

6

3

2

1.7-1.2

1.2

0.9

0.5

0.1 - 0.2

2011-11-15

SÅ HÄR

Under klara vindstilla nätter blir värmeförlusten genom glasen för liten för att balansera utstrålningen mot himlen och hålla glasytans temperatur över daggpunkten

DET BILDAS KONDENS

PÅ DEN YTTRE GLASYTAN

Two concepts to avoid the problem

• Low-emissivity coating reduces cooling power – formation of condensation is supressed – emissivity < 0.4

• Hydrophilic coating causes condensation to form a water film rather than droplets – the view is less obstructed – formation

NOT supressed – emissivity = 0.84, same as for glass

How can we test it?

• A simple test box was constructed to test the occurrence of condensation on test samples by using light scattering as detection system

1

Insulated test box sample thermocouple heater detector

Laser

Insulated test box

Condensation forms droplets which causes light scattering-

Condensation can be detected thermocouple sample heater detector

Laser

2011-11-15

Results

Clear float glass

Low-e (e=0.15)

Hydrophilic (”self clean”)

Reduced signal condensation

1.2

2008_08_31

1

0.8

0.6

0.4

det_sign_float det_sign_Kglass det_sign_Activ

0.2

18 21 24 03 06 09 12

Time of day

The corresponding pane surface temperatures

15

10

25

2008_08_31

20

5 temp_float temp_Kglass temp_Activ temp_ext_air

0

18 21 24 03 06 09 12

Time of day

Condensation experiment

• Two insulated glass units mounted side by side

• Both with U-value 0.65 W/m 2 K

• One with ordinary float glass on external surface

• One with Pilkington Active self cleaning coating on external surface (hydrophilic, photoactive TiO

2

, about 15 nm thick)

Pilkington Activ selfcleaning glass

Uncoated glass

2

2011-11-15

Condensation frozen - Hydrophilic effect gone

BUT, we do get some pretty patterns

Conclusions

• A hydrophilic coating on the external surface drastically reduces the effect of light scattering caused by external condensation

• For frozen condensation the effect seems to be reversed – more ice on the coated surface than on the uncoated

• A low-emissivity coating inhibits the formation of condensation as expected

3

Formation of external condensation on low U-value windows with and without hydrophilic coatings

Arne Roos, Anna Werner The Ångström Laboratory, Uppsala University, Sweden

PROBLEM

High performance windows with low-emissivity coatings => low U-values => low heat losses => temperature of external window surface below outside air dewpoint =>

EXTERNAL CONDENSATION

OCCURS

External condensation occurs mainly during clear nights with high humidity and no wind. Radiative cooling of the external glass surface then brings it to a temperature below that of the ambient air and the dew point. The graph on the right shows the frequency of condensation formation on a test window in Uppsala,

Sweden during September – December

2007

Large area coating technology ”caused the problem”

Large area coating technology can solve ”the problem”

Hydrophilic coating low-e coatings

(”self cleaning”) outside Inside

Glazing U-value = 0.6 W/m 2 K

SOLUTION

External hydrophilic coating No external coating

CONCLUSIONS

A hydrophilic coating on the external surface of a low U-value window does not prevent external condensation, BUT the effect of light scattering and obstructed view is considerably reduced and sometimes almost eliminated

Anna Werner

ÅF-Infrastruktur AB

169 99 Stockholm

Sweden

+46 (0)10505 0016 anna.werner@ afconsult.com

Arne Roos

The Angstrom

Laboratory

Uppsala University,

P.O Box 534,

751 21 Uppsala,

Sweden

Arne.roos@ angstrom.uu.se

How to check the presence of dew on windows

A condensation detection system for glass coating testing

Background

Modern low U-value windows have created a new problem in the form of external condensation. The reason is that the heat loss through the window is so low that the temperature balance between the window surface and the sky becomes negative and the temperature of the external window surface becomes lower than the ambient. Condensation leads to a disturbed view through the windows and customer complaints.

Objective

The objective of this project has been to develop a reliable test site for the detection of condensation on a glass surface so that different surface coatings to prevent condensation can be tested and evaluated.

Method

Figure 1 shows a schematic drawing of the test cell.

When condensation occurs on the glass surface the incident light beam is scattered and the detector signal is reduced. The tested glass surface is tilted towards the sky to increase the tendency for condensation, and the constructed test box allows 6 glass samples to be tested in parallel, as shown in Figure 2.

Calibration

The view through the window depends on the degree of light scattering caused by condensation.

A selection of diffusing plastic films were used as reference samples in order to relate the detector signal to the degree of distorted view. Figure 3 shows how the view of a building façade is seen through two plastic films and in figure 4 we can see how the corresponding detector signal is reduced.

Test samples

Two concepts have been tested. A low emissivity surface increases the temperature of the surface and prevents condensation. A hydrophilic (“self cleaning”) surface smears out the water to form a film thus reducing the light distortion. In this test an uncoated float glass sample was used together with 3 samples with reduced emissivity (0.15, 0.35 and 0.60) and a sample with a hydrophilic surface

The test samples were provided by Pilkington

Floatglass Ab, Halmstad, Sweden..

Results

In figure 5 we show an example of how the system works. Condensation appears at different times for the different samples. Around midnight condensation occurs on the float glass and the coated glass with highest emissivity. A couple of hours later the middle emissivity surface gets condensation. Around 8am all samples are affected, but the hydrophilic coating is less affected than the others. The detected signal is still sufficiently high to allow viewing through the window. It should be noted here that all surfaces were facing the sky (45 degrees tilt angle) and no heating was on.

Light source

Focussing lens

Integrating sphere detector

Fig. 1 Schematic drawing of the test cell

Fig. 2 Photograph of the test cell showing the 6 sample positions with various degrees of condensation

Fig. 3 Photograph taken through two of the diffusing calibration films

The building can be viewed through the left one (film 1), but not through the right one (film 3).

d if f u s e r c a lib r a t io n

1 . 2

1

0 . 8

0 . 6

0 . 4 c l e a r p l a s ti c fi l m d if fu s e f il m 1 d if fu s e f il m 2 d if fu s e f il m 3 d if fu s e f il m 4

0 . 2

0

- 1 0 0 - 5 0 0 t im e

5 0 1 0 0

Fig. 4 Detector signal recorded versus time. At t=0 the calibration plastic films were positioned on the test cell.

1

0 .9

0 .8

0 .7

Condensation

External coating

Sample

Electric heater c o n d e n s a tio n te s t

Conclusions

The results show that the test concept works and that it is possible to evaluate different surface coatings and their effect on the external condensation on modern windows. This could lead to an increased tendency to use the best possible windows in all buildings. A trend that is absolutely necessary if we are to meet future requirements of low energy buildings.

Supported by the Swedish Energy Agency -

CERBOF

0 .6

0 .5

d et _ s ig n _f lo a t d et _ s ig n _e p s 06 0 d et _ s ig n _e p s 03 5 d et _ s ig n _e p s 01 5 d et _ s ig n _H y dr o p h ili c

0 .4

2 0 2 2 24 0 2 0 4 06 0 8 1 0

T im e o f d a y

Fig. 5 Detector signal versus time of day for a night in october.

Along the time axis we can detect the onset of condensation the detector signal level gives an indication of the degree of light distortion according to Fig. 4.

How to Check the Presence of Dew on Windows

Anna Werner

a

Arne Roos

b a

ÅF, Energy Efficiency, 169 99, Stockholm, Sweden b

Department of Engineering Sciences, Solid State Physics, The Ångström

Laboratory, Box 534, 751 21 Uppsala, Sweden

Abstract

The issue of external water condensation on well-insulated windows in cold climates has been studied with a new, unique experimental test facility in Uppsala,

Sweden. The characteristics of the outer surface of the window affects the occurrence, amount and type of external water condensation. Specifically, it influences how good the visibility is through the water layer.

In this article, measurements with this new equipment of the occurrence of dew on glass samples with different coatings are presented and discussed.

These initial results both show that the test facility gives reliable results and give an indication of what surfaces can be used to prevent either dew from occurring or the view through the window from being distorted by dew.

Key words: External water condensation, Thin film coatings, Hydrophilic glazing,

Low-e glazing, Dew, Functional coatings on glass

1 Introduction

In cold climates, where the heat transfer is predominantly from the inside to the outside, well-insulated windows are considered high priority to minimize the (heating) energy use of buildings. Dew sometimes forms on these windows on the surface facing the exterior. It typically happens during still, clear and humid nights. Sometimes the dew remains till the morning and obstructs the view to the outside.

Today, the best insulated windows - a U-value of the glazing of

0.4

W/ ( m 2 , K ) is offered by several window companies - are not chosen because customers are afraid external water condensation will obstruct the outward view through the windows in the morning after a clear night. The dew is formed since the temperature of the outer surface of the glazing is

Submitted to EuroSun 2010 28 June 2010

below that of the ambient air and of the dew point. The surface is not sufficiently heated by the heat transfer from the interior to eliminate the formation of condensation.

Although not many studies have been published on how different surfaces influence the dew formation on glass, it has been indicated that the changes in visibility through a window due to external condensation depend on the outer surface of the outer pane [1–4]. Specifically, it has been shown that different coatings give condensation with different characteristics [2].

Furthermore, it has been pointed out that a low-emissivity (here referred to as low-e) coating could be efficient to reduce the external water condensation and that a self-cleaning coating could smear out the water so that the visibility through the window is not destroyed.

The materials of interest for the coatings are limited. Owing to the required aging stability only hard coatings are possible to use. Fluorine doped tin oxide is one of the most durable transparent conducting oxides known today and it is widely used as a low-e coating. Tin oxide is deposited by atmospheric chemical vapour deposition, commonly referred to as pyrolitic deposition. It has been extensively studied regarding growth mechanism, electrical, optical and mechanical properties [5,6]. Tin oxide is thus expected to be sufficiently durable for the application of condensation suppression coating on windows and was chosen for this project.

Another concept to deal with the problem is to use a hydrophilic coating.

The idea is that even though condensation is formed, it is reduced to a water film on the glass surface rather than light scattering drops of water. For this application titanium oxide was chosen also for its hardness and excellent durability, and for the fact that this coating is already marketed as self-cleaning glass. The optical and hydrophilic properties of titanium oxide have also been extensively studied and a number of papers have been published [7–9].

In this article, we use the test box described in [10] and photographed in figure 1 to test different coatings as to how easily they get condensation on the external surface. Up to three sample panes can be tested simultaneously and under identical conditions.

A laser beam is directed through the glass sample. The transmitted beam hits a detector on the other side. When there is water on the surface, the beam is deviated and does not hit the detector. The detector signal thus decreases. It is also possible to see when the dew disappears since the detector signal then increases again.

These initial measurements were made both to see how the measurement method was working and to get some preliminary results on different

Fig. 1. The test equipment used for the measurements presented in this article. Up to three sample panes can be tested simultaneously under similar circumstances.

coatings.

The U-values of the tested panes, marginally affected by the surface emissivity, lie between 5.7 and 5.9

W/ ( m 2 , K ) . These are U-values calculated under standard conditions for a window assuming an interior temperature of

T i

= 20

◦

C [11]. Under these conditions condensation never appears on the outside of a single glazed window, but by reducing the temperature inside the test box, the power P being conducted through the pane can be reduced.

From P = U · ∆ T = U · ( T i

− T o

) , where T the box, it can be seen that reducing T i o is the air temperature outside is equivalent to reducing the

U-value. Thus different U-values can be simulated using only single panes.

This feature of the test equipment has not been specifically evaluated in this paper.

2 Experimental

The tests have been chosen among many series of measurements because they illustrate different features of the various coatings. The experimental set-ups are described here.

Three low-e coated samples were tested with emissivity values of = 0 .

15 ,

= 0 .

35 and = 0 .

60 , respectively. A self-cleaning pane ( = 0 .

84 ) and an uncoated pane ( = 0 .

84 ) were also tested.

Throughout the night the box was in some tests heated with a power of 8 W.

To make sure that there was no moisture on the panes at the beginning of the test affecting the measurement results, the box was heated with an additional power of 11 W until approximately midnight.

According to our calculations and knowledge of the wall material and geometry of the test box, around half of the dissipated power in the box,

1.2

1

0.8

0.6

0.4

0.2

21 24 03 06 09

Time of Day

7

6

5

4

3

2

1

21 24 03 06 09

Time of Day

(a) Intensity of the detection signal versus time.

(b) Pane temperature versus time.

Solid curve shows outdoor air temperature.

Fig. 2. Three parallel samples with = 0 .

15 (circles), 0 .

35 (squares) and 0 .

60 (no markers), respectively. Internal heating of 8 W applied throughout the night. Until approximately midnight an extra 11 W was applied to make sure that the surfaces were dry during the experiment.

≈ 4 W , escapes through the glazed part. Since the temperature difference was around 4

◦

C , this test situation was approximately equivalent to testing panes in windows with glazing U-values of U = 1 W/ ( m

2

, K ) . Nevertheless, as stated in the introduction, U-value simulations were not the prime object of this investigation. The heating power was low enough to ensure that condensation would occur on some panes during our tests.

It can be seen in figures 2 and 3 that the lower the emissivity the later the formation of condensation starts. The surface with the lowest emissivity is kept free from condensation throughout the night in figure 2 and only shows a dip in detector signal in figure 3.

Due to the internal heating the panes stay warmer than the outside air throughout the night, see figure 2(b). As expected the pane with the lowest emissivity has the highest temperature.

Condensation appears when there is a drop in outside temperature early in the morning.

The night for the test in figure 3 was substantially colder than the night shown in figure 2. Frost instead of water drops formed on the sample panes.

1.2

1

0.8

0.6

0.4

0.2

0

21 24 03 06 09

Time of Day

-1

-2

-3

-4

-5

-6

-7

21 24 03 06 09

Time of Day

(a) Intensity of the detection signal versus time.

(b) Pane temperature versus time.

Solid curve shows outdoor air temperature.

Fig. 3. Three parallel samples with = 0 .

15 (circles), 0 .

35 (squares) and 0 .

60 (no markers), respectively. Internal heating of 8 W applied throughout the night. No preheating applied.

The measurement results in figure 3 show that the test equipment works even during these circumstances, but we did notice something unexpected in our measurement results: The detection signal started to decrease earlier for the pane with = 0 .

15 than for the pane with = 0 .

35 . It could have something to do with the heating inside the box being uneavenly distributed.

Condensation formed on all three panes, but on the pane with the lowest emissivity it had disappeared in the morning.

Next, three different kinds of samples were tested as indicated in figure 4.

The measurement results show that it is possible to see a tendency for the water to form a film on the self-cleaning sample. This makes the visibility through the pane increase at approximately four o’clock in the morning, see figure 4(a), and go back to its initial value. This is probably due to the coalescence of water drops into a film which reduces the scattering.

The slow drop in signal for the low-e coated surfafce is due to a temperature drift in the detection system. No condensation could be seen on this surface.

1.2

1

0.8

0.6

0.4

0.2

0

21 24 03 06 09

Time of Day

17

16

15

14

13

12

11

10

9

21 24 03 06 09

Time of Day

(a) Intensity of the detection signal versus time.

(b) Pane temperature versus time.

Dotted curve with no markers show temperature inside the box and solid curve shows outdoor air temperature.

Fig. 4. Three parallel samples; a low-e sample with = 0 .

15 (circles), a self-cleaning sample with = 0 .

84 (triangles) and an uncoated sample with = 0 .

84 (squares).

Internal heating of 8 W applied.

3 Conclusion and Future Outlook

The test facility was used to test different glass surfaces as to how prone they were to get condensation. These first tests indicate that condensation occurs when there is a drop in the outdoor air (and pane) temperature(s).

This is consistent with theory. When the air temperature drops the difference between the air temperature and the dew point is reduced. The lower the emissivity of the surface, the later the pane temperature drops and the later the formation of condensation starts.

The concept of using light scattering as an indication of condensation works well, even during frost nights.

Different window U-values can be simulated by changing the heating power in the box so that full size windows do not need to be installed. In the present study the power of the internal heater was not adjustable. Therefore the simulated U-value could not be fully controlled. To perform more precise

U-value simulations a flexible internal heater should be installed, the power of which can be regulated to maintain a constant temperature difference

between the inside and the surrounding air.

It could also be of interest to separate the box into three chambers with different temperatures. This way, the same surface could be tested with three different temperatures as if mounted in windows with three different

U-values.

4 Acknowledgements

The work was sponsored by CERBOF, the Centre for Energy and Resource

Efficient Construction and Facilities management, a research and innovation programme initiated by the Swedish Energy Agency, and by Pilkington

European Technical Centre.

References

[1] Ivar Hamberg, J. Stefan E. M. Svensson, Tord S. Eriksson, Claes-Göran

Granqvist, Per Arrenius and Fredrik Norin, Radiative cooling and frost formation on surfaces with different thermal emittance: theoretical analysis and practical experience, Applied Optics, vol. 26, no. 11, June 1, 1987

[2] Anna Werner and Arne Roos, Condensation Tests on Glass Samples for Energy

Efficient Windows, Solar Energy Materials and Solar Cells, vol. 91, no. 7, 609–

615, 2007

[3] Anna Werner and Arne Roos, Simulations of Coatings to avoid External

Condensation on low U-value Windows, Optical Materials, 30, February 6, 968–

978, 2008

[4] Hans Joachim Gläser, Hansjörg Weis, Is it possible to avoid translucence by dew on the outside surface of architectural glazing iwth photocatalytic TiO

2 coatings?, Proceedings from Glass Performance Days, June 12–15, 2009, 625–

629, Tampere, Finland

[5] T. Serin, N. Serin, S. Karadeniz, H. Sari, N. Tugluoglu and O. Pakma, Electrical, structural and optical properties of SnO

2 thin films prepared by spray pyrolysis,

Journal of Non-Crystalline Solids, 352, 209–215, 2006

[6] W. M. Sears and Michael A. Gee, Mechanics of film formation during the spray pyrolysis of tin oxide, Thin Solid Films, 165, 265–277, 1988

[7] Chien-Sheng Kuo, Yao-Husan Tseng and Yuan-Yao Li, Wettability and

Superhydrophilic TiO

2

Film Formed by Chemical Vapor Deposition, Chemistry

Letters, 35, no.4, 356–357, 2006

[8] Pung Keun Song, Yukiko Irie, Shingo Ohno, Yasushi Sato and Yuzo Shigesato,

Crystallinity and Photocatalytic Activity of TiO

2

Films Deposited by Reactive

Sputtering Using Various Magnetic Field Strengths, Japanese Journal of Applied

Physics, 43, no.4A, 442–445, 2004

[9] Andrew Mills, Anne Lepre, Nicholas Elliott, Sharan Bhopal, Ivan P. Parkin and S.A. O’Neill, Characterisation of the photocatalyst Pilkington Activ

T M

: a reference film photocatalyst?, Journal of Photochemistry and Photobiology A:

Chemistry, 160, 213–224, 2003

[10] Anna Werner, Arne Roos and Per Nilsson, Design and Evaluation of a Detection

System for External Water Condensation on low U-value Windows, Sensors and

Actuators A: Physical, 138, 1, 16–21, July 20, 2007

[11] European norm EN 673, Thermal insulation of glazing - Calculation rules for determining the steady state U-value of glazing, 1998