pompy obiegowe lowara

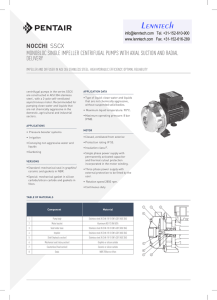

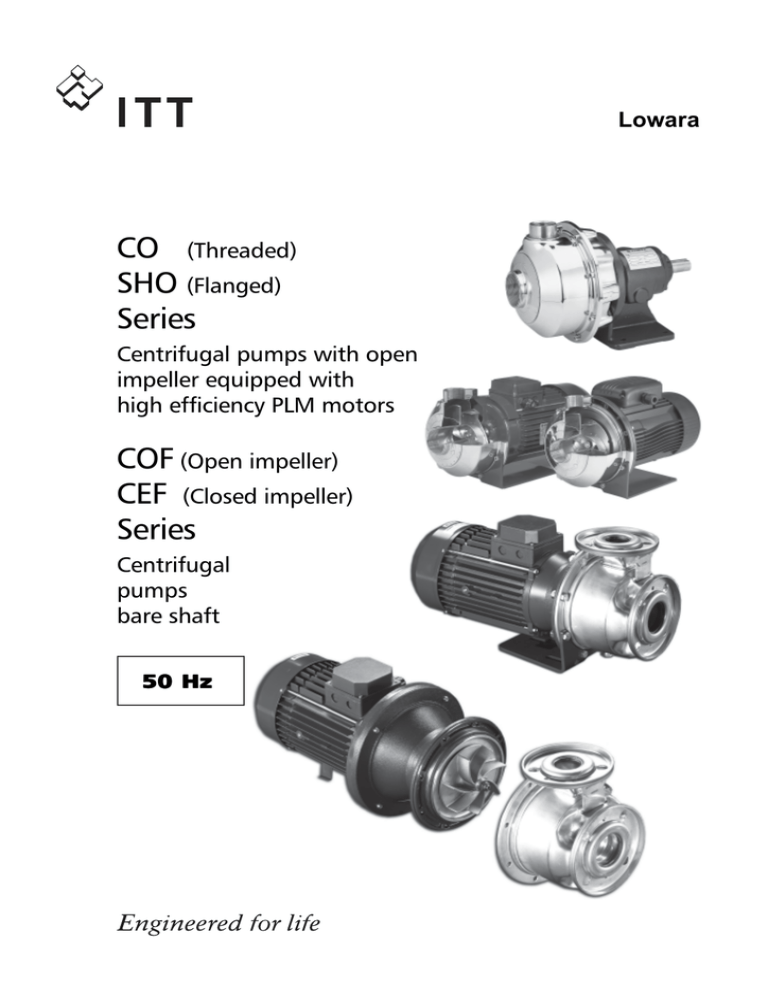

advertisement