Single Phase Burns - Emerson Climate Technologies

advertisement

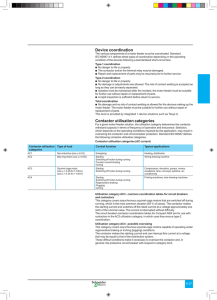

Contractor Service Tips Tip C 2 a rd Single Phase Burns Extensive Copeland testing and field experience has proven that single phase motor burns are caused by the malfunction or misapplication of the system contactor(s). Contactors play a role in any compressor overload protection scheme, but are particularly important when they are part of a pilot-operated protection system. Contactors have a limited life and should be inspected during routine maintenance and replaced every time a compressor is installed. The Copeland warranty does not extend to external electrical components furnished by others, and the failure of such components resulting in compressor failure will be taken into consideration by Copeland in determining the warranty status of returned compressors. Please refer to Copeland Contactor Application Specifications on the back of this card for additional information. Copeland Contactor Application Specifications The followingContactor Copeland Contactor Application Specifications are Selection Guide based on contactor ratings as listed with U.L. Copeland Contactor Application Specifications A. The Thefollowing contactor must meet the operational test criteriaare in Copeland Contactor Applicationand Specifications ARI (Air Conditionings and Refrigeration Institute) based on contactor ratings as listed with U.L.Standard 780-78, “Standard Formeet Definite Purpose Contactors.” A. The contactor must the operational and test criteria in B. The contactor must be certified by the manufacturer to close ARI (Air Conditionings and Refrigeration Institute) Standard at 780-78, 80% of the lowestFor nameplate voltage Contactors.” at normal room “Standard Definite Purpose temperatures (166 Volts for contactors used on 208/230 Volt B. The contactor must be certified by the manufacturer to close rated equipment). at 80% of the lowest nameplate voltage at normal room C. Ontemperatures single contactor the rating contactor (166 applications, Volts for contactors used of onthe 208/230 Volt forrated bothequipment). full load amperes and locked rotor amperes (LRA) must be greater than applications, the corresponding nameplate amperage C. On single contactor the rating of the contactor rating of the motor RLA, plus nameplate for both fullcompressor load amperes and locked rotorthe amperes (LRA) amperage ratingsthan of any or other accessories must be greater thefans corresponding nameplatealso operated through contactor. amperage rating the of the compressor motor RLA, plus the amperage ratings ofeach any fans or othermust accessories D. Fornameplate two contactor applications, contactor have a also operated through therating contactor. part winding locked rotor equal to or exceeding the half locked applications, rotor rating of thecontactor compressor. D. Forwinding two contactor each must have a locked rotor rating than equal50% to orofexceeding the Sincepart half winding the winding LRA is larger the compressor half winding lockeddefinite rotor rating of thecontactor compressor. full winding LRA, some purpose manufacturhalf the winding LRA isfor larger 50% of the compressor ersSince oversize their contactors twothan contactor applications. full winding LRA, some definite purpose contactor manufacturCheck with the contactor manufacturer to determine if larger ers oversize contactors for two contactor applications. contactors aretheir needed for two-contactor applications. Check with the contactor manufacturer to determine if larger contactors are neededTime for two-contactor Delay Relaysapplications. Delay Relays For part winding startTime applications, a time delay relay is required between contactors with a setting 1 second For part winding start applications, a timeof delay relay isplus or minus 1/10between second.contactors The operation a delayofrelay can be required with aofsetting 1 second plus or affected by low voltage. minus 1/10 second. The operation of a delay relay can be In order by to low insure reliability, time delay relays listed as meeting affected voltage. Copeland specifications for nominal 208/230 control In order to insure reliability, time delay relaysVolt listed as meeting systems must be guaranteed by the 208/230 manufacturer to function Copeland specifications for nominal Volt control properly 170 be Volts in a –40°by ambient. systemsatmust guaranteed the manufacturer to function properly at 170 Volts in a –40°F ambient. ForFor information see AE AEBulletin Bulletin10-1244 10-1244. informationon ontime timedelay delay relays, relays, see . Form No. 2000DS-67 R2 Issued 1/06 Emerson Climate Technologies logo is a trademark of Emerson Electric Co. © 2006 Emerson Climate Technologies. Printed in the USA.