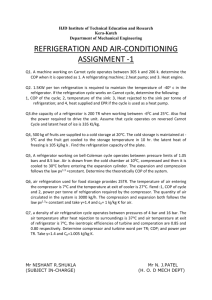

Refrigeration Cycle

advertisement

Basic Refrigeration Cycle Reversed Carnot Cycle Reversed Carnot Cycle Refrigeration Cycle Dr. M. Zahurul Haq Professor Department of Mechanical Engineering Bangladesh University of Engineering & Technology (BUET) Dhaka-1000, Bangladesh zahurul@me.buet.ac.bd http://teacher.buet.ac.bd/zahurul/ ME 415: Refrigeration & Building Mechanical Systems e720 Coefficient of Performance, COP = c Dr. M. Zahurul Haq (BUET) Refrigeration Cycle Basic Refrigeration Cycle ME 415 (2011) 1 / 14 Reversed Carnot Cycle 2 / 14 Reversed Carnot Cycle Carnot cycle demands that the expansion take place isentropically and that the resulting work be used to help drive the compressor. Practical difficulties, however, militate against the expansion engine: the possible work that can be derived from the engine is small fraction that must be supplied to the compressor. practical problems such as lubrication intrude when a fluid of two phases drives the engine. In wet compression, the droplets of the liquids may wash the lubricating oil from the walls of the cylinder, accelerating wear. Dry compression takes place with no droplets and is preferable. Liquid refrigerants may be trapped in the head of reciprocating compressor by the rising piston, possibly damaging the valves or the cylinder head. ME 415 (2011) ME 415 (2011) Expansion Process in Carnot Cycle During compression, droplets present in liquid are vaporised by the internal heat transfer process which requires finite time. High-speed compressors are susceptible to damage by liquid because of the short time available. Refrigeration Cycle Refrigeration Cycle Basic Refrigeration Cycle Wet Compression in Carnot Cycle vs. Dry Compression c Dr. M. Zahurul Haq (BUET) c Dr. M. Zahurul Haq (BUET) TL QL = Wnet TH − TL 3 / 14 the economics of the power recovery have in past not justified the cost of the expansion engine. A throttling device, such as a valve or other restriction, is almost universally used for this purpose. c Dr. M. Zahurul Haq (BUET) Refrigeration Cycle ME 415 (2011) 4 / 14 Basic Refrigeration Cycle Ideal Vapour Compression Refrigeration Cycle Basic Refrigeration Cycle Ideal Vapour Compression Refrigeration Cycle Ideal Vapour Compression Refrigeration Cycle e722 e723 e494 c Dr. M. Zahurul Haq (BUET) Refrigeration Cycle Basic Refrigeration Cycle ME 415 (2011) 5 / 14 c Dr. M. Zahurul Haq (BUET) Ideal Vapour Compression Refrigeration Cycle Refrigeration Cycle Basic Refrigeration Cycle ME 415 (2011) 6 / 14 Ideal Vapour Compression Refrigeration Cycle Processes of VC System QL QH Win COP = = = = Q41 = m(h1 − h4 ) Q23 = m(h2 − h3 ) W12 = m(h2 − h1 ) QL /Win e496 1 → 2: Isentropic compression, Pevap → Pcond 2 → 3: Isobaric heat rejection, QH e721 3 → 4: Isenthalpic expansion, Pcond → Pevap Simple vapour compression cycle with pressure & enthalpy values for R134a 4 → 1: Isobaric heat extraction, QL c Dr. M. Zahurul Haq (BUET) Refrigeration Cycle ME 415 (2011) 7 / 14 c Dr. M. Zahurul Haq (BUET) Refrigeration Cycle ME 415 (2011) 8 / 14 Basic Refrigeration Cycle Ideal Vapour Compression Refrigeration Cycle Basic Refrigeration Cycle Effect of Evaporator Temperature A theoretical single stage cycle using R134a as refrigerant operates with a condensing temperature of 30o C and an evaporator temperature of -20o C. The system produces 50 kW of refrigeration effect. Estimate: o R134a: RE = 50 kW, Tcond = 30 C 10 0.40 9 0.39 1 Coefficient of performance, COP 8 0.38 2 Refrigerant mass flow rate, m 7 0.37 Ref. flow rate QL COP 6 = Q41 = m(h1 − h4 ) = 50 kW m = 0.345 Kg/s = W12 = m(h2 − h1 ) = 12.5 kW = QL /Win = 50.0/12.5 = 4.0 Win COP 0.36 COP 5 0.35 4 0.34 3 0.33 2 0.32 1 0.31 0.30 0 -50 e496 Refrigerant flow rate (kg/s) Example Ideal Vapour Compression Refrigeration Cycle -45 -40 -35 -30 -25 -20 -15 -10 -5 0 o Tevap ( C) e497 c Dr. M. Zahurul Haq (BUET) Refrigeration Cycle Basic Refrigeration Cycle ME 415 (2011) 9 / 14 c Dr. M. Zahurul Haq (BUET) Ideal Vapour Compression Refrigeration Cycle Basic Refrigeration Cycle Effect of Condenser Temperature 10 10 0.40 9 9 0.38 0.34 7 Ref. flow rate 5 5 0.30 4 0.28 3 0.26 1 2 0.24 50 0 20 25 30 35 40 45 Tcond = 30 C 6 0.32 15 o 7 6 10 o Tcond = 20 C 8 COP 0.36 COP 5 4 o Tcond = 40 C 3 2 -50 -45 o Tcond ( C) e499 Refrigeration Cycle -40 -35 -30 -25 -20 -15 -10 -5 0 o e498 c Dr. M. Zahurul Haq (BUET) Ideal Vapour Compression Refrigeration Cycle 11 0.42 Refrigerant flow rate (kg/s) COP 0.44 11 0 10 / 14 12 o 8 ME 415 (2011) Effect of Evaporator & Condenser Temperatures R134a: RE = 50 kW, Tevap = -20 C 12 Refrigeration Cycle ME 415 (2011) 11 / 14 c Dr. M. Zahurul Haq (BUET) Tevap ( C) Refrigeration Cycle ME 415 (2011) 12 / 14 Deviation from Simple Cycle Deviation from Simple Cycle Deviations from Ideal Cycle Super-heating & Sub-cooling 1 Refrigerant pressure drop in piping, evaporator, condenser, receiver tank, and through the valves and passages. 2 Sub-cooling of liquid leaving the condenser. 3 Super-heating of vapour leaving the evaporator. 4 Compression process is not isentropic. e502 e501 Sub-cooling of liquid serves a desirable function of ensuring that 100% liquid will enter the expansion device. Super-heating of vapour ensures no droplets of liquid being carried over into the compressor. Even through refrigeration effect is increased, compression work is greater & probably has negligible thermodynamic advantages. e500 c Dr. M. Zahurul Haq (BUET) Refrigeration Cycle ME 415 (2011) 13 / 14 c Dr. M. Zahurul Haq (BUET) Refrigeration Cycle ME 415 (2011) 14 / 14