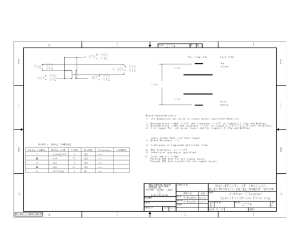

IPC-SM-782 Surface Mount Design and Land Pattern Standard

advertisement