Doosan DBC Series Horizontal Boring Machines Brochure

advertisement

DBC

series

Horizontal

Boring Machine

DBC series

DBC 110S

DBC 130S / SL

DBC 110Ⅱ

DBC 130 / L

DBC 250 / LⅡ

ver. EN 160502 SU

Product Overview

Basic Information

Diverse Line-up

High-Rigidity &

High-Precision

User Convenience

Detailed

Information

Options

Capacity Diagram

Specifications

Customer Support

Service

DBCⅡseries

DBC S series

Column Moving Type NC Boring Machine Featuring the State-of-the-Art Technologies

The DBC series, ranging from compact to super-size models, satisfies customers’ requirements with DOOSAN's

advanced technical prowess. A product line-up has been established for processing from middle to largest size

parts including die / mold parts. We are improving productivity and creating values for our customers on the

basis of our design improvements including enhanced operating convenience and efficiency.

DBC

series

Contents

02 Product Overview

Basic Information

04 Diverse Line-up

08 High-Rigidity & High-Precision

Structure

11 User Convenience

Detailed Information

16 Standard / Optional

Specifications

18 Diagrams

24 Machine / NC Unit Specifications

30 Customer Support Service

Diversified Line-up for Faster Response to

Customers' Requirements

The DBC Series offers a wide line-up from

compact to large models, from heavy-duty

type to high-speed mold processing type.

DBCⅡ series

DBC S series

Enhanced Performance through HighRigidity & High-Precision Structure

A high-rigidity and high-precision structure

has been adopted to improve heavy-duty

machining performance.

A high-rigidity and high-precision structure has

been adopted to improve heavy-duty machining

performance.

B-axis rotary table equipped with high-precision

encoder as a standard

B-axis rotary table equipped with high-precision

encoder as a standard

Increased Convenience and Productivity

The DBC Series offers various options and

customized control functions for maximum

user convenience.

Automatic Tool Changer (ATC)

Automatic Pallet Changer (APC)

Various head attachments

Doosan Easy Operation package

02 / 03

Product Overview

Basic Information

Diverse Line-up

High-Rigidity &

High-Precision

User Convenience

Detailed

Information

Options

Capacity Diagram

Specifications

Customer Support

Service

Diverse Line-up

Complete line-up ranging

from compact to super-large

types, and from heavy-duty

to high-speed machining

models is prepared for

better and faster response

to customer requests.

Optimal Solutions

Diverse Line-up

The DBC series provides various models covering

compact, high-productivity, multi-functional, heavy

duty and large workpieces.

Spindle

Nose-type head structure allows easy access to the

workpiece and minimal protrusion of boring spindle

enables stable cutting.

Diverse Line-up

The DBC series provides

a wide line-up of models

covering compact, highproductivity, multifunctional, heavy loads

and large workpieces.

DBC S series

Compact type DBC 110S / 130S / 130SL

•Designed in compact size for small-medium size works

•Compact structure minimizes machine footprint

DBC 110S / 130S

5

(23 900

2.3 m

inc m

h)

DBC 130SL

mm

20 inch)

5

5 7.3

(21

(2

68

67 00m

.7

in m

ch

)

m

0m

745 3 inch)

3

(29

.

DBC Ⅱ series

Small / medium-sized, high-productivity DBC 110Ⅱ

• High-productivity model featuring high-speed

spindle

• Superior for deep cutting – boring operation is

possible up to the table center due to W-axis

feeding

Multi-purpose (Standard) DBC 130 II / 250 II

• A best-selling, standard model with a sales record

of more than 1,000 units for the last decade –

continuously upgraded with long-term design

know-how and production technology.

• Shortest delivery time by modular system design.

Spindle speed

4000 r/min

DBC 130 II

(Heavy Duty)

DBC 250 II

(High Speed)

Large workpieces DBC 130LⅡ / DBC 250LⅡ

• Suitable for machining large workpieces

X / Y / Z axes travel distance

4000 / 2500 / 2000 mm

(157.5 / 98.4 / 78.7 inch)

Max. workpiece diameter (without splash guard)

DBC 130Ⅱ/ 250Ⅱ

Ø3900 mm (153.5 inch)

DBC 130LⅡ/ 250LⅡ

Ø4800 mm (189.0 inch)

04 / 05

Product Overview

Spindle

Basic Information

Diverse Line-up

High-Rigidity &

High-Precision

User Convenience

Detailed

Information

Options

Capacity Diagram

Specifications

Nose-type head

structure allows easy

access to the work

piece and minimal

protrusion of boring

spindle enables

stable cutting

operation.

Stable cutting performance of highly-rigid spindle

Supported by highly-rigid bearings, the spindle is designed to bear very high axial working

load. In addition, the spindles of the DBC Series have further reinforced rigidity providing

improved cutting performance when the W-axis is in protruding position.

DBC S series

DBC 110S / DBC 130S / DBC 130SL

Offer high-speed, high-power spindles to different boring sizes for higher productivity

Spindle Speed

r/min

Spindle motor

kW(Hp)

Torque

N·m(ft-lbs)

DBC 110S

3000

26 / 22 (34.9 / 29.5)

(30min/cont.)

{30 / 22 (40.2 / 29.5)

(15min/cont.)}*

1137 {1273}*

(839.1 {939.5}*)

DBC 130S

DBC 130SL

2500

37 / 30 (49.6 / 40.2)

(30min/cont.)

3028

(2234.7)

Model

Customer Support

Service

DBCⅡ series

DBC 110 Ⅱ

High-speed, high-performance spindle

Spindle Speed

r/min

Spindle motor

kW(Hp)

Torque

N·m(ft-lbs)

4000

26 / 22 (34.9 / 29.5) (30min/cont.)

{30 / 22 (40.2 / 29.5) (15min/cont.)

45 / 37 (60.3 / 49.6) (30min/cont.)}*

2835

{3259, 3853}*

(2092.2

{2405.1, 2843.5}*)

DBC 130 / L

High-power, high-torque spindle for heavy-duty machining

Spindle Speed

r/min

Spindle motor

kW(Hp)

Torque

N·m(ft-lbs)

2500

26 / 22 (34.9 / 29.5) (30min/cont.)

{30 / 22 (40.2 / 29.5) (15min/cont.)

45 / 37 (60.3 / 49.6) (30min/cont.)}*

3383

{3940, 3703}*

(2496.7

{2907.7, 2732.8}*)

DBC 250 / L Ⅱ

High-speed, high-precision built-in Quill spindle

• Powerful Quill (Ø250mm) feed system (W-axis travel distance: 500 mm)

• Greased-type lubrication for the spindle bearings

• Stable thermal error of the spindle over a long-term operation

Spindle Speed

r/min

Spindle motor

kW(Hp)

Torque

N·m(ft-lbs)

6000

30 / 22 (40.2 / 29.5)

(30min/cont.)

600 (442.8)

* { } : Option

DBC

series

* Note1) Please contact us if you wish to high power spindle. (45 / 37 kW) (60.3 / 49.6 Hp)

DBC 110S

DBC 130S /SL

Spindle motor : 26 / 22 kW

(34.9 / 29.5 Hp)

2835

N·m

(2092.2

ft-lbs)

2835

N·m

(2092.2ft-lbs)

ft-lbs)

937 N·m

(691.5

937

N·m

(691.5

ft-lbs)

(30min.)

26Hp)

kW (34.9

Hp) (30min.)

2393

N·m

(1766.0

ft-lbs)

2393

(1766.0ft-lbs)

ft-lbs)26 kW (34.9

793 N·m

(585.2

793

N·m

(585.2

ft-lbs)

22 kW (29.5

(Cont.)Hp) (Cont.)

22Hp)

kW (29.5

2835

N·m

(2092.2

ft-lbs)

937N·m

N·m

(691.5

ft-lbs)

937

(691.5

248N·m

N·m

(183.0ft-lbs)

ft-lbs) 26 kW (34.9 Hp) (30min.)

248

(183.0

ft-lbs)

2393

N·m

(1766.0

ft-lbs)

4000

210N·m

N·m

(155.0ft-lbs)

ft-lbs) 22 kW (29.5 Hp) (Cont.)

210

(155.0

ft-lbs)

793N·m

N·m

(585.2

ft-lbs)

793

(585.2

4000 (2952.0)

100

100

(2952.0)

(73.0)

(73.0)

937

N·m

(691.5

ft-lbs)

248

(183.0

248 N·m (183.0 ft-lbs)

3383

N·m

(2496.7

ft-lbs)

793

ft-lbs)

210 N·m

(155.0

210

N·m

(155.0 ft-lbs)

3383

N·m(585.2

(2496.7

ft-lbs)

N·m (2112.2 ft-lbs)

26 kW (34.9 Hp) (30min.)

100

100 N·m 2862

2862

(2112.2 ft-lbs)

26 kW (34.9 Hp) (30min.)

(73.0) (73.0)

22 kW (29.5 Hp) (Cont.)

61ft-lbs)

N·m

(45.0 ft-lbs) 22 kW (29.5

61

N·m

(45.0

248

N·m

(183.0

ft-lbs)

Hp) (Cont.)

1144

N·m

(844.3

ft-lbs)

210

N·m

(155.0

ft-lbs)

53ft-lbs)

N·m

(39.1

ft-lbs)

53

N·m

(39.1

1144

N·m

(844.3

ft-lbs)

100

968

N·m

(714.4

ft-lbs)

LOW MIDDLE MIDDLE HIGH

HIGH

96810

N·mLOW

(714.4 ft-lbs)

(73.0)

10

61 N·m (45.0

ft-lbs)

61 N·m

(45.0 ft-lbs)

(7.4 20 (7.4 88

20

88

1000 4000

4000

265ft-lbs)

53 N·m (39.1

ft-lbs)

53 N·m

(39.1

294

N·m

(217.0

ft-lbs) 2651000

294 N·m (217.0

ft-lbs)

248

N·m

(183.0

ft-lbs)

LOW

MIDDLE: r/min

LOW speed

MIDDLE HIGH

HIGH

248

N·m (45.0

(183.0

ft-lbs)

Spindle

300

10

10

61

N·m

ft-lbs)

300

(7.4 (221.4)

(7.4N·m 20

2053

88 ft-lbs)88265

4000 4000

265 1000 1000

(39.1

(221.4)

3000

(2214.0)

10

DBC 130 / L (7.4

LOW

MIDDLE

HIGH

20

88

265

1000

4000

94 N·m (69.4

ft-lbs)

94 N·m (69.4

ft-lbs)(60.5 ft-lbs)

82 N·m

82 N·m (60.5

ft-lbs)

2500

26

Spindle speed

:

r/min

Spindle

motor

:

/ 22 kW

4000

4000

LOW

MIDDLE

HIGH

10 LOW

MIDDLE

HIGH

(2952.0)

10 (2952.0)

29.5 Hp)

(7.4) 10

80

217

845 (34.9 / 2500

(7.4) 10

80

217

845

2500

3383 N·m (2496.7

3383 N·m

ft-lbs)

(2496.7 ft-lbs)

4000 4000

2862 N·m (2112.2

2862 N·m

ft-lbs)

(2112.2 ft-lbs)

(2952.0) (2952.0)

26 kW (34.926

Hp)

kW(30min.)

(34.9 Hp) (30min.)

22 kW (29.522

Hp)

kW(Cont.)

(29.5 Hp) (Cont.)

3383N·m

N·m3383

(2496.7

ft-lbs)

(2496.7

ft-lbs)

4000

1144

(844.3

1144N·m

N·m

ft-lbs)

(844.3 ft-lbs)

2862

N·m

(2112.2

ft-lbs)

2862

N·m

(2112.2ft-lbs)

ft-lbs)26 kW (34.9

(2952.0)

(30min.)

26Hp)

kW (34.9

Hp) (30min.)

968

N·m

(714.4

968 N·m

ft-lbs)

(714.4

22 kW (29.5

(Cont.)Hp) (Cont.)

22Hp)

kW (29.5

3383 N·m

(2496.7

ft-lbs)

1144

N·m

(844.3

ft-lbs)

1144

N·m

(844.3ft-lbs)

ft-lbs)

294

N·m

(217.0

294

N·m

ft-lbs)

(217.0

4000

2862N·m

N·m(714.4

(2112.2

ft-lbs)

4000 (2952.0)

968

ft-lbs)

968

(714.4

248

N·m (183.0

248N·m

N·m

ft-lbs)

(183.0ft-lbs)

ft-lbs) 26 kW (34.9 Hp) (30min.)

300

300

22 kW (29.5 Hp) (Cont.)

(2952.0)

(221.4) (221.4)

30 kW (40.2 Hp)

600

N·m

(442.8

1144

N·m

(844.3

ft-lbs)

30 kW (40.2 Hp)

294

N·m

(217.0

ft-lbs)

294

N·m

(217.0 ft-lbs)

ft-lbs)

600

N·m

(442.8

ft-lbs)

968N·m

N·m(183.0

(714.4

ft-lbs)

15min.

248

ft-lbs)

248 N·m

(183.0

ft-lbs)

15min. 30min.

300

300

22 kW

30min. CONT.

(221.4) (221.4)

22 kW (29.5 Hp)

420

N·m

94 N·m

94ft-lbs)

N·m

(69.4 ft-lbs)

CONT.

294

N·m(69.4

(217.0

ft-lbs)

420

N·m

(310.0

ft-lbs)

(29.5

82 N·m

(60.5

82ft-lbs)

N·m

(60.5 ft-lbs)

20Hp)

kW

(310.0

ft-lbs)

248

N·m

(183.0

ft-lbs)

20 kW (26.8 Hp)

353 N·m

(260.5 ft-lbs)

300 353 N·mLOW

(260.5 ft-lbs)

LOW MIDDLE MIDDLE

HIGH

HIGH

(26.8

Hp)

(221.4)

10

9410

N·m (69.4

ft-lbs)

94 N·m

(69.4

ft-lbs)

18.5 kW (24.8 Hp)

262

N·m

(193.4

ft-lbs)

18.5 kW (24.8

(7.4) 10

(7.4)

262

(193.4

ft-lbs)

80

10

80

217ft-lbs) 217845

845Hp)2500

2500

82

N·m (60.5

ft-lbs)

82 N·m

(60.5

220 N·m (162.4 ft-lbs)

15 kW

220 N·m (162.4 ft-lbs)

15

kW

LOW

MIDDLE MIDDLEHIGH

LOW

HIGH

200

(20.1 Hp)

10

10N·m (69.4

94

ft-lbs)(140.2 ft-lbs)

200

(20.1 Hp)

190 N·m

(147.6)

14.7

kW

(7.4)

(7.4)

190

(140.2

ft-lbs)

82 N·m (60.5

10

80 ft-lbs)

10

80217

217 84514.7 kW

845 2500 2500

(147.6)

(19.7 Hp)

(19.7 Hp)

140 N·m (103.3 ft-lbs)

MIDDLE

HIGH

(103.3

ft-lbs)

10 140 N·m LOW

114

N·m

(84.1speed

ft-lbs) : r/min

Spindle

114 N·m

ft-lbs)

0 (84.1

(7.4)0 10

80

217ft-lbs)

845

2500

84.0 N·m (62.0

84.0 N·m (62.0 ft-lbs)

29.4 N·m (21.7 ft-lbs)

29.4

N·m (21.7

ft-lbs)(17.6 ft-lbs)

4000 L Ⅱ

4000

23.8 N·m

DBC 250 / 250

23.8

10N·m (17.6 ft-lbs)

(2952.0)

(2952.0)

10

(7.4)

350 500 8001002 1500 25006000

(7.4)

1500

350Spindle

500

30 kW

(40.2

30

Hp)

kW/(40.2

600 N·m (442.8

600 N·m

ft-lbs)(442.8

ft-lbs) 8001002

30

22Hp)kW

Spindle speed

: 6000

r/min

motor

:25006000

4000 4000

15min.

15min.

(2952.0) (2952.0)

40

2

.

/ 29.5 Hp)

(

30min. 30min.

22 kW

22 kW

CONT.

CONT.

30 kW (29.5

(40.2

Hp)

420

420N·m

N·m

30Hp)

kW (40.2

600N·m

N·m (442.8

ft-lbs)

600

(442.8 ft-lbs)

(29.5Hp)

Hp)

4000

(310.0 ft-lbs)(310.0 ft-lbs)

20 kW

20 kW

15min.

15min.

(2952.0)

353 N·m (260.5

35330min.

N·m

ft-lbs)(260.5

ft-lbs)

(26.8 Hp) (26.8 Hp)

30min.

22 kWHp) 22 kW

CONT.

CONT.

30

kW

(40.2

420

N·m

420

N·m

600

(442.8

ft-lbs)

18.5

Hp)

kW

262 N·m (193.4

262 N·m

ft-lbs)(193.4 ft-lbs) 18.5 kW (24.8

(29.5

Hp)(24.8

(29.5Hp)

Hp)

(310.0 ft-lbs)

(310.0 ft-lbs)

20 kW15 kW

20 kW 15 kW

15min.

220

220N·m

N·m

ft-lbs)

(162.4ft-lbs)

ft-lbs)

353N·m

N·m(162.4

(260.5

ft-lbs)

353

(260.5

30min.

(26.8 Hp)

(26.8 Hp)

22 kW

200

200

(20.1

Hp) (20.1 Hp)

CONT.

420

N·m

18.514.7

kW kW

(24.8

18.5

kW

190

N·m

(140.2

190N·m

N·m

ft-lbs)

(140.2ft-lbs)

ft-lbs)

(29.5Hp)

Hp)(24.8

262

N·m

(193.4

ft-lbs)

262

(193.4

(147.6) (147.6)

14.7

kW Hp)

(310.0

ft-lbs)

20 kWHp) (19.7 Hp)

(19.7

220

N·m

(162.4

ft-lbs)

220 N·m

(162.4 ft-lbs)

15 kW 15 kW

353N·m

N·m(103.3

(260.5

ft-lbs)

(26.8 Hp)

140

140 N·m

ft-lbs)

(103.3 ft-lbs)

200

200N·m (84.1

(20.1

Hp)

114

114

ft-lbs)

N·m

(84.1

ft-lbs)

18.5 kW (24.8 Hp) (20.1 Hp)

262 N·m

(193.4

190

ft-lbs)

190

N·m

(140.2

0 (140.2

(147.6)0 (147.6)

14.7 kW 14.7 kW

84.0 N·m

(62.0

84.0

ft-lbs)

N·m

(62.0ft-lbs)

ft-lbs)

220 N·m (162.4 ft-lbs)

(19.7 Hp)

(19.7 Hp)

15 kW

29.4

(21.7

29.4

ft-lbs)

N·m

(21.7ft-lbs)

ft-lbs)

140

N·m

(103.3

ft-lbs)

140

N·m

(103.3

200

(20.1 Hp)

23.8

(17.6

23.8

N·m

(17.6

ft-lbs)

114

N·m

(84.1

ft-lbs)

114

N·m

(84.1

ft-lbs)

N·m

(140.2 ft-lbs)

(147.6)

10 0 19010

0

14.7

kW

84.0

ft-lbs)

84.0 N·m

(62.0 ft-lbs)

(7.4)

(7.4)N·m (62.0

Hp)

1500

25006000

1500 25006000

350 500 350

8001002

500(19.7

800

1002

140

ft-lbs)

29.4N·m

N·m(103.3

(21.7

ft-lbs)

29.4 N·m

(21.7 ft-lbs)

114

ft-lbs)

23.8N·m

N·m(84.1

(17.6

ft-lbs)

23.8 N·m

(17.6 ft-lbs)

100 84.0

10 N·m (62.0 ft-lbs)

(7.4)

(7.4)

1500

350 500350800500

1002 800

1500 25006000

100225006000

29.4 N·m (21.7 ft-lbs)

23.8 N·m (17.6 ft-lbs)

10

(7.4)

350 500 8001002 1500 25006000

Output : kW(Hp)

Output : kW(Hp)

Output : kW(Hp)

Hp)

Output : kW(Hp)

Torque : N.m(ft-lbs)

DBCⅡ series

Output : kW(Hp)

Output : kW(Hp)

81 N·m (59.8 ft-lbs)

81 N·m (59.8 ft-lbs)

72 N·m (53.1 ft-lbs)

72 N·m (53.1 ft-lbs)

1200

1200

LOW

HIGH

10

LOW

HIGH

(885.6)

10 (885.6)

(7.4) 10(839.1

ft-lbs)(839.1 ft-lbs)

1137 N·m

225

900

3000

(7.4) 101137 N·m

225

900

3000

933

N·m

(688.6

ft-lbs)

933

N·m

(688.6

ft-lbs)

1200 1200

(885.6) (885.6)

Spindle

speed

:

r/min

1137 N·m1137

(839.1

ft-lbs)

N·m

(839.1 ft-lbs) 26 kW (34.926

Hp)

kW(30min.)

(34.9 Hp) (30min.)

Hp)

kW(Cont.)

(29.5 Hp) (Cont.)

933 N·m (688.6

ft-lbs)

933 N·m

(688.6 ft-lbs) 22 kW (29.522

1200

(885.6)

3000

1137 N·m (839.1 ft-lbs)

(30min.)

26Hp)

kW (34.9

Hp) (30min.)

3000 (2214.0)

284 N·m (209.6

ft-lbs)(209.6 ft-lbs) 26 kW (34.9

284 N·m

(2214.0)

22 kW (29.5

(Cont.)Hp) (Cont.)

22Hp)

kW (29.5

933 N·m (688.6 ft-lbs)

233 N·m (172.0

ft-lbs)

233 N·m

ft-lbs)

2835

N·m(172.0

(2092.2

ft-lbs)

2835 N·m (2092.2 ft-lbs)

26 kW (34.9

Hp)(34.9

(30min.)

26 kW

Hp) (30min.)

100

100N·m (209.6

2393N·m

N·m

(1766.0

ft-lbs)26

284

ft-lbs)

(209.6

ft-lbs)

kW (34.9 Hp) (30min.)

2393

N·m284

(1766.0

ft-lbs)

22 kW (29.5

Hp)(29.5

(Cont.)

22 kW

Hp) (Cont.)

(73.0)

(73.0)

22 kW (29.5 Hp) (Cont.)

233 N·m (172.0

ft-lbs)

233

(172.0

937N·m

N·m

(691.5ft-lbs)

ft-lbs)

937

ft-lbs)

100

100N·m

284

N·m (691.5

(209.6

ft-lbs)

793 N·m (585.2 ft-lbs)

793N·m

N·m(59.8

(585.2

ft-lbs)

(73.0) (73.0)

81

81ft-lbs)

N·m

(59.8 ft-lbs)

233

N·m

(172.0

ft-lbs) ft-lbs)

72

N·m

(53.1

72ft-lbs)

N·m

248

N·m(53.1

(183.0 ft-lbs)

248 N·m (183.0

ft-lbs)

100

LOW ft-lbs)LOW

HIGH

HIGH

210 N·m

(155.0

(73.0)

10

10

210

N·m

(155.0

ft-lbs)

81

N·m (59.8

ft-lbs)

81 N·m

(59.8 ft-lbs)

100

(7.4)

(7.4)

DBC 110 Ⅱ 100 10(73.0)

225ft-lbs) 225900

10

900 3000

3000

72 N·m (53.1

ft-lbs)

72 N·m

(53.1

(73.0)

LOW

HIGH

LOW

HIGH

10 : 4000

8110N·m (59.8

ft-lbs)

26

22

Spindle speed

r/min

Spindle

motor

:

/

kW

(7.4) 10(7.4)

72 N·m10

(53.1

ft-lbs)(45.0

225ft-lbs) 225 900

900 3000 3000

61 N·m

61 N·m (45.0 ft-lbs)

LOW

HIGH (34.9 / 29.5

53 N·m (39.1

ft-lbs)

10

53 N·m (39.1 ft-lbs)

3000

(7.4) 103000

LOW

HIGH

225 MIDDLE MIDDLE

900

10 LOW

HIGH 3000

(2214.0)

10 (2214.0)

(7.4 20

88

265

1000

4000

(7.4 20

88

265

1000

4000

2835 N·m

(2092.2 ft-lbs)

2835 N·m (2092.2

ft-lbs)

3000 3000

26 kW (34.926

Hp)

kW(30min.)

(34.9 Hp) (30min.)

2393 N·m

(1766.0 ft-lbs)

2393 N·m (1766.0

ft-lbs)

(2214.0) (2214.0)

22 kW (29.522

Hp)

kW(Cont.)

(29.5 Hp) (Cont.)

22 kW (34.9 Hp) (30min.)

22 kW (34.918.5

Hp)kW

(30min.)

995 N·m (734.3 ft-lbs)

(34.9 Hp) (Cont.)

995 N·m (734.3

ft-lbs)

807 N·m

(595.6 ft-lbs)

18.5 kW (34.9 Hp) (Cont.)

807 N·m (595.6 ft-lbs)

689 N·m (508.5 ft-lbs)

689 N·m (508.5

ft-lbs)

558 N·m (411.8 ft-lbs)

558 N·m (411.8 ft-lbs)

300

300 (221.4)

226 N·m (166.8 ft-lbs)

(221.4)

226 N·m (166.8 ft-lbs)

183 N·m (135.1 ft-lbs)

183 N·m (135.1 ft-lbs)

93 N·m

93 N·m (68.6 ft-lbs)

(68.6 ft-lbs)

78 N·m

78 N·m (57.6 ft-lbs)

4000

4000

LOW

HIGH

(57.6

ft-lbs)

10

LOW

37HIGH

kW (34.937

Hp)

kW(30min.)

(34.9 Hp)

(30min.)

(2952.0)

10 (2952.0)

445

30

kW

(34.9

Hp)

(Cont.)

30

kW

(34.9

Hp)

(Cont.)

(7.4) 10

445 33355

117

51333

1562 2500

(7.4) 103028 N·m

(2234.7

ft-lbs)

3028 N·m

(2234.7

kW (44.3

Hp)

kW(30min.)

(44.3

Hp)2500

(30min.)

117

355

513 ft-lbs)

1562

2455 N·m (1811.8

2455 N·m

ft-lbs)

(1811.8

4000 4000

27ft-lbs)

kW (36.227

Hp)

kW(Cont.)

(36.2 Hp) (Cont.)

37 kW:(34.9

(30min.)

37Hp)

kW (34.9

Hp) (30min.)

Spindle speed

r/min

(2952.0) (2952.0)

30 kW (34.9

(Cont.)Hp) (Cont.)

30Hp)

kW (34.9

3028 N·m3028

(2234.7

N·mft-lbs)

(2234.733

ft-lbs)

kW

Hp)

(30min.)

3322

kW

(44.3

Hp)

(30min.)

22

kW(44.3

(34.9

Hp)

(30min.)

kW

(34.9

Hp)

(30min.)

995

N·m

(734.3

ft-lbs)

995 N·m

(734.3

2455

N·m

(1811.8

ft-lbs)

4000

2455

(1811.8ft-lbs)

ft-lbs)

27

kWkW

(36.2

Hp)

(Cont.)

kW

(36.2

Hp)

(Cont.)

18.5

(34.9

Hp)

18.5

kW(Cont.)

(34.9

Hp) (Cont.)

3727

kW

(34.9

Hp)

(30min.)

807 N·m (595.6

807 N·m

ft-lbs)(595.6 ft-lbs)

(2952.0)

30

kW

(34.9

Hp)

(Cont.)

4000

4000 (2952.0)

3028

N·m

(2234.7

ft-lbs)

45

kW

(60.3

Hp) (30min.)

33

(44.3

689 N·m (508.5

689 N·m

ft-lbs)(508.5 ft-lbs)

22kW

kW45

(34.9

Hp)

(30min.)

22Hp)

kW(30min.)

(34.9

Hp) (30min.)

kW

(60.3

(30min.)

(2952.0)

2455

N·m

(1811.8

ft-lbs)

995

N·m

(734.3

ft-lbs)

995

(734.3

37Hp)

kW

(49.6

(Cont.)

2718.5

kW (36.2

Hp)

(Cont.)

558

N·m

(411.8

ft-lbs)

558N·m

N·m

(411.8ft-lbs)

ft-lbs)

kW

(34.9

Hp)

(Cont.)

18.5

kW

(34.9

Hp)Hp)

(Cont.)

37 kW

(49.6

Hp)

(Cont.)

3853

(2843.5

807

N·m

(595.6

ft-lbs)

807N·m

N·m

(595.6ft-lbs)

3853

N·m

(2843.5

ft-lbs)

30 kW (40.2 Hp) (30min.)

3168

(233.0

300

300

30

Hp)

(30min.)

689

N·m

(508.5

ft-lbs)

689N·m

N·m

(508.5ft-lbs)

ft-lbs)

22kW

kW(40.2

(34.9

Hp)

(30min.)

N·m

(233.0

ft-lbs)

(221.4) 3168

(221.4)

26

kW

(34.9

Hp)

(Cont.)

995

N·m

(734.3

ft-lbs)

226

ft-lbs)

226N·m

N·m

(166.8ft-lbs)

ft-lbs)

558N·m

N·m(166.8

(411.8

ft-lbs)

558

(411.8

2618.5

kW kW

(34.9

Hp)Hp)

(Cont.)

(34.9

(Cont.)

807

N·m

(595.6

ft-lbs)

N·mN·m

(1075.3

183N·m

N·m1457

(135.1

ft-lbs)

183

(135.1ft-lbs)

ft-lbs)

1457

(1075.3

ft-lbs)

93 N·m 93 N·m

300

300N·m

1198

N·mft-lbs)

(884.1 ft-lbs)

689

(508.5

N·m (884.1

ft-lbs)

(68.6 ft-lbs)(68.6 ft-lbs)

(221.4) 1198

(221.4)

1000

226

ft-lbs)

226 N·m

(166.8 ft-lbs)

558 N·m (166.8

(411.8

1000 (738.0)

72 N·m

72 N·m (53.1 ft-lbs)78 N·m 78 N·m

183 N·m (135.1

ft-lbs)

(738.0)

183 N·m

(135.1 ft-lbs)

93 N·m

300

N·mft-lbs)

(53.1

ft-lbs)

(57.6

ft-lbs)93

(57.6

LOW

HIGH

LOW

HIGH

(221.4)

10

(68.6 ft-lbs)

22610

N·m (166.8 ft-lbs)

62 N·m (68.6 ft-lbs)

445

445 62 N·m (45.8 ft-lbs)

(7.4) Ⅱ

(7.4) 117

DBC 110

10183

355(317.3

513ft-lbs)

2500

10 430ft-lbs)

117

355 513

2500

1562

1562

N·m (135.1

78

N·m

78

N·m

N·m

(45.8 ft-lbs)

93

N·m

430 N·m (317.3

ft-lbs)

(57.6

ft-lbs)

(57.6 ft-lbs)

353

(260.5

LOWN·m

LOW ft-lbs) HIGH

HIGH

353 N·m (260.5

ft-lbs)

(68.6 ft-lbs)

10 speed

10

161

N·m

(118.8

ft-lbs)

4000

45

37

Spindle

:

r/min

Spindle

motor

:

/

kW

445

445

(7.4) 10(7.4)

161 N·m

ft-lbs)

117

355

1562 2500

10 (118.8

117

355 513

2500

1562

78 N·m

133 N·m

(98.2513

ft-lbs)

.3 / 49.6 Hp)

(60

133 N·m (98.2

(57.6

ft-lbs)

LOWft-lbs)

HIGH

10

445

LOW

MIDDLE

HIGH

4000

(7.4) 104000 117

355 MIDDLE

513 45

2500

1562

HIGH

45

kW

(60.3

Hp) (30min.)

kW (60.3

Hp)

(30min.)

(2952.0) (2952.0) LOW

10

111.5 295 37 kW

667(49.6

8401000

26674000

37

kW(Cont.)

(49.6

Hp)

10

111.5

295

667

8401000

2667

4000Hp) (Cont.)

3853 N·m

(2843.5 ft-lbs)

3853 N·m (2843.5

ft-lbs)

4000 3168

4000

30

kW

(40.2

Hp) (30min.)

30 kW45

(40.2

Hp)

(30min.)

3168 N·m

N·m (233.0

ft-lbs)(233.0 ft-lbs)

kW

(60.3

Hp)

(30min.)

45

kW (60.3

Hp) (30min.)

(2952.0) (2952.0)

26

kW

(34.9

Hp)

(Cont.)

26 kW (34.9

Hp)

(Cont.)

37 kW (49.6

(Cont.)Hp) (Cont.)

37Hp)

kW (49.6

3853 N·m3853

(2843.5

ft-lbs)

(2843.5

1457N·m

N·m

(1075.3ft-lbs)

ft-lbs)

ft-lbs)

4000 1457 N·m (1075.3

30 kW45

(40.2

(30min.)

30Hp)

kW (40.2

(30min.)

3168N·m

N·m3168

(233.0

ft-lbs)

(233.0

(884.1

1198N·m

N·m

ft-lbs)

(884.1ft-lbs)

ft-lbs)

kW

(60.3

Hp)Hp)

(30min.)

(2952.0) 1198

26

kW

(34.9

Hp)

(Cont.)

kW

(34.9

Hp) (Cont.)

1000

1000

37 26

kW

(49.6

Hp)

72 N·m

72(Cont.)

N·m

N·m

(2843.5

(738.0)

(738.0) 3853

1457

N·m1457

(1075.3

ft-lbs)

N·mft-lbs)

(1075.3 ft-lbs)

(53.1

(53.1 ft-lbs)

30 kW (40.2

Hp)ft-lbs)

(30min.)

3168

N·m1198

(233.0

ft-lbs)

1198

(884.1

N·m

(884.1 ft-lbs)

4000

4000

26 kW (34.9

(Cont.)

62(60.3

N·m Hp) (30min.)

62Hp)

N·m45

kW

1000 (2952.0)

1000

45 kW

(30min.)

(2952.0)

72(60.3

N·m

72

N·mft-lbs)

(45.8

(45.8

ft-lbs)

37Hp)

kW

(49.6

Hp) (Cont.)

(738.0) 1457

(738.0)

N·mN·m

(1075.3

ft-lbs)

430

N·m

(317.3

ft-lbs)

430

(317.3

ft-lbs)

37

kW

(49.6

Hp)

(Cont.)

(53.1

ft-lbs)

3703ft-lbs)

N·m (2732.8 ft-lbs) (53.1 ft-lbs)

1198

N·mN·m

(884.1

3703

(2732.8

353 N·m

353

N·m

(260.5

ft-lbs)(260.5 ft-lbs) 30 kW (40.2 Hp) (30min.)

3044

N·m

(2246.5

ft-lbs)

1000

62Hp)

N·m(30min.)

62 N·m

kW (40.2

161 N·m

ft-lbs)

161N·m

N·m(2246.5

(118.8

ft-lbs)(118.830

3044

72

N·m

26 kWft-lbs)

(34.9

Hp)ft-lbs)

( Cont.)

(738.0)

(45.8

(45.8

26 kW (34.9

Hp)ft-lbs)

( Cont.)

(53.1

430N·m

N·m(98.2

(317.3

ft-lbs)

430

(317.3

133

133N·m

ft-lbs)

N·m

(98.2 ft-lbs)

1980

(1461.2

ft-lbs)

353N·m

N·m

(260.5

ft-lbs)

353N·m

N·m

(260.5 ft-lbs)

1980

(1461.2

ft-lbs)

1628

(1201.5

ft-lbs) 62 N·m

161N·m

N·m

(118.8

ft-lbs)

161N·m

N·m

(118.8

ft-lbs)

1628

(1201.5

ft-lbs)

LOW

MIDDLE

HIGH

LOW

MIDDLE

HIGH

(45.8 ft-lbs)

430

ft-lbs)

133 N·m (317.3

(98.2

ft-lbs)

133 N·m

(98.2 ft-lbs)

10 353 N·m

111.5

10 (260.5295

111.5 667

2958401000

667 8401000

26674000 26674000

ft-lbs)

161 LOW

N·m (118.8

ft-lbs)

MIDDLE

HIGH

LOW Spindle MIDDLE

HIGH

speed

:

r/min

495

N·m

(365.3

ft-lbs)

500

(98.2ft-lbs)

ft-lbs)

495133

N·mN·m

(365.3

500 (369.0)

407 N·m

(300.4

111.5

295

667

2667400026674000

111.5 ft-lbs)

295 8401000

667 8401000

(300.4

ft-lbs)

(369.0) 10407 N·m10

LOW

MIDDLE

HIGH

185 N·m (136.5 ft-lbs)

163 N·m

ft-lbs)

DBC 130 /10185

L N·m (136.5

152 N·m

(112.2 ft-lbs)

111.5

295

667 8401000

26674000 163 N·m (120.3 ft-lbs)

152 N·m (112.2

ft-lbs)

(120.3 ft-lbs)

135 N·m

Spindle

r/min MIDDLE

Spindle motor

: 45

135

N·m / 37 kW

4000 speed

4000 : 2500LOW

HIGH (99.6 ft-lbs)(99.6 ft-lbs)

10 LOW

MIDDLE 45 kW (60.3

HIGH

45

Hp)

kW(30min.)

(60.3 Hp)

(30min.)

(2952.0)

10 (2952.0)

60

3

.

(

(7.4) 10

116

217 37 kW

579 724Hp)

868

2316 2500 / 49.6 Hp)

kW(Cont.)

(49.6

(7.4) 10

217

724 868(49.637

2316

2500Hp) (Cont.)

3703 N·m116

(2732.8

3703 N·m

ft-lbs)

(2732.8579

ft-lbs)

4000 4000

30

kW45

(40.2

30

Hp)

kW

(30min.)

(40.2

Hp)

(30min.)

3044

N·m

(2246.5

3044

N·m

ft-lbs)

(2246.5

ft-lbs)

kW (60.3

(30min.)

45Hp)

kW (60.3

Hp) (30min.)

(2952.0) (2952.0)

26 kW37

(34.9

Hp)

kW

( Cont.)

(34.9

Hp) (Hp)

Cont.)

kW26

(49.6

Hp)

(Cont.)

37

kW (49.6

(Cont.)

3703N·m

N·m3703

(2732.8

ft-lbs)

(2732.8

1980

(1461.2

1980N·m

N·m

ft-lbs)

(1461.2ft-lbs)

ft-lbs)

4000

30

kW

(40.2

Hp)

(30min.)

30

kW

(40.2

Hp)

(30min.)

1628

N·m

(1201.5

1628

N·m

ft-lbs)

(1201.5

ft-lbs)

3044

N·m

(2246.5

ft-lbs)

3044

N·m

(2246.5

ft-lbs)

45 kW (60.3 Hp) (30min.)

(2952.0)

26 kW37

(34.9

Hp)

( Cont.)

26(49.6

kW (34.9

Hp) ( Cont.)

kW

Hp) (Cont.)

3703

(2732.8

ft-lbs)

1980 N·m

N·m1980

(1461.2

N·mft-lbs)

(1461.2 ft-lbs)

30 kW (40.2 Hp) (30min.)

3044

(2246.5

1628 N·m1628

(1201.5

N·mft-lbs)

(1201.5 ft-lbs)

26 kW (34.9 Hp) ( Cont.)

495

N·m (365.3

495 N·m

ft-lbs)(365.3 ft-lbs)

500

500

1980

N·m

(1461.2

ft-lbs)

407

N·m

(300.4

407 N·m

ft-lbs)

(300.4 ft-lbs)

(369.0) (369.0)

1628 N·m (1201.5 ft-lbs)

185

185N·m

N·m

ft-lbs)

(136.5ft-lbs)

ft-lbs)

163 N·m 163 N·m

495

N·m(136.5

(365.3

ft-lbs)

495

(365.3

500

500N·m

152

152N·m

N·m

ft-lbs)

(112.2ft-lbs)

ft-lbs)

(120.3 ft-lbs)(120.3 ft-lbs)

407N·m

N·m(112.2

(300.4

ft-lbs)

407

(300.4

(369.0) (369.0)

135 N·m 135 N·m

185 N·mLOW

(136.5

185 N·m

(136.5

ft-lbs)

495

(365.3

ft-lbs)

500

163 N·m

N·m

(99.6

ft-lbs)

ft-lbs)163

LOWMIDDLE MIDDLE HIGH

HIGH(99.6

15210N·m

N·m (300.4

(112.2

ft-lbs)

10

152 N·m

(112.2 ft-lbs)

407

ft-lbs)

(369.0)

(120.3 ft-lbs)

(120.3 ft-lbs)

(7.4) 10 (7.4) 116

10

217

116 579

217724 868

579 7242316

868 2500 2316 2500

135 N·m 135 N·m

185 N·mLOW

(136.5 ft-lbs)

163 N·m

ft-lbs)

(99.6 ft-lbs)

LOW MIDDLE MIDDLE HIGH

HIGH (99.6

152

10

10N·m (112.2 ft-lbs)

(120.3 ft-lbs)

(7.4) 10(7.4) 10116

217

579 724 868

2316 2500

116

217

579 724 868

2316

1352500

N·m

(99.6

ft-lbs)

LOW

MIDDLE

HIGH

10

Spindle speed : r/min

(7.4) 10

116

217

579 724 868

2316 2500

Torque : N.m(ft-lbs)

100

(73.0)

Torque : N.m(ft-lbs)

26 kW (34.9 Hp) (30min.)

26 kW (34.9 Hp) (30min.)

22 kW (29.5 Hp) (Cont.)

22 kW (29.5 Hp) (Cont.)

284 N·m (209.6 ft-lbs)

284 N·m (209.6 ft-lbs)

233 N·m (172.0 ft-lbs)

233 N·m (172.0 ft-lbs)

100

(73.0)

Spindle motor : 37 / 30 kW

(49.6 / 40.2 Hp)

4000

4000 (2952.0)

37 kW (34.9 Hp) (30min.)

37 kW (34.9

30Hp)

kW(30min.)

(34.9 Hp) (Cont.)

(2952.0)

kWkW

(34.9

Hp)Hp)

(Cont.)

3028 N·m (2234.7 ft-lbs) 3033

(44.3

(30min.)

3028 N·m 2455

(2234.7

ft-lbs)

33

kW

(44.3

Hp)

(30min.)

N·m (1811.8 ft-lbs) 27 kW (36.2 Hp) (Cont.)

2455 N·m (1811.8 ft-lbs) 27 kW (36.2

Hp) (Cont.)

Output : kW(Hp)

Torque : N.m(ft-lbs)

1200

1200 (885.6)

(885.6)

1137 N·m (839.1 ft-lbs)

1137 N·m (839.1 ft-lbs)

933 N·m (688.6 ft-lbs)

933 N·m (688.6 ft-lbs)

Spindle speed : 2500 r/min

Torque : N.m(ft-lbs)

Spindle speed : 3000 r/min

Torque : N.m(ft-lbs)

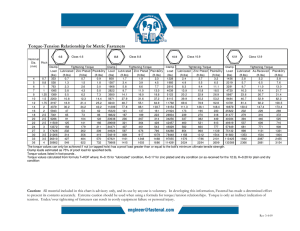

The powerful spindle

motor further improves

productivity.

DBC S series

Torque : N.m(ft-lbs)

Spindle Power –

Torque Diagram

Spindle speed : r/min

06 / 07

Product Overview

Basic Information

Diverse Line-up

High-Rigidity &

High-Precision

User Convenience

Detailed

Information

Options

Capacity Diagram

Specifications

Customer Support

Service

Enhanced Performance

through High Rigid

structure

Together with further

improved high-rigidity

structure and stabilized

travel performance

achieved through structure

analysis, many options are

upgraded to enhance user

convenience

Optimal Solutions

Highly-Rigid

Structure

High Accuracy

For heavier workpieces and

higher processing quality, the

design has been improved

with a cast structure offering

excellent stiffness. The machine

performance has been further

upgraded by structural analysis of

the inner rib structure.

Upgraded with stable travel

performance in heavy-duty

machining by reducing servo load

and increasing axial thrust.

High Productivity and

User Convenience

Diversified options are offered to

improve productivity, operating

environment and operator's

convenience.

Highly-Rigid Structure

For heavier workpieces

and higher processing

quality, the design has

been improved with a

cast structure offering

excellent stiffness. The

machine performance has

been further upgraded by

structural analysis of the

inner rib structure.

Highly Rigid Design of Major Units

Rigidity is enhanced by optimal design of the machine structure. The highest accuracy can be achieved by

minimizing deformation caused by heavy load.

Gravity

center

Low gravity center design to minimize

vibration and column moving

structure suitable for heavy load

Deformation caused by heavy workpiece

minimized with optimal design of table

and table base

Deformation and vibration minimized

by M-type ribs inside the bed.

Stable Machine Structure

A highly-rigid, stable machine structure has been realized by optimizing the design of the column and the

bed. Excellent wear resistance and accuracy for machining quality have been achieved by precision grinding

after heat treatment.

A leveling block is provided to strengthen

anchoring force to the foundation, as well

as enabling fast and easy installation.

* Except DBC110S / 130S / 130SL (leveling bolt type)

Narrow Guide System

Designed with narrow guide system to minimize

axis torque and ensure smooth motion.

4-row Angular Ball Bearings & Ball Screw

Both ends of the shafts are supported by 4-row

angular contact bearings. Low-noise, highly-precise

ball screws are employed for axis travel.

Short distance

* Excluding the X axes of DBC 110S / 110 Ⅱ / 130S / 130SL

* Except DBC 110S / 130S (3-row angular contact bearings)

08 / 09

Product Overview

High Accuracy

Basic Information

Diverse Line-up

High-Rigidity &

High-Precision

User Convenience

Detailed

Rotary Table * Patented

A high-precision, separate type encoder is installed at the table center as a standard to

realize precise rotation of the B-axis.

Upgraded with stable

travel performance in

heavy-duty machining by

reducing servo load and

increasing axial thrust.

Information

Options

Capacity Diagram

Specifications

Customer Support

Service

Locating pin

for positioning

by 90° steps

Gear reducer for axis shafts ( X / Z )

• Servo load is reduced to secure stable feeding characteristics for heavy workpieces (X-axis).

• Axial thrust is increased to improve cutting capacity ( Z-axis ).

Bracket

Gear box

Motor

Standard

Axis

Model

X-axis

Z-axis

DBC

series

DBC 110S

Option

DBC 130S DBC 130SL DBC 110 Ⅱ DBC 130 Ⅱ DBC 130L Ⅱ DBC 250 Ⅱ DBC 250L Ⅱ

ATC Auto Tool Changer

Servo-driven Auto Tool Changer

(ATC)

Auto Tool Changer (ATC)

The adoption of a servomotor for tool magazine

and carriage drive

greatly reduces hydraulic

system load of the entire

machine. Machine

has been improved by

simplifying the structure

to minimize the causes of

failure.

Servo tool magazine

Servo carriage

D

D

Ø4

00

mm

mm

Ø250

Applicable Tool Specification

Specification

Max.

tool dia.

Facing tools: D = ø250 mm

(9.8 inch)

Specification

Max.

tool

length

D

D

Max.

tool

weight

DD

Normal tools: D = ø130 mm

(5.1 inch)

Shape

(Neighboring pots must be empty)

Boring tools: D = ø400 mm

(15.7 inch) D = ø600 mm

(23.6 inch)

ØØ4

4000

0m

mm

m

Tool

storage

capacity

m

mm

Ø25

2500 m

Ø

(Neighboring pots must be empty)

Shape

L = 600 mm (23.6 inch)

L

W = 25 kg (55.1 lb)

W = 30 kg (66.1 lb)

Max. a 무게중심

W

40

{60 / 90} tools

Max. allowable moment: 34 N·m (25.1 ft-lbs)

* Please contact us if you wish to extend the boring tool diameter (D=ø600).

LL

W

W

APC Automatic Pallet Changer

(APC)

While the machine tool

is cutting a workpiece,

the workpiece to be

processed next is set up

on the standby pallet

which can replace

the current pallet

automatically at the

end of cutting to raise

productivity.

무게중심

Max. aa 무게중심

Max.

DBC 130 Ⅱ with APC

3D modeling layout

Detailed specification of APC

Details

No. of Pallets

APC type

Pallet size (W x L) & work load

Unit

Specification

ea

2

-

Parallel shuttle (in Z-axis direction)

mm (inch)

& ton

• 1600 x 1800 & 10 (23.6 x 63.0 & 10)

• 1800 x 2000 & 8 (70.9 x 78.7 & 8)

Note 1) The above specification is for reference to understand the APC option of DBC 130 Ⅱ.

Note 2) Please contact us for further details of the specifications. The specifications are subject to change without prior notice for

performance improvement

10 / 11

Product Overview

Chip Disposal System

Basic Information

Diverse Line-up

High-Rigidity &

High-Precision

User Convenience

Detailed

Information

Options

Capacity Diagram

Specifications

Customer Support

Easy Chip Removal Structure

The DBC series confines chips and coolant to the chip pan to make the chip disposal using

the chip conveyer easier.

Proper chip disposal

is very important

for productivity and

environment protection.

The DBC series provides

various chip disposal

systems designed to

improve productivity

and the working

environment.

Service

Coolant gun

Chip pan

Slope-type chip pan is used for smooth coolant drain

and chip disposal

Built-in, hinge-type belt chip conveyor

DBC

series

Lift-up chip conveyor

Coolant Splash Guard

Semi-splash guard

DBC 110S / 130S

DBC 130SL

DBC 110 Ⅱ

Auto door semi-splash guard (for APC option)

DBC 130 / L

DBC 250 / L Ⅱ

DBC 130 / L Ⅱ

DBC 250 / L Ⅱ

Special Options

Following special options are available on order:

3.

1.

2.

Long type angle head

(manual indexing)

(L=660mm (26.0 inch))

Universal head

(manual indexing)

4.

5.

6.

Please contact us for

further details of

specification.

• DBC 110S / 110 II : L =

200mm (7.9 inch)

• DBC 130S / SL : L = 310mm (12.2 inch)

• DBC 130 / L : L= 310mm (12.2 inch)

Angle head

(manual indexing)

(L=365mm (14.4 inch))

Face plate

(manual indexing)

(Ø650mm (25.6 inch))

Indexable angle head

(90° auto indexing)

Spindle support *

7.

8.

- Manual installation

(For more details,

please contact us.)

• Please contact us for customized specifications.

• Please contact us for further information.

Facing head (Cogsdill)

Angle plate (4 types)

A

Unit : mm (inch)

A

450 (17.7)

500 (19.7)

750 (29.5)

B

600 (23.6)

1000 (39.4) 1250 (49.2) 2000 (78.7)

C

400 (15.7)

550 (21.7)

750 (29.5)

750 (29.5)

1000 (39.4)

C

B

* Please consult us for employing ATC with spindle support attached.

(Note) The head attachments (1 ~ 7) are not applicable for DBC 250 (L) Ⅱ model.

12 / 13

Product Overview

Easy and Convenient

Operation

Operating system for enhanced user convenience

Basic Information

Diverse Line-up

High-Rigidity &

High-Precision

User Convenience

Detailed

Information

Options

Capacity Diagram

Specifications

Customer Support

DOOSAN's new operation panel

Service

With differentiated hotkey, the

DBC Series enables fast access to

frequently used functions

Conventional type

Improved user

convenience with

ergonomic design

Improved type

The tilting operation

panel ensures enhanced

operating convenience.

Productivity improved by adoption of operator panel design optimized for the operation of

large machines

• Mono lever jog switches are provided at the bottom of the main operation panel for easy

traverse on the long axis of large machines (standard).

• Pulse handle for the operator’s convenience and portable MPG for easy workpiece setting

are provided as standard features.

Portable MPG

ATC OP panel

3 Portable MPG

MPG with LCD display

Mono lever jog switch

DBC

series

Easy Operation Package

Tool Load Monitoring

Periodic Inspection Function

Automatic Backlash Compensation

• Automatically detects tool wear and tear in the

case of abnormal workloads using M-code.

• Workpiece-specific machining data can be saved.

This function updates the operator with

maintenance-related information such as oil

refill timing.

After setting up the workpiece, feed backlash is

automatically detected and compensated by the

G-code instruction or though the function screen.

Tool Life Management

Easy Pattern Cycle

Tools are protected from abnormal load on the

servo shaft, by skipping the tool or generating

a freehold alarm.

Major processing pattern cycles and programs can be created by simply entering major factors. This function

is built in the CNC, thus drastically reducing programming time and enabling easy use on site. A total of 22

patterns including basic 5 patterns are provided.

Drilling pattern

End-mill pattern

Variable Work Load Control Ⓡ

When the operator enters the M-code for the weight of the workpiece, the system automatically determines the table feed pattern to perform cutting.

M-Code

Work Load Control

M380

5tons or less

M381

10tons or less

M382

15tons or less

M383

20tons or less

DBC 110S

DBC 130S / SL

DBC 110 II

DBC 130 II

DBC 130L II

Standard

Option

DBC 250 / L II

Selection Function

Easy Set-up Guidance Touch Sensor (including OMP60)

Support Function for Maintenance - Easy Operation Guidance

This function enables the simple setting up of workpiece coordinates, using an

automatic or semi-automatic measuring probe. When using an auto-measuring

probe, place the probe close to the set up surface, select the setup configuration,

and press the cycle start button. The system touches the point and sets the

workpiece coordinates automatically.

Machine faults including problems with the ATC magazine are detected and

troubleshooting suggestions are proposed for corrective action. For guidance

on easy operation, display windows - including function selection, thermal error

setting, program progress display, and operation report display - are provided.

14 / 15

Product Overview

Standard / Optional

Specifications

Basic Information

Diverse Line-up

High-Rigidity &

High-Precision

User Convenience

Various options are

available to satisfy

the customers’

requirements.

DBC S series

Standard

NO. Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

Detailed

Information

Options

Capacity Diagram

Specifications

Customer Support

Service

36

* Note 1) Please contact us for further

details

*

DBC

series

Note 2) This specification applies to

APC option.

* Note 3) 30 min/continuous For DBC

250(L)

SPINDLE

MOTOR POWER

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

ATC

WORKPIECE SETTING DEVICE

TABLE SIZE

Features

26 / 22 KW (34.9 /29.5 Hp) (30WORKPIECE

SETTING DEVICE)

30 / 22 KW (40.2 /29.5 Hp) (15WORKPIECE

SETTING DEVICE) (AMP UP)

45 / 37 KW (60.3 /49.6 Hp) (30WORKPIECE

SETTING DEVICE)

37 / 30 KW(49.6 /40.2 Hp) (30WORKPIECE

SETTING DEVICE)

40 TOOLS

60 / 90 TOOLS

CENTER BUSH

EDGE LOCATOR

1400 X 1600 mm(55.1X63.0 inch)

1400 X 1800 mm(55.1X70.9 inch)

1600 X 1800 mm(63.0X70.9 inch)

1800 X 2000 mm(70.9X78.7 inch)

2000 X 2200 mm(78.7X86.6 inch)

1800 X 2000 mm(70.9X78.7 inch)_20 ton

2000 X 2200 mm(78.7X86.6 inch)_19 ton

1600 X 3000 mm(63.0X118.1 inch)_20 ton

APC (1)

LINEAR SCALE (X / Y / Z)

RAISED COLUMN (1)

ABSOLUTE

SPLASH GUARD

SPLASH GUARD W/O TOP

AUTO DOOR SEMI GUARD (1) (2)

COOLANT TANK

LIFT UP CHIP CONVEYOR

Flood Coolant

TSC

OIL SKIMMER

COOLANT GUN

AIR GUN

AIR BLOWER

6-AXIS OPTION (1)

AUTO WORKPIECE MEASURING

DEVICE

MASTER TOOL FOR AUTO TOOL

MEASUREMENT

AUTO TOOL MEASURING DEVICE

Optional X Not applicable

DBC

110S

DBC

130S

DBC

130SL

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

1.5 KW (2.0 Hp)_2.0 MPA_BAG FILTER

1.5 KW(2.0 Hp)_2.0 MPA_CYCLON FILTER

5.5 KW(7.4 Hp)_7.0 MPA_DUAL BAG FILTER

BELT TYPE

DISK TYPE

1 AXIS_WIRE AND PIPING_HYD

OMP60_RENISHAW

RMP60_RENISHAW

CALIBRATION BLOCK

TS27R_RENISHAW

SIZE 450 X 600 X 400

SIZE 500 X 1000 X 550

ANGULAR FIXTURE

SIZE 750 X 1250 X 750

SIZE 1000 X 2000 X 1000

90˚ ANGLE HEAD_L365

90˚ ANGLE HEAD_L660

FACE PLATE_Ø650

INDEXABLE ANGLE HEAD_90° INDEX

ATTACHMENT

MANUAL UNIVERSAL HEAD_1000

SPINDLE SUPPORT_310 MM

SPINDLE SUPPORT_200 MM

COGSDILL READY

ATTACHMENT SPEED LIMIT CONTROL

ATTACHMENT SPEED LIMIT CONTROL

THERMAL DISPLACEMENT OF SPINDLE

TEST BAR

BT50

Y-AXIS ADDITIONAL BRAKE SYSTEM (1)

10.4 INCH(COLOR)

NC SCREEN SIZE

15.0 INCH(COLOR)

GRAVITY SHAFT FALL PREVENTION SYSTEM (AT POWER FAILURE)

TRANSFORMER

POWER PANEL AIR CONDITIONER

POWER PANEL LIGHT

POWER PANEL LINE FILTER

AUTO NC POWER OFF

AUTO NC POWER ON

MACHINE WARMING UP

DOOSAN TOOL MANAGEMENT PACKAGE

DOOSAN TOOL LOAD MONITORING

1 MPG_PORTABLE_W/ENABLE TYPE

MPG

3 MPG_PORTABLE_W/ENABLE TYPE

ALARM GUIDANCE

EASY SETUP GUIDANCE

DSQ1 (AICC I_40 BLOCKS)

DSQ1 (AICC II_200 BLOCKS)

DSQ1.2.3.4

DSQ2 (DSQ1 & DATA SERVER 1GB)

DSQ3 (DSQ2 & 600 BLOCKS)

DSQ4 (DSQ3 & 1000 BLOCKS)

COUNTER FUNCTION

WORK/TOTAL/DAILY

X

X

DBC II series

Standard

NO. Description

Features

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

26 / 22 KW(34.9 /29.5 Hp) (30min/continuous)

30 / 22 KW(34.9 /29.5 Hp) (15min/continuous) (AMP UP)

45 / 37 KW(34.9 /29.5 Hp) (30min/continuous)

37 / 30 KW(34.9 /29.5 Hp) (30min/continuous)

40 TOOLS

60 / 90 TOOLS

CENTER BUSH

EDGE LOCATOR

1400 X 1600 mm (55.1X63.0 inch)

1400 X 1800 mm (55.1X70.9 inch)

1600 X 1800 mm (63.0X70.9 inch)

1800 X 2000 mm (70.9X78.7 inch)

2000 X 2200 mm (78.7X86.6 inch)

1800 X 2000 mm (70.9X78.7 inch)_20 ton

2000 X 2200 mm (78.7X86.6 inch)_19 ton

1600 X 3000 mm (63.0X118.1 inch)_20 ton

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

SPINDLE MOTOR POWER

ATC

WORKPIECE SETTING DEVICE

TABLE SIZE

APC (1)

LINEAR SCALE (X, Y, Z-AXIS)

RAISED COLUMN (1)

ABSOLUTE

SPLASH GUARD

SPLASH GUARD W/O TOP

AUTO DOOR SEMI GUARD (1) (2)

DBC

110 Ⅱ

DBC

130 Ⅱ

DBC

130L Ⅱ

Optional X Not applicable

DBC

250 Ⅱ

DBC

250L Ⅱ

X

X

(3)

X

(3)

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

COOLANT TANK

LIFT-UP CHIP CONVEYOR

Flood Coolant

1.5 KW_2.0 MPA_BAG FILTER

1.5 KW_2.0 MPA_CYCLON FILTER

5.5 KW_7.0 MPA_DUAL BAG FILTER

BELT TYPE

DISK TYPE

TSC

OIL SKIMMER

COOLANT GUN

AIR GUN

AIR BLOWER

6-AXIS OPTION

(1)

AUTO WORK MEASURING DEVICE

MASTER TOOL FOR AUTO TOOL

MEASUREMENT

AUTO TOOL MEASURING DEVICE

1 AXIS_WIRE AND PIPING_HYD

OMP60_RENISHAW

RMP60_RENISHAW

CALIBRATION BLOCK

TS27R_RENISHAW

SIZE 450 X 600 X 400

SIZE 500 X 1000 X 550

ANGULAR FIXTURE

SIZE 750 X 1250 X 750

SIZE 1000 X 2000 X 1000

90˚ ANGLE HEAD_L365

90˚ ANGLE HEAD_L660

FACE PLATE_Ø650

INDEXABLE ANGLE HEAD_90° INDEX

ATTACHMENT

MANUAL UNIVERSAL HEAD_1000

SPINDLE SUPPORT_310 MM

SPINDLE SUPPORT_200 MM

COGSDILL READY

ATTACHMENT SPEED LIMIT CONTROL

SAFETY FENCE AND INTERLOCK SWITCH

CORRECTION OF SPINDLE'S THERMAL DISPLACEMENT

TEST BAR

BT50

Y-AXIS ADDITIONAL BRAKE SYSTEM (1)

10.4 INCH(COLOR)

NC SCREEN SIZE

15.0 INCH(COLOR)

GRAVITY SHAFT FALL PREVENTION SYSTEM (AT POWER FAILURE)

TRANSFORMER

POWER PANEL AIR CONDITIONERPOWER PANEL AIR CONDITIONER

POWER PANEL LIGHT

POWER PANEL LINE FILTER

AUTO NC POWER OFF

AUTO NC POWER ON

MACHINE WARMING UP

DOOSAN TOOL MANAGEMENT PACKAGE

DOOSAN TOOL LOAD MONITORING

1 MPG_PORTABLE_W/ENABLE TYPE

MPG

3 MPG_PORTABLE_W/ENABLE TYPE

ALARM GUIDANCE

EASY SETUP GUIDANCE

DSQ1 (AICC I_40 BLOCKS)

DSQ1 (AICC II_200 BLOCKS)

DSQ1.2.3.4

DSQ2 (DSQ1 & DATA SERVER 1GB)

DSQ3 (DSQ2 & 600 BLOCKS)

DSQ4 (DSQ3 & 1000 BLOCKS)

COUNTER FUNCTION

WORK/TOTAL/DAILY

X

X

X

X

X

X

16 / 17

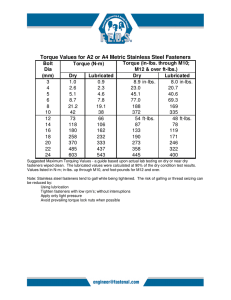

Product Overview

External Dimensions

Basic Information

DBC 110S

Unit: mm(inch)

Diverse Line-up

High-Rigidity &

High-Precision

User Convenience

Top View

Front View

Detailed

Information

ATC 40 TOOLS

Options

Capacity Diagram

384

(15.1)

Specifications

Customer Support

4230(166.5)

5902(232.4)

Service

1000(39.4) 1000(39.4)

X-axis Travel : 0~2000(0~78.7)

5518(217.2)

Table

Side View

1400 x 1600 (55.1 x 63.0)

50(2.0)

1700(66.9)

DBC

series

0

00

Ø2

800(31.5)

800(31.5)

1600(63.0)

165

(6,.5)

24(0.9)

42(1.7)

19

(0.7)

TABLE TOP

24H8(0.9H0.3)

50(2.0)

TABLE CENTER

700(27.6)

700(27.6)

1400(55.1)

60 8 X 160 = 1280 (8 X 6.3 = 50.4)

(2.4)

Ø110

1150(45.3)Y-axis Travel : 0~1500(0~59.1)

W-axis Travel : 0~500Z-axis Travel : 0~1200

((0~19.7)

(0~47.2)

External Dimensions

DBC 130S

Unit: mm(inch)

Top View

Front View

4230(166.5)

5902(232.4)

384

(15.1)

ATC 40 TOOLS

1000(39.4) 1000(39.4)

X-axis Travel : 0~2000(0~78.7)

5518(217.2)

Table

Side View

1400 x 1600 (55.1 x 63.0)

0

00

Ø2

800(31.5)

800(31.5)

1600(63.0)

24(0.9)

42(1.7)

19

(0.7)

TABLE TOP

24H8

50(2.0)

TABLE CENTER

700(27.6)

700(27.6)

1400(55.1)

60 8 X 160 = 1280(8 X 6.3 = 50.4)

(2.4)

Ø130

1150(45.3)Y-axis Travel : 0~1500(0~59.1)

1800(70.9)

W-axis Travel : 0~600

Z-axis Travel : 0~1200(0~47.2)

(0~23.6) 50(2.0)

165

(6.5)

18 / 19

Product Overview

External Dimensions

Basic Information

DBC 130 SL

Unit: mm(inch)

Diverse Line-up

High-Rigidity &

High-Precision

User Convenience

Top View

Front View

Detailed

Information

Options

Capacity Diagram

Service

4295(169.1)

4785(188.4)

6796(267.6)

Customer Support

490

(19.3)

Specifications

FL

1250(49.2) 1250(49.2)

X-axis Travel 2500(98.4)

7452(293.4)

Side View

Table

DBC

series

900(35.4)

900(35.4)

1800(70.9)

4xC50

165

(6.5)

24H8(0.9H0.3)

19

(0.7)

50(2.0)

W-axis Travel 600(23.6)

Z-axis Travel1500

(59.1)

550

(21.7)

60 8x160=1280(8x6.3=50.4)

(2.4)

700(27.6) 700(27.6)

1400(55.1)

1245(49.0)Y-axis Travel 2000(78.7)

1000(39.4)1000(39.4)

1400 x 1800 (55.1 x 70.9)

24(0.9)

42(1.7)

External Dimensions

DBC 110 Ⅱ

Unit: mm(inch)

Top View

Front View

4865(191.5)

6978

530

(20.9)

ATC 40 TOOLS

1250(49.2) 1250(49.2)

X-axis Travel : 0~2500(0~98.4)

7473(294.2)

Table

Side View

1400 x 1600 (55.1 x 63.0)

900(35.4)

900(35.4)

1800(70.9)

4xC50

50(2.0)

24H8(0.9H0.3)

19

(0.7)

TABLE TOP

8x160=1280(8x6.3=50.4)

TABLE CENTER

60

(2.4)

700(27.6) 700(27.6)

1400(55.1)

1245(49.0) Y STROKE : 2000(78.7)

Ø110

2050(80.7)

W-axis Travel : 0~550Z-axis Travel : 0~1500

(0~21.7)

(0~59.1)

24(0.9)

42(1.7)

165

(6.5)

20 / 21

Product Overview

External Dimensions

Basic Information

DBC 130 / L

DBC 250 / L Ⅱ

Diverse Line-up

High-Rigidity &

Unit: mm(inch)

High-Precision

User Convenience

Top View

Front View

Detailed

Information

Options

Capacity Diagram

D

G

Specifications

Customer Support

E

F

Service

A1

A2

B : X-axis Travel

C

DBC 130 / L

DBC 250 / L Ⅱ

Side View

Side View

L : Y-axis Travel

Ø130

Ø250

W-axis Travel : 500H

TABLE CENTER

TABLE TOP

DBC

series

J

I : Z-axis Travel

270

TABLE CENTER

TABLE TOP

K

K

L : Y-axis Travel

J

W-axis Travel : 0~700H I : Z-axis Travel

Machine

A1 / A2

B

C

D

E

F

G

H

I

J

K

L

DBC 130 Ⅱ

1500

(59.1)

0-3000

(0-118.1)

8970

(353.1)

7660

(301.6)

1103

(43.4)

4905

(193.1)

527

(20.7)

0-700

(0-27.6)

0-1600

(0-63.0)

2300

(90.6)

1275

(50.2)

0-2000

(0-78.7)

DBC 130L Ⅱ

2000

(78.7)

0-4000

(0-157.5)

9970

(392.5)

8085

(318.3)

1103

(43.4)

5406

(212.8)

527

(20.7)

0-700

(0-27.6)

0-2000

(0-78.7)

2700

(106.3)

1275

(50.2)

0-2500

(0-98.4)

DBC 250 Ⅱ

1500

(59.1)

0-3000

(0-118.1)

8970

(353.1)

7660

(301.6)

1103

(43.4)

4905

(193.1)

527

(20.7)

0-500

(0-19.7)

0-1600

(0-63.0)

2100

(82.7)

1275

(50.2)

0-2000

(0-78.7)

DBC 250L Ⅱ

2000

(78.7)

0-4000

(0-157.5)

9970

(392.5)

8085

(318.3)

1103

(43.4)

5406

(212.8)

527

(20.7)

0-500

(0-19.7)

0-2000

(0-78.7)

2500

(98.4)

1275

(50.2)

0-2500

(0-98.4)

External Dimensions

DBC 130Ⅱ with APC

Unit: mm(inch)

Front View

5155(203.0)

11301(444.9)

PALLET TOP

1525(60.0)

5461(215.0)

2853(112.3)

5840(229.9)

Top View

DISTANCE BETWEEN

THE PALLET CENTER : 3000(118.1)

5414(213.1)

8970(353.1)

* Please contact us for further details of the specifications. The specifications are subject to change without prior notice for performance improvement.

900(35.4) 900(35.4)

900(35.4) 900(35.4)

900(35.4)

900(35.4)

1800(70.9) 1800(70.9) 4xC50

1800(70.9)

4xC504xC50

4-C50

240

(9.4)

19(0.7)

24(0.9)

42(1.7)

24(0.9)

24(0.9)

24(0.9)

42(1.7)

42(1.7)

42(1.7)

1000(39.4) 1000(39.4)

1000(39.4) 1000(39.4)

1000(39.4)

1000(39.4)

240

2000(78.7) 2000(78.7)

4-C50

2000(78.7)

4-C504-C50 (9.4) 240 240

(9.4) (9.4)

240

240

(9.4) 240 (9.4)

(9.4)

19(0.7) 19(0.7)

50(2.0)

50(2.0) 50(2.0)

24H8(0.9H0.3)

24H8(0.9H0.3)

24H8(0.9H0.3)

50(2.0)

19(0.7)

1000(39.4) 1000(39.4)

2000(78.7)

240

(9.4)

24H8(0.9H0.3)

100(3.9)10X160=1600(10X6.3=63.0)

4xC50

900(35.4) 900(35.4)

1800(70.9)

900(35.4)900(35.4)

900(35.4)900(35.4)

1800(70.9)

1800(70.9)

900(35.4) 900(35.4)

1800(70.9)

100(3.9)10X160=1600(10X6.3=63.0)

900(35.4)

900(35.4)

1800(70.9)

1800 x 2000 (70.9 x 78.7)

APC loading capacity : 8 tons

160(6.3)8x160=1280(8x6.3=50.4)

800(31.5) 800(31.5)

1600(63.0)

800(31.5)800(31.5)

800(31.5)800(31.5)

1600(63.0)

1600(63.0)

800(31.5) 800(31.5)

1600(63.0)

160(6.3)8x160=1280(8x6.3=50.4)

1600 x 1800 (63.0 x 70.9)

APC loading capacity : 10 tons

100(3.9)1100(3.9)

0X160=1600(10X6.3=63.0)

10X160=1600(10X6.3=63.0)

T-Slot

160(6.3)8x160=1280(8x6.3=50.4)

160(6.3)8x160=1280(8x6.3=50.4)

APC Pallet

Table

24H8(0.9H0.3)

24H8(0.9H0.3)

24H8(0.9H0.3)

24H8(0.9H0.3)

1600(63.)1600(63.)

10x160=1600(10x6.3=63.0)

160

(6.3)

1600(63.)

10x160=1600(10x6.3=63.0)

10x160=1600(10x6.3=63.0)

160

160

(6.3)

(6.3)

10x160=1600(10x6.3=63.0)

160

(6.3)

1600(63.)

3000(118.1)3000(118.1)

3000(118.1)

9(0.7)

9(0.7)

)

24H8(0.9H0.3)

24H8(0.9H0.3)

24H8(0.9H0.3)

3000(118.1)

50(2.0)

50(2.0)

190

1000 [1100] 1000 [1100]

190(7.5)

(7.5)

(39.4) [43.3]) (39.4) [43.3])

4xC50

4xC50

900(35.4) 900(35.4)

900(35.4) 900(35.4)

190

2000 [2200](78.7

1000

[1100][86.6])

190 1000 [1100]

190(7.5) 190(7.5)

900(35.4)

900(35.4)

[1100]

[1100]

1800(70.9)

1000 1000

[1100]

1000 1000

[1100]4xC50

(7.5) 190 (7.5)(39.4) [43.3])

190(7.5)

1800(70.9)

(39.4)

[43.3])

1800(70.9)

(7.5)

(39.4)

[43.3])

(39.4)

(39.4)

[43.3])

(39.4)

[43.3])[43.3])4xC504xC50

4xC50

24H8(0.9H0.3)

4xC504xC50

2000 [2200](78.7

[86.6])

[2200](78.7

2000 2000

[2200](78.7

[86.6])[86.6])

DBC 130 Plane Table

)

160(6.3) 8x160=1280(8x6.3=50.4)

800(31.5)800(31.5)

800(31.5)800(31.5)

1600(63.0)

1600(63.0)

160(6.3) 8x160=1280(8x6.3=50.4)

800(31.5) 800(31.5)

1600(63.0)

160(6.3) 160(6.3)

8x160=1280(8x6.3=50.4)

8x160=1280(8x6.3=50.4)

800(31.5) 800(31.5)

1600(63.0)

900(35.4)

900(35.4)

1800(70.9)

900 [1000] 900 [1000]

(35.4[39.4]) (35.4[39.4])

1800

[2000](70.9

[78.7])

900

[1000]

900900

[1000]

[1000]

900 [1000]

(35.4[39.4])

(35.4[39.4])

(35.4[39.4])

(35.4[39.4])

100 [130]

10X160=1600

100 [130]

900 [1000]

[1000]

1800

[2000](70.9

1800900

[2000](70.9

[78.7])

[78.7])

(35.4[39.4])

(35.4[39.4])

(3.9 [5.1])

(10X6.3=63.0)

(3.9 [5.1])

1800

[2000](70.9

[78.7])

100 [130]

100

10X160=1600

[130] 10X160=1600

100 [130]100 [130]

(3.9 [5.1])(3.9

(10X6.3=63.0)

[5.1]) (10X6.3=63.0)

(3.9 [5.1])(3.9 [5.1])

100 [130] 10X160=1600 100 [130]

(3.9 [5.1]) (10X6.3=63.0) (3.9 [5.1])

1800 x 2000 [2000 x 2200]

(70.9 x 78.7 [78.7 x 86.6])

1600 x 1800(63.0 x 70.9)

22 / 23

Product Overview

Basic Information

Diverse Line-up

High-Rigidity &

Machine Specifications

DBC S

Description

Unit

series

High-Precision

Travel

distance

User Convenience

Travels

Detailed

Information

Options

Capacity Diagram

Specifications

Feedrate

Customer Support

mm (inch)

2000 (78.7)

2500 (98.4)

Y-axis

mm (inch)

1500 (59.1)

2000 (78.7)

Z-axis

mm (inch)

1200 (47.2)

1500 (59.1)

W-axis

mm (inch)

500 (19.7)

600 (23.6)

mm (inch)

Distance from spindle

nose to table center

mm (inch)

550 ~ 1750 (21.7~2.9)

X, Y, Zaxes

m/min

12

W-axis

m/min

6

mm/min

1 ~ 6000

Rapid

traverse

Swing

diameter

X, Y, Zaxes

0 ~ 1500 (0~59.1)

mm (inch)

1400 x 1600 (55.1x63.0)

1400 x 1800

(55.1x70.9)

Without semiS/G

mm (inch)

ø2550

Ø3400

With semi-S/G

mm (inch)

ø2100

Ø2250

kg (lb)

7000

(15432.1)

8000 {10000}

(17636.7 {22045.9})

-

1400 x 1800

mm

kg (lb)

-

-

22045.9

1600 x 3000

mm

kg (lb)

-

-

-

1600 x 1800

mm

kg (lb)

-

-

-

1800 x 2000

mm

kg (lb)

-

-

-

2000 x 2200

mm

kg (lb)

-

-

-

Max. spindle speed

r/min

3000

2500

Max. spindle speed

mm (inch)

110

130

Quill diameter

mm (inch)

-

kW (Hp)

26 / 22(34.9 / 29.5)

{30 / 22

(40.2 / 29.5)}*

Load

capacity

Spindle motor

(30 min/cont.)

{AMP UP: 15 min/cont.}

Tool storage capacity

-

Max. tool diameter

mm (inch)

ø130 / 250 / 400 / 600(1)

Max. tool length

mm (inch)

600

Max. tool weight

kg (lb)

25 (55.1) / 30 (66.1)

Electric power supply

(rated capacity)

Height

Machine

Length x Width

dimensions

Weight

NC system

DBC

series

37 / 30 (49.6 /40.2)

MAS403 BT50

Method of tool selection

Power

source

-

40 / 60 / 90

ea

Tool shank

ATC

0~2000 (0~78.7)

1400 x 1600

mm

Table

Motor

DBC 130SL

X-axis

Table size

Spindle

DBC 130S

Distance from spindle

nose to table top

Cutting

feedrate

Service

DBC 110S

Fixed address

70

kVA

mm (inch)

4230 (166.5)

4860 (191.3)

mm (inch)

5520 x 5900 (217.3 x 232.3)

7450 x 6800

(293.3 x 267.7)

kg (lb)

29000 (63933.1)

-

FANUC 32i

30000 (66137.7)

36000 (79365.2)

DOOSAN FANUC i

* { } : Option

(1) For Ø250 and Ø400 mm tools, neighboring pots must be empty. For Ø600 mm tools, neighboring two pots must be empty.

Machine Specifications

DBCⅡ

Description

series

Travel

distance

Travels

Feedrate

Unit

DBC 110 Ⅱ

DBC 130 Ⅱ

DBC 130L Ⅱ

DBC 250 Ⅱ

DBC 250L Ⅱ

2500 (98.4)

3000 (118.1)

4000 (157.5)

3000 (118.1)

4000 (157.5)

2500 (98.4)

2000 (78.7)

2500 (98.4)

2000 (78.7)

1600 (63.0)

2000 (78.7)

X-axis

mm (inch)

Y-axis

mm (inch)

Z-axis

mm (inch)

1500 (59.1)

W-axis

mm (inch)

550 (21.7)

mm (inch)

Distance from spindle

nose to table center

mm (inch)

550 ~ 1750

(21.7 ~ 68.9)

X, Y, Zaxes

m/min

12

W-axis

m/min

Rapid

traverse

X, Y, Zaxes

Table size

700 (27.6)

500 (19.7)

500 (19.7)

0 ~ 2500

(0~98.4)

0 ~ 2000

(0~78.7)

0 ~ 2500

(0~98.4)

700 ~ 2300

(27.6 ~ 90.6)

700 ~ 2700

(27.6 ~ 106.3)

770 ~ 2370

(30.3 ~ 93.3)

770 ~ 2770

(30.3 ~ 109.1)

10

10 / 8 / 10

{7 / 8 / 10}*

10

10 / 8 / 10

6(0.2)

mm/min

1 ~ 6000

mm (inch)

1400 x 1800

(55.1 x 70.9)

10

1 ~ 4000

1600 x 1800

(63.0 x 70.9)

{1800 x 2000 (70.9 x 78.7),

2000 x 2200 (78.7 x 86.6)}*

Ø3400

ø3900

ø4800

ø3900

ø4800

Ø2250

ø3400

ø3400

ø3400

ø3400

1400 x 1600 mm

kg (lb)

-

-

-

-

-

1400 x 1800 mm

kg (lb)

10000

(22045.9)

-

-

-

-

1600 x 3000 mm

kg (lb)

-

-

-

-

-

1600 x 1800 mm

kg (lb)

-

Load

capacity

15000 (3306.9)

1800 x 2000 mm