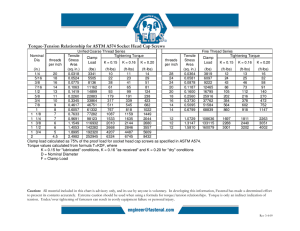

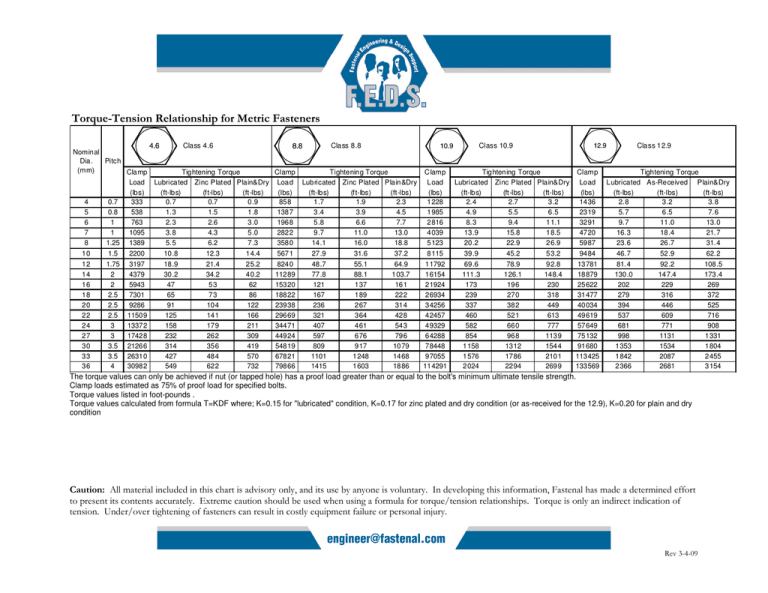

Torque-Tension Relationship for Metric Fasteners

advertisement

Torque-Tension Relationship for Metric Fasteners Class 4.6 Class 8.8 Nominal Dia. Pitch (mm) Clamp Clamp Tightening Torque Tightening Torque Load Lubricated Zinc Plated Plain&Dry Load Lubricated Zinc Plated Plain&Dry (lbs) (ft-lbs) (ft-lbs) (ft-lbs) (lbs) (ft-lbs) (ft-lbs) (ft-lbs) 4 0.7 333 0.7 0.7 0.9 858 1.7 1.9 2.3 5 0.8 538 1.3 1.5 1.8 1387 3.4 3.9 4.5 6 1 763 2.3 2.6 3.0 1968 5.8 6.6 7.7 7 1 1095 3.8 4.3 5.0 2822 9.7 11.0 13.0 8 1.25 1389 5.5 6.2 7.3 3580 14.1 16.0 18.8 10 1.5 2200 10.8 12.3 14.4 5671 27.9 31.6 37.2 12 14 16 18 20 22 24 27 30 33 36 1.75 2 2 2.5 2.5 2.5 3 3 3.5 3.5 4 3197 4379 5943 7301 9286 11509 13372 17428 21266 26310 30982 18.9 30.2 47 65 91 125 158 232 314 427 549 21.4 34.2 53 73 104 141 179 262 356 484 622 25.2 40.2 62 86 122 166 211 309 419 570 732 8240 11289 15320 18822 23938 29669 34471 44924 54819 67821 79866 48.7 77.8 121 167 236 321 407 597 809 1101 1415 55.1 88.1 137 189 267 364 461 676 917 1248 1603 64.9 103.7 161 222 314 428 543 796 1079 1468 1886 Class 10.9 C lamp Load (lbs) 1228 1985 2816 4039 5123 8115 11792 16154 21924 26934 34256 42457 49329 64288 78448 97055 114291 Class 12.9 Tightening Torque Lubricated Zinc Plated Plain&Dry (ft-lbs) (ft-lbs) (ft-lbs) 2.4 2.7 3.2 4.9 5.5 6.5 8.3 9.4 11.1 13.9 15.8 18.5 20.2 22.9 26.9 39.9 45.2 53.2 69.6 111.3 173 239 337 460 582 854 1158 1576 2024 78.9 126.1 196 270 382 521 660 968 1312 1786 2294 92.8 148.4 230 318 449 613 777 1139 1544 2101 2699 Clamp Load (lbs) 1436 2319 3291 4720 5987 9484 13781 18879 25622 31477 40034 49619 57649 75132 91680 113425 133569 Tightening Torque Lubricated As-Received Plain&Dry (ft-lbs) (ft-lbs) (ft-lbs) 2.8 3.2 3.8 5.7 6.5 7.6 9.7 11.0 13.0 16.3 18.4 21.7 23.6 26.7 31.4 46.7 52.9 62.2 81.4 130.0 202 279 394 537 681 998 1353 1842 2366 92.2 147.4 229 316 446 609 771 1131 1534 2087 2681 The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum ultimate tensile strength. Clamp loads estimated as 75% of proof load for specified bolts. Torque values listed in foot-pounds . Torque values calculated from formula T=KDF where; K=0.15 for "lubricated" condition, K=0.17 for zinc plated and dry condition (or as-received for the 12.9), K=0.20 for plain and dry condition Caution: All material included in this chart is advisory only, and its use by anyone is voluntary. In developing this information, Fastenal has made a determined effort to present its contents accurately. Extreme caution should be used when using a formula for torque/tension relationships. Torque is only an indirect indication of tension. Under/over tightening of fasteners can result in costly equipment failure or personal injury. Rev 3-4-09 108.5 173.4 269 372 525 716 908 1331 1804 2455 3154