Brushless EC motor, external and internal rotor with crown gearhead

advertisement

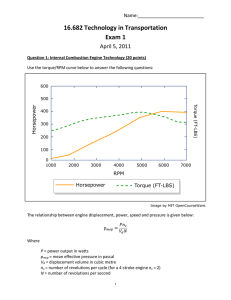

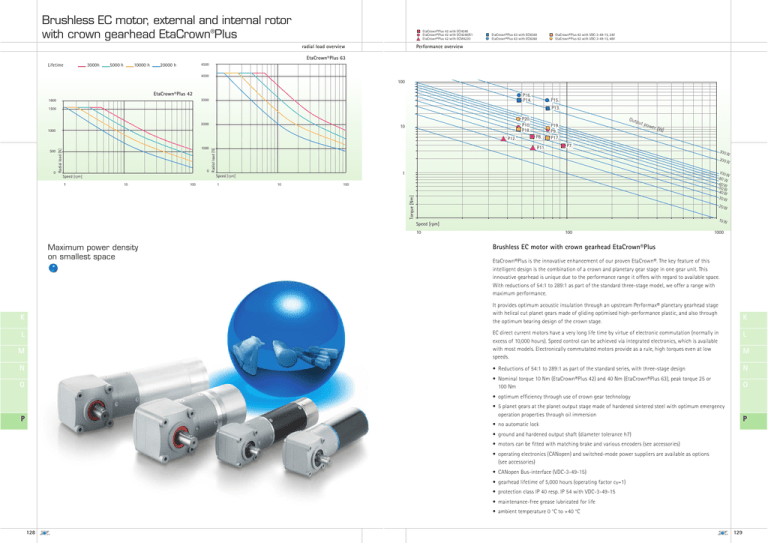

Brushless EC motor, external and internal rotor with crown gearhead EtaCrown®Plus EtaCrown®Plus 42 with ECI4240 EtaCrown®Plus 42 with ECI4240/K1 EtaCrown®Plus 42 with ECM4230 radial load overview EtaCrown®Plus 63 with ECI6340 EtaCrown®Plus 63 with ECI6360 EtaCrown®Plus 63 with VDC-3-49-15, 24V EtaCrown®Plus 63 with VDC-3-49-15, 48V Performance overview EtaCrown®Plus 63 Lifetime 3000h 5000 h 10000 h 20000 h 4500 4000 100 EtaCrown®Plus 42 P16. P14. 3000 1600 P15. P13. 1500 2000 P20. P10. P18. 10 1000 P12. 0 100 1 wer [W] P7. 300 W 200 W 10 100 W 80 W 60 W 50 W 40 W 30 W 20 W 100 Torque [Nm] 10 ut po 1 Speed [rpm] Speed [rpm] 1 P11. Radial load [N] 0 1000 Radial load [N] 500 P8. Outp P19. P9. P17. 10 W Speed [rpm] 10 Maximum power density on smallest space 100 1000 Brushless EC motor with crown gearhead EtaCrown®Plus EtaCrown®Plus is the innovative enhancement of our proven EtaCrown®. The key feature of this intelligent design is the combination of a crown and planetary gear stage in one gear unit. This innovative gearhead is unique due to the performance range it offers with regard to available space. With reductions of 54:1 to 289:1 as part of the standard three-stage model, we offer a range with maximum performance. It provides optimum acoustic insulation through an upstream Performax® planetary gearhead stage with helical cut planet gears made of gliding optimised high-performance plastic, and also through the optimum bearing design of the crown stage. K K EC direct current motors have a very long life time by virtue of electronic commutation (normally in excess of 10,000 hours). Speed control can be achieved via integrated electronics, which is available with most models. Electronically commutated motors provide as a rule, high torques even at low speeds. L N • Reductions of 54:1 to 289:1 as part of the standard series, with three-stage design N O • Nominal torque 10 Nm (EtaCrown®Plus 42) and 40 Nm (EtaCrown®Plus 63), peak torque 25 or 100 Nm O L M M • optimum efficiency through use of crown gear technology • 5 planet gears at the planet output stage made of hardened sintered steel with optimum emergency operation properties through oil immersion P P • no automatic lock • ground and hardened output shaft (diameter tolerance h7) • motors can be fitted with matching brake and various encoders (see accessories) • operating electronics (CANopen) and switched-mode power suppliers are available as options (see accessories) • CANopen Bus-interface (VDC-3-49-15) • gearhead lifetime of 5,000 hours (operating factor cB=1) • protection class IP 40 resp. IP 54 with VDC-3-49-15 • maintenance-free grease lubricated for life • ambient temperature 0 °C to +40 °C 128 129 Brushless EC motor, internal rotor with crown gearhead EtaCrown® Plus 42 Output torque Mout [Nm] i Brushless EC motor, internal rotor with crown gearhead EtaCrown® Plus 63 Output speed nout [rpm] Output torque Mout [Nm] three-stage i Output speed nout [rpm] three-stage ECI4240 EtaCrown®Plus 42 ECI4240/K1 EtaCrown®Plus 42 ECM4230 EtaCrown®Plus 42 3,9 10,0 3,5 5,6 10 Max. radial load (FR) see graphic page 128 Max. axial load 200 N 8 6 Lifetime at Mout[Nm] 5000 h Operating factor cB=1 4 2 0 ECI6340 EtaCrown®Plus 63 ECI6360 EtaCrown®Plus 63 92,6 54,0 84,8 54,0 84,8 54,0 84,8 6,2 8,7 59,0 40,0 40,0 40,0 47,2 59,3 37,7 0 20 Output shaft bearing assy. combined sliding/ ball bearing 40 54,0 84,8 54,0 84,8 26,4 74,1 60 80 Gearhead play approx. 0,7° to 1,2° depending on reduction 50 100 Protection IP 40 Max. radial load (FR) see graphic page 128 Max. axial load 300 N 40 30 20 Lifetime at Mout[Nm] 5000 h Operating factor cB=1 10 0 74,1 47,2 74,1 47,2 0 Output shaft bearing assy. combined sliding/ ball bearing 20 40 60 80 Gearhead play approx. 0,7° to 1,2° depending on reduction 100 Protection IP 40 Feather key DIN 6885 A-5x5x20 Feather key DIN 6885 A-4x4x14 146.1 for ECI6360 126.1 for ECI6340 at ECI4240/K1 = 45° at ECM42x30 = 15° 10 ± 0.5 bared plug 8-pin 3 Litz wires AWG 12 5 Litz wires AWG 26 7 ± 0.2 bared 500 ± 10 from motor K K 4xM4 8 deep 4xM5 10 deep L L M M N N 5x 5 ± 2 tin-plated 3x 7 ± 1 tin-plated O O 300 ± 30 from motor Crown gearhead Brushless EC motor, internal rotor Circuit diagram SB07, page 170 P Circuit diagram SB08, page 170 5000 rpm/52 W ECI4240/K1 EtaCrown®Plus 42 ECI4240 electronic integrated 24 V No. 130 4000 rpm/92 W 24 V ECM4230 P 7. P 8. Reduction i / no. of stages 54 / 3 84,8 / 3 Output torque Mout[Nm]* 3,9 6,2 Output speed nout[rpm] 92,6 59 Output power Pout [W] 38 38 ECI4240 ECI4240 P 9. P 10. 54 / 3 84,8 / 3 8,7 10 74,1 47,2 67 49,4 ECI4240/K1 ECI4240/K1 42.3.E4240.EP03 42.3.E4240.EP04 P 11. P 12. 54 / 3 84,8 / 3 3,5 5,6 59,3 37,7 22 22 ECM4230 ECM4230 42.3.E4230.EP05 42.3.E4230.EP06 Add-on components Motor Circuit diagram SB11, page 172 Order No. Rated current I [A] 42.3.E4240.EP01 3 42.3.E4240.EP02 3 Weight m [kg] 1,05 1,05 Length L [mm] 188 188 5,1 5,1 0,93 0,93 194 194 1,55 1,55 0,85 0,85 165 165 ECI4240 ECI4240/K1 ECM4230 Electronics CAN01, S01-S02 Brake B01 Brake B01 Encoder G04 Electronics V04-V05, CAN01, S01-S02 3200 rpm/30 W 24 V Encoder G01-G05 Brushless EC motor, internal rotor EtaCrown®Plus 63 ECI6340 4000 rpm/280 W 24 V Output torque Mout[Nm]* 26,4 40 Output speed nout[rpm] 74,1 47,2 Output power Pout [W] 205 200 ECI6340 ECI6340 Rated current I [A] 63.3.E6340.EP01 14 63.3.E6340.EP02 14 40 40 74,1 47,2 310 270 ECI6360 ECI6360 63.3.E6360.EP03 63.3.E6360.EP04 No. Reduction i / no. of stages P 13. 54 / 3 P 14. 84,8 / 3 P 15. P 16. 54 / 3 84,8 / 3 *maximum continuous output torque · Mmax[Nm] see page 24-25 · Brake: Page 145 · Encoder: Page 146-148 · Electronics: Page 154-167 ECI6360** Motor 4000 rpm/370 W 24 V Order No. P Weight m [kg] 2,2 2,2 Length L [mm] 242 242 2,5 2,5 262 262 17,6 17,6 **especially suitable for torque peaks Add-on components Electronics V04-V05, CAN01, S01-S02 Circuit diagram SB08, page 170 Crown gearhead ECI6340 Brake B03 Encoder G04 ECI6360 Electronics V04-V05, CAN02, S03 Brake B03 Encoder G04 Elektronik V04-V05, CAN02, S03 *maximum continuous output torque · Mmax[Nm] see page 24-25 · Brake: Page 145 · Encoder: Page 146-148 · Electronics: Page 154-167 131 Brushless EC motor, external rotor with crown gearhead EtaCrown®Plus 63 Output torque Mout [Nm] i Output speed nout [rpm] three-stage VDC-3-49-15, 24V EtaCrown®Plus 63 VDC-3-49-15, 48V EtaCrown®Plus 63 54,0 84,8 54,0 84,8 5,9 9,3 9,8 15,5 20 Max. radial load (FR) see graphic page 128 Max. axial load 300 N 15 10 5 Lifetime at Mout[Nm] 5000 h Operating factor cB=1 0 74,1 47,2 74,1 47,2 0 Output shaft bearing assy. combined sliding/ ball bearing 20 40 60 80 Gearhead play approx. 0,7° to 1,2° depending on reduction 100 Protection IP 40 4,209 drive solutions CANopen-Bus-interface if required, order code: C01 Feather key DIN 6885 A-5x5x20 48 hour service detailed specification of interface see circuit diagram SB12 4xM5 10 deep Keep-Word-Warranty tin-plated 4 ± 0.5 K K L L M M Standard N M03 M02 M04 Additional order details for motor fixing position O P Crown gearhead Brushless EC motor, external rotor EtaCrown®Plus 63 VDC-3-49-15 No. Reduction i / no. of stages P 17. 54 / 3 P 18. 84,8 / 3 P 19. P 20. 4000 rpm/63 W 24 V electronic integrated Output torque Mout[Nm]* 5,9 9,3 Output speed nout[rpm] 74,1 47,2 Output power Pout [W] 46 46 9,8 15,5 74,1 47,2 77 77 54 / 3 84,8 / 3 Add-on components Motor N 3D data available free of charge O Circuit diagram SB12, page 173 VDC-3-49-15 Elektronik integriert Order No. 4000 rpm/105 W 48 V Rated current I [A] VDC-3-49-15, 24V 63.3.C4915.EP01 3,5 VDC-3-49-15, 24V 63.3.C4915.EP02 3,5 Weight m [kg] 1,6 1,6 VDC-3-49-15, 48V 63.3.C4915.EP03 VDC-3-49-15, 48V 63.3.C4915.EP04 1,6 1,6 2,9 2,9 P Length L [mm] 177 177 177 177 www.zeitlauf.com VDC-3-49-15 Electronics S01-S02 132 *maximum continuous output torque · Mmax[Nm] see page 24-25 · Electronics: Page 166-167 133