Dow Corning ® Dispensable Thermal Pads for

Advanced Electronics

Dow Corning® Brand Dispensable Thermal Pads

Offer Your Electronics Applications:

n

Reduced Total Cost of Ownership: As dispensable thermal pads can be

dispensed or printed directly onto a substrate, they potentially reduce material

costs by 30 to 60 percent by eliminating the waste more common to conventional

fabricated thermal pads. This capability also allows dispensable thermal pads to

help accelerate manufacturing cycles, further minimizing costs.

n

Enhanced Reliability: Dispensable thermal pads contribute to more reliable product

performance by protecting against impact, shock and thermal cycling. They also

pose a lower risk of drying out compared to conventional thermal grease, which is

important for outdoor lighting applications.

n

Enhanced Design and Thermal Management: Offering thermal conductivity as

high as 2.5 W/mK, dispensable thermal pads also eliminate the need for fiberglass

carriers used in conventional fabricated pads. Thus, the technology can enable

thinner bond lines and excellent compression, yet deliver higher thermal resistance.

n

Expanded Manufacturing Latitudes: Dispensable thermal pads are compatible

with a wide range of efficient application processes, including standard screen or

stencil print, or via standard dispensing equipment. The materials easily conform

to complex and unevenly shaped substrates and cure in place, helping increase

throughput and provide greater flexibility over deposited layer thickness.

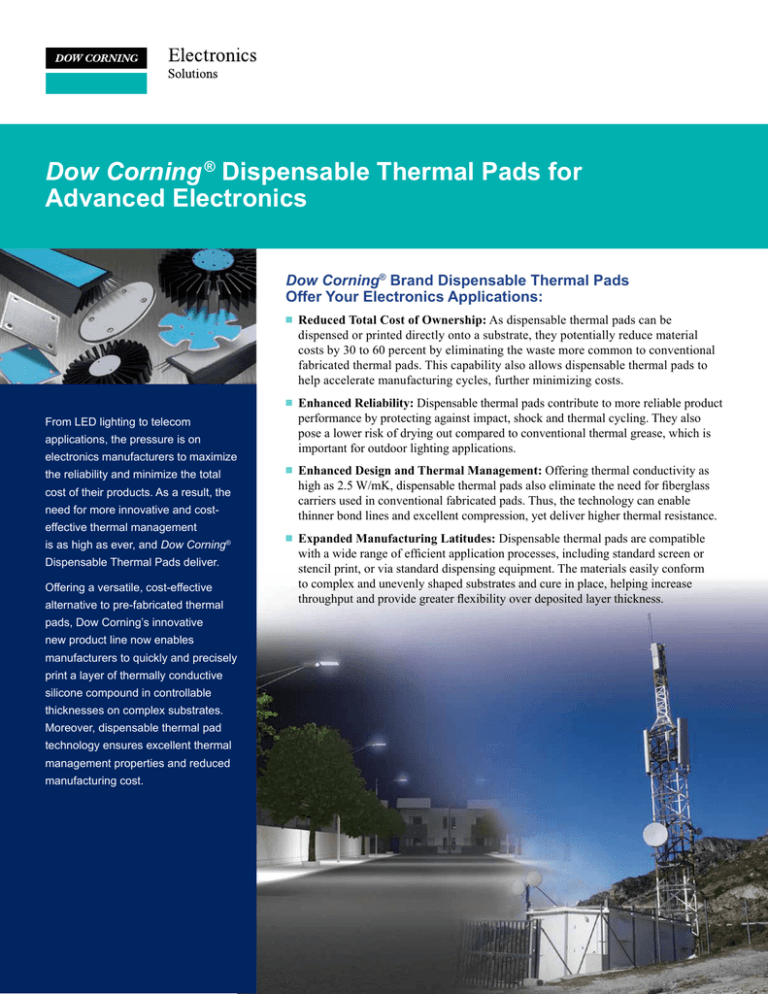

From LED lighting to telecom

applications, the pressure is on

electronics manufacturers to maximize

the reliability and minimize the total

cost of their products. As a result, the

need for more innovative and costeffective thermal management

is as high as ever, and Dow Corning®

Dispensable Thermal Pads deliver.

Offering a versatile, cost-effective

alternative to pre-fabricated thermal

pads, Dow Corning’s innovative

new product line now enables

manufacturers to quickly and precisely

print a layer of thermally conductive

silicone compound in controllable

thicknesses on complex substrates.

Moreover, dispensable thermal pad

technology ensures excellent thermal

management properties and reduced

manufacturing cost.

Dow Corning ®

Dispensable Thermal Pads

for Advanced Electronics

Benefits of Dow Corning Dispensable Pads

LED Lamp and Luminaire

Lower total cost

of ownership

n Better thermal

performance

n No dry-out compared

to traditional grease

n Longer pot life

n Reworkable

n

Telecom

Thermal Performance Benchmarking

Thickness vs. Pressure

1.2

10

1

Thickness (mm)

Thermal Resistance (K-cmˆ2/W)

Thermal Resistance vs. Thickness

12

8

6

4

0.6

0.4

0.2

2

0

0.8

0

0

0.2

0.4

0.6

0.8

1

1.2

1.4

0

10

20

30

Dow Corning® TC-4015 Thermal Pad, 1.7 W/mk

Dow Corning® TC-4025 Thermal Pad, 2.5 W/mk

50

60

70

80

Dow Corning® TC-4015 Thermal Pad

Dow Corning® TC-4025 Thermal Pad

Competitor 1 Pad, 1.2 W/mk

Competitor 1 Pad, 3.0 W/mk

Competitor 2 Pad, 1.5 W/mk

Thermal pad is soft and compresses to thinner bond lines with

increased pressure.

Dispensable pad outperforms fabricated pad on lower thermal resistance.

Thermal Resistance vs. Thickness

Reliability Test of Dow Corning® TC-4025 Thermal Pad

10

4.5

Thermal Resistance (K-cmˆ2/W)

Thermal Resistance (K-cmˆ2/W)

40

Pressure (psi)

Thickness (mm)

8

6

4

2

0

0

0.2

0.4

0.6

0.8

1

1.2

1.4

Thickness (mm)

Dow Corning® TC-4015 Thermal Pad, 1.7 W/mk

Dow Corning® TC-4025 Thermal Pad, 2.5 W/mk

Thermal resistance of Dow Corning® TC-4015 and Dow Corning® TC-4025

Dispensable Thermal Pads increase with thickness.

4.0

3.5

3.0

+

x

2.5

2.0

x

xx

1.5

+

++

x

x

1.0

.50

0.0

0

200

400

Time 0

85°C, 85% RH, 500 hrs.

Thermal Shock, 500 cycles

x 85°C, 85% RH, 1000 hrs.

600

800

1000

1200

BLT (µm)

Thermal Shock, 1000 cycles

Dow Corning® TC-4025 Thermal Pad, 85°C, 85% RH, 2k hrs. average

+ Dow Corning® TC-4025 Thermal Pad, -40~125°C, 2K cycles average

Samples are cured into thin sheets 0.25-1 mm thick and then brought

for reliability tests: 85°C/85%, thermal shock -40~125°C. Thermal

resistance after reliability test (500, 1000, 2000 hrs/cycles) obtained

based on ASTM 5470 standard and compared with time 0 testing.

Product Features and Technical Details

Dow Corning’s line of dispensable thermal pads currently encompasses four products,

distinguished by varying levels of thermal conductivity with or without controlled

bond line thicknesses.

Material Properties

Dispensable Thermal Pad

Key Properties

Units

One- or Two-Part

Mix Ratio

Dow Corning®

TC-4025 Dispensable

Thermal Pad

Dow Corning®

TC-4026 Dispensable

Thermal Pad

Dow Corning®

TC-4015 Dispensable

Thermal Pad

Dow Corning®

TC-4016 Dispensable

Thermal Pad

two-part

two-part

two-part

two-part

1:1

1:1

1:1

1:1

Viscosity

cP

A:73000

B:74000

A:73000

B:74000

A:104000

B:124000

A:104000

B:124000

Mixed Viscosity

cP

70000

70000

103000

103000

blue

blue

blue

blue

N/A

N/A

N/A

N/A

2.83

2.83

2.6063

2.6063

Color

Bleed

%

Specific Gravity

Working Time at 25°C

hours

>3

>3

4

4

Cure Time at 25°C

hours

24

24

24

24

minutes

40 minutes (75°C)

15 minutes (100°C)

10 minutes (120°C)

40 minutes (75°C)

15 minutes (100°C)

10 minutes (120°C)

48 minutes (75°C)

16 minutes (100°C)

10 minutes (120°C)

48 minutes (75°C)

16 minutes (100°C)

10 minutes (120°C)

50

50

50

50

%

209

209

262

262

Heat Cure Time

Durometer Shore 00

Elongation

Thermal Conductivity

W/mK

2.5

2.5

1.71

1.71

Thermal Resistance

@ 40 psi

°C*cm2/W

N/A

N/A

N/A

N/A

Dielectric Strength

kV/mm

18

18

18

18

Dielectric Constant

6.4 (100kHz)

6.4 (100kHz)

5.78

5.78

Dissipation Factor

0.001 (100kHz)

0.001 (100kHz)

0.002 (100kHz)

0.002 (100kHz)

3.90E+12

3.90E+12

5.18E+12

5.18E+12

UL94 V-0

UL94 V-0

UL94 V-0

UL94 V-0

without

with

without

with

Volume Resistivity

ohm*cm

Agency Listing

Glass Beads

Process Guidance

Manual or Automatic Printing

• Manual (manual mix + manual printing)

• Semi-automatic (manual mix + programmable printing)

• Printing modes: screen/stencil printing (thickness, design)

Automatic Dispensing with Static Mixer

How can we help you today?

Tell us about your performance, design and manufacturing

challenges. Let us put our silicon-based materials expertise,

application knowledge and processing experience to work

for you.

For more information about our materials and capabilities,

visit dowcorning.com.

To discuss how we could work together to meet your specific

needs, email electronics@dowcorning.com or go to

dowcorning.com/contactus for a contact close to your location.

Dow Corning has customer service teams, science and

technology centers, application support teams, sales offices

and manufacturing sites around the globe.

Images: Page 1: AV16700, AV16447, AV20983; Page 2: AV16438, AV20982, AV21065; Page 3: AV16641,

AV21056, AV16291; Page 4: AV12934

LIMITED WARRANTY INFORMATION – PLEASE READ CAREFULLY

The information contained herein is offered in good faith and is believed to be accurate. However, because

conditions and methods of use of our products are beyond our control, this information should not be used

in substitution for customer’s tests to ensure that our products are safe, effective and fully satisfactory for the

intended end use. Suggestions of use shall not be taken as inducements to infringe any patent.

Dow Corning’s sole warranty is that our products will meet the sales specifications in effect at the time of shipment.

Your exclusive remedy for breach of such warranty is limited to refund of purchase price or replacement of

any product shown to be other than as warranted.

DOW CORNING SPECIFICALLY DISCLAIMS ANY OTHER EXPRESS OR IMPLIED WARRANTY

OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY.

DOW CORNING DISCLAIMS LIABILITY FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Dow Corning is a registered trademark of Dow Corning Corporation.

We help you invent the future is a trademark of Dow Corning Corporation.

©2013 Dow Corning Corporation. All rights reserved.

AMPM262-13

Form No. 11-3401-01