bright led electronics corp.

advertisement

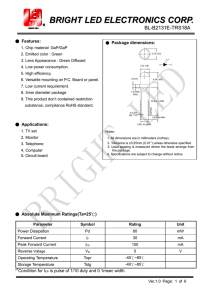

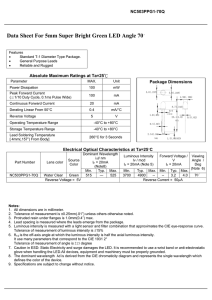

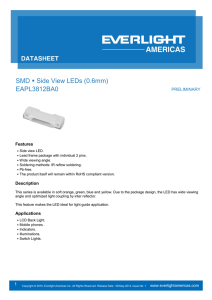

BRIGHT LED ELECTRONICS CORP. BD-A514RI ● Features : 1. 0.56 inch (14.20mm) Digit Height. 2. Continuous uniform segments. 3. Low power requirement. 4. Excellent characters appearance. 5. Solid state reliability. 6. Categorized for luminous intensity. 7. Direct drive common anode. ● Package Dimensions : 8.10(.315) ● 1. Description : 2. This product use hi-eff red chips, 3. This product have a gray face and white segments. This product doesn't contain restriction substance, comply ROHS standard. ● 14.20(.560) 19.00(.748) PIN 1. 15.24(.600) 1.70(.067) 25.00(.984) 8.00(.315) 0.5(.020) 4.3±0.5(.169±020) The BD-A514RI is a 14.20mm(0.56") high dual digit seven segments display. 4. 8 2.54(.100) Notes: 1. All dimensions are in millimeters(inches). 2. Tolerance is ±0.25mm(.01")unless otherwise specified. 3. Specifications are subject to change without notice. Internal Circuit Diagram : Ver.1.0 Page 1 of 4 BRIGHT LED ELECTRONICS CORP. BD-A514RI ● Absolute Maximum Ratings(Ta=25℃) Parameter Symbol Rating Unit Power Dissipation Per Segment Pd 80 mW Forward Current Per Segment IF 30 mA IFP (Duty 1/10, 1KHZ) 150 mA VR 5 V Operating Temperature Topr -40℃~85℃ - Storage Temperature Tstg -40℃~85℃ - Peak Forward Current Per Segment Reverse Voltage Per Segment ● Electrical And Optical Characteristics(Ta=25℃) Parameter Symbol Condition Min. Typ. Max. Unit Forward Voltage Per Segment Vf IF=10mA - 1.9 2.5 V Luminous Intensity Per Segment Iv IF=10mA - 2.5 - mcd Reverse Current Per Segment IR VR=5V - - 100 µA Peak Wave Length λp IF=20mA - 640 - nm Dominant Wave Length λd IF=20mA 626 - 636 nm Spectral Line Half-width ∆λ IF=20mA - 40 - nm Ver.1.0 Page 2 of 4 BRIGHT LED ELECTRONICS CORP. BD-A514RI Typical Electro-Optical Characteristics Curves (25℃ Ambient Temperature Unless Otherwise Noted) Fig.1 Relative Radiant Intensity VS. Wavelength Relative Radiant Intensity 1.0 0.5 0 560 590 620 Relative Luminous Intensity (@20mA) Fig.2 Forward Current VS. Forward Voltage 40 30 20 10 0 3.0 650 Wavelength(nm) 0 1 2 3 4 Forward Voltage (V) 5 Fig.4 Relative Luminous Intensity VS. Forward Current 1.0 0.0 10 20 30 40 Forward Current(mA) 3.0 50 710 740 Fig.3 Relative Luminous Intensity VS. Ambient Temperature 2.5 2.0 1.5 1.0 0.5 0 -40 50 2.0 0 680 -20 0 20 40 60 Ambient Temperature Ta( C) Forward Current(mA) Forward Current (mA) 50 Relative Luminous Intensity (@20mA) ● Fig.5 Forward Current Derating Curve VS. Ambient Temperature 40 30 20 10 0 0 20 40 60 80 100 120 Ambient Temperature Ta( C) Ver.1.0 Page 3 of 4 BRIGHT LED ELECTRONICS CORP. BD-A514RI ● Dip Soldering TEMPERATURE( °C) 300 Max:260℃,5sec. Suggest:2~3sec. 250 200 150 100 Fluxing 50 30 Preheat 10 20 30 40 50 60 70 80 90 100 110 120 TIME(sec.) 1. Please avoid any external stress applied to the lead-frames and epoxy while the LEDs are at high temperature,especially during soldering 2. DIP soldering and hand soldering should not be done more than one time. 3. After soldering, avoid the epoxy lens from mechanical shock or vibration until the LEDs are back to room temerature. 4. Avoid rapid cooling during temperature ramp-down process 5. Although the soldering condition is recommended above, soldering at the lowest possible temperature is feasible for the LEDs ● IRON Soldering 300℃ Within 3 sec.,One time only. Ver.1.0 Page 4 of 4