CEILING-MOUNTED AIR-HANDLING UNITS PKU Series

advertisement

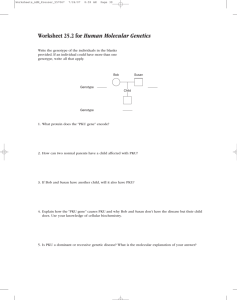

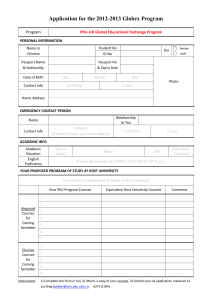

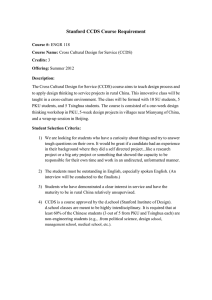

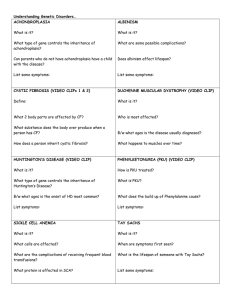

CEILING-MOUNTED AIR-HANDLING UNITS PKU Series proKLIMA 2 CEILING-MOUNTED AIR-HANDLING UNITS - PKU Series Owing to an extraordinarily flexible range of products the PKU series is undoubtedly able to offer solutions which will best meet your specific requirements for air conditioning and ventilation of: industrial plants, workshops, warehouses ..... shopping malls, supermarkets ... shops, points of sale .... restaurants, cafés, bars .... offices, business premises .... or residential buildings. proKLIMA 3 FEATURES 1 Air-handling units are designed to maintain purity, temperature and humidity of air by means of air filtration, heating, cooling and humidification or dehumidification. In most cases the air treatment process in air-handling units is completely automatic. TABLE OF CONTENTS 1 Features p. 3 2 Installation p. 4 3 Dimensions p. 4 4 Description of units p. 5 5 Standard configurations p. 6 6 Fan features p. 8 7 Pressure drops p. 9 p. 10 9 Cooler features p. 11 p. 12 11 Electrical data p. 13 Air-handling units in 3 different sizes cover the air flow volumes ranging from 500 - 4,000 m3/h. The combination of sizes and designs provides a maximum adaptability to the space available. The devices are manufactured as single units or blocks comprising more elements depending on the airhandling unit size and conditions of transporting and bringing the device into a building. Commonly used air-handling blocks are offered as standard systems, with elements to be assembled into wholes, thus reducing the costs of transport, handling and installation. Ceiling-mounted air-handling units are made of aluminium profiles and galvanized double steel plate lining with a 15mm thick thermal insulation. The lining meets the basic thermal and sound insulation requirements and falls within A1 category of non-combustible materials according to DIN 4102. The heat transfer coefficient of the devices is k=1.4 W/m2K. On customer’s request the outer lining of units may have a plastic coating of a RAL colour as desired. Locks, handles and metal fittings can be easily operated. All connections are sealed with a special waterproof and airtight rubber band and a silicone-free sealing material. The design and quality of units and built-in materials allow a carefree and quiet operation that meets the noise level requirements prescribed. 12 Wiring diagram p. 13 13 Tender text (example) Air-handling units dimensions are determined on the basis of the module dimension of 305 mm, or rather basic filter insert dimensions of 290 x 595 mm and 290 x 290 mm. Air-handling units are manufactured in conformity with EN 1886. 8 Heater features 10 Sound attenuator features Ceiling-mounted air-handling units of PKU series, size 1 - 3, are air treatment units that provide a comfort environment of air-conditioned rooms. By combining diverse functional units it is possible to provide equipment with options ranging from common ventilation with filtration to a complete air treatment that includes exploitation of exhaust air heat. They are primarily used for installation under the ceiling or into the ceiling structure and intended for horizontal or vertical installation, for connecting to ventilation ductwork or for a direct blowing of treated air into the room. p. 13 The fan and filter manipulation doors placed on the bottom side and the heat exchanger connections placed laterally facilitate access to built-in units, their maintenance and replacement. Diverse modifications in the design and connections are possible on request, depending on the on-site situation or project requirements. 4 CEILING-MOUNTED AIR-HANDLING UNITS - PKU Series 2 INSTALLATION Ceiling (horizontal) installation Vertical installation Rooftop (external) installation 3 DIMENSIONS Basic dimensions of ceiling-mounted air-handling units are determined according to standard dimensions of filter inserts and nominal air flow volume and dependent on the handling method (from the bottom side - as standard, from the upper side or laterally on request). FILTER 595«290 325 FILTER 595«290 670 PKU-3 FILTER 290«290 FILTER 595«290 960 FILTER 595«290 1265 Dimensions and location of flexible connections and dampers are shown in the drawing and the table attached. Type PKU1 PKU2 PKU3 Front 210 x 605 310 x 605 210 x 885 310 x 885 210 x 1195 310 x 1195 Location Lateral AIR FLOW DIRECTION On the top 310 x 275 210 x 605 310 x 450 210 x 885 310 x 800 210 x 1195 The dampers are 125 mm and flexible connections 135 mm wide. Subject to technical alterations! 350 PKU-2 350 PKU-1 FROM ABOVE LATERAL AIR FLOW DIRECTION FRONTAL proKLIMA 5 DESCRIPTION OF UNITS 4 FILTER UNIT (F) is a segment of an air-handling unit that separates impurities from the air. It is normally constructed as a panel filter class G3 and G4, but other filter types (bag filter, etc.) may also be installed if required. In accordance with EN 779 and the EUROVENT 4/5 classification dimensions and types are adjusted to the air-handling unit size and the level of separation or rather efficiency. The filter is made of glass fibre, synthetic fibre, fabric, etc. with a labyrinth structure. ELECTRIC HEATER (GE) is a heat exchanger in which electrical energy is transformed into thermal. It has a form of a circular, alloy steel rod. It is used mostly in cases when no other thermal energy source is available (warm water or vapour) or as an alternative heater. The heater supply voltage is 230 or 400 V/50 Hz. Depending on the capacity or requirement the heater may be actuated stepwise (1 - 6 stages linearly or 64 stages binary) or continuously. It is recommended to mount the electric heater on the discharge side of the fan. A flow separator is to be installed between the fan and the electric heater to enable the air current distribution over the entire electric heater cross section. A protective thermostat is used to limit the maximum temperature of air passing the fan to 60°C (40°C in case of a PKU1 model with an electric motor of Pm = 1 kW). HEATER (G) is a heat exchanger between warm water and air or vapour and air made of aluminium fins placed on mechanically expanded copper tubes which allows for a high heat transfer coefficient. Manifold connections may be threaded or flanged (on request) and are to be attached in the counterflow. COOLER (H) is a heat exchanger between cold water and air or rather freon and air. It is made of aluminium fins placed on mechanically expanded copper tubes, which allows for a high heat transfer coefficient. A cooler of a standard design includes also a droplet eliminator, but on request or if possible (for lower air velocity) it can also be supplied without a droplet eliminator which will reduce the unit. The unit is equipped with a stainless steel condensate receiver with a 1/2” connection for condensate removal and a corresponding siphon. Manifold connections may be threaded or flanged (on request) and are to be attached in the counterflow. FAN UNIT (F) is an air-handling device driving unit in which the air is given energy necessary to overcome resistance to the flow through the device (internal pressure drop) and through air circuit elements (external pressure drop). The electric motor supply voltage is 230 V / 50 Hz. According to the requirements and depending on the electric motor power, the motor turnovers may be controlled by a transformer, voltage or frequency regulator of the rated speed, which enables the accurate adjustment of the required air volume flow. SOUND ATTENUATOR (PZ) is a unit designed to reduce the fan-generated noise level. It consists of barriers made of a special paper lined mineral wool stuffed into galvanized steel frames. The material used for barriers is highly absorbing, does not absorb moisture and is non-combustible according to DIN 4102 class A1. The barriers are wear resistant. Air deflectors built in on the front side provide favourable air flow conditions. The unit is available in lengths of 600 and 900 mm, depending on the attenuation level required. When installing a sound attenuator on the discharge side of the fan, a space of 200 mm is to be left free in front of the barriers to allow for the air flow tranquillization and distribution. An alternative solution for sound attenuation may also be the installation of a sound attenuator in the ventilating duct. 6 CEILING-MOUNTED AIR-HANDLING UNITS - PKU Series PLATE RECUPERATOR (RP) is used for exploitation of return air heat, which helps achieve considerable energy savings. It is made of specially formed interconnected aluminium fins that facilitate cross-exchange of heat between the return and fresh air flow. The plate exchanger design allows for an absolute separation of airflow, thus preventing the transfer of any impurity, smell, moisture, bacteria, etc. from the return to the fresh air. On request and in accordance with the project requirements it is possible to mount a droplet eliminator and a by-pass duct for the air flow to circumvent the heat exchanger partly or completely. AIR MIXING (M) OR AIR DOUBLE-MIXING UNIT (MM) with dampers and necessary flexible connections enables mixing of fresh and return air in a desired proportion for energy-saving purposes. The dampers may be manually or electric motor operated. On request or according to project requirements other functional units (humidifier, empty units, etc.) may also be mounted. In such a case please contact the manufacturer. 5 STANDARD CONFIGURATIONS 350 x W SP-1 Type PKU 1 Length L (mm) 550 Width B (mm) 680 Weight (kg) 56 L PKU 2 660 960 76 PKU 3 660 1270 103 PKU 2 960 960 114 PKU 3 960 1270 153 PKU 2 1460 960 122 PKU 3 1460 1270 162 PKU 2 1540 960 148 PKU 3 1880 1270 194 PKU 2 1530 960 154 PKU 3 1530 1270 208 350 x W SP-2 Type PKU 1 Length L (mm) 850 Width B (mm) 680 Weight (kg) 85 L 350 x W SP-3 Type PKU 1 Length L (mm) 1350 Width B (mm) 680 Weight (kg) 94 L W x 350 SP-4 350 x W L L Type PKU 1 Length L (mm) 1200 Width B (mm) 680 Weight (kg) 113 SP-5 Type PKU 1 Length L (mm) 1420 Width B (mm) 680 Weight (kg) 114 350 x W proKLIMA L NOTE: With one heat exchanger (heater/cooler). For rating purposes apply a heater with the fin spacing s = 2.5 mm and a safety factor of 100%. SP-5GH Type PKU 1 Length L (mm) 1220 Width B (mm) 670 Weight (kg) 95 PKU 2 1330 960 127 PKU 3 1330 1270 170 PKU 2 2220 960 258 PKU 3 2420 1270 338 PKU 2 2950 960 320 PKU 3 3150 1270 422 SP-6 350 x W Type PKU 1 Length L (mm) 2000 Width B (mm) 680 Weight (kg) 197 L 350 x W SP-7 L Type PKU 1 Length L (mm) 2700 Width B (mm) 680 Weight (kg) 243 SP-8 W x 350 Type PKU 1 PKU 2 PKU 3 L (mm) 2400 2800 3250* W (mm) 1400 1980 2590 Weight (kg) 386 530 731 * for a maximum air flow volume of 3,000 m3/h NOTE : Insulation thickness 25 mm. Heat transfer coefficient k = 0.92 W/m2K Additional noise damping by the unit casing Lp1(A)add = Lp1 (A) - 3 dB L W x 350 SP-9 Type L (mm) B (mm) W (kg) PKU 1 1780 1480 241 PKU 2 2150 2040 318 PKU 3 2470 2660 420 Alternative: Placement of dampers on the front side of the unit (dashed). SP-10 Type PKU 1 PKU 2 PKU 3 Sound attenuator L=600 mm L (mm) 1900 2010 2010 Weight (kg) 104 138 184 350 x W L L Sound attenuator L=900 mm L (mm) 2500 2610 2610 Weight (kg) 118 157 209 W (mm) The standard system weights specified are approximate values only. Block lengths L are maximum values, but can be smaller depending on the elements built in. 680 960 1270 7 8 CEILING-MOUNTED AIR-HANDLING UNITS - PKU Series 6 FAN FEATURES Apply for air density of 1.2 kg/m3. PKU 1 1500 400 2900 1000 2800 900 360 1300 [230V] rpm 64dB 320 700 500 300 2700 [180V] rpm Speed nv[rpm] Speed nv[rpm] 900 Static pressure PV[Pa] 1100 65dB 280 [120V] 64dB 240 66dB 200 2600 2500 2400 Static pressure PV[Pa] rpm 800 rpm 700 75dB 600 500 61dB 65dB 75dB 400 160 120 300 69dB 60,5dB 67dB 200 80 60dB 40 120V 50Hz 180V 50Hz 100 230V 50Hz 230V 50Hz 0 0 0 500 1000 1500 0 2000 500 Air flow volume V[m3/h] 1000 1500 2000 2500 3000 Air flow volume V[m3/h] PKU 2 1500 600 1300 540 1500 800 1300 720 rpm rpm 700 500 300 Static pressure PV[Pa] Speed nv[rpm] 900 480 1100 65,9dB [230V] Speed nv[rpm] 1100 420 [180V] 360 65,4dB [120V] 68,6dB 63,7dB 300 900 700 500 Static pressure PV[Pa] rpm rpm 74,5dB 74,5dB [180V] 640 74dB rpm 75dB 74dB 560 75,5dB [120V] 73,5dB 73dB 400 180V 50Hz 320 67,2dB 240 180 230V 50Hz 73,5dB 480 73dB 300 240 [230V] rpm 72dB 71,6dB 65dB 120 160 120V 50Hz 68,2dB 80 60 120V 50Hz 180V 50Hz 230V 50Hz 0 0 0 500 1000 1500 2000 3 Air flow volume V[m /h] 2500 3000 0 500 1000 1500 2000 2500 3 Air flow volume V[m /h] 3000 proKLIMA 9 PKU 3 1500 600 1500 800 [230V] 540 1300 rpm rpm 700 500 300 65,9dB 420 [180V] 360 65,4dB [120V] 63,7dB 300 1100 [230V] Speed nv[rpm] Speed nv[rpm] 900 480 Static pressure PV[Pa] 1100 68,6dB 900 700 500 720 Static pressure PV[Pa] 1300 rpm [180V] rpm 77,5dB [120V] 78dB rpm 640 77dB 78dB rpm 77dB 560 78,5dB 76,5dB 480 230V 50Hz 77dB 76dB 400 76dB 240 300 67,2dB 180 180V 50Hz 320 240 74dB 71,6dB 65dB 120 160 68,2dB 120V 50Hz 60 120V 50Hz 180V 50Hz 80 230V 50Hz 0 0 0 1000 2000 3000 4000 5000 6000 0 1000 Air flow volume V[m3/h] 2000 3000 4000 5000 Air flow volume V[m3/h] 7 PRESSURE DROPS Pressure drops on the air side [Pa] for individual structural elements and units are shown in the following table: PKU 1 Type 3 Air flow volume [m /h] Damper inlet Panel filter G3 and G4 Electric heater Heater 2R (double-row) Cooler 4R (four rows)* Cooler 5R (five rows)* Cooler 6R (six rows)* Droplet eliminator Sound attenuator Plate recuperator ** 500 10 130 4 5 12 17 20 6 7 60 1000 20 150 9 21 45 62 75 11 12 120 PKU 2 1500 30 165 20 45 100 133 160 22 17 160 1500 20 150 10 19 45 57 91 11 13 80 2000 25 160 15 33 80 98 118 17 16 120 PKU3 2500 30 170 21 50 120 150 180 26 19 140 2500 25 155 14 28 65 83 100 16 15 140 3250 30 170 20 46 110 136 164 26 18 190 4000 35 185 24 68 160 201 242 34 21 220 NOTES: *The pressure drop in the cooler unit equals the sum of the pressure drop over the heat exchanger with a selected number of rows (4R, 5R or 6R) increased by the pressure drop over the droplet eliminator. ** The pressure drop over the plate recuperator related to the plate heat exchanger only (pressure drops over the droplet eliminator and filter are not taken into account and should be added to the pressure drop over the plate recuperator). 6000 10 CEILING-MOUNTED AIR-HANDLING UNITS - PKU Series 8 HEATER FEATURES Ratings for 2R (double-row) water heater. Fin spacing s = 2.1 mm. PKU 1 Pipe connection R 1/2” 500 50/45°C 80/60°C 90/70°C Air flow volume [m3/h] tin[°C] -20 -15 -10 -5 0 5 10 -20 -15 -10 -5 0 5 10 -20 -15 -10 -5 0 5 10 Q[kW] 11.2 10.6 10.0 9.4 8.9 8.3 7.7 10.0 9.4 8.8 8.2 7.6 7.1 6.5 7.7 7.1 6.5 5.9 5.3 4.8 4.2 tout[°C] 46.0 45.6 49.1 50.7 52.7 53.9 55.4 38.8 40.4 41.9 43.5 45.1 46.7 48.2 25.2 26.8 28.3 29.9 31.5 33.1 34.7 1000 ∆pW[kPa] 1.6 1.5 1.3 1.2 1.1 1.0 0.8 1.4 1.2 1.1 1.0 0.8 0.7 0.6 11.2 9.7 8.3 7.0 5.8 4.7 3.8 PKU 2 90/70°C 80/60°C 50/45°C tin[°C] -20 -15 -10 -5 0 5 10 -20 -15 -10 -5 0 5 10 -20 -15 -10 -5 0 5 10 1500 Q[kW] 26.7 25.3 23.9 22.5 21.1 19.7 18.3 23.8 22.4 21.0 19.5 18.1 16.7 15.3 18.5 17.1 15.6 14.2 12.8 11.4 10.0 tout[°C] 32.6 34.8 37.0 39.3 41.5 43.7 46.0 26.7 29.0 31.2 33.4 35.7 37.9 40.1 16.3 18.5 20.8 23.0 25.2 27.5 29.7 Q[kW] 22.3 21.1 19.9 18.7 17.5 16.3 15.2 19.7 18.6 17.4 16.2 15.0 13.8 12.7 15.5 14.3 13.1 11.9 10.7 9.6 8.4 tout[°C] 23.8 26.4 29.1 31.8 34.5 37.1 39.8 18.8 21.5 24.2 26.9 29.5 32.2 34.9 10.5 13.1 15.8 18.5 21.1 23.8 26.5 Q[kW] 36.3 34.3 32.4 30.5 28.6 26.6 24.7 32.2 30.3 28.3 26.4 24.5 22.6 20.6 25.2 23.3 21.3 19.4 17.5 15.6 13.6 tout[°C] 22.8 25.5 28.2 31.0 33.7 36.4 39.1 18.0 20.7 23.4 26.2 28.9 31.6 34.3 9.7 12.5 15.2 17.9 20.6 23.4 26.1 ∆pW[kPa] 5.6 5.1 4.6 4.1 3.7 3.2 2.8 4.7 4.2 3.7 3.3 2.9 2.5 2.1 39.6 34.4 29.4 24.8 20.5 16.6 13.1 Q[kW] 31.8 30.1 28.4 26.8 25.1 23.4 31.7 28.3 26.6 24.9 23.2 21.5 19.8 18.2 22.1 20.4 18.7 17.0 15.3 13.6 12.0 tout[°C] 26.9 29.4 31.9 34.5 37.0 39.5 42.0 21.7 24.2 26.7 29.2 31.7 34.3 36.8 12.5 15.0 17.6 20.1 22.6 25.1 27.6 2500 ∆pW[kPa] 4.9 4.4 4.0 3.6 3.2 2.8 2.5 4.1 3.6 3.2 2.9 2.5 2.2 1.8 34.1 29.5 25.3 31.4 17.7 14.4 11.3 ∆pW[kPa] 6.2 5.6 5.0 4.5 4.0 3.5 3.1 5.1 4.6 4.1 3.6 3.1 2.7 2.3 43.4 37.6 32.2 27.1 22.5 18.2 14.4 Pipe connection R 3/4” 2500 Air flow volume [m3/h] 90/70°C 1500 ∆pW[kPa] 3.6 3.3 3.0 2.7 2.4 2.1 1.8 3.0 2.7 2.4 2.1 1.9 1.6 1.4 25.4 22.0 18.8 15.9 13.2 10.7 8.4 2000 ∆pW[kPa] 3.6 3.2 2.9 2.6 2.3 2.1 1.8 3.0 2.7 2.4 2.1 1.8 1.6 1.4 24.8 21.5 18.4 15.5 12.9 10.5 8.3 PKU 3 80/60°C tout[°C] 31.5 33.8 36.1 38.4 40.7 42.9 45.2 25.8 28.1 30.3 32.6 34.9 37.2 39.5 15.7 17.9 20.2 22.5 24.8 27.1 29.3 Pipe connection R 1/2” Air flow volume [m3/h] 50/45°C Q[kW] 17.5 16.6 15.6 14.7 13.8 12.9 11.9 15.5 14.6 13.7 12.8 11.8 10.9 10.0 12.1 11.2 10.2 9.3 8.4 7.5 6.6 tin[°C] -20 -15 -10 -5 0 5 10 -20 -15 -10 -5 0 5 10 -20 -15 -10 -5 0 5 10 Q[kW] 41.1 39.0 36.8 34.6 32.5 30.3 28.1 36.5 34.4 32.2 30.0 27.9 25.7 23.5 28.5 26.3 24.1 22.0 19.8 17.6 15.4 tout[°C] 28.5 31.0 33.4 35.8 38.3 40.7 43.2 23.1 25.5 28.0 30.4 32.9 35.3 37.8 13.6 16.0 18.5 20.9 23.3 25.8 28.2 3250 ∆pW[kPa] 4.6 4.2 3.8 3.4 3.0 2.7 2.3 3.9 3.5 3.1 2.7 2.4 2.1 1.8 32.3 28.0 24.0 20.3 16.8 13.6 10.8 Q[kW] 48.0 45.5 42.9 40.4 37.8 35.3 32.8 42.6 40.1 37.5 35.0 32.5 29.9 27.4 33.4 30.8 28.3 25.7 23.2 20.6 18.1 Ratings for other modes of operation available on request. tout[°C] 23.6 26.3 29.0 31.7 34.3 37.0 39.7 18.7 21.4 24.1 26.8 29.5 32.1 34.8 10.3 13.0 15.6 18.3 21.0 23.7 26.4 4000 ∆pW[kPa] 6.1 5.6 5.0 4.5 4.0 3.5 3.1 5.1 4.6 4.1 3.6 3.1 2.7 2.3 43.0 37.3 31.9 26.9 22.3 18.1 14.2 Q[kW] 54.1 51.2 48.4 45.5 42.6 39.7 36.8 48.0 45.1 42.3 39.4 36.5 33.6 30.8 37.7 34.8 31.9 29.0 26.1 23.2 20.4 tout[°C] 19.9 22.8 25.7 28.5 31.4 34.3 37.2 15.4 18.3 21.2 24.0 26.9 29.8 32.7 7.8 10.7 13.5 16.4 19.3 22.1 25.0 ∆pW[kPa] 7.6 6.9 6.2 5.6 4.9 4.4 3.8 6.3 5.7 5.0 4.4 3.9 3.3 2.8 53.6 46.4 39.6 33.4 27.7 22.5 17.7 proKLIMA 11 COOLER FEATURES 9 WATER COOLER Fin spacing s = 2.5 mm PKU 1 Pipe connection R 3/4” 500 Air flow volume [m3/h] No.of rows tin[°C] r.v.in[%] Q[kW] Water 7/12°C 4R 5R 6R 34 32 29 34 32 29 34 32 29 45 40 46 45 40 46 45 40 46 5.8 4.4 3.8 6.5 5.0 4.3 7.0 5.4 4.7 tout[°C] r.v.out[%]∆pW[kPa] Q[kW] 14.4 14.1 13.7 12.3 12.2 12.0 10.8 10.8 10.7 91 88 90 95 93 94 97 96 96 PKU 2 9.5 7.0 6.0 11.0 8.3 7.2 12.2 9.3 8.1 1500 No.of rows tin[°C] r.v.in[%] Q[kW] 4R Water 7/12°C 3 2 2 5 3 2 7 4 3 1500 tout[°C] r.v.out[%]∆pW[kPa] Q[kW] 17.7 17.2 16.4 15.4 15.0 14.5 13.6 13.4 13.0 82 78 81 88 84 87 91 89 90 8 5 4 13 8 6 18 11 9 12.4 9.1 7.8 14.7 10.9 9.4 16.5 12.4 10.8 tout[°C] r.v.out[%]∆pW[kPa] 19.8 19.0 18.0 17.4 16.9 16.1 15.5 15.1 14.5 77 73 76 82 78 62 87 83 86 13 8 6 22 13 10 31 19 15 Pipe connection R 1” Air flow volume [m3/h] 5R 6R 34 32 29 34 32 29 34 32 29 45 40 46 45 40 46 45 40 46 14.5 10.8 9.3 16.9 12.8 11.1 18.7 14.2 12.4 2000 tout[°C] r.v.out[%]∆pW[kPa] Q[kW] 17.5 17.0 16.2 15.0 14.7 14.2 13.3 13.0 12.7 83 79 82 88 85 87 92 89 91 PKU 3 9 5 4 15 9 7 20 12 10 17.5 13.0 11.2 20.8 15.6 13.5 23.2 17.6 15.3 2500 tout[°C] r.v.out[%]∆pW[kPa] Q[kW] 19.0 18.3 17.3 16.5 16.0 15.3 14.6 14.3 13.8 79 75 78 85 81 84 89 86 88 13 8 6 21 13 10 30 18 14 20.2 14.9 12.8 24.2 18.1 15.7 27.3 20.6 17.9 tout[°C] r.v.out[%]∆pW[kPa] 20.1 19.3 18.2 17.6 17.0 16.2 15.7 15.3 14.7 76 72 75 82 78 81 86 82 85 17 10 7 28 17 13 40 24 19 Pipe connection R 1” 2500 Air flow volume [m3/h] No.of rows tin[°C] r.v.in[%] Q[kW] 4R Water 7/12°C 1000 5R 6R 34 32 29 34 32 29 34 32 29 45 40 46 45 40 46 45 40 46 22.6 16.7 14.3 23.4 16.7 14.1 26.2 19.0 16.1 3250 tout[°C] r.v.out[%]∆pW[kPa] Q[kW] 18.5 17.9 17.0 17.6 17.2 16.6 15.9 15.6 15.2 80 76 79 85 82 84 89 86 88 12 7 5 14 8 6 20 11 8 26.7 19.7 16.9 27.9 19.9 16.7 31.6 22.8 19.3 4000 tout[°C] r.v.out[%]∆pW[kPa] Q[kW] 19.9 19.1 18.0 18.8 18.3 17.5 17.1 16.7 16.1 77 72 76 81 78 81 86 83 85 16 9 7 20 11 8 28 16 11 30.4 22.3 19.1 32.0 22.7 19.0 36.5 26.3 22.1 tout[°C] r.v.out[%]∆pW[kPa] 20.9 20.0 18.8 19.8 19.2 18.2 18.0 17.6 16.8 Ratings for other modes of operation and refrigerants (ethylene-glycol mixture) available on request. 74 69 74 79 75 78 83 80 83 20 11 9 25 14 10 36 20 15 12 CEILING-MOUNTED AIR-HANDLING UNITS - PKU Series FREON COOLER Fin spacing s = 2.5 mm PKU 1 500 R22 ti = +5°C Air flow volume [m3/h] No.of rows tin[°C] r.v.in[%] 34 45 32 40 4R 29 46 34 45 32 40 5R 29 46 34 45 32 40 6R 29 46 Q[kW] 6.5 5.1 4.6 7.2 5.7 5.1 7.7 6.1 5.5 tout[°C] 12.5 12.1 11.7 10.5 10.2 10.0 9.1 8.9 8.8 1000 r.v.out[%] 92 89 91 85 93 94 98 96 97 Q[kW] 10.7 8.4 7.4 12.2 9.6 8.5 13.3 10.5 9.4 tout[°C] 16.2 15.5 14.7 13.9 13.4 12.8 12.2 11.8 11.3 1500 r.v.out[%] 84 79 82 89 85 87 92 89 91 Q[kW] 14.0 10.9 9.6 16.2 12.6 11.2 17.6 14.0 12.5 tout[°C] 18.4 17.6 16.5 16.1 15.4 14.6 14.6 13.7 13.0 r.v.out[%] 78 74 77 84 79 82 88 84 87 PKU 2 1500 R22 ti = +5°C Air flow volume [m3/h] No.of rows tin[°C] r.v.in[%] 34 45 32 40 4R 29 46 34 45 32 40 5R 29 46 34 45 32 40 6R 29 46 Q[kW] 16.3 12.7 11.3 18.6 14.6 13.1 20.3 16.0 14.3 tout[°C] 16.0 15.3 14.5 13.6 13.1 12.5 11.9 11.5 11.0 Q[kW] 25.4 19.8 17.5 29.2 22.9 20.4 32.0 25.3 22.6 tout[°C] 17.1 16.3 15.4 14.7 14.1 13.4 13.0 12.4 11.9 2000 r.v.out[%] 84 80 83 89 86 88 93 90 92 Q[kW] 19.7 15.3 13.6 22.8 17.9 15.9 24.7 19.8 17.7 r.v.out[%] 81 77 80 87 83 85 91 87 89 Q[kW] 30.1 23.4 20.7 34.7 27.4 24.3 38.1 30.4 27.2 tout[°C] 17.6 16.8 15.8 15.2 14.5 13.7 13.6 12.8 12.2 2500 r.v.out[%] 80 75 79 86 82 84 90 86 88 Q[kW] 22.7 17.6 15.6 26.2 20.8 18.5 28.8 23.1 20.6 r.v.out[%] 78 73 77 83 79 82 87 84 86 Q[kW] 34.0 26.5 23.5 39.6 31.3 27.8 43.8 34.6 31.2 tout[°C] 18.8 17.9 16.8 16.6 15.6 14.8 14.9 14.0 13.2 r.v.out[%] 77 72 76 83 79 82 87 83 86 PKU 3 2500 R22 ti = +5°C Air flow volume [m3/h] No.of rows tin[°C] r.v.in[%] 34 45 32 40 4R 29 46 34 45 32 40 5R 29 46 34 45 32 40 6R 29 46 3250 tout[°C] 18.5 17.7 16.6 16.3 15.4 14.6 14.6 13.7 13.1 4000 tout[°C] 19.7 18.7 17.5 17.5 16.5 15.5 15.8 15.0 14.0 r.v.out[%] 75 70 74 81 76 80 85 81 84 Ratings for other modes of operation, refrigerants or evaporation temperatures available on request. Inlet and outlet connection sizes depend on cooling capacity and are available on request. 10 SOUND ATTENUATOR FEATURES SOUND ATTENUATORS FAN NOISE ABSORPTION BY UNIT CASING The sound attenuator performance [dB] at a specific frequency is showed in the following table: The sound power level of fans LW(A) (“A” scale) measured in a free field at a distance of d = 1 m can be read off from the fan diagrams. Length [mm] 600 900 Length [mm] 600 900 Length [mm] 600 900 63 2 3 63 4 5 63 4 5 125 5 7 PKU 1 Frequency [Hz] 250 500 1000 2000 4000 8000 12 12 19 20 17 11 15 15 23 24 20 15 125 5 9 PKU 2 Frequency [Hz] 250 500 1000 2000 4000 8000 12 12 15 10 7 7 19 20 22 14 10 9 125 5 9 PKU 3 Frequency [Hz] 250 500 1000 2000 4000 8000 12 12 15 10 7 7 19 20 22 14 10 9 The data specified apply to a free air suction and escape into the ventilating duct. The fan noise absorption by means of the unit casing may be calculated according to the formula: Lw1 (A) = Lw (A) - R R values (dB) may be found in the table attached. Noise absorption by means of the unit casing at a distance of 1 m in front of the unit (according to DIN 52210): 63 11 125 12 Frequency range [Hz] 250 500 1000 2000 4000 8000 13 15 25 26 26 26 proKLIMA 13 ELECTRICAL DATA 11 ELECTRIC HEATER Type Air volume V[m3/h] Capacity Q[kW] Temperature rise ∆tZ[°C] PKU 1 PKU 2 PKU 3 1500 2500 4000 11 17 26 22,0 20,0 19,5 Supply voltage 230 V or 400 V / 50 Hz. Heaters may be activated in 1 - 6 stages or continuously (on request). Installation of other (higher) electric heater power available on request. ELECTRIC MOTOR Type PKU 1 PKU 2 PKU 3 Electric power 300 W 1000 W 550 W 2«550 W No. of poles 4 2 4 4 Supply voltage 230 V 50 Hz 230 V 50 Hz 230 V 50 Hz 230 V 50 Hz Mechanical Max. air Thermal protection temperaprotection class ture DA IP44 60°C DA IP20 40°C DA IP44 60°C DA IP44 60°C Max. current 2,6A 8,5A 6,0A 2«6A Speed regulator type RVM 3 RT 10 RVM 9 RT 10, RT 12 NOTE: Frequency regulator available (on request). WIRING DIAGRAM 12 TO THE CABINET TO THE CHAMBER STAGE 1 STAGE 2 STAGE 3 Symbols: FV VAR INT KV - manual switch - speed regulator - switch (ON/OFF) - fan switch K1 - time relay KR 1-4 - heater element contactors Th - step-by-step thermostat P - pressure differential cut-out0 FR 1-4 - heater fuses BSC - overheat control (limit thermostat) STAGE 4 14 CEILING-MOUNTED AIR-HANDLING UNITS - PKU Series 12 TENDER TEXT (example) Ceiling-mounted air-handling unit, type PKU 3 SP-5, external plastic coating (with ceiling suspension brackets). Dimensions: WxHxL = 665 x 1440 x 3080 mm System: CORRIDOR 1. FLOOR Technical specifications: EXHAUST (DISCHARGE) SOUND ATTENUATOR 600 mm long • flexible connection • damper (electric-motor drive on/off) • sound attenuation at 250 Hz FILTER, class G3 PLATE RECUPERATOR • with spare inserts • filter dirt control: inclined pressure gauge 0-500 Pa • fresh/return air flow volume V = m3/h • fresh air temperature/relative humidity tzul/rv = °C/% • pressure drop on the air side dpzr = Pa • return air temperature/relative humidity tzizl/rv = °C/% • pressure drop on the air side dpzr = Pa • heat recovery coefficient h=% • with by-pass installed (and droplet eliminator) ELECTRIC HEATER • electric heating capacity Qg = kW (- inlet/outlet air temp.) tzul/tziz = °C • heater actuation: stepwise (,continuously) HEATER • heating capacity • inlet/outlet air temperature • pressure drop on the air side • inlet/outlet temperature of medium • pressure drop on the water side • design: standard (,epoxy layer) Qg = kW tzul/tzizl = °C dpzr = Pa twul/twizl = °C dpw = Pa WATER COOLER • cooling capacity Qh = kW • inlet air temperature/relative humidity tzul/rv = °C/% • outlet air temperature/relative humidity tzizl/rv = °C/% • pressure drop on the air side dpzr = Pa • medium: water (30% glycol) • inlet/outlet temperature of medium twul/twizl = °C • pressure drop on the water side dpw = Pa • design: standard (,epoxy layer) • with droplet eliminator (• w/o droplet eliminator) FREON COOLER • cooling capacity Qh = kW • inlet air temperature/relative humidity tzul/rv = °C/% • outlet air temperature/relative humidity tzizl/rv = ˚C/% • pressure drop on the air side dpzr = Pa • refrigerant: R22 (R407C,...) • evaporation temperature ti = ˚C • design: standard (,epoxy layer) • with Droplet eliminator (• w/o droplet eliminator) FAN UNIT • air flow volume V = m3/h • external pressure drop dpext = Pa • total pressure drop dptot = Pa • design: standard (,explosion-proof, ...) • electric motor power Pm = kW • protection class: IP54 (,IP57) • (double-speed electric motor, triple-speed electric motor) • design: standard (explosion-proof, tropic, marine) (• prepared for frequency regulator) • with RVM 3 speed regulator (• with frequency converter) MIXING UNIT dB(A) proKLIMA 15 Our partners and representatives: proKLIMA Manufacture and installation of ventilation, air-conditioning and heating equipment Head: Talani 14, HR-10000 Zagreb, Croatia Office and Factory: Luje NaletiliÊa 10a, HR-10020 Zagreb, Croatia Phone: +385 1 / 6546-343 Fax: +385 1 / 6546 - 344 Email: proklima@proklima.hr Internet: www.proklima.hr PB-PKU03-ENG