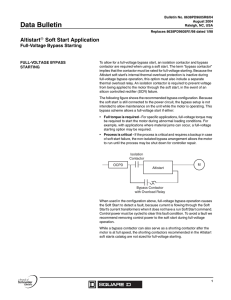

SED2 VFD Electronic Bypass Options Operating

advertisement