GQFN Package Data Sheet | UTAC Semiconductor Packaging

GQFN Package Data Sheet

UTAC offers the next generation in leadframe packaging: Grid Array Quad Flat No-Lead (GQFN). A revolutionary package that is capable of providing the highest I/O density of any lead frame based package technology. GQFN uses routable technology to produce cost effective lead frame packaged devices in the smallest possible footprint while providing superior electrical and thermal performance. GQFN is a fully customizable technology that provides a solution to restrictions in package design rules and enables manufacturers to shrink die sizes and benefit from the latest fab technology. On a 10x10 footprint, GQFN is capable of offering 200 or more I/O as compared to the current limitation of 100 I/O on a 10x10 QFN design. GQFN offers the freedom of design to create an unlimited variety of packages, and can support stacked die, multi-chip, and passive component attach capability using flip chip and/or wirebond interconnection. For devices currently targeted for 2-layer laminate BGA, WLCSP, or QFN, designers can consider the potential for better performance, smaller footprint, and lower cost that may be achieved using GQFN.

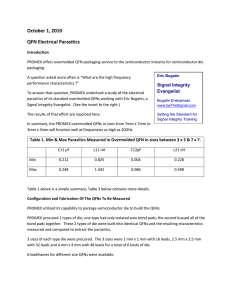

Electrical Performance Advantages

• GQFN uses routing (including under the die) to increase I/O counts and achieve package sizes of die plus 1 mm

• Has the freedom of design to create an unlimited variety of packages and land patterns

• Reduces package footprint by as much as 85% and total wire used by up to 75%

• Supports stacked die, multi-chip and passive component attachment using flip chip and / or wirebond.

• Dramatically reduces total signal lengths over QFP or QFN

• Delivers MSL-1 not achievable in substrate based packages

Typical Applications

• HDD/ DVD motor control, low power amps, power mgmt

• High-speed networks

• RF applications / telecommunications (WiFi, Bluetooth)

• Keyboard touchpad interface, audio DAC’s

• Microcontrollers (MCU)

• Standard logic, analog and mixed signal ICs

Package footprint comparison:

GQFN

QFP

(Footprint 144 sq mm)

QFN

(Footprint 81 sq mm)

GQFN

(Footprint 25 sq mm)

GQFN Process Flow

Features

• Body sizes up to 10 mm SQ

• Lead counts up to 268 I/O

• 0.40, 0.50 and 0.65 mm pitch available

• Package thickness down to 0.4mm max

• Package stand-off provides self-centering during SMT

• Strip-testable (no additional processes required)

• Bussless designs, no exposed copper on sidewalls

• Standard assembly materials, equipment and processes

• Can be customized per customer requirements

Metal frame

Partial etch and plating

Die attach, and wire bond

Encapsulation

Etch back

Insulation Mold and final package www.utacgroup.com

GQFN Package Data Sheet

Cross section: After Etch

Cross section: After Insulation Mold

GQFN Before Insulation Mold GQFN After Insulation Mold

Reliability

• Preconditioning (J-STD-20D.1) MSL-1

• Temp Cycle (JESD22-A118, Cond. C (-65 to 150 ° C)

• High Temp. Storage (JESD22-103 & A113) 150 ° C

• Unbiased Temp./Humidity (JESD-22A118) 130 ° C/85%

RH

Standard Materials

• Leadframe: High Conductivity copper alloy

• External lead finish: Solder coat, solder ball, Ag or Cu OSP

• Die attach: Non-electrically conductive

• Mold compound: Halogen-free

• Marking: Laser

• Packaging: Tray

Moisture Sensitivity Level

UTAC’s GQFN package is capable of MSL-1 per JEDEC standard J-STD-020 on body sizes up to and including 10x10mm. MSL-1 packages have unlimited floor life provided the environmental conditions do not exceed 30˚C and 85% RH. As a result, bake and dry pack are not required.

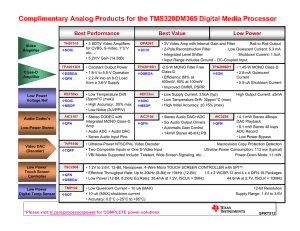

I/O Density Comparison:

2x2 mm

Die Size

44L 5x5 mm DR-QFN

60L 5x5 mm TLA

3x3 mm

Die Size

32L 5x5 mm QFN

36L 5x5 mm TLA

4x4 mm

Die Size

N/A

5x5 mm QFN

N/A

5x5 mm TLA

100L 5x5 mm GQFN 88L 5x5 mm GQFN 64L 5x5 mm GQFN

Note:

GQFN packages are constructed with standard materials and can be designed to meet your special packaging requirements. To learn more about GQFN please visit www.utacgroup.com

and download the application notes from our technical library.

Edition: Q12015, rev A

GQFN Body Size and Leadcount Options

pitch

2x2

3x3

4x4

5x5

6x6

7x7

8x8

9x9

10x10

96

132

72

96

144

Max. die size = body size - 1mm Max. die size = body size - 2mm

0.65mm

0.5mm

0.4mm

0.65mm

0.5mm

0.4mm

9

16

36

60

16

36

52

68

25

44

68

84

---

---

---

64

---

---

64

88

---

49

88

112

84

100

116

132

148

108

124

148

164

188

80

112

128

160

176

112

136

160

184

204

148

172

208

232

268