Optimal Thermal Design of Forced Conwection Heat Sinks

advertisement

Optimal Thermal Design of Forced

Conwection Heat Sinks-Analytical

R. W. Knight

Assistant Professor.

J. S. Goodling

Professor.

D. J. Hall

Graduate Student.

Mechanical Engineering Department,

Auburn University,

Auburn, AL 36849

For fully developed flow in closed finned channels used to augment heat transfer,

there exists an optimal geometrical design of the size and number of cooling channels.

In this paper, the problem is generalized with a statement of dimensionless thermal

resistance in terms of

9

the number of channels

9

a fin to channel thickness ratio

8

the length to width {planar dimensions) ratio of the heat source, and

9

a specified fin efficiency or fin length

9

a fluid to fin thermal conductivity ratio

9

the Prandtl Number of the coolant

8

a dimensionless pressure term, which incorporates the maximum allowable pressure

drop through the cooling channels or alternatively,

9

a dimensionless work rate term, which incorporates the maximum allowable coolant pumping power required,

An optimization scheme is described and used for comparison with two previously

published cases wherein both designs were restricted to afixedfin to channel thickness

ratio and laminar flow; one by Goldberg (1984) using air and copper and a second

one only by Tuckerman and Pease (1981) for water-cooled Silicon wafers. Results

from the present optimization scheme show that upon reexamination of the first

study by Goldberg, significant reduction of thermal resistance can be obtained

by using fin/channel dimensions other than unity. A similar reduction is found in

the second instance (Tuckerman and Pease) with the relaxation of the laminar

limitation.

1

Introduction

For over a decade, efforts have been expended to provide

innovative methods of heat removal from increasingly powerful electronic circuits. The methods used and being investigated are summarized in the recent book by Bar-Cohen and

Kraus (1990).

The present work is inspired by a technique devised by Tuckerman and Pease in 1981, which used very narrow channels

etched onto the backside of a silicon wafer. Designed for optimal performance subject to some constraints (pressure drop,

planar dimensions, fin efficiency, etc.) with laminar flow in

mind and for water as the coolant, these authors made a test

section which achieved a flux level of 790 W/cm2 with a maximum temperature rise of 71 °C. Their pioneering work is invariably referenced in successive papers on microchannel

cooling.

Goldberg (1984) built and tested an air cooled narrow channel heat sink. Three different fin thicknesses were considered,

with the channel thickness always made equal to the fin thickness. All cases were restricted to laminar flow. The pressure

drop across each device was adjusted to provide an air flow

rate of 30 liters per minute. The lowest thermal resistance was

Contributed by the Electrical and Electronic Packaging Division for publication in the JOURNAL OF ELECTRONIC PACKAGING. Manuscript received by the

EEPD August 27, 1990; revised manuscript received June 25, 1991. Associate

Editor: W. Z. Black.

found from the design with the smallest channel width and the

highest pressure drop.

Sasaki and Kishimoto (1986) optimized the dimensions of

channels at a given pressure loss through the water cooled fins

in a silicon chip. Again, the criterion of fin to channel thickness

ratio of unity was invoked. The analysis matched the experimental results well, however, the former is not presented. The

optimal channel thickness was found to be at 340 /xm for a

pressure drop of either 200 or 2000 kg/m2.

Hwang et al. (1987) designed a novel cooling package which

places the cooling channels just beneath and parallel to the

heat source. This design, which differs considerably from the

fin concept of Tuckerman and Pease where the channels are

perpendicular to the source, was suggested in an earlier work

by Tuckerman (1984, Fig. 2-7, p. 36). For Hwang's design,

the fluid dynamics of the channel flow dominate the fin effects.

A two-dimensional conduction analysis was performed with

boundary conditions at the solid/liquid interface which used

either laminar or turbulent convective correlations. Channel

dimensions were systematically varied over a limited range of

Reynolds numbers (1100 to 1600 for laminar flow and 12,000

to 13,000 for turbulent flow) and over a large pressure range

from 13.1 to 682.4 kPa (1.9 to 99 psi).

Nayak, Hwang et al. (1987) followed the previous cited work

with experiments using the designs chosen above for a multichip module. Coolant flows were regulated so the convection

Journal of Electronic Packaging

SEPTEMBER 1991, Vol. 113 / 313

Copyright © 1991 by ASME

Downloaded 25 Dec 2011 to 160.75.22.2. Redistribution subject to ASME license or copyright; see http://www.asme.org/terms/Terms_Use.cfm

Ap

thermal conductivity to present appropriate dimensionless parameters and to examine trends for the simplest of geometries.

This is followed by an analysis for the more realistic case of

finite fins, where the problem cannot be optimized analytically.

/I

insulation

^ ^ ^ ^ ^ ^

2

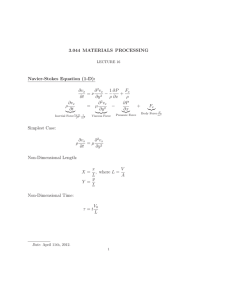

Fig. 1

Schematic of heat spreader with infinitesimally thin fins

in the channels was clearly in either the turbulent or laminar

flow region and, as expected, the former gave lower thermal

resistance than the latter.

Phillips (1990) recently authored an article in which he reviews recent works as well as his own on microchannel heat

sinks. Extensive discussion is offered on the influencing effects

(simplifying assumptions, properties, friction factors, viscous

dissipation, developing flow, etc.) and quantifies many of these

parameters with a computer solution of the governing thermal

resistance equation. Most results are presented in the form of

thermal resistance as a function of channel width with all other

parameters predetermined and specified, including the fin to

channel thickness ratio. For the test case discussed, turbulent

flow is shown to provide a lower value for thermal resistance

than laminar flow.

This paper generalizes the optimization method for sizing

coolant channels for any scale heat sink (spreader), be it microscopic or macroscopic in size. Furthermore, the restrictions

of laminar flow and fixed fin to channel thickness ratio are

lifted. The first section deals analytically with a highly simplified model that includes infinitesimally thin fins with infinite

Model

The structure under study is shown in Figs. 1 and 8. It

consists of a flat rectangular energy source whose cooling is

enhanced by the addition of multiple parallel fins closed at the

tips with a cover plate and with a coolant forced through the

array. In a design setting, the size and circuit power are constrained. Therefore, in addition to the physical dimensions of

width (W) and length (L), the rate of thermal energy to be

removed (q) is fixed. Furthermore, the pressure drop across

the fin array (Ap) would be a predetermined value due to

specified pump or air handler. The usual assumptions for this

type of analysis are made (steady state, constant properties,

adiabatic end plate, two-dimensional analysis, and fully developed). It is recognized that the last item is not usually true

for microchannels and that the heat transfer and frictional

losses are larger for developing flow. For very narrow channels

when n is large, the flow could be laminar. Conversely, the

flow could be turbulent. The problem here is to design channel

dimensions so the thermal resistance is a minimum.

The thermal spreader can be analyzed as two-dimensional

flow through narrow channels with the thermal boundaries

held at either constant temperature or constant flux. Figures

2 and 3 display the temperature profiles through the heat sink

for the two cases analyzed here. It is probable that the true

solution lies somewhere between these two boundary conditions. However, results shown later indicate that the two solutions yield quite similar results.

Using standard descriptors and nomenclature of heat exchangers where the wall temperature is constant in the streamline direction, the following equations are applicable (Incropera

and DeWitt, 1990):

q = mcp[Tft0-Tfi,]

(1)

Nomenclature

A

area

cp

constant pressure specific

heat

C\, C->

coefficients defined by

Eqs. (57) and (65)

D = depth of heat sink, see

Fig. 1

D„ = hydraulic diameter of

fluid flow channel

/ = friction factor, (Ap/L)Dh/

(pU2m/2)

G = a parameter defined by

Eq. (38)

h = heat transfer coefficient

k = thermal conductivity

I = channel width

L = length of heat sink in the

direction of fluid flow

flP,fin 1/2

m =

Kfin^4c,fin

m = total mass flow rate of

coolant through channels

n = number of cooling channels

N&p = pressure difference number,

(Ap/L)W3/(pv2)

•Nwork = work rate n u m b e r ,

wW/(pvl)

3 1 4 / V o l . 113, SEPTEMBER 1991

7i

Nu = Nusselt number, hDh/kan[i

Ap = pressure drop through the

heat sink channels

P = perimeter

Pr = Prandtl number, v/a

<7 - heat source power

Rec„ = Reynolds number based

on hydraulic diameter

^ t l a m = laminar Stanton number,

Nu(L/W)/(NApPr)

Stturb = turbulent Stanton number,

(L/W)/(N)&?T2n)

T = temperature

AT = largest temperature difference between coolant and

source

fluid velocity

uVm == mean

volumetric flow rate

w = pumping power

W = width of heat sink

a = thermal diffusivity of

fluid

n> 73 = coefficients defined by

Eqs. (37), (49), and (59)

of fin thickness to

r = ratio

channel width

i) = fin efficiency

V = kinematic viscosity of

fluid

mass density

thermal resistance, AT/q

Q = dimensionless thermal reAT

sistance, — : —

q

P

=

e=

fcfluidW

Subscripts

c = cross sectional available

for flow

c,fin = cross sectional of fin

/ . ' = fluid inlet

f,o = fluid outlet

h = hydraulic

H = constant flux case

lam = laminar

opt = optimal

optJam = optimal laminar case

opt-turb = optimal turbulent case

^ = surface available for heat

transfer

s,i = surface at the fluid inlet

face

S,0 = surface at the fluid outlet

face

turb = turbulent

T = constant temperature case

Transactions of the ASME

Downloaded 25 Dec 2011 to 160.75.22.2. Redistribution subject to ASME license or copyright; see http://www.asme.org/terms/Terms_Use.cfm

CI)

V—

•*-•

T

s

T

s

crj

1—

CD

Q.

T

E

CD

T

fo

CD

*™

td

i_

AT

AT

CD

Q.

E

'f,o

CD

f,i

\i

Length

Fig. 2

Length

Constant temperature walls

(T s - 7),0) = (T s - 7),,)exp( - hAs/mcp)

Fig. 3

(2)

Upon defining thermal resistance as the largest temperature

difference between source and coolant (TSi0 - 7},,) divided by

the electrical power of the source, these two equations are

combined to form thermal resistance as

A dimensionless thermal resistance 0 =

q = hAs[TSJ- 7),,] = hAs[Ts,0 - 7>,0]

q = mcp[Tf,0-Tfi,]

(4)

(5)

Using the same procedure to define thermal resistance in terms

of the largest temperature difference between source and coolant (Ts<0- Tf,d, Eqs. (4) and (5) are combined to form thermal

resistance as

0 = A7 y^

*+J_

(6)

hAs mCp

2.A

Infinitesimally Thin Fins (Partitioning Walls)

2.A.1 Laminar Flow. With the use of several common

heat transfer groups, the equations for thermal resistance are

simplified.

• In this problem, no characteristic velocity is specified.

However, the friction factor based on hydraulic diameter

can be manipulated to define one as:

2(Ap/L)Dh

2Ap/LDh 1/2

Va,b)

/=

Um =

pU2m '

pf

For very narrow channels, the laminar friction factor for

fully developed flow is 9 6 / R e ^ .

• The Nusselt number (hDh/kaaii). For fully developed laminar channel flow, it achieves constant values of 8.24 and

7.54 for the constant flux and constant temperature cases,

respectively.

• The Prandtl number {v/a).

Further, when two groups are introduced, Eqs. (3) and (6)

are made dimensionless.

• A laminar Stanton number with L/W included

I Stiam =

— ) . The Stanton number is normally de\

NApPr Wj

fined as Nu/RePr, but in this case NAp (defined below)

takes the place of the Reynolds number .(L/W) is included

for the sake of notational brevity.

A dimensionless pressure drop number, NAp

(Ap/L) W3

. This group is similar to the friction factor.

pv

It arises since, rather than velocity, the pressure drop is

dictated by the fluid handler (pump or fan).

Journal of Electronic Packaging

AT

Using this definition of dimensionless thermal resistance, Eqs.

(3) and (6) are now concisely rewritten respectively as:

1

• AT/q = —

(3)

mcp[\ - exp( - fiAs/mcp)]

This heat sink can also be modeled as though the coolant

experiences a nonvarying flux of energy as it progresses through

the channel. Again using the nomenclature of constant flux

heat exchangers,

Constant flux walls

a.

\2rf

NApPr(D/W)

[l-exp(-12Stian,«4)]-'

for constant temperature

(8)

\2n

[1 +1/(12 St l a m « 4 )]-'

~'NApPr(D/W)

for constant flux

(9)

l

©la

The minima of (8) and (9) are found to occur, respectively,

when

12 Stlam/z4= 1.256

for constant temperature

(10)

12 Stiamn4 = 1.000

for constant flux

for

(11)

It is noteworthy that the two models yield values of n

for lowest thermal resistance which differ by only [1.256/

1.000]<1/4) or about 6 percent. This suggests that the choice of

the model (constant temperature or constant flux) is of little

consequence.

For the case of laminar flow through narrow channels, the

lowest temperature rise of the hottest portion of the circuit is

obtained by partitioning the width approximately into n channels where

(12)

« = (12St lam ) ( - 1 / 4 )

This means that once the physical (W, D, L) and system

(<y, A/?) parameters and the fluid (with properties p, v, a, k,

cp) are chosen, if the flow is constrained to be laminar, which

sets the Nusselt number, then the minimum thermal resistance

occurs when n is determined by Eq. (12). Once n is determined,

Reynolds number based on hydraulic diameter must be calculated and shown to be less than the critical Reynolds number

(~ 2300) for laminar flow. For the problem at hand, this means

that

Reiam = N A / /(6« 3 )<2300

(13)

2.A.2 Turbulent Flow. The procedure above is now repeated for the turbulent analysis. Here the friction factor,/,

for fully developed flow in smooth channels (Incropera and

DeWitt, 1990) becomes

(/ = 0.316 Rej,"

1/4)

(14)

The Nusselt number is no longer a constant but its value can

be obtained through the Chilton-Colburn analogy

Nu

/

(15)

1

8 RePr,1/3

'

The dimensionless group hAs/mcp becomes for the turbulent

case

SEPTEMBER 1991, Vol. 113 / 315

Downloaded 25 Dec 2011 to 160.75.22.2. Redistribution subject to ASME license or copyright; see http://www.asme.org/terms/Terms_Use.cfm

1.5

Optimal

Laminar Solution

•

-

Optimal

/ ^

Turbulent Solution

0.5

Turbulent

'%

Transilion

-

-10'°

20

40

60

Laminar

,

I

80

100

120

n

n!?mh-, ^ll^LTil*!°nlefs'h0ermal

resistanpes as a function of the

1.5

Optimal

Turbulent Solution

by choosing n from Eqs. (19) or (20). Reynolds number based

on hydraulic diameter must then be found and shown to be

greater than the Reynolds number (~ 4000) which assures turbulent flow and allows proper use of these equations. For the

problem at hand, this means that

Optimal

Laminar Solution

\

^

1

~~~~—-—_!_____

optjaminar

Fig. 6 R a t i o o f d i m e n S ionless thermal resistances as a function of the

number of channels for W i p = 1012

Ret„rh =

9

2A

- 4,12/7

^4000

(21)

•

0.5

Turbulent

N

1

AP= °

Transition

where 9.42 is (2 16 /0.316 4 ) 1/7 .

In cases where the resulting Reynolds number is less than

4000, Eq. (21) with Re turb = 4000 must be solved for n to find

the best available turbulent solution.

Laminar

8

10

i

i

20

30

40

n

Fig. 5 Ratio of dimensionless thermal resistances as a function of the

number of channels for AVAp= 108

0.045 {L/W)nh

(16)

< 7 Pr 2/3

Again for the sake of notational brevity, Stturb, defined as (L/

W)/(NXH Pr 2/3 ), is introduced and Eqs. (3) and (6) simplify

after non-dimensionalization for constant temperature and

flux, respectively, to:

hAs/mcp

-

„5/7

«*°~

0.21,1'

[1 - e x p ( - 0.045 St turb H 10/7 )r

N%Vr(D/W)

0.21« 5

©turb —

NfJPr(D/W)

[1 + 1/(0.045 St t u r i y 0 / 7 )]

(17)

(18)

Noting that 0.316 is the coefficient of the friction factor Eq.

(14), the constant 0.21 is determined from (0.316 4 /2 9 ) 1/7 while

0.045 is found from (0.316 8 /2 18 ) 1/7 . Optimization of thermal

resistance with respect to n for the turbulent cases yields

0.045 Stturbn10 = 1.256 for constant temperature

(19)

and

0.045 St turb n 10/7 = 1.000 for constant

flux

(20)

These four equations ((17) through (20)) are similar to their

counterparts for the laminar development above, both in form

and the exponential power of n in the two competing terms

(one is the square of the other). The latter comes about as a

result of the surface and cross sectional area dependencies on

n. What was said about the significance of these equations for

laminar flow applies here also.

As for laminar flow, once the physical and system parameters and the fluid are chosen and the flow is constrained to

be turbulent, then the minimum thermal resistance is obtained

316 / Vol. 113, SEPTEMBER 1991

2.A3

Laminar or Turbulent Flow. It is now possible to

combine results from the constant flux cases above and provide

a procedure which minimizes thermal resistance without imposing either the laminar or turbulent flow condition. This

procedure is shown by use of an example in which 7VAp is fixed

at a realistic value of 1010. This value corresponds to the cooling

of a 5 cm by 5 cm heat source with room air at a pressure

drop of about 1 kPa (or 5 inches of water) through the heat

spreader. Equations (9) and (18) for laminar and turbulent

cases are normalized against the thermal resistance occurring

for the optimal laminar case (Eq. (9) with the solution to Eq.

(11) inserted) and plotted as a function of discrete number of

channels in Fig. 4. Several observations are made:

• turbulent flow occurs at 63 or fewer channel (n found

from Eq. (21) for Re = 4000)

• laminar flow occurs at 90 or greater channels (« found

from Eq. (13) for Re = 2300)

• 6oPt_turbuient °r optimal turbulent thermal resistance occurs

at n = 70 channels (solution of equation (20))

• ©opt_iaminar or optimal laminar thermal resistance occurs

at n = 92 channels (solution of equation (11))

Designing a device for operation in the transition zone of

Reynolds numbers between 2300 and 4000 (63 < n < 90) should

be avoided since the flow is not characterized as being either

laminar or turbulent. For the case at hand, a heat sink with

70 channels should not be used. The best design incorporates

63 channels where the flow is certainly turbulent. Lifting the

constraint of laminar flow from the problem gives a turbulent

thermal resistance which is 12% lower than that for the best

laminar case (« = 92).

Two other examples are presented for the same values of

L/W and Prandtl number but differing NAp. For the case of

a low NAp (108), Fig. 5 shows that the best laminar case (n = 29)

produces a thermal resistance which is 30 percent better than

the best available turbulent case (« = 13). At7V Ap =10 12 , Fig.

6 indicates the best laminar solution is not available. Equation

(12) yields n = 293 for the best laminar case, but Eq. (13) reveals

that this occurs at Re = 6626, well into the turbulent region.

Transactions of the ASME

Downloaded 25 Dec 2011 to 160.75.22.2. Redistribution subject to ASME license or copyright; see http://www.asme.org/terms/Terms_Use.cfm

1000

:

:

1E-03

. . - • " • ' "

" " ^

^_^^J 1E-04

^ \

opt lam

100

'opt

/I

c

500

200

Ap-

insulation

^^^S^^^^^^^m^^^^^

I

1E-05

20

optjurb

10

y.

^ ^ ^ \ •'

Laminar Turbulent

5

1E+08

i

1E+09

1E+10

1E+11

1E-06

1E+12

W

flow

Fig. 8 Schematic of heat spreader with finite fins

Fig. 7 Optimal number of channels and dimensionless thermal resistances as a function of W4n

The trend here is that for a given L/WanA fluid, there exists

a value of NAp above which turbulent flow thermal resistance

is lower than that for laminar flow and below which the opposite is true. If the design is restrained to laminar flow for

some reason such as noise or erosion, there is an optimal

number of channels which minimizes thermal resistance. If

turbulence is allowed, the optimal design may be either in the

laminar or turbulent regime depending on NAp. This point is

expressed by use of Fig. 7 where the optimal number of fins

is shown as a function of NAp over the realizable range of

values for fixed L/W=\,

D/W=\ and Pr = 0.71. The discontinuity in the nopt line which occurs at about 109 is due to

the avoidance of solution in the transition zone

(2300<Re<4000). Below NAp = 2x 1010, the optimal n found

from the solution of Eq. (20) results in Re< 4000. Hence, Eq.

(21) is solved for «opt_tUrb with Re = 4000. For NAp>2x 10fo

Eq. (20) yields the optimal number of channels for Reynolds

number greater than 4000. Here Eqs. (19) and (20) can be

solved to show that «0pt_turb is proportional to NApw,°, whereas

it is proportional to NApl when Eq. (21) is used. The best

dimensionless thermal resistance is also plotted on that figure.

It is noted that four orders of magnitude change in NAp results

and only two orders of magnitude change in 9 .

2.B

Finite Fins (Partitioning Walls)

Overview. A more realistic model includes fins of finite

thickness. Figure 8 defines the geometric parameters of this

model. For this configuration there are n channels and n— 1

fins. The two effects resulting from the use of the finitely thick

fins are a reduction of cross sectional flow area for fixed overall

geometry (D and W) and the introduction of an influential

fin efficiency. The same assumptions are made here regarding

properties, steady state, entrance effects, etc. as were made in

Section 2.

To the previous list of fixed quantities must now be added

the fin thermal conductivity, k(in. The variables to be determined by optimization are the number of channels and the

channel (/) and fin (IV) thicknesses. As in the previous problem, the problem is constrained by specifying the pressure drop

through the heat spreader. In addition, the fin length or fin

efficiency is limited due to space considerations. If the problem

is constrained solely by maximum pressure drop, resulting

optimal designs could require, due to very high volumetric

flow rates, pumping power comparable in magnitude to the

rate of thermal energy to be removed from the heat source.

Therefore, the problem could be further inhibited to a specified

maximum pumping power. As before the formulation is made

concise and general by non-dimensionalizing the thermal resistance equation and expressing it in terms of dimensionless

parameters.

Journal of Electronic Packaging

Geometrical Factors. Figure 8 shows the geometry of the

heat spreader being analyzed. V is the ratio of fin to gap

thickness. The following four Eqs. (22)-(25) are strictly geometric. They describe respectively the hydraulic diameter of

one channel, the cross-sectional area available for flow in the

system, the aspect ratio for one channel, and the surface area

available for heat transfer.

D„ =

2W

T(n-\)+W/D

n+

nWD

n + T(n-l)

W/D

l/D =

n + T(n-V)

Ae =

nWL

+

As = n + Y(n-\)

2r,DL(n-l)

(22)

(23)

(24)

(25)

The first term of (25) is the area available for heat transfer at

the base and between the channels; the second is the effective

fin area, with fin efficiency accounted for. The tip ends of the

fins are assumed to be insulated, as are the two outer sides of

the array.

Dimensionless Groups.

group introduced earlier,

In addition to the pressure drop

NAp =

(Ap/L)W3

(26)

pv1

a dimensionless form of pumping work is also required.

Nwork=

wW

pv

f

(27)

This problem can be driven by specifying a maximum pressure

loss value, NAp. With that limitation alone, it is possible that

the best solution will occur when the ratio of pumping work

to heat source power is larger than unity, a clearly undesirable

solution. The use of Nmrk will be demonstrated in Section 3.

The relationship between NAp and N work is

W work

knmiW

Ap

WPr

(28)

One Dimensional Fins. Invoking the usual notation associated with one dimensional fins with a constant heat transfer

coefficient, the following relation defining m is useful.

hPn

kfm ^4c,fin

2h

(29)

%rT7

For the approximate equality, it has been assumed that the

length of the fin is much more than its thickness, L> >Tl.

From the definition of N u ^

SEPTEMBER 1991, Vol. 113 / 317

Downloaded 25 Dec 2011 to 160.75.22.2. Redistribution subject to ASME license or copyright; see http://www.asme.org/terms/Terms_Use.cfm

NUj,, kg

(30)

h=-

Dh

Use of Eqs. (22), (24), and (30) in Eq. (29) yields the following.

n + Tin

imDf^u^

ZT

W/D

kf\n

W/Dn+ {

l TW/D

:^ l)

(3D

An infinitely long fin of constant cross-sectional area, with

constant heat transfer coefficient and heat transfer in one

dimension will transport heat through it equal to q!\n,«<7fin,oo = [h Pfia ^fin^cfin]

[Tbase

—

Tfluid]

(32)

A fin of finite length D with an insulated tip, still assuming

one dimensional heat transfer and constant h, will transfer

heat through it equal to <jfi„.

?fin= [hPtinknnACi[in]W2tanh(mD)[Tbaxrnuid]

(33)

Under these constraints, an infinitely long fin will transfer the

greatest amount of heat possible, for a given h, PSin, Acjin, kSm

and T b a s e - 7>luid. Division of Eq. (33) by Eq. (32) reveals that

a fin of finite length with an insulated tip will transfer tanh

(m D) of the heat that an infinitely long fin will transfer.

The efficiency of a fin with one-dimensional heat transfer,

constant convective heat transfer coefficient and an insulated

tip is

tanh (m D)

V=

n

(34)

m D

In this analysis, the percent of infinite fin efficiency is chosen

as a design constraint. It should be recognized that when fins

are in the 90 percent efficiency range, an increase of several

percent efficiency could require a considerable lengthening of

the fin.

Dimensionless Thermal Resistance. For an array of channels and fins as seen in Fig. 8, where the heat source is one of

constant flux at the base of the fins, the dimensional thermal

resistances are the same as for the array with infinitesimally

thin fins, equation (6).

hA

mc„

(6)

mc„

(35)

Traditionally, the first term in 8 is known as the convective

resistance and the second term has been called the caloric

resistance. The latter will be referred to as the capacity term,

a phrase more appropriate to modern heat exchanger terminology. These two terms will now be represented by the above

named dimensionless parameters for laminar and turbulent

flow.

Flow Characterization

2.B.1

Laminar Flow

Capacity Term. For fully developed flow in a channel, the

friction factor is defined by

/=

2(Ap/L)D„

pU2m

(36)

For laminar f l o w , / i s given by

/=

7i

Re Dh

(37)

The value of 71 is determined by the aspect ratio of the rectangular channel. A parameter G is defined as suggested by

Bejan, 1984.

3 1 8 / V o l . 113, SEPTEMBER 1991

Equation (39) yields results which agree with exact values (Kays

and Crawford, 1980) to within 3 percent. For a fixed l/D, Eq.

(38) gives G, (39) gives 71, a n d / i s determined from (37).

Combination of Eqs. (36) and (37) with the definition of

Reynolds number and solution for mean velocity yields the

following relationship.

U„ =

2ApD,,

(40)

jiLvp

From the definition of Reynolds number, Eq. (40) and Eq

(22), the Reynolds number for laminar flow is

2 ApW3

7i Lpv2 n +

Re

Dh-

(41)

Y(n-l)+W/D

Use of the definition presented in Eq. (26) yields

Re'Dh

7i

n+

(42)

T(n-l)+W/D

for laminar flow.

Since the mass flow rate, m, is equal to p Ac Um, use of

Eqs. (22), (23) and (40) reveals the capacity thermal resistance

in laminar flow

yt(n+T{n-\)+W/D)2(n

NApVrD/Wn

^fiuid^

mc„

+

T(n-\))

(43)

Substitution of Eq. (43) into Eq. (28) yields the relationship

between geometry, pressure drop and pumping work for laminar flow.

=

With the definition of dimensionless thermal resistance as before, (6) becomes

hA,

(l/D)2+\

(38)

(i/D+iy

Note that G is invariant to an / to D transformation. This

means that an aspect ratio of l/D gives the same G as an aspect

ratio of D/l, as it should. Performance of least squares fit of

a straight line in G to available values for 71 yields the result

that

(39)

7 l = 18.80 + 78.57 G.

G=

i

work

7l

N\P(D/W)n

[n + Y(n-\)+W/D]2[n

+ T(n-\)]

L_

W

(44)

Convective Term. The Nusselt number for fully developed

laminar flow in a rectangular channel is also a function only

of aspect ratio of the channel. Use of the same parameter G

defined in Eq. (38), a least squares fit to the exact values

available gives

Nu Z 3 / „ / / =-1.047 +9.326 G

(45)

Nu Dh,T = -1.681 + 9.139G

(46)

NuDjiiH is the Nusselt number which results from a boundary

condition of constant heat flux around the channel and Nu BA>r

results from a constant temperature of the channel wall (Kays

and Crawford, 1980). These equations agree with analytical

results to within 3 percent. For this study, Nu flfr// is used to

be consistent with the thermal resistance model.

Equation (31) can be rewritten as follows.

(D/W)2+(D/W)

n+

1

T(n-l)

(mD)2T

2=0

NuflA knuili/kfm[n + T (n - 1)]

(47)

NuD/] in the above equation is found from Eq. (45), and it

should be noted that NuflA is a function of n, T, and D/W.

The convective component of thermal resistance is found

from the definition of Nu fl/| and Eq. (25) as

Transactions of the ASME

Downloaded 25 Dec 2011 to 160.75.22.2. Redistribution subject to ASME license or copyright; see http://www.asme.org/terms/Terms_Use.cfm

AW

hAs

2.B.2

HuDh (n + T(n-l)+W/D)[n

n + T(n-\)

+ 2r1(D/W)(n-l)(n

Low Reynolds Number Turbulent Flow

Capacity Term.

factor is given by

2.B.3

For turbulent flow in channels, the friction

/=72Re5 A

1/

(49)

where y2 is 0.316. Equation (49) is valid, according to Incropera

and DeWitt (1990), for fully developed flows with turbulent

Reynolds numbers up to 20,000. This relation is valid, according to White (1974), for ducts of any cross section, as long

as the ducts are not too thin. The mean velocity in turbulent

flow in a channel is found by combination of Eqs. (36) and

(49).

2 Ap

72 L n +

u„,=

2W

T(n-l)+W/D

1

(50)

pv

From the definition of Reynolds number

Re

<

Dh-

1

T(n-l)+W/D

?

n+

(51)

Use of the relationship between mass flow rate and mean

velocity yields the capacity component of thermal resistance

in low Reynolds number turbulent flow.

l5/7

5

[n + T(n-l)][n + T(n-l)+

W/D]

9

U1

{2 /y$) Ntp Pr n (D/W)

knuidW

m cp

(52)

^ Mvork

(2V^)'

[n + T(n-l)][n

/7

~.

< n (D/W)

+ T(n \)+W/Df

W

/ ^ p „ l / 3

7=73Re^1/

1

Y(n-\)+W/D

n+

hA„ " "M/2

Pr'

(55)

(mDfT

m

?r

(k

nuii/klin)ln

NTP

n

+

T(n-\)\

(57)

Combination of the definition of Nu/)A, Eq. (55) and Eq. (25)

yields the convective component of thermal resistance for low

Reynolds number turbulent flow.

iW

1

T(n-\)+W/D

(61)

[n +

T(n-l)][n+T(n-l)+W/D)2n

(2 /yl) N5A/p9Prn(D/W)

,1

i/9

(62)

Convective Term. From the Chilton-Colburn analogy, Eq.

(54), an expression for the Nusselt number in high Reynolds

number flows is found.

1/9

A

1

n+

T(n-Y)+W/D

Substitution of Eq. (63) into Eq. (31) yields

NuDft =

<

2"

9

(D/W)1 - (D/W)[n + T(n-\)]C2-C2

Pr 1

(63)

=Q

(64)

where

(mD)2T

n U9

hl/2 ] K

9

P r " 3 ( W * n n ) [n + T (n - 1)]

(65)

The convective component of thermal resistance for high Reynolds number flows can also be found.

+

T(n-l)])]

(66)

Solution Procedure

Generally, the overall size and configuration of the heat

source to be cooled is known. The material from which the

fins are to be made is usually known, from weight, economic

and other considerations. As discussed above, the fraction of

infinite fin performance can be specified and space or weight

considerations can set a maximum allowable value for fin

length. Identification of a cooling fluid and a nominal oper-

[[n +

V(n~l)]+W/Df

' [y2/29}ulN\npWn(L/W)[7,(n-l)(D/W)+n/(2[n

Journal of Electronic Packaging

n+

3

(56)

where

hAs

N Ap

mc„

{[n +

T(n-l)]+W/D]1

(L/W)[v(n-l)(D/W)+n/(2[n

(D/W)s - (D/W) [n + T (n - l)]Q - Q = 0

(y\/2y

^ =

knMW

11,1/99 ».,4/9p r l i

' N:

2W

T(n-\)+W/D

The relation between mean velocity and m reveals that

C2 =

Substitution of Eq. (55) into Eq. (31) gives

C,=

2_Ap

73 L n +

1

(60)

1/5

pv

From the definition of Reynolds number it is found that ReDh

takes the following form for high Reynolds number flows.

Um =

Substitution of Eqs. (49) and (51) into (54) yields

N Ap

(59)

The value of 73 is 0.184. The use of Eq. (49) for Reynolds

numbers up to 20,000 and the use of Eq. (59) for Reynolds

numbers greater than 20,000 leads to a discontinuity in / at

20,000. This was considered to be unacceptable. Equations

(49) and (59) have identical / values at a Reynolds number of

49,820. In this study, Eq. (49) was used to determine / for

Reynolds numbers up to 49,820, and Eq. (59) was used for

values greater than that. The maximum difference in/values

predicted by the two equations for Reynolds numbers between

20,000 and 49,820 is less than 5 percent.

As in low Reynolds number flow, Eq. (59) and Eq. (37) are

combined to find the following expression for mean velocity.

(53)

(54)

Nu^-Re^Pr

(48)

Capacity Term. Equation (49) is traditionally cited as being

valid for turbulent flows whose Reynolds numbers are less

than 20,000 (Incropera and DeWitt, 1990). For high Reynolds

numbers, the following relationship is given.

/7

Convective Term. To find the heat transfer coefficient in

turbulent flow, the Chilton-Colburn analogy between friction

factor and heat transfer coefficient is used. The analogy is

given by Incropera and DeWitt (1990) in the following form.

Nu Dh~

T(n-l))](L/W)

High Reynolds Number Turbulent Flow

R e

Substitution of Eq. (52) into Eq. (28) gives the relationship

between geometry, pressure drop and pumping work for a

given cooling fluid in low Reynolds number turbulent flow.

+

+ T(n- 1)])]

(58)

SEPTEMBER 1991, Vol. 113 / 319

Downloaded 25 Dec 2011 to 160.75.22.2. Redistribution subject to ASME license or copyright; see http://www.asme.org/terms/Terms_Use.cfm

ating temperature range gives fluid properties. A maximum

pressure drop available across the array is often known. Additionally, the amount of pumping work to be expended to

cool a device is prescribed. Therefore values of NAp and A^ork

can be computed from Eqs. (26) and (27), respectively. The

dimensionless quantities oiL/W, D/W (maximum), k!m/kf\u\i,

Pr and {m D) can also be computed. Once these parameters

are known, the governing equations above can be used to find

the optimal design in terms of the smallest thermal resistance.

The number of channels, n, and the ratio of fin thickness

to channel thickness, Y, are systematically varied through a

wide range of values. For a given n and Y:

3.A

3.A.I.

Solution in the Laminar Region

Solve Eq. (44) for NAp and Eq. (47) for D/W simultaneously. If either NAp or D/W is greater than the

maximum allowable value, use trje appropriate maximum.

3.A.2. Calculate the Reynolds number using Eq. (42). If ReD/i

is greater than 2300, the geometry under examination

will not yield laminar flow, so skip to 3.B.

3.A.3. Calculate the thermal resistance using Eq. (43) and

(48) in Eq. (35). If this 9 is lower that any previously

calculated G, save n, Y, 0 , D/W, NAp and other appropriate values.

3.B Solution in the Low Reynolds Number Turbulent

Region.

3.B. 1. Solve Eq. (53) for NAp and Eq. (56) for D/W simultaneously. If either NAp or D/W is greater than the

maximum allowable value, use the appropriate maximum.

3.B.2. Calculate the Reynolds number using Eq. (51). If ReD^

is less than 4000, the geometry under examination will

not yield completely turbulent flow, so go to 3.B.4.

If ReC/i is greater than 49,820, the geometry under

examination will not yield low Reynolds number turbulent flow, so skip to 3.C. If R e ^ is between 4000

and 49,820, proceed to 3.B.3.

3.B.3. Calculate the thermal resistance using Eqs. (52) and

(58) in Eq. (35). If this 0 is lower than any previously

calculated 0 , save n, Y, 0 , and other appropriate

values.

3.B.4. Change n or Y and return to step 3.A.

3.C Solution in the High Reynolds Number Turbulent

Region:

3.C1. Solve Eq. (63) for NAp and Eq. (65) for D/W simultaneously. If either NAp or D/W is greater than the

maximum allowable value, use the appropriate maximum.

3.C.2. Calculate the Reynolds number using Eq. (61). If ReflA

is less than 49,820, the geometry under examination

will not yield high Reynolds number flow, so skip to

3.C.4. If ReD/i is greater than 49,820, proceed to 3.C.3.

3.C.3. Calculate the thermal resistance using Eqs. (62) and

n

Case I

Goldberg (/ = 0.127 mm)

Present Study

Same pressure drop, Ap

Same pumping power, w

Case II

Goldberg (/ = 0.254 mm)

Present Study

Same pressure drop, Ap

Same pumping power, w

Case III

Goldberg (/ = 0.635 mm)

Present Study

Same pressure drop, Ap

Same pumping power, w

320 / Vol. 113, SEPTEMBER 1991

r

(66) in Eq. (35). If this 0 is lower that any previously

calculated 0 , save n, Y, 0 , and other appropriate

values.

3.C.4. Change n or Y and return to step 3.A.

In this study, n values ranging from 2 to 500 channels and

F values ranging from 0.01 to 2.0 are considered. In this manner, the optimal design for laminar and turbulent flow are

found.

4

Results

The results obtained here are applied to two previous studies:

one by Goldberg (1984) with a copper thermal spreader and

air as the coolant; and another work by Tuckerman and Pease

(1981) with water-cooled silicon fins. In both studies, the fin

to channel thickness ratio was set to unity and only laminar

flow was considered. Use of the present optimization scheme

shows that upon reexamination of the cases studied by Goldberg, significant reduction of thermal resistance can be obtained by using fin/channel dimensions other than unity. A

similar reduction is found to be true for the case investigated

by Tuckerman and Pease with the relaxation of the laminar

limitation.

4.A Goldberg (1984)

Goldberg designed, built and tested systems fashioned from

the design procedure of Tuckerman and Pease (1981). The size

of the square heat source was 0.635 x 0.635 cm (1/4 x 1/4 in.)

with fins fixed at 1.27 cm (1/2 in.) length and a fin to channel

thickness ratio equal to unity. The Nusselt number was chosen

to be constant at 8 and the flow constricted to laminar. Air

was the coolant and the material for the heat spreader was

copper. Properties were evaluated at room temperature. Futher,

the design by Goldberg hinged on a constant volumetric flow

rate of 30 liters/min., thus fixing the capacitance component

of thermal resistance. An "average" value of 0 c a p(=l/

2mcp) was used, whereas the total capacitance value (0CaP= 1/

mcp) is used here. For a fixed flow rate of 30 liters/min,

Goldberg's value of 0cap (0.9 C/W) corresponds to 1.8 C/W

for comparison purposes in this paper. Goldberg did not optimize the design, but rather chose three values of fin and

channel thickness of 0.127, 0.254 and 0.635 mm (5, 10 and 25

mils) for his experiments. In the present study, all conditions

and properties were maintained the same as those of Goldberg;

however, the fin to channel thickness ratio and the nature of

the flow were allowed to vary. Comparisons are shown below

for all the three cases investigated by Goldberg. In each instance, the optimization scheme described above was used by

fixing either the pressure drop through the device or the power

consumed by the fan at the same value set by Goldberg. In

every case for these low pressures, the minimum thermal resistance was found in the laminar regime. NAp varied from

5 . 5 x l 0 6 to 1.34 x10 s for Cases I and III. As identified in

Section 4. A.3, laminar solutions are better than turbulent ones

in this low NAp range. The last column quantifies the improvement in thermal resistance, A6.

Ap

kPa(in H 2 0)

vv,

Watts

V

1/min

25

1

1.17(4.68)

0.583

30

24

20

0.435

0.39

1.17(4.68)

0.73(2.92)

1.747

0.583

89.9

48.2

12.5

1

0.29(1.17)

0.146

30

18

20

0.316

0.39

0.29(1.17)

0.26(1.06)

0.239

0.146

49.2

32.8

5

1

0.047(0.19)

0.024

30

12

15

0.25

0.32

0.047(0.19)

0.075(0.30)

0.018

0.024

22.4

19.1

Ad,

%

32.4

15.4

18.4

11.4

38.6

46.2

Transactions of the ASME

Downloaded 25 Dec 2011 to 160.75.22.2. Redistribution subject to ASME license or copyright; see http://www.asme.org/terms/Terms_Use.cfm

In the three cases above, the optimal design occurs with T

considerably below a value of unity: the fins are thin compared

to the channel width. In case I and case II, there is some penalty

for optimization in the form of added flow rate, yet the total

pumping power still is relatively small in comparison with the

heater power. In case III, for the same pressure drop, a reduced

flow rate of about 50 percent leads to a reduced thermal resistance of nearly 40 percent.

ixm. wide, separated by fins of 191 /*m thick and 442 pm in

depth. These data are not shown in the above table.

It is recognized that entrance effects on both friction and

heat transfer could influence the results presented herein. Care

should be exercised to restrict the use of these results or procedures to cases where fully developed flow exists in the channels.

4.B Tuckerman and Pease (1981)

A comparison is made below between the results of Tuckerman and Pease (1981) and the present analysis. In the former,

very narrow channels were etched onto the backside of a silicon

wafer for use as coolant passageways. Designed for optimal

performance subject to laminar flow and for water as the

coolant, these authors made a test section with a designed

thermal resistance of 0.086 C/W.

*

It can be seen from the calculated values of the capacity and

convective thermal resistance terms, that relaxation of the Y

5

Constraints

Size, Length (L) by Width (W)

pressure drop, Ap

fin efficiency, 77

Coolant

Fin Material

fin to channel thickness ratio, V

Nusselt Number

type of flow

71, laminar friction factor

Dimensionless Groups

L/W

maximum N&p

maximum jVwork

Calculated Results

n, number of channels

Depth, D, (im

Fin thickness, fim

Channel thickness, y.m

Reynolds Number

Volumetric Flow Rate, cm3/sec

Aspect Ratio

Nusselt Number

Yi, laminar friction factor

NAp

^"work

Capacity Thermal Res, C/W

Convective Thermal Res, C/W

Total Thermal Resistance, C/W

Reduction in thermal resistance

Tuckerman

and Pease

1 cm x 1 cm

206.8 kPa (30 psi)

76%

water

Silicon

1

6

laminar

96

Present Study

same

same

same

same

same

unrestricted

unrestricted

laminai• or turbulent

a funct ion of aspect ratio

1

2.82 X 10'°

3.62 x 10'3

same

same

unrestricted

88

365

57

57

730

11

6.4

6

96

2.82 x 10'°

3.62 x 10'3

0.022

0.064

0.086

Laminar

83

357

60

61

834

12.4

5.8

5.9

77.8

2.82 X 10'"

4.08 X 10'3

0.019

0.058

0.077

10.5%

constraint results in a reduction of both terms for the laminar

case. When turbulent flow is allowed, these terms are reduced

by 40 and 75 percent from those for the laminar analysis. The

wide channels found for the best turbulent solution allow, for

fixed pressure drop, a greatly increased mass flow, thereby

reducing the capacity term. Comensurately, the heat transfer

coefficient increases due to the presence of turbulence.

The overall thermal resistance for the turbulent solution is

reduced by 34 percent from that of Tuckerman and Pease

whose design was confined to laminar flow. A maximum pressure drop of 206.8 kPa (30 psi) is common to all three cases,

but there was no need to place an upper limit on pumping

power in the present case. By doing so, the power consumed

is raised by a factor of 2.5 over that of Tuckerman and Pease,

from 2.27 Watts (corresponding to 11 cmVs flow rate at 206.8

kPa, or 30 psi) to 5.77 Watts. When compared to the maximum

power of the electronic device (-790 Watts), the pumping to

circuit power ratio is still less than 1 percent.

If instead of the pressure drop through the device, the pumping power is limited to a maximum of 2.27 Watts, a reduction

in thermal resistance of 13 percent is realized by lifting the

laminar restriction. However, the pressure drop through the

channels for the optimal turbulent solution is found to be 39

percent of the Tuckerman and Pease laminar case, or 79.2 kPa

(11.7 psi). For this solution, there are 24 channels, each 234

Journal of Electronic Packaging

Future Work

The authors are currently testing two microchannel heat

spreaders designed along the guidelines of Tuckerman and

Pease; one optimized for performance in the laminar zone and

one for peak performance with turbulent flow. In addition,

the same effort is being made for macrochannel heat spreaders

of dimensions 5 cm by 5 cm using aluminum and water and

large heat sinks designed for optimal use with air. The modeling

equations are also being modified to include entrance effects.

Results will be reported in later publications.

Turbulent

33

319

134

173

4006

27.9

1.85

35.8

not applicable

2.82 x 10'°

9.19 x 1013

0.009

0.048

0.057

33.7%

References

Bar-Cohen, A., Kraus, A. D., 1990, Advances in Thermal Modeling of Electronic Components and Systems, Volume 2, ASME Press, New York, N.Y.

Bejan, Adrian, 1984, Convection Heat Transfer, Wiley, New York, N.Y.,

pp. 75-82.

Goldberg, N., 1984, "Narrow Channel Forced Air Heat Sink," IEEE Transactions, Components, Hybrids and Manufacturing Technology, Vol. CHMT,

No. 1, pp. 154-159.

Hwang, L. T., Turlik, I., and Reisman, A., 1987, " A Thermal Module Design

for Advanced Packaging," Journal of Electronic Materials, Vol. 16, No. 5, pp.

347-355.

Incropera, F. P., and DeWitt, D. P., 1990, Fundamentals of Heat and Mass

Transfer, Wiley, New York.

Kays, W. M., and Crawford, M. E., 1980, Convective Heat and Mass Transfer,

McGraw-Hill, New York.

Nayak, D., Hwang, L. T., Turlik, I., and Reisman, A., 1987, "A HighPerformance Thermal Module for Computer Packaging," Journal of Electronic

Materials, Vol. 16, No. 5, pp. 357-364.

Phillips, R. J., 1990, "MicroChannel Heat Sinks," Chapter 3 of Advances in

thermal Modeling of Electronic Components and Systems, Volume 2, Ed. by

A. Bar-Cohen and A. D. Kraus, ASME Press, New York, N.Y.

Sasaki, S., and Kishimoto, T., 1986, "Optimal Structure for Microgrooved

Cooling Fin for High-Power LSI Devices," Electronics Letters, Vol. 22, No.

25, pp. 1332-1334.

Tuckerman, D. B., 1984, "Heat Transfer Microstructures for Integrated Circuits," S.RC Technical Report No. 032, SRC Cooperative Research, Box 12053,

Research Triangle Park, NC 27709.

Tuckerman, D. B., and Pease, R. F. W., 1981, "High-Performance Heat

Sinking for VLSI," IEEE Electron Device letters, Vol. EDL-2, No. 5, pp. 126129.

White, F. M., 1974, Viscous Fluid Flow, McGraw-Hill, New York.

SEPTEMBER 1991, Vol. 113 / 321

Downloaded 25 Dec 2011 to 160.75.22.2. Redistribution subject to ASME license or copyright; see http://www.asme.org/terms/Terms_Use.cfm