Electric Heaters

advertisement

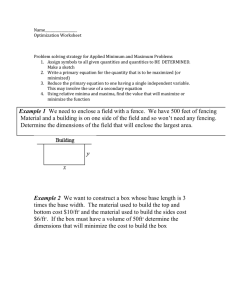

Hotwatt, made in USA, is a quality supplier to oem’s in the industrial, medical, commercial, packaging, instrumentation, aviation, transportation and military fields. Contents Basics of Electric Heaters The simplest definition of an electric heater is any device that changes electrical energy into heat energy. But from that simple explanation, electric heaters explode into a myriad of types, sizes, applications, and designs depending upon what’s being heated, the degree of heating needed, and the method by which the heat is applied. The measure of electrical energy is called the Joule after its discoverer, James Prescott Joule. Through numerous experiments, Joule determined that the quantity (Q) of heat transferred from electrical energy is proportional to the square of the current (I 2 ) multiplied by the resistance (R) for the period of time (t) through which it passes: Q ∝ I2 × R × t However, one seldom sees a reference to Joules used in modern Instead, Q ∝ I 2electric × R × circuits. t the controlling factor P =becomes I 2 × R that of power (P): P = I2 × R A = πD × h or 6π × 5 = 941/4 in2 You’llS note the only difference between the formula for determining power and that of determining Joules is the time component.2 AS =factor πD ×inhheating or 6π becomes × 5 = 941/4 in The time readily ×c× �Fhot when apparent in any devicemthat gets W= an electric current flows through 3.412 × T it: its temperature rises as time passes. m × c × �F W= Types of heaters 3.412 × T Heaters come in Wmany = WL/SFdifferent × A styles and configurations, each design optimized Sponsored by Hotwatt W = WL/SF × A m ×H Types of heaters …1 Transfer of heat …2 Heat losses …2 Basic heat equations …3 Specific applications …3 An application example …4 for a specific application. The selection of a heater depends on the material being heated, the heater style, the sheath material that surrounds the heating element and protects it from the material being heated, and the operating voltage of the heater. Styles of heaters include strip, ring, rope and cable, cartridge, tubular, band, immersion, circulation, process air and duct, radiant, comfort, flexible, tote, and drum. The style of heater chosen depends on the application. The type chosen depends on the heated object’s shape, size, and mass, as well as performance requirements. For example, band heaters work best on cylindrical object such as tanks and pipes. Cartridge heaters are typically inserted in close fitting holes in large blocks of metal 1 Watt density …5 Presented by March 2013 Type of heater …1 Basic heat equations …3 An application example …4 Watt density …5 Hotwatt manufactures cartridge, air process, immersion, strip and finned strip, tubular, band, foil, flexible glasrope®, crankcase and ceramic heaters. such as platens and molds. And immersion heaters may, as their name implies, be immersed directly into the material being heated. As added protection, an immersion heater may use a heat well, a protective device that isolates the heater from the material being heated but still allows heat transfer to the material. Heat wells also allow immersion heaters to be replaced without the need to drain the tank. Sheath materials can include steel, Incoloy, iron, silicone, Kapton, copper, ceramic, and glass overbraid among others to handle specific materials. The choice of sheath material depends upon the material being heated. infrared wavelengths, although that’s not the only frequency used. For example, microwave ovens use wavelengths many times longer than infrared to heat food while medical diathermy machines use even lower radio frequencies to warm parts of the human body. Electric heaters use all three methods to warm specific objects. Which of the three methods becomes the best choice depends upon the application. Transfer of heat When a body starts to generate heat, meaning its temperature rises above that of other nearby objects, it is called a heat source. As its temperature rises, it starts to raise the temperature of the materials in its vicinity using any combination of three different methods. Those three methods are known as conduction, convection, and radiation. Conduction transfers heat energy from one material to another via direct contact. It is the most direct method of transferring heat energy, and is usually considered the most efficient: the highest percentage of heat energy created transfers to the colder object from the heat source. Convection also uses physical contact to transfer heat energy, but the contact entails the use of an intermediary gas, typically air. In convection heating, the heat source warms the gas. The warmed gas now weighs less per volume measure, producing a buoyancy effect. This buoyancy is easily seen in the flight of hot air balloons. The hot gas rises, creating convection currents that move the heated gas into contact with the colder objects, warming them. The now cooled gas flows back to the heat source where it is warmed again, and the process repeats. The third method of transferring heat energy, radiation, does not rely on any physical contact between the heat source and the object to be heated. Instead, heat energy is transmitted through space from the heat source to the object in the form of electromagnetic radiation: typically as Sponsored by Hotwatt Heat losses As stated previously, an object subjected to electric heating continues to become hotter as long as current passes through it until it reaches its burn out temperature and the heat source is destroyed. Obviously, when used properly modern electric heaters do not experience this burn out condition. The answer lies in heat losses, or the transfer of heat away from the heat source that keeps its temperature down. The term heat loss is typically reserved for heat energy transferred to undesired areas, but heat energy is also transferred to the desired point. All three methods of heat transfer can lead to heat losses. For example, a contact heater placed on the bottom of a container heats the contents of the container. The primary form of heat transfer is via conduction from the heater to the container and then its contents, but conduction losses can occur between the container and any supporting structure. As the container and heater are both in air, a convection heat loss occurs as air circulates around the container. In addition, a hand held one foot away from the side of the container can feel the radiated heat loss. Needless to say, the size of these objects also plays a considerable role. For a container the amount of radiated 2 March 2013 Type of heater …1 Hotwatt can also supply compatible accessory items to offer our customers a complete heater system. heat energy lost isQdetermined ∝ I 2 × R ×by t the outer surface area. Assume the container is a cylinder 6-in. diameter and 5-in. tall. The surface area of the container (AS) equals the circumference of the container (calculatedP as 2 = Ieither × R π times the diameter D, or 2π times the radius R) multiplied by its height (h): Transfer of heat …2 AS = πD × h or 6π × 5 = 941/4 in2 Just enlarging the diameter of the container by one inch means the surface area of the container increases by 15.7 in2, an almost 17% increase in surface area and thus heat loss.mWhen determining the size × c × �F W = needed to reach a specific of the heating element 3.412 × T temperature, all of these heat losses must be taken into effect. Q ∝ I2 × R × t Basic heat equations W = WL/SF × A It would appear at first that calculating all of the heat transfers and losses in a design would be a daunting task. Fortunately Q ∝ I 2 a×number R × t of equations were developed that help simplify this task. First the equations m ×H were divided intoWthree = tasks referred to as Equations A, 3.412 × B, or C: the wattage needed to Theat a material to a specific temperature in a given amount of time (Equation A); P = I 2 ×the R losses at operating the wattage needed to overcome 2 temperature (Equation special calculation needed Q B); ∝ I and × Ra × t WL/SF × A(Equation C.) × c × �F m to reach a melting or vaporizing point W= + Equation A 3.412 calculates × Tthe amount 2 of wattage2 (W) needed = πD × h ofora 6π × 5 =a specific 941/4 inamount in °F to raise the Atemperature material S (ΔF) in a given number Pof=hours I 2 × R(T), you first need to know the mass (m) of the material being heated and its specific heat m × c × �F2 WL/SF × A c ×value �F1 (c): m × Hf m× + +m × c × �F + W= 3.412 × T 2 3.412 × T 3.412 × W T = AS = πD × h or3.412 6π ××5T = 941/4 in2 cylindrical objects as well as the top surface losses from a horizontal surface laid flat. Curve B shows the average heat loss from the and×Qbottom ofR × a×horizontal laid AStop = πD h∝or 6π 5t = 941/4 surface in2 I2 × flat while Curve C shows the heat loss from the bottom only of a horizontal surface laid flat. The final equation, Equation C, determines the additional wattage necessary for melting or vaporizing a 2 P =mI × ×c × R �F material. Whenever a W material changes state, whether from = 3.412 a solid to liquid, or liquid to gas, × it T requires an additional influx of energy to initiate the change. The heat needed to melt a solid material is known as 2 AS =of πD × h (Hf or 6π × 5 the = 941/4 the latent heat fusion ) while latentinheat of W = WL/SF A vaporization (Hv) determines the×energy needed to change a substance from a liquid to a vapor. The equation for both is identical, with the value of Hf or Hv substituted as necessary for the value H: m × c × �F W= m ××HT 3.412 W= 3.412 × T ) ( Sponsored by Hotwatt 3 ) March 2013 Watt density …5 The mass and specific heat of some materials may be found on our Web site at: www.hotwatt.com/table1.htm for metallic solids, table2.htm solids W = for WL/SF × A other than metals, and 320 in.3 ×table3.htm 2 × 0.284for = certain 181.7 lb ×m0.12 BTU/lb/°F × (400-70)°F Again, m is the weight of the material in lb, while T is liquids gases. ×and c× �F = 2,110 W W = the heat-up time in hours. The values Equation3.412 B calculates the amount of wattage (W) needed 3.412 × T W= W × A for the latent heat of × 1hr fusion or vaporization can beL/SF found in the same look-up to maintain the temperature of a material based upon its WL/SF × A c × �F m × A. tables used in Equation known wattage loss per square foot (WL/SF) multiplied by W= + 3 area (A) in square feet: m ×H 3.412 × T 2 = 270 in.the × 2 × 0.286 = 154.5 W =lb × 0.12 BTU/lb/°F × (400-70)°F = 1,800 W 3.412 × T Specific applications W = WL/SF × A 3.412 × 1hr m ×H To heat a liquid requires W = additional energy due to losses 3.412 × T by adding half of The wattage loss per square foot is found for specific by evaporation. This is usually covered materials in tables located at www.hotwatt.com/heatloss.htm. themwattage to maintain the m material’s WL/SF × A × c × �Ftemperature m× Hf × c × �Fneeded 2 1 + 5.6 lb × 0.55 BTU/lb/°F × Metal (400-70)°FW (Equation + heating period +(Equation ×A WL/SF A sample table is shown Uninsulated B) to that of its initial ==300 W × �F from m × c(Losses 3.412 × T 2 3.412 × T 3.412 × T m× = some materials +H have Surfaces). NoteWthat different A): 3.412 × 1hr W =×T 3.412 2 three 3.412 × T A represents the WL/SF × A curves identified as A, B, or C. Curve m × c × �F W = + heat losses from vertical surfaces of tanks, pipes, and other 3.412 × T 2 An application example …4 ( P = I2 × R WL/SF × A= 320 in.3 × 2 × 0.284 = 181.7 lb × 0.12 BTU/lb/°F × (400-70)°F c ×A�F2 (10×8×4) m × c × �F1 10 × 4m××4H+ f 8 × 4W ×m4×× W = WL/SF × A Hotwatt is a quality supplier to oem’s in the industrial, medical, commercial, Q ∝ I × R × t m ×H packaging, instrumentation, aviation, W= 3.412 ×fields. T transportation and military Type of heater …1 2 P = I2 × R WL/SF × A m × c × �F + To heat a solid to a liquid state temperature requires 3.412three × T different2calculations. First, use the solid calculation W= (Equation A) from the initial temperature of the material to its melting point. Then add in the wattage needed to AS = πDC). × hFinally, or 6πuse × 5the=equation 941/4 in2 for a liquid material from its melting point to the transition from solid to liquid (Equation final temperature: W= m × Hf m × c × �F1 + + 3.412 × T 3.412 × T W × c × �F + ( m3.412 ×T L/SF 2 ×A 2 ) Transfer of heat …2 m × c × �F For example, you want to raise the temperature W = of solid lead from a room temperature of 70°F to a molten 950°F. × Tlead is 620°F. That makes the first change in temperature, From Table 1 on our Web site, the melting point3.412 of solid ∆F1, equal to 620° - 70° or 550°F. The second change in temperature, ∆F 2, equals 950° - 620° or 330°F. (10×8×4) = 320 in.3 × 2 × 0.284 = 181.7 lb × 0.12 BTU/lb/°F × (400-70)°F An application example Basic heat equations …3 W= Watt density …5 = 2,110 W W =3.412 WL/SF × ×A A steel mold is being used to form polyethylene parts.1hr Every hour 90 ounces of nylon is introduced to the mold. The mold itself measures 10 × 8 × 4 in. The mold is attached between two stainless steel platens, each measuring 15 × 12 × 1.5 in. thick. The platens are=insulated press=mechanism with BTU/lb/°F 0.5 in. thick (15×12×1.5) 270 in.3 from × 2 ×the 0.286 154.5 lb × 0.12 × insulation. (400-70)°FOperating temperature 1,800 W of the mold is 400°F and must reach this temperature in 1 hour from an ambient temperature of=70°F. 3.412 × 1hr From Table 1: Properties of Metals m ×H W= Specific heat of steel: 0.12 BTU/lb/°F 3.412 × T Specific heat of stainless steel: 0.12 BTU/lb/°F 5.6 lb × 0.55 BTU/lb/°F × (400-70)°F Converting cubic inches into pounds (density lb/in2) = 300 W 3.412 × 1hr WL/SF × A m × c × �F + 3.412 × T 2 From Table 2: Properties of Non-Metallic Solids 10 × 4 × 4 + 8 × 4 × 4 = 2 ft2 × 350 W/ft2/hr Specific heat of polyethelyne: 0.55 BTU/lb/°F 144 in.2/ft2 W m × c × �F + ( 3.412 × T 1.5 × 15 × 4 + 1.5 × 12 × 4 × c Heat × �F1 Lossesm × Hf m for From Graph 1: Guide + + W= Heat losses curves: A + 3.412 B @ 400°F ×T 3.412 × T 2 ×A 2 ) = 1.1 ft2 × 350 W/ft2/hr = 385 W 144 in.2/ft2 Equation A: Wattage required for heat-up L/SF = 700 W To heat the mold: 15 × × 2 - BTU/lb/°F (10 × 8 × 2)× (400-70)°F (10×8×4) = 320 in.3 × 2 × 0.284 = 181.7 lb12 × 0.12 = 1.3 ft2 × 250 W/ft2/hr = 350 W = 2,110 W 144 in.2/ft2 3.412 × 1hr To heat the platens: × 12 × 2 × (400-70)°F 2 (15×12×1.5) = 270 in.3 × 2 × 0.286 = 154.5 lb × 0.1215 BTU/lb/°F = 2.5 ft2 × 100 W/ft /hr W = 250 W = 1,800 144 in. 3.412 × 1hr To heat the polyethelyne (90 oz / 16 oz/lb = 5.6 lb): (700W + 385W + 350W + 250W) × 0.20 = 340 W 5.6 lb × 0.55 BTU/lb/°F × (400-70)°F = 300 W 3.412 × 1hr Compensation Factor: 20% (2,101 + 1,800 + 300) × 0.20 = 840 W AS = 𝜋𝜋D × L Total wattage needed for heat-up = 5,050 W 2 3.1416 × 0.75 × 9 = 21.1 in 10 × 4 × 4 + 8 × 4 × 4 144 in. /ft 2 Sponsored by Hotwatt 2 = 2 ft2 × 350 W/ft2/hr 500W ÷ 21.1 in2 = 23.7W /in.2 1.5 × 15 × 4 + 1.5 × 12 4× 4 2 2 = 700 W = 1.1 ft2 × 350 W/ft2/hr = 385 W March 2013 = 1, Type of heater …1 (10×8×4) = 320 in. × 2 ×W0.284 = WL/SF=×181.7 A lb × 0.12 BTU/lb/°F × (400-70)°F = 2,110 3.412 × 1hr W 3.412 × 1hr ESTABLISHED HOTWATT IS A LEADER 5.6 lb × 0.55 BTU/lb/°F × (400-70)°F (15×12×1.5) = 270 in.3 ×IN 2 ×1952, 0.286 = 154.5 lb × 0.12 BTU/lb/°F × (400-70)°F = = 1,800 W m × H RESISTANCE HEATING IN MANUFACTURING 3.412 × 1hr W= 3.412 × 1hr 3.412 × TOVER ELEMENTS FOR 60 YEARS. 5.6 lb × 0.55 BTU/lb/°F × (400-70)°F = 300 W WL/SF × A 3.412 × 1hr 10 × 4 × 4 + 8 × 4 × 4 m × c × �F = 2 ft2 × 350 W/ft2/hr W= + 2 2 3.412 × at T operating2 temperature (See graphs: Guide for Heat Losses) Equation B: Wattage losses 144 in. /ft = Heat loss from mold (vertical surfaces) 1.5 × 15 × 4 + 1.5 × 12 × 4 10 × 4 × 4 + 8 × 4 × 4 = 1.1 ft2 × 350 W/ft2/hr = 2 2 = 2 ft × 350 W/ft /hr = 700 W m × c × �F2 WL/SF × A 2 2 m × Hf m × c × �F1 144 in. /ft + + +2 W= 144 in.2/ft 3.412 × T 2 3.412 × T 3.412 × T ) ( 144 in. /ft 2 2 Transfer of heat …2 Heat loss from platen (vertical surfaces) 1.5 × 15 × 4 + 1.5 × 12 × 4 15 × 12 × 2 - (10 × 8 × 2) = 1.3 ft2 × 250 W/ft2/hr = = 1.1 ft2 × 350 W/ft2/hr = 385 W 144 in.2/ft2 10in×the 4 ×mold 4 + would 8 × 4AS× =4𝜋𝜋D ×theL2 The number of holes dictate = 2 ft × 350 W/ft2/hr = 700 W 500W ÷ 21.1 in2 = 23.7W /in.2 2 the 2 wattage by the number of heaters required. Dividing 1443.1416 in. /ft × 0.75 × 9 = 21.1 in2 number of heaters will equal the wattage rating of each heater. Our Web site at www.hotwatt.com/watt.htm lists 1.5 × 15 × 4 + 1.5 × 12 × 4 2 suggested wattW densities for use with various materials. = 1.1 ft2 × 350 W/ft /hr = 385 Watt density 2 144 in. /ft2 ÷ 21.1 in2 = 23.7W /in.2 Safe values vary with operating temperature, flow 500W Watt density is the rated wattage of the heater divided velocity, and heat transfer rates. In general, the higher the by the overall area being heated. The watt density permitted material temperature, the lower the watt density should for any given application depends on how well the material be, especially those materials which coke or carbonize, 15 × 12 × 2 - (10 × 8 × 2) = 1.3 ft2 × 250 W/ft 2 350Watt W densities should be low if a material is being heated distributes its heat throughout its volume. such/hras = oils. 2 2 /ft 144 in. Water, light oils, and metals typically have high heat being heated to a temperature near the change of state checked. However, no responsibility for possible errors or omissions can be assumed. It is the express responsibility of the customer to determine the suitability of the product for the intended application and Hotwatt Inc. makes no claims or provides no guarantee in this respect, either written or applied. AS = 𝜋𝜋D × L 3.1416 × 0.75 × 9 = 21.1 in2 Then divide the wattage of the heater by the surface area: Sponsored by Hotwatt 500W ÷ 21.1 in2 = 23.7W /in.2 5 March 2013 An application example …4 distribution rates that permit the use of high watt densities. to a vapor occurs, such as water to steam at 212°F. The Heavy oils, syrups, hydraulic fluid, and other materials with vapor state has much poorer heat transfer capabilities 15 ×densities 12 × 2 to prevent low heat distribution need lower watt than 2 2 liquids, and a watt density chosen for a liquid might = 2.5 ft × 100 W/ft /hr = 250 W spot overheating. This can lead to damage of the heating be too great for a gas. 144 in. element, the well, and even the heated material. As an example, a 10 in. immersion heater is rated at 500 W. There is a 0.5 in. cold area at each end, making its total (700W + 385W + 350W + 250W) × 0.20 = 340 W heating length (L) 9 in. The diameter (D) of the heating area is 0.75 in. To calculate the watt density of this heater, first All information, data and dimension tables in this article have been carefully compiled and thoroughly determine the total surface area (AS) being heated: Basic heat equations …3 8×4) = 320 in.3 × 2 × 0.284 = 181.7 lb × 0.12 BTU/lb/°F × (400-70)°F = 2,110 W Heat loss from platen (horizontal surfaces, uninsulated) 3.412 × 1hr 15 × 12 × 2 15 × 12 × 2 - (10 × 8 × 2) = 1.3 ft2 × 250 W/ft2/hr = 350 W = 2.5 ft2 × 100 W/ft2/hr = 2 2 144 in. 144 in. /ft 12×1.5) = 270 in.3 × 2 × 0.286 = 154.5 lb × 0.12 BTU/lb/°F × (400-70)°F = 1,800 W Heat loss from platen surface) 3.412 (insulated × 1hr (700W + 385W + 350W + 250W) × 0.20 = 15 × 12 × 2 = 2.5 ft2 × 100 W/ft2/hr = 250 W 144 in. 5.6 lb × 0.55 BTU/lb/°F × (400-70)°F = 300 W Compensation factor: 20% 3.412 × 1hr = 𝜋𝜋D (700 + 385 + 350 + 250) × 0.20 W ×L (700W + 385W + 350W + 250W) × 0.20 ==A340 340 W S Total wattage losses at operating temperature = 2,025 W 3.1416 × 0.75 × 9 = 21.1 in2 Total wattage required for heat-up = 5,050 W Total wattage required = 7,075 W