Trim Flange Install Guide

advertisement

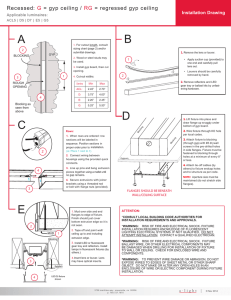

Recessed: XP = trim f lange Installation Drawing Applicable luminaires: ACL 5 | D5 | D7 | E5 | G5 | G6 A 1. Prepare the rough opening. GYP or TILE or SLAT 1 2. For cutout length, consult sizing chart (page 2) and/or submittal drawings. 1. Remove the lens or louver. 2 • Apply suction cup (provided) to one end and carefully pull lens out. 1 3. Cut-out widths: 3 ROUGH OPENING B Series Min Max ACL: 2.43” 2.68” D: 3.75” 4.00” E: 2.18” 2.43” G: 5.25” 5.50” • Louvers should be carefully removed by hand. 2 2. Remove reflectors and/or LED gear tray by unfastening hardware. As seen from from above C D Installation Option 1: Threaded Rod Rows: 1. When rows are ordered: row sections will be labeled in sequence. Position sections in proper order prior to installation. (ie: Place 1 next to 1). 2 1 LED Driver 2. Connect wiring between housings using the provided quick connects. 4 1 Slat, gyp or panel 3. Line up pins and bang extrusion pieces together using a mallet until no gap remains. 1 1. Use pre-drilled holes in top of fixture to attach a ¼-20 threaded rod (by others) and tie to structure. Draw fixture up snugly under bottom of ceiling slats/tiles and fasten with flange nuts (by others). Structure D5 2. Install LED or fluorescent gear tray and install lamps in fluorescent fixtures (by others). 3. Insert lens or louver. Lens may have optical inserts. 4. Secure extrusions with joiner brackets using a threaded rod or bolt with flange nuts (provided). 3 ATTENTION: E Installation Option 2: a·clamp 1. Apply clamp above each tophole location. Twist clamp to insert into rough opening. 2 LED Driver 1 Slat, gyp or panel D5 Use tie-off cables through endcap holes when blocking is not viable, such as amongst acoustic paneling. 2. Tighten 1/4-20 bolt (provided) to press together panels in between extrusion flange and clamp flange to keep panels from moving. 3. Install LED or fluorescent gear tray and install lamps in fluorescent fixtures (by others). 4. Insert lens or louver. Lens may have optical inserts. *CONSULT LOCAL BUILDING CODE AUTHORITIES FOR INSTALLATION REQUIREMENTS AND APPROVALS. *WARNING: RISK OF FIRE AND ELECTRICAL SHOCK. FIXTURE INSTALLATION REQUIRES KNOWLEDGE OF FLUORESCENT LIGHTING ELECTRICAL SYSTEMS. IF NOT QUALIFIED, DO NOT ATTEMPT INSTALLATION. CONTACT A QUALIFIED ELECTRICIAN. *WARNING: RISK OF FIRE AND ELECTRICAL SHOCK. FIXTURE BALLAST WIRE, OR OTHER ELECTRICAL COMPONENTS MAY BE DAMAGED WHEN DRILLING FOR INSTALLATION OF FIXTURE TO WALL OR CEILING. CHECK FOR ENCLOSED WIRE AND COMPONENTS. *WARNING: TO PREVENT WIRE DAMAGE OR ABRASION, DO NOT EXPOSE WIRES TO EDGES OF SHEET METAL OR OTHER SHARP OBJECT. DO NOT MAKE OR ALTER ANY OPEN HOLES IN AN ENCLOSURE OF WIRE OR ELECTRIC COMPONENT DURING FIXTURE INSTALLATION. 3728 mari time way ocean s ide , ca 9205 6 p. 760 .727 .767 5 a·light | © November 2014 Recessed: XP = trim flange Installation Drawing Applicable luminaires: ACL5 | D5 | D7 | E5 | G5 | G6 Notes Applicable Luminaires * Always consult submittal drawings (if applicable) for run length cut-outs as special lengths may have been ordered. * When ordering, note the difference between aperture length and cut-out length in areas with tight architectural constraints. * For staggered lamping, note that almost any target length is possible by varying stagger length and lamp size, so consult factory for special sizes. ACL5 Flange Dimensions D5 tile, slat or gypsum panel 0.30” 0.50” visible powdercoated D7 Sizing Chart for Cutout Lengths LED FIXTURES ROUGH OPENING MIN ROUGH OPENING MAX 2 23.250 23.500 3 34.750 35.000 4 46.250 46.500 5 57.500 5 .750 6 69.250 69.500 7 80.500 80.750 8 92.000 92.250 9 103.000 103.250 10 115.000 115.250 NOMINAL LENGTH 11 126.250 126.500 12 143.500 14 .750 13 155.000 155.250 14 166.250 16 .500 15 178.000 178.250 16 189.250 189.500 17 200.750 201.000 18 212.250 212.500 19 223.500 223.750 20 235.000 235.250 21 252.250 252.500 22 263.750 264.000 23 275.250 275.500 24 286.750 287.000 E5 G5 G6 a·light reserves the right to make improvements w w w. a l i g h t s . c o m