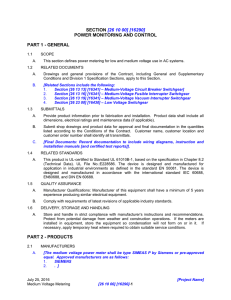

Specification – Technical Requirements for Ring Main Units (RMU

advertisement