generic document template

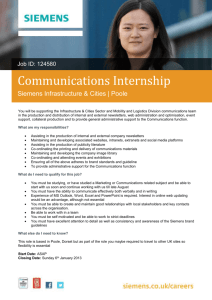

advertisement