IEC 60623 Ed 4 English Version

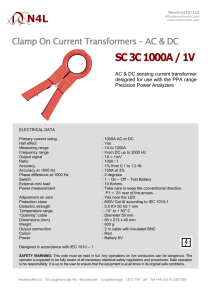

advertisement

Future 62XXX/Ed1/NP IEC(E) –1– 9/1884/NP 1 2 Foreword 3 4 5 This draft Standard was prepared by the Ad Hoc Working Group 10 of TC9, Electromechanical material on board of rolling stock, of Technical Committee TC 9, Electrical equipment and systems for railways. It is submitted to the IEC enquiry. 6 7 8 9 As grounding standards for Li-Ion industrial batteries (non-market specific, excluding road applications), 2 standards are under development or finalization (as per IEC SC21A meeting in th th Orlando on February 28 & 29 ): 10 11 12 IEC 62620: Secondary cells and batteries containing alkaline or other non-acid electrolytes – Large format secondary lithium cells and batteries for use in industrial applications, 13 14 15 IEC 62619: Secondary cells and batteries containing alkaline or other non-acid electrolytes – Safety requirements for large format secondary lithium cells and batteries for use in industrial applications. 16 17 18 19 20 21 In addition, an integration standard for all energy storage technology is useful, especially concerning the electrically connected ones. A call for expert had been issued in that direction, as mentioned in the TC 9 CAG Recommendation 14/02 decided on April 18th, 2012. The Japanese TC9 NC proposed convenor for this “NP on hybrid system with energy storage for rolling stock”. 22 23 24 25 It appeared that for EDLC type of energy storage units , the existing standardization has been already created and can support the introduction of those technologies and is already started. For Li-Ion batteries, although the battery part itself is under creation, a standard specifying the specific rules to be applied for rolling stock would be requested, as done for EDLCs. 26 27 28 29 30 The 1st Meeting of IEC/TC9/AHG7 on September 6th, 2012, in Erlangen, Germany, concluded, as per convenor report:(point 4) that “As for energy storage systems, application standards for traction batteries, flywheel, etc. are missing. Need of a new application standard of traction batteries, especially Lithium-Ion, for TC9 was identified.” 31 32 Therefore the current standard proposal was generated as per results of 9/1770/RQ 33 34 Inquiry, on 2013-01-18, to answer the need to define complementally specific requirements for Raiways considering: 35 on-board installation (for traction) as concluded at AHG7 36 “Railways adaptations” versus those general standards 37 38 39 This standard prIECxxxx shall be read in conjunction with PT 62864-1 “Railway applications – Rolling stock – Power supply with onboard energy storage system - Part 1: Series hybrid system”. 40 41 It should be mentioned that the auxiliary onboard battery type are not concerned in the present document. 42 This standardization project was derived from the EU-funded Research project CleanER-D. 9/1884/NP –2– Future 62XXX/Ed1/NP IEC(E) 43 44 It is part of a series of standards, referring to each other. The hierarchy of the standards is intended to be as follows in Railway specific area: 45 46 and is grounded on global standards dealing with industrial Li-ion batteries: 47 48 2 Future 62XXX/Ed1/NP IEC(E) –3– 9/1884/NP CONTENTS 49 50 51 INTRODUCTION ..................................................................................................................... 5 52 1 General ............................................................................................................................ 6 53 54 2 1.1 Scope ...................................................................................................................... 6 Normative references........................................................................................................ 6 55 3 Terms and definitionsr ...................................................................................................... 6 56 57 58 59 60 61 4 3.1 Battery state of charge (SOC) .................................................................................. 7 3.2 8 hybrid ............................................................................................................................... 8 3.3 8 hybrid system vehicle ........................................................................................................ 8 Abbreviations .................................................................................................................... 9 62 5 Parameter measurement tolerances ................................................................................ 10 63 64 6 Selection of the most railways relevant regulations applicable to Li-ion railways batteries ......................................................................................................................... 10 65 66 67 68 69 70 71 72 73 74 7 6.1 Mechanical ............................................................................................................ 10 6.2 Environment .......................................................................................................... 10 6.3 Electrical ............................................................................................................... 11 6.4 Integration ............................................................................................................. 12 6.5 Fire protection ....................................................................................................... 12 6.6 Safety .................................................................................................................... 13 6.7 Electromagnetic compatibility EMC ........................................................................ 14 6.8 Software ................................................................................................................ 14 6.9 Miscellaneous / Sundries ....................................................................................... 14 Designation and marking ................................................................................................ 15 8 Battery designation ................................................................................................ 15 Battery termination ................................................................................................ 15 Marking ................................................................................................................. 15 7.3.1 Nameplate ................................................................................................. 15 7.3.2 Cells, Battery-pack, Tray, crate or other nameplates inside the battery ....... 16 7.4 Safety recommendations ....................................................................................... 16 7.4.1 Safety signs ............................................................................................... 16 Storage and transportation conditions ............................................................................. 18 83 84 85 9 8.1 Transportation ....................................................................................................... 18 8.2 Storage of batteries ............................................................................................... 18 Dimensions ..................................................................................................................... 18 86 10 Electrical interface requirements ..................................................................................... 18 87 88 89 10.1 Communication ...................................................................................................... 18 10.2 Dead start battery .................................................................................................. 19 11 Sizing requirements ........................................................................................................ 19 90 91 92 93 94 11.1 Discharging requirements ...................................................................................... 20 11.1.1 Load profile ............................................................................................... 20 11.2 Requirements for battery sizing for emergency operations ...................................... 22 11.2.1 Long-time discharge .................................................................................. 22 11.2.2 Low temperature performance (if applicable) .............................................. 22 75 76 77 78 79 80 81 82 7.1 7.2 7.3 9/1884/NP –4– Future 62XXX/Ed1/NP IEC(E) 95 96 97 98 99 100 101 11.3 Charge retention (self discharge) ........................................................................... 22 11.4 Operationnal requirements (charge & discharge) .................................................... 22 11.5 Type of load profiles (duty cycles) requested to size the Railways traction battery ................................................................................................................... 23 11.6 Functions considered (examples, eg auxiliary loads) .............................................. 23 11.7 Requests for cooling / heating (if requested, as per the sizing) ............................... 23 12 Electrical tests : specific (additionnal to 62619/620) testing requirements ........................ 23 102 103 104 105 106 107 108 109 110 111 112 113 12.1 Specific (additionnal to 62619/620) testing requirements ........................................ 23 12.2 Specific operational conditions for Railways (eg long storage,…) ............................ 23 12.3 Load profile verification .......................................................................................... 23 12.3.1 General ..................................................................................................... 23 12.3.2 General methodology ................................................................................. 23 12.3.3 Sizing description (calculation, simulation or preliminary tests) ................... 24 12.3.4 Sizing documentation ................................................................................. 24 12.3.5 Operational verification (load profile test) ................................................... 24 12.3.6 Test report ................................................................................................. 25 12.4 Endurance ............................................................................................................. 26 12.4.1 Endurance in cycles ................................................................................... 26 13 Physical appearance ....................................................................................................... 26 114 14 Conditions for approval and acceptance .......................................................................... 27 115 116 117 14.1 Type approval ........................................................................................................ 27 14.2 Batch acceptance .................................................................................................. 27 Bibliography ........................................................................................................................ 28 118 119 Figure 1 – Safety signs outside the battery box ...................................................................... 16 120 Figure 1 – Safety signs inside the battery box ........................................................................ 17 121 Figure 1 - Example of load profile in emergency operation (standstill of the train) ................... 21 122 Figure 1 - Example of load profile in driving operation (driving without battery charging) ......... 21 123 Figure 1 - Example of speed limit profile attached to a specific track ...................................... 19 124 Figure 1 Example of altitude profile attached to a specific track ............................................. 19 125 126 Table 1a – Dimensions for vented nickel-cadmium prismatic cells in steel containersError! Bookmark not defin 127 Table 1b – Dimensions for vented nickel- cadmium prismatic cells in plastic containersError! Bookmark not de 128 Table 2 – Measurement tolerances in millimetres (valid for widths and lengths) .................... 18 129 Table 3 – Discharge performance at 20 °C ................................ Error! Bookmark not defined. 130 Table 4 – Discharge performance at +5 °C ................................ Error! Bookmark not defined. 131 Table 5 – Discharge performance at –18 °C .............................. Error! Bookmark not defined. 132 Table 6 – High currents values .................................................. Error! Bookmark not defined. 133 Table 7 – Endurance in cycles ................................................... Error! Bookmark not defined. 134 Table 8 – Constant voltage charging conditions ......................... Error! Bookmark not defined. 135 Table 9 – Sequence of tests for type approval ........................... Error! Bookmark not defined. 136 Table 10 – Recommended test sequence for batch acceptance . Error! Bookmark not defined. 137 138 4 Future 62XXX/Ed1/NP IEC(E) –5– 9/1884/NP 139 INTRODUCTION 140 141 142 Concerning secondary lithium technology, as per the market started it development mainly with portable batteries in the 90’s, existing standards are currently available focused on those smaller batteries than considered in the present document: 143 144 • IEC 61960 Ed. 2: Secondary cells and batteries containing alkaline or other nonacid electrolytes - Secondary lithium cells and batteries for portable applications 145 146 147 • IEC 62133 Ed. 1: Secondary cells and batteries containing alkaline or other nonacid electrolytes - Safety requirements for portable sealed secondary cells, and for batteries made from them, for use in portable application. 148 149 150 Those standards are not covering the large cells and batteries for industrial applications, used in railway applications, which are non-portable, with a mass of hundreds of kilograms. Therefore, they will not be mentioned in the following parts. 151 152 153 In March 2007, it was decided to start work on large capacity lithium cells & batteries, during the general meeting of TC 21 & SC 21A in Beijing (China). Works done from then led to the following standards under construction: 154 155 156 • IEC 62620: Secondary cells and batteries containing alkaline or other non-acid electrolytes – Large format secondary lithium cells and batteries for use in industrial applications, 157 158 159 • IEC 62619: Secondary cells and batteries containing alkaline or other non-acid electrolytes – Safety requirements for large format secondary lithium cells and batteries for use in industrial applications. 160 161 It is on interest to mention that railways are specifically mentioned as an example in those standards, to illustrate the scope difference versus portable. 162 163 164 Li-ion railways batteries can be applied as pure traction Li-ion railways batteries, as pure auxiliary Li-ion railways batteries, as Li-ion railways batteries to start a diesel engine or as a combined Li-ion railways battery for two or even all three applications. 165 166 167 Each application brings its own demands, often even its own standards. One has to differentiate between standards on a component level (mainly valid for all three applications) and standards on integration or function level. 168 169 170 171 172 The latter standards are often generic and not direct linked to an Li-ion railways batteries technology, but to the function the Li-ion railways batteries has to provide in a train. It can also happen that these standards diminish limits set by other only component relevant standards. For example a battery standard can allow a relative wide range of voltage, but due to the direct connection to a train safety system this range is diminished by another standard. 173 174 175 176 Every Li-ion railways batteries technology needs further components, not for storage of energy but for control or safety functions – or for integration in the train like supporting frames. These kind of additional components are normally not a new technology, in principle not even new for train application. Therefore a wide range of standards can be applied on these components. 177 178 179 In case an Li-ion railways batteries is built as a battery pack, some standards may by applied to the whole battery pack, not just for the part the standard was originally written. An example for that would be shock and vibration tests. 180 9/1884/NP 181 182 183 184 185 186 –6– Future 62XXX/Ed1/NP IEC(E) RAILWAY APPLICATIONS – ROLLING STOCK EQUIPMENT – ONBOARD LITHIUM-ION TRACTION BATTERIES 187 1 General 188 1.1 Scope 189 This International Standard applies to Li-ion traction batteries for railway applications. 190 191 It specifies the design, operation parameters, safety requirements, routine and type tests, as well as marking, designation and dimensions. 192 193 194 When there is an existing IEC standard specifying test conditions and requirements for batteries used in special railway applications and which is in conflict with this standard, the former shall take precedence. 195 196 Possible use cases for the railway hybrid vehicle with onboard Li-ion traction batteries are described in IEC 62864-1. 197 2 Normative references 198 199 200 201 202 203 204 The following normative documents contain provisions which, through reference in this text, constitute provisions of this International Standard. For dated references, subsequent amendments to, or revisions of, any of these publications do not apply. However, parties to agreements based on this International Standard are encouraged to investigate the possibility of applying the most recent editions of the normative documents indicated below. For undated references, the latest edition of the normative document referred to applies. Members of IEC and ISO maintain registers of currently valid International Standards. 205 206 IEC 60050(486), International Electrotechnical Vocabulary – Chapter 486: Secondary cells and batteries 207 208 IEC 60051 (all parts), Direct acting indicating analogue electrical measuring instruments and their accessories 209 IEC 60410, Sampling plans and procedures for inspection by attributes 210 IEC 60417 (all parts), Graphical symbols for use on equipment 211 IEC 60485, Digital electronic d.c. voltmeters and d.c. electronic analogue-to-digital converters 212 213 IEC 61438, Possible safety and health hazards in the use of alkaline secondary cells and batteries – Guide to equipment manufacturers and users 214 3 Terms and definitionsr 215 216 For the purpose of this document, the terms and definitions given in IEC 60050-482 and ISO/IEC Guide 51 as well as the following apply. 6 Future 62XXX/Ed1/NP IEC(E) –7– 9/1884/NP 217 218 219 220 3.1 capacity recovery capacity that a cell or battery can deliver after the charge following the charge retention test according to 221 222 223 224 3.2 charge (capacity) retention capacity that a cell or battery can deliver after storage, at a specific temperature, for a specific time without subsequent recharging as a percentage of the rated capacity 225 226 227 228 3.3 final voltage end-of-discharge voltage specified closed circuit voltage at which a discharge of a cell or battery is terminated 229 230 231 232 233 234 235 3.4 nominal voltage suitable approximate value of voltage used to designate or identify the voltage of a cell or battery 236 237 238 239 240 3.5 rated capacity quantity of electricity C 5 Ah (ampere-hours) declared by the manufacturer which a single cell or battery can deliver during a 5-h period, when charging, storing and discharging under the conditions specified in 6.3.1 241 3.1 Battery state of charge (SOC) 242 243 residual capacity of battery available to be discharged, normally expressed as a percentage of full charge 244 245 246 247 248 3.6 Cell (secondary lithium) a cell whose electrical energy is derived from the oxidation and the reduction of lithium. It is not ready for use in an application since it is not yet fitted with its final housing, terminal arrangement and electronic control device 249 250 251 252 253 3.7 cell block A group of cells connected together in parallel configuration. It is not ready for use in an application since it is not yet fitted with its final housing, terminal arrangement and electronic control device. 254 255 256 257 258 3.8 module A group of cells connected together either in a series and/or series/parallel configuration with or without protective devices (e.g. fuse or PTC) and monitoring circuitry. It can be transported and replaced when the battery system is maintained. 259 See Note at Table 1. 260 261 262 263 264 3.9 battery pack A unit which incorporates one or more cells or modules. It incorporates adequate housing and a terminal arrangement and may have protective devices or circuits. It gives control information based on cell voltage to a battery system. Note 1 the battery maker may provide the nominal voltage. Note 2 the nominal voltage of a battery of n series connected cells is equal to n times the nominal voltage of a single cell. 9/1884/NP –8– Future 62XXX/Ed1/NP IEC(E) 265 266 3.10 battery system (equal to battery) 267 268 269 270 271 A system which incorporates one or more cells, modules or battery packs. It has a battery management unit to cut off in case of over charging, over current, and over heating. It may have cooling or heating units. In this particular standard, battery is restricted to xxx (take from PT 62864-1). TBD. 272 3.2 273 hybrid 274 a system that combines two (or more) different types of components for a specific purpose 275 276 An approach for using multiple motive power sources and one for using multiple electric power sources exist for rolling stock applications. 277 3.3 278 hybrid system vehicle 279 280 A vehicle that can store energy in an onboard energy storage system and is driven by using the stored energy as well as electric power from a generator or overhead lines 281 282 283 3.4 safety freedom from unacceptable risk 284 285 286 3.5 risk a combination of the probability of occurrence of harm and the severity of that harm 287 288 289 3.6 harm physical injury or damage to the health of people or damage to property or to the environment 290 291 292 3.7 hazard potential source of harm 293 294 295 296 3.8 intended use use of a product, process or service in accordance with specifications, instructions and information provided by the supplier 297 298 299 300 3.9 reasonably foreseeable misuse use of a product, process or service in a way which is not intended by the supplier, but which may result from readily predictable human behaviour 301 302 303 3.10 leakage visible escape of liquid electrolyte 304 305 306 307 3.11 venting release of excessive internal pressure from a cell, module, battery pack, or battery system in a manner intended by design to preclude rupture or explosion 8 Future 62XXX/Ed1/NP IEC(E) –9– 9/1884/NP 308 309 310 311 3.12 rupture mechanical failure of a cell container or battery case induced by an internal or external cause, resulting in exposure or spillage but not ejection of materials 312 313 314 315 3.13 explosion failure that occurs when a cell container or battery case opens violently and major components are forcibly expelled 316 317 318 3.14 fire the emission of flames from a cell, module, battery pack, or battery system 319 320 321 322 3.15 upper limit charging voltage the highest charging voltage in the cell operating region from a safety stand point specified by the cell manufacturer 323 324 325 326 3.16 maximum charging current the maximum charging current in the cell operating region from a safety stand point specified by the cell manufacturer 327 3.17 ESS 328 3.18 ESU 329 3.19 BMS or BMU (requirement for this to be reflected in the text) 330 3.20 BTMS (requirement for this to be reflected in the text) 331 332 4 Abbreviations 333 For the purpose of this document, the following abbreviations apply. 334 AC Alternating Current 335 C5 Capacity at the 5-hour rate 336 DC Direct Current) 337 DoD Depth of Discharge 338 EMU Electrical Multiple Unit 339 H Height 340 HVAC Heating, Ventilation, Air Conditioning 341 L Length 342 LRU Line replaceable Unit 343 LVPS Low Voltage Power Supply 344 SOC State of Charge 345 W Width 346 347 9/1884/NP – 10 – Future 62XXX/Ed1/NP IEC(E) 348 5 Parameter measurement tolerances 349 350 The overall accuracy of controlled or measured values, relative to the specified or actual values, shall be within these tolerances: 351 a) +1 % for voltage; 352 b) +1 % for current; 353 c) +2 °C for temperature; 354 d) +0,1 % for time; 355 e) +1 % for capacity. 356 357 These tolerances comprise the combined accuracy of the measuring instruments, the measurement techniques used, and all other sources of error in the test procedure. 358 359 360 For assistance in selecting instrumentation see IEC 60051 for analogue instruments and IEC 60485 for digital instruments. The details of the instrumentation used shall be provided in any report of results. 361 6 Relevant railway standards 362 363 6.1 Mechanical 364 365 In the mechanical point of view, IEC 61373 “Railway applications - Rolling stock equipment. Shock and vibration tests” appears as very relevant for energy storage systems. 366 367 Also, EN 15085 "Railway applications - Welding of railway vehicles and components" is valid for container and supporting frames. 368 369 As for calculations for structures, the EN 12663 “Prescription for sizing of railways vehicles structures” should be applied. 370 371 6.2 Environment 372 The following standards define environmental demands for railway components: 373 374 IEC 60068-2-38: Environmental testing - Part 2-38: Tests - Test Z/AD: Composite temperature/humidity cyclic test 375 IEC 60068-2-1: Environmental testing - Part 2-1: Tests - Test A: Cold (2007) 376 IEC 60068-2-2: Environmental testing - Part 2-2: Tests - Test B: Dry heat 377 IEC 60068-2-27: Environmental testing - Part 2-27: Tests - Test Ea and guidance: Shock 378 379 IEC 60068-2-30: Environmental testing - Part 2-30: Tests – Test Db: Damp heat, cyclic (12h + 12h cycle) 10 Future 62XXX/Ed1/NP IEC(E) – 11 – 9/1884/NP 380 381 IEC 60721-1: Railway application - Environmental conditions for equipment. Part 1: Equipment on board rolling stock. 382 IEC 529: Degrees of protection provided by enclosures (IP Code) 383 is relevant for the enclosures of Li-ion railways batteries systems. 384 385 IEC 60721-3-2 Classification of environmental conditions - Part 3: Classification of groups of environmental parameters and their severities; section 2: Transportation 386 387 6.3 Electrical 388 389 390 391 392 393 394 Considering the electrical point of view, the following European railway standards applicable to Li-ion railways batteries have been selected. One has to differentiate the potential of an Li-ion railways batteries component when applying these standards. Some are only valid for low voltage (e.g. 24 V DC for controllers), some are valid for mid voltage (e.g. 750 V DC link). The latter should be applied for electric Li-ion railways batteries like batteries, EDLCs or flywheels as these Li-ion railways batteries interfere with existing technologies like traction converters, what for the standards have been written. 395 396 IEC 62497-2: Railway application - Insulation coordination. Part 1: Basic requirements. Clearances and creepage distances for all electrical and electronic equipment 397 398 EN 61991: Railway applications. Rolling stock. Protective provisions relating to electrical hazards 399 400 This regulation takes an important place considering an electrical storage supplying traction power in rolling stock. Protective provision have to be taken. 401 IECC 60721-1 Railway applications - Electronic equipment used on rolling stock 402 403 This standard is mainly valid for the low voltage components, but it also refers to environment standards and defines applicable limits depending on the place of integration. 404 IEC 60850: Railway applications - Supply voltages of traction systems 405 406 407 408 409 This regulation is related to the EN 50153 about storage system used to supply traction power. Regulation EN 50163 gives the requirement to guarantee quality of voltages supplied by the storage system. This standard and its voltage ranges could be applied to electric Li-ion batteries as per extension (currently, it is not applicable as only directly connected equipment are concerned) 410 IEC 61287-1: Railway applications – Electronic power converter for rolling stock 411 IEC 60050-826: Low-voltage installations - Part 200: Definitions 412 413 IEC 60077-1: Railway applications - Electric equipment for rolling stock - Part 1: General service conditions and general rules 414 415 IEC 60077-2: Railway applications - Electric equipment for rolling stock - Part 2: Electrotechnical components; General rules 416 417 IEC 60364-5-56: Low-voltage electrical installations - Part 5-56: Selection and erection of electrical equipment - Safety services 9/1884/NP – 12 – Future 62XXX/Ed1/NP IEC(E) 418 EN 60439: Low-voltage switchgear and control gear assemblies 419 420 This regulation has to be taken into account in the case of a storage system used to supply auxiliaries connected to the low-voltage bus. 421 IEC 60571: Electronic equipment used on rail vehicles 422 423 IEC 60893-1: Insulating materials - Industrial rigid laminated sheets based on thermosetting resins for electrical purposes - Part 1: Definitions, designations and general requirements 424 UIC 550: Power Supply Installations for Passenger Stock 425 426 Cabling Installation 427 EN 50343: Railway application - Rolling stock. Rules for installation of cabling. 428 429 Cables standards: 430 EN 50264-1, EN 50264-2 , EN 50264-3 431 EN 50306-1, EN 50306-2, EN 50306-3, EN 50306-4 432 EN 50355 433 434 All these standards refer to Railway applications - Railway rolling stock cables having special fire performance. 435 436 EN 50382-1, EN 50382-2, EN 50382-3, Railway applications – Railway rolling stock high temperature power cables having special fire performance 437 438 6.4 Integration 439 440 441 442 443 Considering integration of embedded energy storage, regulation EN 50272-3 titled “Safety requirements for secondary batteries and battery installations. Traction batteries” is very relevant for traction batteries. However, it doesn’t appear the same regulation about other type of energy storage system (only lead-acid & alkaline batteries are concerned, with mention of possible other technologies that could be added). 444 6.5 Fire protection 445 446 447 448 449 450 Considering exported safety, the series of regulation “EN/TS 45545 / prEN 45545” under vote procedure about fire protection is very relevant about the requirement on the material and components in the train. Specially the two series prEN/TS 45545-2 and prEN/TS 45545-4 titled “Railway applications. Fire protection on railway vehicles. Requirements for fire behaviour of materials and components” and “Railway applications. Fire protection on railway vehicles. Fire safety requirements for railway rolling stock design”. 451 452 453 Li Ion batteries and EDLC, with metallic components and no plastic do not have specific testing in these standards. This is a gap and should be considered in future updates of EN 45545 or with application rules in the current Li-ion traction battery standard. 12 Future 62XXX/Ed1/NP IEC(E) 454 455 456 457 – 13 – 9/1884/NP WARNING: This part is not developed enough and should be discussed in the working group with participation of experts from the sector (operators, OEMs, manufacturers). This is key for railways industry, especially after the events that did occur in aviation sector and are generating questions from operators, with possible use of rolling stocks in long tunnels. 458 459 460 461 6.6 Safety 462 The IEC 62619 should be considered as a basis. 463 464 465 466 467 In addition for railways, this theme is more generic and has to be considered especially on the integration level. For all new and modified railway vehicles the "Commission Regulation (EC) No 352/2009 of 24 April 2009 on the adoption of a common safety method on risk evaluation and assessment as referred to in Article 6(3)(a) of Directive 2004/49/EC of the European Parliament and of the Council" has to be considered. 468 469 470 471 472 473 In this regulation common safety methods (CSM) for risk evaluation are defined. This CSM shall be applied not only on a component level, but also on an integration and functional level. Here it is a big difference whether an Li-ion railways batteries is for traction only or also providing onboard power supply for e.g. safety relevant components like train controller or radio. A risk evaluation and assessment provides the necessary safety integrity level (SIL) for each function and finally each component. 474 475 476 477 478 For batteries it will be also important which cell type is used, as some types (e.g. lithium iron phosphate base) could show lower risks to have cell opening or flames in abusive situations than others. The FP7 project OSIRIS launched in January 2012 will have a specific part concerning safety if Li-ion cells, and will allow selecting the Li-ion electrochemistry taking into consideration such point. 479 *** Regulation examples to be inserted as an annex *** 480 481 482 483 484 485 486 487 488 489 As an EC regulation the - COMMISSION REGULATION (EC) No 352/2009 of 24 April 2009 on the adoption of a common safety method on risk evaluation and assessment as referred to in Article 6(3)(a) of Directive 2004/49/EC of the European Parliament and of the Council - may not be transferred to national law. Nevertheless national authorities may decree national rules how to apply it. In Germany for example this was done by the Eisenbahn Bundesamt (EBA) by the "Hinweise für die Anwendung der Verordnung (EG) Nr. 352/2009 der Kommission vom 24.04.2009 über die Festlegung einer gemeinsamen Sicherheitsmethode für die Evaluierung und Bewertung von Risiken gemäß Artikel 6 Abs. 3 Buchstabe a der Richtlinie 2004/49/EG des Europäischen Parlaments und des Rates durch das Eisenbahn-Bundesamt " (reference to apply the EC 352/2009 …). 490 491 492 493 494 Based on the CSM the EBA together with the sector has developed the SIRF method ("Sicherheitsrichtline Fahrzeug", in English "safety rule vehicle"), which has to be applied in Germany since 2011, as a detailed definition of the CSM. NeverthelLi-ion railways batteries EBA also allows performing safety analysis according comparable standards like ISO 13849 or EN 61062. 495 496 497 498 WARNING: This part is not developed enough and should be discussed in the working group with participation of experts from the sector (operators, OEMs, manufacturers). This is key for railways industry, especially after the events that did occur in aviation sector and are generating questions from operators, with possible use of rolling stocks in long tunnels. 9/1884/NP – 14 – Future 62XXX/Ed1/NP IEC(E) 499 500 6.7 Electromagnetic compatibility EMC 501 The common EMC standards for rail should be applied to Li-ion railways batteries: 502 503 IEC 62236: Railway application - Electromagnetic compatibility (all parts), especially the IEC 62236-3-2 504 505 6.8 Software 506 Software in Li-ion railways batteries components must fulfil the common rail standards: 507 508 EN 50126: Railway Applications - The Specification and Demonstration of Reliability, Availability, Maintainability and Safety (RAMS) 509 510 IEC 61508: Functional safety of electrical, electronic programmable electronic safety-related systems 511 IEC 62279: Railway Applications - Software for railway control and protection systems 512 513 6.9 Miscellaneous / Sundries 514 The following standards do not fit in the above structure, but should be applied as well: 515 516 ISO 3095 or 3381 “Railways application – acoustics – measurement of noise inside railbound vehicles” 517 IEC 62079: Preparation of instructions - Structuring, content and presentation 518 519 Instructions and manuals are an important input for safety analysis, as the manufacturer has to describe here risks and how to deal with them during operation. 520 IEC 61123: Reliability testing; compliance test plans for success railways batteries ratio 521 522 This standard can be important if a risk assessment is asking for a certain reliability for an Liion battery. 523 UIC 640 Motive power units - Inscriptions, marks and signs 524 Here are the correct labels (e.g. "Danger, high voltage") described. 525 526 EN 50215: Railway applications. Rolling stock. Testing of rolling stock on completion of construction and before entry into service 527 This standard describes the test procedures for the complete train. 528 EN 50272-2-3: Ventilation requirements on batteries 529 530 531 Although this standard is not valid for Li Ion batteries, ventilation might be a topic for this type of batteries as well. At present there is no rail standard dealing with this topic, this could be an issue for future standardisation. 14 Future 62XXX/Ed1/NP IEC(E) – 15 – 9/1884/NP 532 533 Verwaltungsrichtlinie für Überwachungsbedürftige Anlagen (administrative regulation for safety relevant components) 534 535 536 537 538 539 In this regulation the EBA defined rules for homolgation and operation of components with safety aspects like pressure vessels (brake), fuel tanks or batteries. The latter were included due to the risk of explosive gases (H2 and O2) which can occur with lead acid batteries. Although Li-ion batteries show a much lower risk of producing explosive gases, at the moment the complying with this regulation has to be discussed with the EBA, as there are no rail standards for this topic. Especially the annex 4.7 and 6 should be considered. 540 541 542 543 Common regulations in Europe are very poor as each country has its own railway regulation. Even if these regulations are very similar, they are not necessary regrouped in one European regulation. Considering France, it exist many railway regulations applicable to EES that could be relevant in this study. 544 545 546 547 548 549 550 Not a standard, but nevertheless a regulation to be observed is UN38.3 “Classification Procedures, Test Methods and Criteria Relating to Class 9, Lithium Batteries” (UN transport testing for lithium batteries) issued by the United Nations. Since Li-ion railways batteries for railway systems will typically consist of (redundant) battery branches, which are made up of several battery modules, which in turn consist of several battery cells, some clarification would be welcome as to what units (cells/modules/battery branch/complete battery system) need to pass the tests specified herein. 551 552 553 7 Designation and marking 554 7.1 Battery designation 555 556 Each battery by the unit that is installed or maintained shall carry clear and durable markings giving the following information as per the IEC 62620. 557 558 559 In addition, the total energy content shall be provided; it shall be calculated based on the current & voltage integration of the IEC 62620 nominal conditions for discharge, from cell or module data to battery content by proportional rule. 560 561 7.2 Battery termination 562 This standard does not specify cell termination. 563 7.3 Marking 564 7.3.1 Nameplate 565 566 567 Each battery shall carry durable markings (considering railways harsh environment) giving the minimum information as requested in IEC 62620, on a visible & non removable surface. In addition, the following marking information is requested for Railways. 568 The nameplate of the battery shall be included following information: 569 570 571 − serial number; − part number; − weight; 9/1884/NP 572 573 574 575 – 16 – Future 62XXX/Ed1/NP IEC(E) − revision level (if applicable); − name of manufacturer. − Battery energy as defined in 7.1. 576 7.3.2 Cells, Battery-pack, Tray, crate or other nameplates inside the battery 577 578 579 580 The nameplate tray, crate or other nameplates inside the box shall comply with EN 50272-3. In case of multiple trays, the number and position of trays shall be given either on the trays or in the instruction manual if trays reference cannot generate misassembling. 581 7.4 Safety recommendations 582 583 The manufacturer shall provide recommendations for the safe handling of the battery. See also IEC 61438 and IEC 62620. 584 7.4.1 Safety signs 585 7.4.1.1 Outside the box 586 587 As a minimum ffollowing safety signs shall be placed outside the box: Warning signs (according to EN ISO 7010): 588 - W012 - Warning; Electricity 589 - W026 - Warning; Battery Charging 590 Prohibition sign (according to EN ISO 7010): 591 - P003 - No open flame; Fire, open ignition source and smoking prohibited 592 593 594 Figure 1 – Safety signs outside the battery box 595 596 7.4.1.2 Tray, crate or other places inside the box 597 598 Following Safety signs shall be placed inside the box: Warning signs (according to EN ISO 7010): 599 - W012 - Warning; Electricity 600 - W026 - Warning; Battery Charging 601 - W002 – Warning; Explosive material 16 Future 62XXX/Ed1/NP IEC(E) – 17 – 9/1884/NP 602 Prohibition sign (according to EN ISO 7010): 603 - 604 Mandatory action signs (according to EN ISO 7010): 605 - M002 – Refer to instruction manual/booklet 606 - M004 – Wear eye protection 607 - M009 – Wear protective gloves 608 - M010 – Wear protective clothing 609 If the safety signs fixed on the tray or crate, the signs can be in black and white or colour. P003 - No open flame; Fire, open ignition source and smoking prohibited 610 611 612 613 614 Figure 2 – Safety signs inside the battery box 9/1884/NP – 18 – Future 62XXX/Ed1/NP IEC(E) 615 8 Storage and transportation conditions 616 8.1 Transportation 617 618 According to EN 50272-2 or the valid regulations of the respective country and the battery manual. This should accompany the batteries. 619 8.2 Storage of batteries 620 621 622 623 624 625 626 For storage batteries shall be placed in a frost-free, dry room. The battery shall not be exposed to direct sunlight. in order to protect the battery, the battery shall be recharged in regular intervals. For Li-ion batteries this can be up to 12 months. The battery manufacturer has to specify the charging methods and intervals to be applied. For further details please refer to the battery manual. The battery manufacturer has to specify the method of storage in his manual. 627 COMMISSIONING AFTER LONG STORAGE 628 629 630 631 632 After a long storage, some checks must be done before using the battery: - With the diagnostic tools, checks for alarms (no alarm should be declared except the low SOC one) - Recharge with the external charger under IMR current until the SOC reaches at least 95% for optimum balancing 633 634 If there are some difficulties or doubt for commissioning, please contact the manufacturer. 635 9 Dimensions 636 637 . 638 639 Table 2 – Measurement tolerances in millimetres (valid for widths and lengths) Up to and including 60 mm 0 to –2 Above 60 mm, up to and including 120 mm 0 to –3 Above 120 mm 0 to –4 640 641 10 Electrical interface requirements 642 10.1 Communication 643 644 There are different means for communication; the choice should be the subject of agreement between the customer and the manufacturer at contractual stage. 645 18 Future 62XXX/Ed1/NP IEC(E) – 19 – 9/1884/NP 646 10.2 Dead start battery 647 648 In case of a fully discharge battery, the power to revive the Li-ion battery traction electronics shall be available at train level. 649 11 Design requirement 650 12 12.1 Design energy & power calculation methodology 651 There are different sizing requirements (for the battery to deliver a specified load profile): 652 − Emergency or seldom happening requirements, that are not regularly repeated 653 − Repetitive requirements, when the rolling stock is operated on a regular type of route. 654 655 656 657 658 659 The batteries will be sized in order to perform the required profiles, at beginning as well as at the end of their operating life. It is therefore necessary to have a clear definition of the different profiles, as well as of their expected repetition over daily operation (with possible insertion of emergency profile at some point). It is to be noted that those profiles could be season dependant (eg winter / summer / mid-season variations, especially when comfort auxiliaries take a significant part of the global profile). 660 661 662 Sizing is key in order the battery can fulfil its role without going to area outside of their intended use (meaning a loss of operational availability with safety protection features activation if necessary). 663 664 665 666 Responsibilities are shared from the operator to train and battery manufacturers in order to define such operational profiles. In order to clarify the impact of each of the parties, the expected outputs are defined below, as these profiles are highly dependent of the specific requirement for each track, as well as of the vehicle design selected by the train manufacturer. 667 668 669 Identification of the track constraints (operator level): Speed limit 160 velocity in km/h 140 120 100 80 60 40 20 0 0 20 000 30 000 40 000 50 000 60 000 70 000 80 000 distance in m 670 671 672 673 10 000 Figure 3 - Example of speed limit profile attached to a specific track With possible impact of the altitude (operator level): height in m alternative height 160 140 120 100 80 60 40 20 0 0 10 000 20 000 30 000 40 000 50 000 60 000 70 000 80 000 distance in m 674 675 Figure 4 Example of altitude profile attached to a specific track 9/1884/NP 676 677 678 679 680 – 20 – Future 62XXX/Ed1/NP IEC(E) With a target timetable to reach within such constraints, the train manufacturer can then define the driving profile to be applied to its rolling stock, which will serve as a basis for the traction calculation: 681 682 Figure 5 - Example of load profile as defined per the train manufacturer 683 684 685 686 687 688 689 690 691 The train manufacturer, based on the acceleration level selected & the repartition of the requested power between the different energy sources, can then define the power requested along the profile at Li-ion battery level. In order to harmonize the sign conventions with those existing already for auxiliary batteries, the positive power at battery level is defined as corresponding to the train acceleration (taking energy from the battery to accelerate or power the auxiliaries for example), when the negative power at battery level corresponds to a deceleration (and recuperation of the energy into the Liion battery). 692 The following sub-chapters provide some examples of such type of profiles. 693 12.1 Discharging requirements (emergency profiles or unusual operation) 694 There are different discharging requirements: 695 − load profile (emergency or driving operation); 696 − long-time discharge; 697 − low temperature discharging requirements; 698 − self discharge; 699 The requirements are described at the following subclauses. 700 12.1.1 Load profile 701 Several typical load profiles requirement are possible: 702 − emergency auxiliary operation (see Error! Reference source not found.); 703 − driving operation (see Error! Reference source not found.). 704 705 706 Error! Reference source not found. and Error! Reference source not found. show typical load profiles for emergency operation for trains with restarting operation, or without in case of a forced continued operation. 20 Future 62XXX/Ed1/NP IEC(E) 707 – 21 – 9/1884/NP 12.1.1.1 Emergency load profiles (eg auxiliaries back-up) Loads All Loads (1) Start up (5) Important loads (2) Emergency loads (3) Longtime discharging (4) 708 709 Time Figure 6 - Example of load profile in emergency operation (standstill of the train) Loads All Loads (1) 710 711 Important loads (2) Time Figure 7 - Example of load profile in driving operation (driving without battery charging) 712 713 12.1.1.2 Traction emergency load profile 714 Two different types of load profiles are possible: 715 − emergency operation (see Error! Reference source not found.); 716 717 − driving operation (see Error! Reference source not found.), eg operation to exit /enter the depot. 9/1884/NP – 22 – Future 62XXX/Ed1/NP IEC(E) 718 719 720 12.2 Requirements for battery sizing for emergency operations 721 Train manufacturer shall define the following parameters: 722 723 724 725 SOC in emergency condition; ambient temperature in emergency condition; load profile (see 12.1.1) including auxiliaries if necessary; minimum voltage at battery level for the whole load profile. 726 Battery manufacturer shall define 727 728 - 729 as the emergency profile shall be possible at the battery end of life 730 731 732 733 SOC and ageing factors shall be taken into account for battery sizing, depending on battery technology and operating conditions. The selected values are typically between 60 % and 100 %. The manufacturer shall state the expected SOC and ageing behaviour for a given specification and provide evidence of the expected battery behaviour. ageing factor, expected battery life impact under specified conditions, 734 735 12.2.1 Long-time discharge 736 737 Long-time discharge is for example a discharging time longer than four days with a defined consumption. Such discharge cannot entirely be excluded. 738 739 Li-ion Batteries shall be able to withstand deep discharge without permanent damage see also IEC 62619. 740 741 742 The operator shall define the maximum duration until the battery will be recharged after such event, in order that the proper energy is kept in the battery to accept such duration, as well as some possible profiles (eg restart of the train system). 743 12.2.2 Low temperature performance (if applicable) 744 745 746 The admissible battery temperature is typically -18°C or as agreed with the customer. At this temperature, the charged battery shall still be able to supply a “deep temperature load profile” as specified by the customer. 747 In addition, no permanent damage shall occur at this temperature. 748 12.2.3 Charge retention (self discharge) 749 750 The reversible loss of capacity shall be maximum 10 % of the rated capacity after 30 days of storing at o 20 C for Li-ion railways batteries. 751 For storage of batteries see 8.2. 752 12.3 Operational requirements (charge & discharge) 753 There are different discharging requirements: 754 − Regular repeated operation profile (driving operation); 755 756 − Non-regular but expectable operation profiles (eg in case of a congestion seldom happening for non isolated tracks); 757 758 − Some specific pre-identified degraded modes (eg in case of a failure of some components not preventing continuation of operation); 22 Future 62XXX/Ed1/NP IEC(E) 759 760 761 762 763 – 23 – 9/1884/NP All those requirement shall be précised in terms of repetitions (eg for a round trip or a back & forward trip: Nd of trips expected per day & Nb of operation days per year), as well as possible interactions (eg position of a congestion profile within a day among repetitive profiles). Variations of those profiles for seasons could be considered if having a significant impact on the load profile. 764 765 12.3.1 Functions considered (examples, eg power boost & regenerative braking) 766 767 12.3.2 Type of load profiles (duty cycles) requested to size the Railways traction battery 768 769 12.3.3 Positionning / interaction of the load profiles over operation duration 770 771 772 12.4 Requests for cooling / heating (if requested, as per the battery manufacturer recommendations) 773 774 13 Electrical tests : specific (additionnal to 62619/620) testing requirements 775 776 Specific testing requirement for railways are expected in addition to 62619 and 62620. They are detailed in the following sub-capters. 777 13.1 Specific (additionnal to 62619/620) testing requirements 778 779 13.2 Specific operational conditions for Railways (eg long storage,…) 780 781 13.3 Load profile verification 782 783 13.3.1 General 784 785 786 787 788 This Chapter is applicable for the specification and verification of battery aptitude to supply requested load profiles, if specified by the customer. The aim is to control conformity of design and later of realization with the relevant specification. It is recommended that the number of tests is limited to those which are proven to be necessary. NOTE 789 13.3.2 790 791 The procedure and the parameters shall be specified by agreement between the battery manufacturer and the customer including 792 • cumulated discharged energy vs. load profile, 793 • power available vs. load profile. A load profile and the operating conditions may be optimized during the project. General methodology 9/1884/NP – 24 – Future 62XXX/Ed1/NP IEC(E) 794 Also realistic train operation has to be taken into account 795 • environment (e.g. temperature), and 796 • operational requirements (e.g. minimum voltage). 797 798 799 800 An important part is the charge level of the battery and its ageing. This process requires a well defined and harmonised methodology for specification and verification of the load profile compliance (as contractually defined). The selected approach has two steps: 801 802 803 • simulation by calculation or testing of the compliance of the battery vs. load profile of the train, for one or several specific load profiles over a defined environment (temperature) under defined operational conditions (voltages); 804 805 • measurements on real battery for the verification of the compliance vs. load profile shall be realized under simulation conditions; 806 807 808 • profiles shall be initially requested by the operator or by the train system integrator, including adjustments to take into account final release of architecture and equipments installed on the train (eg energy reserve of 20% or power reserve of 5%). 809 810 811 812 In case several profiles are requested, all load profiles shall be calculated or tested. Each battery manufacturer shall provide to the customer his sizings for all requested load profiles in the tendering phase. Those sizings shall be available for the operator on request. If acceptable by the customer it may be sufficient to do the worst case only. 813 13.3.3 814 815 816 817 818 819 The battery sizing shall be done by the battery manufacturer, in order to make sure that the required profile will be met in all identified discharge conditions agreed (e.g. environment, sizing factors for charge or ageing). This can be done through numerical calculation (e.g. simulation) or laboratory testing – or both in case numerical calculation is not considered precise enough. 820 13.3.4 821 822 The results of the calculations and simulations shall be documented in a report. The minimum requirements for the contents of the report are 823 824 • key data for the battery: technology, type, capacity & quantity of cells for the whole train, electrical architecture as initially defined by the train system integrator, 825 826 827 • description of the battery behaviour over discharge time, with indication of compliance vs. requested conditions (e.g. minimum voltage) for each profile segment in their occurrence order, 828 829 • environmental conditions (e.g. temperatures for charging, discharging) and derating factors (e.g. ageing, initial SOC depending on charging condition). 830 13.3.5 831 832 833 834 As the main concept of this standard is to allow for standardization of batteries, it is essential that the final design data document (initial or updated) is filed: load profile test to be realized as defined in agreement between operator, train system integrator and cell or battery manufacturer: 835 • test temperature corresponding to selected sizing; 836 837 838 839 • minimum representative quantity of cells or monoblocs for performance tests (typically over 10% of the total cell quantity connected in series respectively a corresponding number of monoblocs): in case paralleling profile will be adjusted proportionally, in representative arrangement of cells. This will be referred later on as “battery” for the testing purposes. Sizing description (calculation, simulation or preliminary tests) Sizing documentation Operational verification (load profile test) 24 Future 62XXX/Ed1/NP IEC(E) – 25 – 9/1884/NP 840 841 842 • minimum representative quantity of cells or monoblocs for functionnal : tiotal battery system. in case paralleling profile cannot be adjusted proportionally. This will be referred later on as “complete battery” for the testing purposes. 843 • 844 The following tolerances are admitted for performance tests: 845 • ambient temperature: ± 5K; 846 847 • cell temperature dispersion in the battery at test start: ± 2K. The test shall not start before reaching the testing temperature for at least 1 h. 848 Battery preparation: 849 • cells or battery could be submitted to a suitable number of pre-activation cycles; 850 • complete charge as per IEC62620; 851 852 853 854 • application of the derating factors as mentioned in agreed simulation / calculation / lab. testing stage, through partial discharge in relation to the rated capacity C n (e.g. 90 % ageing and 90 % SOC => 90 %*90 %=81 % initial situation, thus 19 % partial discharge) for emergency tests; 855 856 • cells or battery should then immediately be installed to reach temperature situation (agreed temperature), until stable temperature is obtained. 857 858 859 860 Profile should then be realized as mentioned in agreed simulation / calculation / lab. testing stage, and all load profile parameters (time, voltage, current, temperature) should be recorded. The test plan shall be agreed between at least train & battery manufacturers prior to the tests. This plan especially contains 861 • the conditions for preparation, 862 • the conditions for the specific test, 863 864 865 • the scaling factor if needed (number of representative cells). Acceptance criterion: compliance with minimum Voltage (depending form battery type) all along the testing profile. 866 13.3.6 867 868 869 The results of the verification measurements shall be documented in a report that should remain attached with the train documentation. The minimum requirements for the contents of the report are 870 871 • key data for the battery: technology, type, capacity and quantity of cells for the whole train, electrical architecture, 872 873 874 • description of the battery behaviour over operation time, with indication of compliance vs. requested conditions (e.g. minimum voltage) for each profile segment in their occurrence order, 875 • tested sample manufacturing traceability (identification as per chapter at minimum). 876 877 • environmental conditions (e.g. temperatures) and derating factors (e.g. ageing, initial SOC of tested battery), 878 • description of the measurement equipment used, with calibration certificates, 879 880 • any observations during the tests which might have an effect on the interpretation of the test results. 881 882 In case of scaling, it might be necessary to apply a factor to compare test to the load profile. This should then be clearly mentioned. Test report 9/1884/NP 883 13.3.7 884 TBD – 26 – Future 62XXX/Ed1/NP IEC(E) Lifetime projections 885 886 13.4 Endurance 887 13.4.1 Endurance in cycles 888 889 Endurance tests are extremely long & resources consuming. Moreover, their result is an entrance point for battery sizing. Therefore they cannot be applied on a specific profile basis. 890 891 892 893 The endurance test is therefore extended from the IEC 62620 endurance testing at cell level, with results not only after 500 cycles, but to be continued especially as some cells can be specifically designed in order to provide a higher number of cycles. As an option, such cells or batteries could be identified as such with mention of the class of cycle rating for those cells. 894 895 This mention will be provided with the NC followed by the class of endurance expressed in cycles. 896 The following steps should then be realized after completion of the test in chapter 4.4.1: 897 898 Step 1 - The decrease rate shall be calculated from the rated capacity and the capacity measured in step chapter 4.4.1 or in step 5. 899 900 901 Step 2 – If the capacity after additional 100 cycles is higher than 60% of the rated capacity, the endurance tests in table 7 can be repeated until the capacity during the cycling test reaches 62.5% of the rated capacity. 902 Step 3 – The capacity at 0,2 I t A is determined according to 4.2.1 903 904 905 Step 5 – If the capacity is higher than 60% of the rated capacity, step 2 to step 3 are repeated 100 times followed by step 3. If the capacity is lower or equal to 60% of the rated capacity, go to step 5. 906 Step 5 – End of cycling test 907 908 909 The cycle life of the cell or battery is given by the total number of cycles performed to reach 60% of the initial capacity at the 0,2 I t A rate. When the battery fails to reach 60% of the rated capacity, the number of cycles shall be rounded to the nearest multiple of 100 (eg 800, 1500). 910 911 14 Mechanical tests 912 15 14.1Physical appearance 913 914 915 Visual inspection shall be performed on samples submitted to tests. No cracking, damage or corrosion shall be apparent. Any deformation shall be within the tolerances of the dimensions specified in the manufacturer’s drawings. 26 Future 62XXX/Ed1/NP IEC(E) – 27 – 9/1884/NP 916 16 14.2 Shock & vibration 917 17 14.3 Safety 918 18 Conditions for approval and acceptance 919 18.1 Type approval 920 921 922 The type test shall be done on conditions to be agreed by train & battery manufacturer, to validate the performance of the battery. It shall be done accordingly to chapter 12.3.5 and 12.3.6. 923 18.2 Sampling 924 925 This test shall ensure that the technical characteristics are maintained. They can be done on a partial of more than 10% of the battery. 926 9/1884/NP – 28 – Future 62XXX/Ed1/NP IEC(E) Bibliography 927 928 929 930 IEC 61434, Secondary cells and batteries containing alkaline or other non-acid electrolytes – Guide to designation of current in alkaline secondary cell and battery standards 931 932 IEC 60050-482 International Electrotechnical Vocabulary - Part 482: Primary and secondary cells and batteries 933 934 ___________ 28