Workplace Hazardous Materials Information System

advertisement

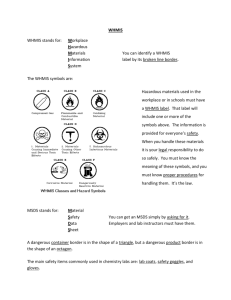

EVERYONE'S RESPONSIBILITY Workplace Hazardous Materials Information System (WHMIS) Guide 2014 Workplace Hazardous Materials Information System (WHMIS) Guide Last reviewed/revised: February, 2014 Workplace Safety and Health Table of Contents Introduction...........................................................................................2 Starting a WHMIS program..................................................................3 What is WHMIS........................................................................................... 3 WHMIS legislation....................................................................................... 4 Federal WHMIS legislation.......................................................................... 4 What is a controlled product........................................................................ 5 WHMIS hazard symbols.............................................................................. 5 Supplier label............................................................................................... 7 Supplier MSDS............................................................................................ 8 Information items on an MSDS.................................................................... 9 Exemption from federal WHMIS requirement............................................ 13 Federal WHMIS legislation........................................................................ 13 Confidential business information – federal............................................... 14 Provincial WHMIS regulation..................................................................... 14 Enforcement of Manitoba’s WHMIS legislation.......................................... 15 Requirement for worker training................................................................ 15 Labelling requirements.............................................................................. 16 Labelling bulk shipment............................................................................. 17 Controlled products produced in the workplace........................................ 17 Labelling decanted products and exemption for portable containers........ 17 Controlled product in piping system or vessel........................................... 18 Labels for laboratory chemicals................................................................. 18 Summary of labelling requirements........................................................... 19 Provincial requirement for MSDS for employers....................................... 19 Confidential business information, employer confidentiality...................... 20 Manitoba WHMIS and hazardous wastes................................................. 20 WHMIS Guide 1 Workplace Safety and Health INTRODUCTION Introduction The purpose of this guide is to provide information on hazardous substances (also called controlled products) that will allow workers and employers to work together and create safer, healthier workplaces. A safe workplace is one where safety and health hazards are eliminated, reduced and/or controlled. Workplace Safety and Health Regulation Requirements Under Part 35 of The Workplace Safety and Health Regulation, M.R. 217/2006, the employer is responsible for educating and training workers who are using, producing, storing or handling hazardous products in the workplace so that the workplace remains free of safety and health hazards, occupational illness and disease. To conduct effective worker training, the employer must first understand the information presented on the supplier label and in the material safety data sheets (MSDS). The employer must also provide the necessary engineering controls and personal protective equipment (PPE) to protect workers from exposure to hazardous chemicals. This guide briefly describes the step-by-step WHMIS process and provides information to help start a WHMIS program in the workplace. Federal and provincial WHMIS requirements are described in this guide. WHMIS Guide 2 Workplace Safety and Health STARTING A WHMIS PROGRAM • Consult with the workplace safety and health committee or representative to appoint a co-ordinator responsible for developing a WHMIS program and putting it in operation. • Determine what controlled products are used in the workplace and check for hazardous products with exemptions under WHMIS. • Obtain the current MSDS for controlled products from the supplier or manufacturer. The Canadian Centre for Occupational Health and Safety (CCOHS) may also be contacted for information on MSDS. • Create a master file of the MSDS. Make a copy of the file available to all workers. • Designate an area where MSDS will be kept. All MSDS must be kept for 30 years from the date they were received or produced. • Ensure containers of controlled products feature a proper supplier label. Replace damaged supplier labels with new supplier labels or appropriate workplace labels. • Check regulations for process vessel, pipe, laboratory and other requirements. • Develop safe work procedures. • Consult with the workplace safety and health committee or representative to develop a workplace specific WHMIS training program for workers. Evaluate and revise the program annually. If a new controlled product is introduced in the workplace, train workers to use, handle and store it. • Make sure workers know how to read labels, WHMIS symbols and MSDS, and if required, how to use PPE. • Train workers to handle, use and store existing workplace chemicals safely. • Evaluate worker training needs annually. What is WHMIS? WHMIS (Workplace Hazardous Materials Information System) is a Canada-wide system designed to provide employers and workers with information about the hazardous materials (also called controlled products) used in the workplace. The intent of this regulation is to inform employers of the safety and health hazards associated with the hazardous products used in their facility. Employers can use this information to control hazards and train workers to recognize them. WHMIS Guide 3 Workplace Safety and Health Workers must be informed of and understand the hazards associated with handling, storing, processing or working with hazardous materials in a safe and healthy manner. WHMIS information helps employers and workers prevent or reduce the likelihood of disease or injury in the workplace. WHMIS was developed by labour and industry with help from federal, provincial and territorial regulatory agencies. This regulation became effective on October 31, 1988. WHMIS Legislation WHMIS is governed by combined federal and provincial legislation. The main purpose of federal WHMIS legislation is to require suppliers and importers of hazardous materials to provide health and safety information about their products as a condition of sale. The main purpose of provincial WHMIS legislation is to require employers to obtain health and safety information about hazardous materials in the workplace and educate workers accordingly. Under WHMIS, there are three ways to provide information on hazardous materials: 1. supplier’s labels on the containers of hazardous materials 2. material safety data sheets to supplement the supplier’s label with detailed hazard and precautionary information 3. worker training programs Federal WHMIS Legislation Three areas of federal legislation implement WHMIS: 1. The Hazardous Product Act (HPA) requires suppliers who sell or import a hazardous product for use in a workplace in Canada, responsible for providing labels and material safety data sheets to their customers. 2. The Controlled Products Regulation (CPR), under the authority of HPA, defines what a controlled product is and identifies the information the supplier is required to put on a label and in a MSDS. 3. The Ingredient Disclosure List, issued under the HPA, contains the names of the chemicals which must be identified on a MSDS if they are ingredients of a controlled product, and found at a concentration greater than specified. WHMIS Guide 4 Workplace Safety and Health What is a Controlled Product? A controlled product is any product that can be included in any of the following six classes: • • • • • • Class A Class B Class C Class D Class E Class F compressed gas flammable and combustible material oxidizing material poisonous and infectious material corrosive material dangerously reactive material Classes B and D are further subdivided as follows: • Class B • Division 1 • Division 2 • Division 3 • Division 4 • Division 5 • Division 6 flammable and combustible material flammable gases flammable liquids (flash point < 38°C) combustible liquids (flash point > 38°C but < 93°C) flammable solids flammable aerosols reactive flammable materials (ex: materials that are dangerous when wet) • Class D poisonous and infectious material • Division 1 materials causing immediate and serious toxic effects - Subdivision A very toxic material - Subdivision B toxic material • Division 2 materials causing other toxic effects • - Subdivision A very toxic material - Subdivision B toxic material • Division 3 biohazardous infectious material Specific criteria have been developed for each of these categories. If a property of a product meets any of these criteria, the product is then referred to as a controlled product. These specific criteria can be found in the Controlled Products Regulation. WHMIS Hazard Symbols There are eight WHMIS hazard symbols. Each class of controlled product has its own symbol, except for Class D, which has different symbols for class D1, D2 and D3. Employers must train workers to recognize these symbols and know what they mean. WHMIS Guide 5 Workplace Safety Health Division Workplace Safety andand Health CLASS A: COMPRESSED GAS This class includes compressed gases, dissolved gases and gases liquefied by compression or refrigeration. CLASS B: FLAMMABLE AND COMBUSTIBLE MATERIAL This class includes solids, liquids and gases capable of catching fire in the presence of a spark or open flame under normal working conditions. CLASS C: OXIDIZING MATERIAL These materials increase the risk of fire if they come in contact with flammable or combustible materials. CLASS D: POISONOUS AND INFECTIOUS MATERIAL Division 1: Materials Causing Immediate and Serious Toxic Effects These materials can cause death or immediate injury when a person is exposed to small amounts. Examples: sodium cyanide, hydrogen sulphide CLASS D: POISONOUS AND INFECTIOUS MATERIAL Division 2: Materials Causing Other Toxic Effects These materials can cause life-threatening and serious long-term health problems as well as less severe but immediate reactions in a person who is repeatedly exposed to small amounts. CLASS D: POISONOUS AND INFECTIOUS MATERIAL Division 3: Biohazardous Infectious Material These materials contain harmful micro-organisms that have been classified into Risk Groups 2, 3, and 4 as determined by the World Health Organization (WHO) or the Medical Research Council of Canada. CLASS E: CORROSIVE MATERIAL This class includes caustic and acid materials that can destroy the skin or eat through metals. Examples: sodium hydroxide, Workplace Safety and Health Division hydrochloric acid, nitric acid CLASS F: DANGEROUSLY REACTIVE MATERIAL WHMIS Guideline These products may self-react dangerously (for example, they may explode) upon standing or when exposed to physical shock or to increased pressure or temperature, or they emit toxic gases when exposed to water. 6 Supplier Label WHMIS Guide Federal WHMIS legislation requires suppliers to put a supplier label on containers of controlled products sold for use in Canadian workplaces. The label, 6 Workplace Safety and Health Supplier Label Federal WHMIS legislation requires suppliers to put a supplier label on containers of controlled products sold for use in Canadian workplaces. The label, together with worker education should convey the same information as the workplace label specified above. Seven items of information must be included within the distinctive hatched border: 1. product identifier: chemical name of the product or the trade name, common name or code number 2. hazard symbol: one or more of the eight WHMIS symbols indicating the hazard classes of the controlled product 3. risk phrases: phrases that alert workers to specific hazard(s) of the product 4. precautionary statements: statements that describe essential precautions to be taken and specific personal protective clothing and equipment to be worn when handling the product 5. first aid measures: statements that describe immediate first aid measures required 6. supplier identification: the name, address and the telephone number of the supplier (manufacturer or distributor) 7. reference to MSDS: a statement indicating that an MSDS is available Written information in a supplier label must be shown in both English and French. Federal WHMIS legislation requires that the supplier label should not be removed, defaced, modified or altered. If the supplier label becomes damaged or illegible during shipment or in the workplace, it must be replaced with a new supplier label or appropriate workplace label. A controlled product may be received at a workplace without a supplier label only if the employer agrees to fasten a supplier label to the package on the supplier’s behalf. WHMIS Guide 7 Workplace Safety and Health Example of a WHMIS Supplier Supplier Material Safety Data Sheets (MSDS) Federal WHMIS requires suppliers and manufacturers of controlled products to provide a current or unexpired (less than three years old) MSDS at the point of sale. A MSDS is a technical bulletin that provides specific hazard information, safe handling information and emergency procedures for a controlled product. Since the MSDS contains detailed safety and health information specific to each controlled product, it should be used as a key source of information for developing training programs and safe work procedures. It is also a valuable reference source of safety and health information for workers, safety and health WHMIS Guide 8 Workplace Safety Safety and and Health Health Division Workplace committees and be easily easily committees and emergency emergency service service personnel. personnel. MSDS MSDS should should be accessible to all workers in the workplace. accessible to all workers in the workplace. WHMIS legislation legislation lists lists general WHMIS general guidelines guidelines and and the the minimum minimum content content requirements for an MSDS. WHMIS requires 54 items of information requirements for an MSDS. WHMIS requires 54 items of information in in nine nine sections. sections. The following are the nine recommended section headings and the types of information to be provided in each section. Material Information items on an MSDSSafety Data Sheets (MSDS) Item Description Section 1: Product Information product identifier The name of the product as it appears on the label. This is often the chemical name of a product but can also be the trade name, common name or code number. product use The product use(s) intended by the manufacturer or supplier. manufacturer’s name, address and emergency phone number The manufacturer of the product. An emergency phone number must be listed if one is available. supplier’s name, address and emergency phone number The seller or distributor (which may be the same as the manufacturer). Section 2: Hazardous Ingredients hazardous ingredients Each hazardous ingredient must be listed by its specific chemical name (not its generic name). percentages The percentages or range of percentages for each hazardous ingredient. CAS registry number The unique number assigned to each hazardous ingredient by the Chemical Abstract Service (CAS) registry. current LD50 for each hazardous ingredient A measure of the short-term poisoning potential of a hazardous ingredient, LD50 is the lethal single dose at which 50 per cent of a specified test population dies. Note: LD50 can be determined for many routes of entry, but oral (given by mouth) and dermal (applied to skin) LD50s are used for WHMIS classification. Section 3: Physical Data physical state WHMIS Guideline Guide WHMIS The physical state of the product (gas, liquid, solid, paste, powder, or gel) at room temperature. 99 Workplace Safety and Health Division odour and appearance Odour describes the quality of the odour of the product (for example, fruity, sharp, almond-like). Appearance describes colour and texture for most products and includes particle size for solids. odour threshold The lowest airborne concentration that can be detected by the human sense of smell. specific gravity The ratio of the weight of a substance compared with water. vapour density A ratio of the molecular weight of a gas or vapour compared with the equivalent weight of air. vapour pressure A measure of the ability of a substance to form vapours—the higher the vapour pressure, the more quickly a substance evaporates. evaporation rate The ratio of how fast a substance evaporates relative to a known reference standard (usually n-butyl acetate = 1). boiling point The temperature at which a liquid changes to a gas (at normal room pressure). freezing point (melting point) The temperature at which a liquid changes to a solid or a solid to a liquid (at normal room pressure). pH A value that indicates the acidity or alkalinity of a product (usually liquid)—pH values between 0 and 7 are considered acidic and pH values between 7 and 14 are considered alkaline (7 is neutral). coefficient of water/oil distribution A number that indicates how easily a product may be absorbed into the body. A value greater than one means a substance may enter the body through the mucous membranes of the eyes, nose and lungs. A value less than one means the substance may be absorbed by the fatty tissue below the skin. Section 4: Fire and Explosion Hazard flammability Whether a product is classified as flammable or combustible under WHMIS. means of extinction Fire extinguishers or the extinguishing material suitable for use on the burning product or fire. flash point and test method used The lowest temperature at which the product will catch fire (or explode) when there is a nearby source of ignition such as a spark or open flame—a flash point is determined either by a closed cup (cc) or open cup (oc) method. upper flammable limit These are the highest and lowest concentrations at which a gas or vapour in air (expressed as percentage) will catch fire or explode if near an ignition source such as a spark or open flame. These are also referred to as explosive limits. These concentrations, and all concentrations in between, form the flammable range. lower flammable limit WHMIS Guideline Guide 1010 Workplace Safety and Health Division auto-ignition temperature The temperature above which the substance (usually the vapour) may self-ignite without an external flame or spark—auto-ignition temperatures are available only for flammable liquids or gases. hazardous combustion products Hazardous products produced when the substance burns or is exposed to extreme heat. sensitivity to mechanical impact Whether the product may explode due to physical impact (for example, being dropped, bumped, or knocked over). sensitivity to static discharge Whether the product may explode or catch fire if there is a nearby spark from static electricity. Section 5: Reactivity Data chemical stability Whether the product is chemically stable when exposed to normal intended use or when placed in extended storage. incompatible substances Other chemicals or chemical groups (for example, acids and caustics) that will cause violent reactions when the two products contact each other. conditions of reactivity When hazardous reactions (for example, vigorous polymerization) may occur. hazardous decomposition products Hazardous substances produced or released due to aging or reaction with air or moisture—these do not include thermal decomposition products from burning or excess heating. Section 6: Toxicological Properties routes of entry How the product enters the body during normal use: skin contact, skin absorption, eye contact, inhalation or ingestion. effects of acute exposure Adverse health effects resulting from short-term exposure to the substance, either as a single exposure or as multiple exposures occurring within a short time, usually 24 hours or less. effects of chronic exposure Adverse health effects resulting from repeated exposure over a relatively long period of time, anywhere from several days to years. exposure limits The exposure limit for the product, usually the eight-hour timeweighted average and the name of the regulatory agency. The legal exposure limits may be different may be different from those listed on the MSDS. irritancy of product Whether the product may irritate the skin, eyes, nose, throat, or any other part of the body that it contacts to produce tearing, reddening, swelling, itching or pain. Irritancy is often described as mild, moderate or severe. sensitization Whether the product may cause sensitization—a sensitizer may cause severe allergic reactions with repeated exposure. WHMIS Guideline Guide 1111 Workplace Safety and Health Division Workplace Safety and Health carcinogenicity Whether the product is classified as a human carcinogen by the International Agency for Research on Cancer (IARC) or by the American Conference of Governmental Industrial Hygienists (ACGIH). Reproductive toxicity Whether the product may cause reproductive problems. teratogenicity Whether the product may cause birth defects in a fetus at exposures that do not cause damage or injury to the mother. mutagenicity Whether the product may cause change to the genetic material (DNA) of living cells. synergistic products These products, when combined with exposure to the controlled product, may cause a toxic effect greater than the sum of the effects of the individual materials. For example, product A increases the chance for getting cancer by two times, but when product A and B are used together, cancer risk is increased by 50 times. Section 7: Preventive Measures personal protective equipment Specific personal protective equipment, required to prevent exposure to the product. specific engineering controls Recommended engineering controls, such as ventilation and process equipment design, to be used with the product. leak and spill procedures Safe procedures to clean up spills, leaks and other accidental releases of the product. waste disposal Information such as proper waste container design, safe procedures for handling waste and agencies to contact regarding disposal requirements. handling procedures and equipment Particular procedures and equipment required to handle the product safely. storage requirements Specific safe storage information such as separation from other incompatibles, shelf life, testing for peroxide formation and sensitivity to light, temperature or moisture. special shipping information Safe shipping information such as: • sensitivity to shock and temperature • product identification number (PIN) or United Nations number (UN number) Transportation of dangerous goods (TDG) information (for example, classification, proper shipping name and packaging group) may also be included. Section 8: First Aid Measures specific first aid Specific first aid measures in the event of: Workplacemeasures Safety and Health Division • inhalation • ingestion • skin contact • eye contact WHMIS Guideline Section 9: Preparation Data WHMIS Guide date of original preparation and date of 12 12 The date that the MSDS was first prepared and when it was last reviewed. It should be within three years of the current date, Workplace Safety and Health Division Workplace Safety and Health • eye contact Section 9: Preparation Data date of original preparation and date of last review The date that the MSDS was first prepared and when it was last reviewed. It should be within three years of the current date, providing the date that the MSDS was printed is not acceptable. name and phone number of preparer Gives the name and phone number of the person or group who prepared the MSDS. Exemption from Federal WHMIS Requirement Somefrom controlled products are either partially exempt or completely exempt from Exemption Federal WHMIS Requirement federal WHMIS requirements. The exemption applies to the supplier requirement Some controlled products are either partially or completely exempt from and does not relieve the employer from dutiesexempt imposed under WHMIS for the federal WHMIS management of requirements. these products in the workplace. Partially exempt products Products covered by other federal legislation and exempt from federal WHMIS requirements for supplier labels and MSDS include: 1. explosives within within the the meaning meaning of of the the Explosives 1. explosives Explosives Act Act 2. cosmetics, drugs, within the 2. cosmetics, drugs, food food and and devices devices within the meaning meaning of of the the Food Food and and Drug Act Drug Act 3. 3. 4. 4. pest control within the the meaning meaning of of the the Pest Products Act pest control products products within Pest Control Control Products Act prescribed substances the meaning meaning of of the prescribed substances within within the the Nuclear Nuclear Safety Safety and and Control Act Control Act 5. product, material or substance included in Part II of Schedule 1 of 5. consumer products packaged in accordance the Consumer the Hazardous Products Act and packaged aswith a consumer product in Chemicals and Containers Regulations, 2001. quantities normally used by a member of the general public. These products may have labels and other information provided that meet the Completely exempt products applied legislation rather than WHMIS. When these products are used in workplace, it is theare employer’s dutywhen to train andproducts educate are workers their WHMISa labels and MSDS not required these sold. in If these safe use, storage and handling. products are used in a workplace, it is the employer’s duty to train and educate workers in their safeproducts use, storage and handling. Products that are completely Completely exempt exempt include: WHMIS labels and MSDS are not required when these products are sold. If these 1. wood made ofitwood products are and usedproducts in a workplace, is the employer’s duty to train and educate workers in their safe use, storage and handling. Products that are completely 2. manufactured articles such as appliances, car batteries, etc. exempt include: 3. tobacco and products made tobacco 1. wood and products made of of wood 4. goods handledarticles and transported under the Transportation of Dangerous 2. manufactured such as appliances, car batteries, etc. Goods Act 3. tobacco and products made of tobacco 4. goods handled and transported under the Transportation of Dangerous Goods Act WHMIS Guideline 13 WHMIS Guide 13 Workplace Safety and Health Federal legislation pertaining to WHMIS is available from: Hazardous Products Act: http://laws.justice.gc.ca/en/H-3/62898.html Controlled Products Regulations: http://laws.justice.gc.ca/en/H-3/SOR-88-66/132214.html postal address: Supply and Services Canada Ottawa, Ontario, Canada K1A 0S9 telephone: 1-819-997-2560 Confidential Business Information—Federal Supplier Confidentiality WHMIS legislation attempts to balance the workers’ right to know about hazardous materials in the workplace with manufacturers’ and suppliers’ rights to protect the confidentiality of certain information from their business competitors. WHMIS regulations allow the supplier to withhold specified information only if they comply with certain procedures. If a supplier wishes to limit the release of information, that supplier must file a claim for exemption with the commission established under the Hazardous Materials Information Review Act (HMIRA). A supplier claim for exemption on a label and MSDS can be made for: • the chemical identity, chemical name, common name, generic name, trade name or brand name of a controlled product or the concentration of any ingredient of a controlled product • the name of a toxicological study that identifies an ingredient of a controlled product • information about the supplier When the claim is determined to be valid, the above information can be withheld for a period of three years following the date of ruling by HMRIC. In an emergency, the supplier must disclose the information withheld as confidential business information to a safety and health officer or a medical professional for the purpose of diagnosing or treating a person. Persons receiving this information must keep it confidential. (For more information, visit the Hazardous Materials Information Review Commission website at http://www.hmirc-ccrmd.ca.) WHMIS Guide 14 Workplace Safety and Health Provincial WHMIS Requirements Provincial WHMIS legislation, previously referred to as MR 52/88, became effective October 31, 1988 along with the federal WHMIS legislation. Amended in 2006, the provincial WHMIS legislation is now referred to as Part 35 of the Manitoba Workplace Safety and Health Regulation, M.R. 217/2006. In Manitoba, the Workplace Safety and Health (WSH) Division of Manitoba Labour and Immigration is responsible for enforcement of both federal and provincial WHMIS legislation. This is the result of an agreement between the federal and provincial governments that only the latter would enforce the legislation so that employers and suppliers would not be subjected to inspections by both federal and provincial inspectors. This means, while enforcing WHMIS, safety and health officers of the Workplace Safety and Health Branch have the duty to monitor compliance with the federal HPA, CPR, and Part 35 of the Workplace Safety and Health Regulation. The above is true only for workplaces under provincial jurisdiction. For federally regulated workplaces such as banks, post offices and airports, inspectors from Human Resources and Skills Development Canada (HRSDC) enforce WHMIS legislation. Enforcement of Manitoba’s WHMIS Legislation To enforce provincial WHMIS legislation, safety and health officers of the Workplace Safety and Health Branch primarily check on the following: • controlled products are properly labelled or identified. • MSDS are present in the workplace and are current (no more than 3 years old). All MSDS must be kept for 30 years from the date they were received or produced. • worker training programs have been carried out. Under Manitoba WHMIS legislation, the employer has an obligation to verify that all controlled products are labelled, labels are not damaged and workers have access to current MSDS. Manitoba WHMIS legislation adopts the same exemption as the federal legislation. This means that some hazardous materials will be labelled according to other legislation (ex: Food and Drug Act or Pest Controlled Products Act) and will not display the WHMIS supplier label. If a controlled product has been shipped to a workplace without an MSDS, the employer may receive and store that product in the workplace only if the employer is actively seeking to obtain a MSDS. Until the MSDS is obtained, the product may not be used in the workplace. WHMIS Guide 15 Workplace Safety and Health Requirement for Worker Training Employers in Manitoba must train their workers about the safety and health hazards associated with the controlled products in their workplaces. The training program must be developed and put in place after consulting the workplace safety committee or representative, or workers, depending upon the situation. The training program must be workplace specific, effective and reviewed at least annually or more frequently if new chemicals or other changes are introduced in the workplace. Training should result in worker understanding of: • WHMIS labels • WHMIS symbols • classification of controlled products • MSDS • procedures if there are fugitive emissions • procedures in the event of an emergency involving a controlled product • procedures for identifying, storing, using, and handling of the specific controlled products used at the workplace Employers must also train workers to protect themselves if they are exposed to emissions from a process at the workplace and train them how to handle hazardous waste produced within the workplace. Training should also cover precautions to be taken in case of an emergency such as a spill or fire. Labelling Requirements WHMIS legislation requires that the supplier label not be removed, defaced, modified or altered. If the supplier label becomes damaged or illegible either during shipment or in the workplace, it must be replaced with a new supplier label or appropriate workplace label. Federal legislation identifies specific situations where a supplier label need not be applied. This most commonly occurs where smaller containers are encased in a larger shipping container. In these situations, the purchaser must agree to attach the supplier label before the product is used. The employer must attach an appropriate workplace label to containers for each controlled product produced or used on-site, on secondary containers after a product has been transferred from the original container and on containers where the supplier label is missing or not readable. Workplace labels provide three types of information: • product identifier • specific safe handling information such as personal protective clothing and WHMIS Guide 16 Workplace Safety and Health equipment required • reference to the MSDS, if it is available in the workplace The format of a workplace label is fairly flexible, as follows: • the format can be written directly on the container using a permanent marker. • the language(s) can be chosen to fit the specific workplace. • hazard symbols and hatched borders are optional. A label can be any mark, sign, device, stamp, seal, sticker, ticket, tag, placard or wrapper. Example of a Workplace Label Acetone Extremely Flammable Keep away from all sources of ignition Wear butyl rubber gloves and chemical splash goggles See MSDS Labelling Bulk Shipment Bulk shipment means a shipment of a controlled product that is contained without intermediate packaging in: • a vessel with a water capacity of more that 454 litres • a freight container, a road vehicle, a railway vehicle, a portable tank • a freight container carrier on a road vehicle, railway vehicle, ship or aircraft • a portable tank carried on a road vehicle, railway vehicle, ship or aircraft • the hold of a ship • a pipeline For a controlled product that is received at the workplace as a bulk shipment, the employer is required to attach a label to the container of the controlled product or to the controlled product. Depending on the circumstances, the employer can use either: • a supplier label WHMIS Guide 17 Workplace Safety and Health • a workplace label Controlled products produced in the workplace In Manitoba, where an employer produces a controlled product in a workplace, that product must also be labelled (a workplace label will do for this). For fugitive emissions containing controlled products produced in a workplace, there is no requirement for labelling, but the employer must prepare a MSDS for fugitive emissions. Labelling transferred or decanted products and exemption for portable containers When a product is transferred from the supplier’s original container to another container (decanted), a workplace label must be put on the new container. No label is required if the product transferred to the new container: • is for use by the worker who originally placed the product into a container under his/her own control • will be completely used during that worker’s shift • has its contents clearly identified on the container Controlled product in piping system or vessel The employer must ensure the safe use, storage and handling of a controlled product through a combination of worker education and the use of colour coding, labels, placards or any other mode of identification when a controlled product in a workplace is contained or transferred by the following or similar conveyances: • a pipe • a piping system that involving valves • a process vessel • a reaction vessel • a tank car • a tank truck • an ore car • a conveyor belt Labels for laboratory chemicals • Definition: A laboratory sample is a sample of a controlled product (less than 10 kilograms) intended solely for laboratory analysis, testing or evaluation. A laboratory sample cannot be used for testing other products, WHMIS Guide 18 Workplace Safety and Health Workplace Safety and Health Division for educational and demonstration purposes or for marketing. • A laboratory chemical must be obtained from a laboratory supply house • for A laboratory chemical must a laboratory supplyishouse use in a laboratory only. be Theobtained quantityfrom of laboratory chemical less for use in10a kilograms. laboratory only. The quantity of laboratory chemical is less than than 10 kilograms. There are specific provisions for chemicals used in a laboratory: There are specific provisions for chemicals used in a laboratory: • supplier label not required on chemicals intended for use in laboratory • supplier label not required on chemicals intended for use in laboratory • workplace label not required if employer develops an internal system to decanted products • identify workplace label not required if employer develops an internal system to identify decanted products • Laboratory samples do not require full WHMIS labels but do require a identifier, ingredient disclosure and a statement • product Laboratory samples do not require full WHMIS labels butindicating do require Hazardous Laboratory Sample and emergency contact number. a product identifier, ingredient disclosure and a statement phone indicating Hazardous Laboratory Sample and emergency contact phone number. Summary of Labelling Requirement Summary of Labelling Requirement REQUIREMENTS Product Identifier Supplier Identifier MSDS Statement Hazard Symbol(s) Risk Phrase(s) Precautionary Measures First Aid Measures Safe Handling Info Ingredients Hazard Statement Border Bilingual SUPPLIER LABEL <100 >100 ml ml X X X X X X X X X WORKPLACE LABORATORY PLACARD LABEL LABEL Supply House Sample <10 kg <10 kg X X X X X X X X X X X X X X X X X X X X X X X X Provincial Requirements for MSDS for Employers Provincial Requirements for MSDS for Employers 1. Employer must obtain from the supplier the current MSDS of all controlled the workplace (no morethe than 3 years old).of all controlled 1. products Employerused mustinobtain from the supplier current MSDS products used the workplace (noasmore than when 3 years old). expire. 2. Employer mustinupdate the MSDS required MSDS WHMIS Guide WHMIS Guideline 19 19 Workplace Safety and Health 2. Employer must update the MSDS as required when MSDS expire. 3. If employer is unable to obtain current MSDS, employer must review and revise the existing supplier’s MSDS based on the available information and put a new date (of review) on the MSDS. 4. Employer may provide an MSDS in a format that differs from the supplier format, provided the supplier MSDS is also available in the workplace, and the employer MSDS contains at least as much hazard information as the supplier MSDS. 5. Employer must make both the supplier and employer produced MSDS available to the workplace safety and health committee and other workers, upon request. 6. Employer can make deletions in the supplier MSDS as per confidential business information clause but can not alter the hazard information. Confidential Business Information, Employer Confidentiality Similar to a supplier, if an employer wishes to withhold information on employer MSDS, the employer will also have to follow the federal process established in the HMIRA. In an emergency, suppliers and employers may be required to disclose confidential business information to a safety and health officer or a medical professional for the purpose of diagnosing or treating a person. Persons receiving this information must keep it confidential. Manitoba WHMIS and Hazardous Wastes Part 35 of the Workplace Safety and Health Regulation, M.R. 217/2006, requires that for the hazardous waste (containing controlled product) generated at a workplace, the employer must prepare a MSDS or similar waste profile sheet, and post a label or placard to identify the waste clearly. The MSDS should be made available to workers handling and disposing this waste. The employer may not sell hazardous waste to a person unless the proper MSDS and labels/ placards are provided to the buyer. All supplier MSDS and the employer produced MSDS must be kept for 30 years. WHMIS Guide 20 Workplace Safety and Health WHMIS Guide 21 Workplace Safety and Health WHMIS Guide 22 Workplace Safety and Health WHMIS Guide 23 Prepared by Manitoba Labour and Immigration Workplace Safety & Health