1397 400-600 HP SCR Replacement Procedure

advertisement

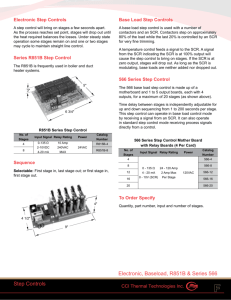

Service Bulletin 1397 400-600 HP SCR Replacement Procedure This publication will guide you through replacement of a 1397 SCR assembly. For additional drive information, refer to the 1397 User Manual, publication 1397-5.0. Replacement Procedure ! ! ! ATTENTION: The drive contains ESD (Electrostatic Discharge) sensitive parts and assemblies. Static control precautions are required when installing, testing, servicing or repairing this assembly. Component damage may result if ESD control procedures are not followed. If you are not familiar with static control procedures, reference A-B publication 8000-4.5.2, “Guarding Against Electrostatic Damage” or any other applicable ESD protection handbook. ATTENTION: Only qualified electrical personnel familiar with the construction and operation of this equipment and hazards involved should install, start and/or adjust this equipment. Read and understand these instructions in their entirety before proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life. ATTENTION: To avoid a shock hazard, assure that all power to the drive has been removed before proceeding. In addition, verify with a voltmeter that no voltage exists at power terminals 181, 182, and 183 before touching any internal parts of the drive. Failure to observe these precautions could result in severe bodily injury or loss of life. Important: If multiple SCRs are being replaced, it is recommended that you remove and replace one heat sink at a time. This helps to ensure that parts are properly replaced. 1. Verify that all incoming power is removed to the drive. 2. Remove the drive cover. Remove the AC Bus Plate 3. For easier access to the AC Bus Plates, remove the Door and Regulator Assemblies. Label and remove wiring/electrical connections as needed. Refer to Figure 1. 2 1397 400-600 HP SCR Replacement Procedure Figure 1 Door Assembly AC Bus Plates (1 of 3) Insulation Plate & Right Angle Bracket (6 ea./drive) Top Phase M10 x 30 AC Bus Bar Bolts Current Transformer Connector M6 x 12 AC Bus Plate Bolts M6 x 12 Insulation Plate Bolts Regulator Assembly 4. Remove the (2) M10 x 30 bolts (22.6 N-m, 200 lb.-In.) that secure the incoming AC Bus Bar connection. See Figure 1. 5. Remove the (8) M6 x 12 bolts (6.2 N-m, 55 lb.-In.) that secure the AC Bus Plate to the top heat sink assemblies. Do Not remove the bus bar from the bus plate. 6. Disconnect the current transformer connector (if working on one of the two phases with this component). 7. Remove the AC Bus Plate/Bus Bar (and possible current transformer). 8. Remove the (2) M6 x 20 bolts (6.2 N-m, 55 lb.-In.) that secure the Insulation Plate and Right Angle Bracket below the bus plate. 9. Remove the (2) M6 x 12 bolts (6.2 N-m, 55 lb.-In.) that secure the Insulation Plate to the heat sink. Remove the Heat Sink Remove and replace one heat sink at a time if multiple SCRs are being replaced. This helps ensure parts are replaced in their proper locations. 1397 400-600 HP SCR Replacement Procedure 3 Figure 2 SCR Clamp Screws SCR Locations for Middle Phase Additional SCR Locations for Regenerative Drives 10. Re-insert the (2) M6 x 20 bolts in diagonally opposite holes of the heat sink to help in the removal and replacement. The bolts will also keep the side bus bar pieces from sliding out of the heat sink after removal. Important:A connector is screwed into the heat sink. Use care during removal to not stress this connector. Use the insulator pieces previously removed for support. See Figure 3. Figure 3 Insulation pieces provide support under the heat sink. Without support, heat sink weight would be supported by the connector, once the SCR clamp is removed. 4 1397 400-600 HP SCR Replacement Procedure 11. Remove the (2) bolts holding the SCR Clamp (refer to Figure 2) in place. Remove the SCR Clamp assembly and set it aside. 12. The heat sink can now be removed. Set it aside, and avoid contact with the machined SCR mating area. Figure 4 Note the bent pieces on the top of the heat sink. The M6 x 20 bolts will guard against the heat sink sliding off of these pieces. 13. Before removing the SCR, note the orientation of the Anode and Cathode (outer ring with red wire). Also, note the connections of the gate lead wires that are attached to the SCR. The replacement SCR must be installed in the same orientation and with the same gate lead connections. Refer to Figure 5. Figure 5 SCR 1397 400-600 HP SCR Replacement Procedure 5 14. Disconnect the leads of the SCR from the tabs on the dV/dt PCB. Remove the SCR from the drive. Note the captive ring opening for the gate lead wires of the SCR. Carefully push the SCR out of its captive ring and set the ring aside. It will be required for the replacement SCR. Replace the SCR 15. Fit the SCR into the captive ring that was just removed. Verify that the gate lead wires have sufficient clearance within the captive ring opening and are not bent or otherwise stressed by the ring. Figure 6 16. Ensure that the pole faces of the SCR are clean, then apply a thin, uniform layer of silicone oil (Allen-Bradley #109704, GE SF 1154, Cerac Special G or equivalent) to each face. 17. Insert the SCR into its proper location. Verify that the cathode outer ring orientation is correct. 18. Attach the gate leads to the gate lead connectors. The red lead connects to “K” and the white lead connects to “G.” Route the gate lead wires such that they do not interfere with the heat sink assemblies. Replace the Heat Sink 19. Orient the heat sink so that the connector and its mating receptacle on the dV/dt PCB are aligned. Press the heat sink firmly against the SCR. Make sure the heat sink is properly supported as shown in Figure 3. 20. Proper assembly of the SCR clamp is shown in Figure 7. Insert the clamp assembly, ensuring that the spring bars and pressure pad remain in position. Alternately finger tighten the bolts, so that the clamp spring bars remains parallel to the heat sink surface. Figure 7 Insulator Sleeves Pressure Pad 3 Spring Bars 6 1397 400-600 HP SCR Replacement Procedure 21. Verify planarity using a PIP Gauge (Rockwell #119518 or equivalent). The gauge should indicate in the “Calibration” region at this point. The PIP Gauge performs a three point planarity check on the surface of the SCR clamp top spring bar. When the surface is deflected during clamp down, the gauge provides an indication of the clamping force exerted. See Figure 8. Figure 8 22. Secure the clamp by alternately turning each bolt 1/4 turn clockwise until the PIP Gauge is aligned with the VE2500 notch. This should require approximately 2 to 3 full turns of the bolts after they have been finger tightened. Regenerative drives have two SCRs under each heat sink piece and two clamps on each heat sink. Proper bolt tightening sequence must be performed as shown below. Figure 9 Tightening Sequence (Regenerative Drives) 2 3 4 1 1397 400-600 HP SCR Replacement Procedure 7 Replace the AC Bus Plate 23. Secure the AC Bus Plate assembly to the drive with (8) M6 x 12 bolts, tightened to 6.2 N-m (55 lb.-In.). 24. Reconnect current transformer electrical connection if applicable 25. Secure the Insulation Plate directly to the heat sink with (2) M6 x 12 bolts. Then secure the Right Angle Bracket to the heat sink with (2) M6 x 20 bolts, tightened to 6.2 N-m (55 lb.-In.). 26. Reconnect the AC Bus Bar connection with (2) M10 x 30 bolts, tightened to 22.6 N-m (200 lb.-In.). 27. Reassemble the Regulator carrier assembly and door assembly to the drive if previously removed. 28. Reconnect all electrical connections disconnected in previous steps (see Figure 10). 29. SCR replacement procedure is complete. Supersedes 1397-SB001B-EN-P – July, 2004 dV/dT PCB 1 THY1 WHT_G4 RED_K4 RED_K3 WHT_G3 THY11 dV/dT Circuit Detail S6/S6R 0.22 µF (3) 20 Ohm (3) 20 Ohm All dV/dT Circuits Located on dV/dT PC Boards. RED_K2 WHT_G2 THY14 281 THY4 WHT_G1 RED_K1 dV/dT PCB 2 RED_K2 WHT_G2 THY16 383 THY6 WHT_G1 RED_K1 WHT_G4 THY2 dV/dT PCB 2 WHT_G4 THY1 dV/dT PCB 1 382 THY5 WHT_G1 RED_K1 dV/dT PCB 3 (Top) THY3 WHT_G4 RED_K4 THY6 WHT_G1 RED_K1 383 THY3 WHT_G4 RED_K4 RED_K3 WHT_G3 THY13 dV/dT PCB 3 (Top) S6 Armature Supply RED_K4 THY2 WHT_G4 RED_K4 RED_K3 WHT_G3 THY12 RED_K4 281 THY4 WHT_G1 RED_K1 RED_K2 WHT_G2 THY15 381 THY5 WHT_G1 RED_K1 S6R Armature Supply 45 (-) 47 (+) 45 (-) 47 (+) 4 11 5 12 6 A C A C A C 14 1 15 2 16 A C A C A C 45 (-) 3 Top 4 5 6 A A A 47 (+) 1 2 3 C C C 45 (-) S6 Thyristor Arrangement 281 382 383 13 47 (+) 281 382 383 Top S6R Thyristor Arrangement Anode Cathode Face Up Anode Face Up 500 thru 700 HP at 575V AC 400 thru 600 HP at 460V AC = on dV/dt PC Boards R = Red W = White Cathode C A 8 1397 400-600 HP SCR Replacement Procedure Figure 10 www.rockwellautomation.com Power, Control and Information Solutions Headquarters Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA,Tel: (1) 414.382.2000, Fax: (1) 414.382.4444 Europe/Middle East/Africa: Rockwell Automation, Vorstlaan/Boulevard du Souverain 36, 1170 Brussels, Belgium,Tel: (32) 2 663 0600, Fax: (32) 2 663 0640 Asia Pacific: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong,Tel: (852) 2887 4788, Fax: (852) 2508 1846 Publication 1397-SB001C-EN-P – August, 2006 Copyright © 2006 Rockwell Automation, Inc. All rights reserved. Printed in USA.