Thyristor Based HVDC with Forced Commutation

advertisement

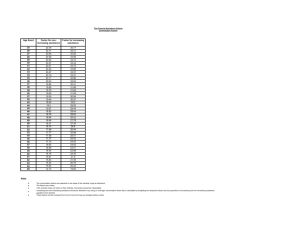

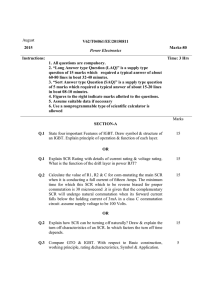

1 Thyristor Based HVDC with Forced Commutation D. Jovcic, Member IEEE Abstract—This paper presents a novel converter configuration, based solely on conventional thyristors and aimed for the use with High Voltage DC (HVDC) Transmission. The converter utilizes resonant turn off and forced commutation with auxiliary thyristors to aid commutation in the converter switches. The PSCAD/EMTDC simulation confirms that the HVDC inverter is capable of operating with a wide range of firing angles, including operation with reactive power export. Further simulation proves that the system is immune to commutation failure even in the case of most severe close single-phase faults. The harmonic generation is comparable to the conventional converter and also the thyristor voltage stress is not significantly increased. The auxiliary thyristors do increase costs, but this is offset by the elimination of reactive power support and the improvements in performance. Index Terms— HVDC transmission, HVDC converters, commutated circuits, reactive power. I. INTRODUCTION HVDC has found many applications in countries worldwide since the first installation in 1954. There are however well known limitations that have hampered further proliferation of conventional HVDC transmission [1]: • The need for reactive power support and in particular variable reactive support which increases costs. • Even modest (around 10%) voltage decrease at the inverter AC terminals will cause commutation failure. Commutation failure causes a short-circuit on DC voltage and thus power transfer is interrupted. • The inability to operate with weak inverter AC systems, which is indirectly caused by poor control capabilities at the inverter side and the above two issues. Recently, HVDC transmission based on Voltage Source Converters has been introduced and some medium-power systems have been installed [2]. VSC Transmission has none of the above issues with conventional HVDC, however other notable limitations are present: • The rating of the converters is limited, presently to around 360MW. • The losses are noticeably higher than with conventional HVDC, caused primarily by the increased switching losses. • The cost of this technology is high. In parallel with the developments in VSC transmission, there has been a stream of research on improving D. Jovcic is with Department of Engineering, University of Aberdeen, Aberdeen, AB24 3UE, UK d.jovcic@abdn.ac.uk conventional, thyristor based, HVDC. In particular the concept of Capacitor Commutated Converters (CCC) has shown promising results [3-7]. The researchers in [3] have concluded that only series capacitor configuration might be of practical importance for improving commutation in HVDC converters. The CCC technology was further investigated and improved in a series of projects [4-7] and recently it has been installed in a practical back-to-back HVDC at Garabi station Brasil. [8]. The CCC concept offers HVDC converters that could operate at an improved power factor and with reduced commutation failure probability. However the following issues with CCC HVDC have been identified: • The occurrence of ferromagnetic resonance [7]. Research shows that this can be resolved using thyristor controlled capacitors or advanced feedback control [5,7], but at the increased costs. • Typically CCC achieves around 10-15% reactive power consumption. In order to operate with a leading power factor, and to completely eliminate commutation failure, very large series capacitors would be needed. This increases voltage stress, harmonics and costs. • The increased voltage stress on thyristors, which can be 2 p.u. or even 3p.u with very large capacitors, • The insulation of series commutating capacitors, • The harmonic generation is somewhat increased, and in particular DC harmonics are significantly larger. It is clear that there is incentive and the scope for further development of HVDC transmission and that the potential benefits are significant. Ideally, the research on HVDC converters would improve HVDC technology: • To operate at higher firing angles enabling reactive power export, • To eliminate commutation failure issues, if possible including most severe single-phase faults, • Not to significantly increase harmonic pollution, or thyristor voltage stress or costs. In this paper, a new HVDC converter that potentially meets the above goals is studied. The concept is based on combining forced commutation and the resonant turn off methods. The basic principles of these techniques are known since they have been used with some low power DC-DC choppers [9-11], although such techniques have not been employed in high power, three-phase circuits. The paper will further give detailed analysis of operation and the method of calculating optimum parameters. A wide range of PSCAD/EMTDC simulation results will be presented to evaluate performance of the new scheme in terms of: reactive power exchange, commutation failure resilience, harmonic generation and stability aspects. 2 II. CIRCUIT DESCRIPTION Figure 1 shows the proposed converter and the AC system at the inverter side of an HVDC. There are two six-pulse bridges in Y and ∆ transformer connections. Thyristors TY1TY6 and T∆1-T∆6 are the main thyristors in the conventional Graetz connection. Each main thyristor has one auxiliary thyristor to aid commutation (TY1a-TY6a and T∆1a-T∆6a). There are also three commutating capacitors Cc and a single resonant capacitor Cs (per 6-pulse bridge). The complete HVDC test system is based on the CIGRE HVDC Benchmark model and all parameters can be found in [12]. This is a monopolar 12-pulse HVDC system with 1000MW, 500kV, 2000A rating, and with weak AC systems at both ends. It is desired to keep the test systems as close as possible to the original CIGRE model, to enable comparisons. Some minor modifications are made, however. Since the new converters enable zero reactive power exchange, implying higher AC voltage, the reactive power support capacitors are removed, and also the transformer ratio is changed. In this way the same DC voltage level is achieved, the same power transfer and with a similar AC voltage level. The remaining circuit including the filters is identical to that in CIGRE Benchmark model. The switchable load zload is added in some tests to simulate large disturbances. All the standard labeling for HVDC variables is used [1]. lower implying less heating and losses [9,10]. This method has not been used in high power applications primarily because large oscillations (resonant conditions) would not be acceptable to the components. However, with 12-pulse HVDC the 6-pulse bridge oscillation may be induced in such way to enable cancellation between Y and ∆ groups. With HVDC converters each thyristor conducts for 120deg intervals, once per cycle. In order to have the minimum current at the end of each thyristor conduction interval, the frequency of the oscillations fc should be triple multiple of the fundamental frequency. Considering further an oscillatory circuit on any phase, where two thyristors are involved, the condition for frequency of oscillations is: (1) fc = n × 6 × f , f = 50 Hz , n = 1,2,... The second condition is that the oscillations mutually cancel in a 12-pulse configuration. Since the Y and ∆ thyristor groups are displaced by 30deg, their oscillations could be cancelled if half the period is a multiple of (1/f)2π/12. This condition is same as that that in (1) and therefore the final formula for frequency in the resonant circuit is (1). The resonant condition is created on each 6-pulse bridge between the transformer impedance Ltr and the resonant capacitors Cs. The value for the capacitance is calculated from the resonant frequency for a LC circuit: III. RESONANT TURN-OFF FOR HVDC Some converters in low power applications use resonant turn-of principle to enable low currents and voltages at switching instants. As a result, thyristor switching stresses are Idc Ls VTY Vdc TY2 2 TY2a Cs Vd1 ITY2a Icc Cc VCc ITY2 TY6 TY3 TY5 TY3a a b c TY1 T∆6 T∆5a Vc T∆4 T∆4a Cc T∆3 T∆3a Y ∆ fault a b c Cc T∆5 Ltr TY1a T∆6a Cc T∆2a (2) TY4 TY4a Cc TY6a Cc T∆2 Cs 1 2 Ltr (2πf c ) Ic TY5a Vd2 Cs = T∆1 a bc Ltr ∆ ∆ Vacinv Pinv, Qinv CBl zf zload T∆1a zinv Figure 1. The proposed inverter converters and the AC system configuration. Pload, Qload Current [kA] 4.00 3.00 2.00 1.00 0.00 -1.00 -2.00 -3.00 -4.00 0.004 IT4 ICc IDC IT1 IC 0.009 0.014 0.019 0.029 0.034 0.039 0.044 Vdc 600 Voltage [kV] 0.024 Time [s] a) Currents 400 200 0 -200 -400 0.004 VCc 0.009 0.014 0.019 Vd2 Vd1 0.024 time [s] 0.029 0.034 0.039 0.044 b) Voltages Figure 2. The resonant turn off principle. A) DC and valve side AC Currents, b) DC voltages and commutating capacitor voltages. 3.0 190 THD 2.5 Alpha inv 2.0 1.5 1.0 180 170 THD Conventional Inv. Commutation failure 160 Commutation failure 0.5 150 Alpha [deg] Assuming that n=1, and using the transformer impedance value Xtr=18%, (Ltr=0.0512H) as given in the PSCAD tutorial model, the capacitance is calculated as Cs=5.5µF. This is a theoretical value assuming ideal LC resonant circuit. By observing the harmonic level during PSCAD simulations, it was found that the best value is lower, around Cs=4.5µF. Note that the resonant circuit is also affected by impedance of the inverter AC system and other parameters, but this influence is not significant, as it will be shown in the simulation section. A remark is also made that there is no benefit in selecting larger n in (1), since at larger frequencies the oscillations are more attenuated and the current minima are higher. Higher switching current implies higher harmonics. Figure 2 shows traces of the variables (PSCAD simulation) in the resonant circuit. In Figure 2a) we see that the AC current has two full cycles in each 120deg interval and it is at its minimum (almost zero) at the instant of commutation. The DC current has no oscillations because of the Y-∆ cancellation. In Figure 2b) it is observed that each 6-pulse group has large oscillations on the DC voltage but the main DC voltage is unaffected by these oscillations and the profile is similar to the conventional inverter circuit. This is important conclusion since DC cable insulation is normally vulnerable to AC currents. It should be noted that the simulation in Figure 2 uses the final circuit, i.e. it also includes the forced commutation circuit presented in Section IV (hence distortion at the end of conduction). Figure 3 shows the benefits of the resonant turn-off circuit by comparing with the conventional inverter. In this figure, the inverter firing angle (α) is gradually increased from 145deg to 180deg. With the conventional inverter the commutation failure occurs below 150deg because of the large commutation overlap and the lack of sufficient commutation margin. With the resonant circuit, better responses are observed. As a consequence of smaller thyristor switching currents, the commutation overlap is smaller, and smaller commutation margin can be allowed. The commutation failure occurs at larger angles, close to 180deg. Harmonics [% of fund] 3 140 0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 Figure 3. Variation in THD, Gamma and Inverter power as Alpha at inverter increases. Case with only resonant capacitors. Note that these results are applicable only at steady state, and because of the presence of disturbances in the actual circuit much larger practical margins should be allowed. As seen in Figure 3, the Total Harmonic Distortion (THD) on the AC voltage is somewhat increased with the resonant circuit. Since the resonant circuit gives only limited improvement in performance, an additional forced commutation circuit is included. IV. FORCED COMMUTATION A. Principles of operation There are a number of forced commutation circuits for conventional thyristors [9,11]. In practice they have been primarily used at very low-power, low-cost circuits and with DC-DC converters. The main issue with forced commutation is the cost of additional thyristors and the increase in harmonic pollution. Nevertheless, with HVDC applications, the additional cost might be offset by the savings in the reactive power supply and significant improvement in the performance like stability and the resilience to commutation failures. The forced commutation circuit shown in Figure 1 is found to be most suitable for HVDC applications. The principle of operation is explained with reference to Figure 4, and considering the commutation from valve TY2 to TY4. Figure 4a) shows the circuit configuration at the instant of ending TY2 conduction and closing TY2a. Prior to this commutation it is assumed that the commutating capacitor Cc is charged to the polarity as shown. At the same instant of firing T4, the auxiliary thyristor TY2a is also fired and this brings the Vcc across the thyristor TY2, implying that cathode of TY2 becomes positive. Since the capacitor Cc brings the highest positive voltage at phase c, the capacitor will take over the load current. Consequently, current through TY2 reduces to zero and assuming that it stays zero for at least the interval equal to the extinction period, thyristor TY2 regains blocking state. In a short time capacitor Cc changes polarity, reducing the capacitor current. At this stage, Thyristor TY4 takes over the load current and commutation is complete. At the end of commutation, capacitor Cc is charged to the reverse polarity as shown in Figure 4b). It is now ready to assist commutation of thyristor TY5. The instant of turning off TY5 (i.e starting of conduction in TY1) is shown in Figure 4b). Figure 5 shows the firing sequence for the main thyristors 4 Idc Ls + Ls TY2 TY2 TY2a TY2a Cs Vd1 - Ic Cc + Cs + Vd1 c Cc Ic - c TY5a TY5 TY5a TY5 - a) Circuit at the instant of closing TY2a 4.00 3.50 3.00 2.50 2.00 1.50 1.00 0.50 0.00 -0.50 0.0200 a) currents Current [kA] + b) Circuit at the instant of closing TY5a Figure 4. The forced commutation. a) Switching TY2a to turn off TY2, b) Switching TY5a to turn off TY5. Voltage [kV] Idc 500 400 300 200 100 0 -100 -200 -300 0.0200 IT2 Ic=ICc TY5a Phase C TY1 Phase A 0 60 TY3 TY6a TY6 Phase B TY2a TY2 120 TY1a ICc 180 240 TY3a 300 TY4 firing TY2 turn off 0.0205 IT4 TY2a turn off 0.0210 0.0215 0.0220 0.0225 0.0230 Vd2 Vd1 VT2 Vc VCc 0.0205 0.0210 0.0215 0.0220 0.0225 0.0230 time [s] Figure 6. Forced commutation between TY2 and TY4, a) corresponding currents, b) corresponding voltages. TY5 TY4 IDC TY2a firing b) Voltages Gate pulses Ic=IT2 TY4a 360 ωt [deg] Figure 5 Firing sequence for the main and the auxiliary thyristors. and the auxiliary thyristors. The conduction intervals for the main thyristors are shown shaded. The pulses for the auxiliary thyristors are supplied at the firing instant of the next thyristor on the same half bridge. The auxiliary thyristors conduct for short periods, usually 10-15deg. Figure 6 shows the actual currents and voltages during the commutation from TY2 to TY4. In Figure 6a) it is seen that the current in the outgoing thyristor TY2 is rapidly brought to zero when the auxiliary thyristor TY2a fires. This implies that there is no commutation overlap in the proposed converter. Note that commutation overlap in conventional converters is usually 15-25deg [1], which deteriorates power factor. It is also seen in Figure 6a) and 2a) that the current in the auxiliary thyristors is small, and the RMS value is calculated to around 12% of the RMS current of the main thyristors. Considering that the voltage across the commutating thyristors is similar to the main thyristors, the commutating thyristors will have below 1/8 of the power rating of main thyristors. In Figure 6b) we observe that the voltage across the main thyristors (Vt2) reverses during the commutation, as the result of the connection of commutating capacitors, and this enables thyristor turn-off. The additional benefit is that this reverse voltage will also accelerate regrouping of charges on p-n junction and it will shorten the thyristor extinction time [9,10]. To appreciate the benefit of the proposed converter, it is emphasized that the commutating capacitors are charged from the DC voltage. If the DC voltage is at a required level, the capacitors Cc will be charged enabling commutation of the main thyristors, regardless of the actual AC voltage levels. The commutating voltage is therefore provided from the DC side, rather than from the AC side as in conventional inverters. This is very important for HVDC applications since DC faults are rare, whereas AC faults more frequent. B. Sizing of commutating capacitors The size of the commutating capacitors Cc is determined considering the required performance. Theoretically, commutating capacitors should be large enough to store energy required to sustain the load current for the interval larger than the extinction time of thyristors Te. As seen in Figure 2b), the voltage on commutating capacitors changes polarity at each commutation, but only the first half of the voltage change interval enables reverse voltage across main thyristors. A simplified calculation for the capacitor is [11]: Cc dVcc = icc dt dt Cc = t2 1 i dt ∫ t (Vcc 2 − Vcc1 ) 1 cc (3) (4) where the capacitor voltage changes from Vcc1 to Vcc2, in the interval t2-t1 assuming the capacitor current is icc. The time interval for capacitor voltage reversal is: t 2 − t1 = 2(Te + Tm ) (5) where Te is the extinction time, and Tm is the commutating margin in seconds. The extinction time for high-power thyristors varies widely with the power rating, the circuit conditions, the manufacturer and type, and in general it is between few tens of microseconds and several hundreds of microseconds [10]. Since the forced commutation introduces fast voltage reversal across thyristors, the extinction time will be smaller than with conventional inverters and it is initially taken as Te=200µs. The additional margin for safe commutation Tm, is required to enable thyristors achieving blocking state even under disturbances when current might increases or DC voltages reduces, and simulation tests indicate 5 that around 1-1.5deg is adequate. This is significant improvement since in conventional inverters the commutation margin is usually over 10deg. The total interval for the voltage Vcc reversal is therefore taken as (t2-t1)=500µs. The change in capacitor voltage is close to twice the 6-pulse bridge DC voltage, and it can be taken as approximately (Vcc2Vcc1)=400kV. The capacitor current ICc is assumed as: I Cc = I m + I o sin(6ω o t ), (6) where: Io=1.7kA - the peak current, Im=2kA – the DC current, ωo=314.15rad/s, - the fundamental frequency. Replacing (6) in (4) we obtain the formula for capacitor Cc: 2π I o cos(π − (t2 − t1 ) ) − cos(π ) 1 / 300 + I m (t2 − t1 ) (7) Cc = − ∆V 6ω0 ∆V but the following design aspects reduce harmonics: • The proposed converter operates at firing angles closer to 180deg where the harmonic generation is lowest because of small difference between phase voltages. Conventional inverters operate around 140deg. • There is no commutation overlap because of the fast turn-off of the thyristors. Conventional inverters have commutation overlap of 15-25deg, which deteriorate voltage profile. Analysing the results in Figure 7, the system with Cc=4.0µF is selected as the base model for all further tests, since it has good overall performance. With this system the maximum extinction time should be below 200µs to enable operation without commutation failure under most sever faults. The system is capable of operating at high firing angles corresponding to around 500MVar reactive power export. THD Extinction time The required capacitor value is initially calculated as Cc=3.4µF. The final value for the capacitance Cc is determined using simulation testing. By reducing the value of commutating capacitors the harmonics are reduced, but too low value would jeopardize safe commutation during faults. A series of test is performed by varying the capacitor Cc size and considering a range of values for the extinction time (50<Te<300µs). The following observations are made: • The harmonic level on AC and DC voltage (individual harmonics and total harmonic distortion (THD)) • The incidence of commutation failure during single and three-phase faults, and current step changes. In the commutation failure tests, the value of the inverter firing angle is limited to 190deg and the most severe zeroimpedance single-phase faults at the inverter terminal are applied. The capacitor value that enables operation without commutation failure is recorded. The summary of these results is shown in Figure 7. The test results show that, as an example, selecting Cc=4.0µF, the converter can operate with no commutation failure if the thyristor extinction time is 200µs. Note that this system would be able to operate with larger extinction angles at steady-state but the commutation failure would occur if the voltage on a single phase drops to some low values. The Figure also shows the THD level assuming operation at zero reactive power exchange. It is seen that total harmonic level is higher but it is of the same order of magnitude as with equivalent conventional inverter. Table 1 specifies further the values of individual harmonics. We can conclude that the filtering costs would not be significantly increased. Furthermore, the DC side harmonics are lower because of the additional capacitors. The overall harmonic generation would be similar or better than with CCC HVDC. The low THD level might be surprising considering the additional “spikes” introduced by the commutating thyristors, THD conventional inverter Figure 7. The AC voltage total harmonic distortion [THD] and the maximum extinction time as the function of the commutating capacitance. TABLE 1. INDIVIDUAL HARMONICS AS THE FUNCTION OF COMMUTATING CAPACITOR SIZE. Harm. [%] 0.22µ µF 1.2µ µF 4µ µF 10µ µF 5th AC side 7th AC side 11th AC side 13th AC side THD AC volt 6th DC side 12th DC side 0.13 0.07 0.55 0.69 1.0 0.1 1.13 0.07 0.03 0.8 1.32 1.47 0.04 2.44 0.07 0.03 1.33 0.94 1.29 0.04 1.46 0.07 0.03 1.32 1.2 1.51 0.04 1.61 Conv. Invert. 0.027 0.014 0.89 0.61 0.97 0.05 3.00 C. The operating parameters The results for the harmonic level in Figure 7 are obtained by assuming steady-state operation at around neutral reactive power exchange. As with conventional converters, the harmonic level will change as the operating point changes. In Figure 8, the inverter firing angle is increased in the interval 155-190deg, while keeping the inverter AC voltage constant (an AVR is used at the AC source). The operating point at approximately 2.65s (with around 165deg angle) corresponds to the results in Figure 7. Note that the neutral reactive power exchange is achieved at around 165deg since the series connected commutating capacitors contribute to the additional reactive power generation. Also, over 500Mvar is exported at 190deg as seen in Figure 8b. We observe in Figure 8a) that the harmonics are minimal around 165deg and they increase with the increase or decrease of the firing angle. As an example if 300MVar is exported the harmonic level would be 3 times that with conventional inverter. It is presumed that such system would be normally 6 4.0 3.5 3.0 2.5 2.0 1.5 1.0 0.5 0.0 12thDC Alpha inv 13th THD 11th 5th 1.2 1.7 2.2 2.7 7th 3.2 3.7 190 185 180 175 170 165 160 155 150 Alpha [deg] Harmonics [% of fund] operated around neutral reactive power exchange and only transient variations in a certain firing angle range would be allowed. If a permanent operation at a wide range of firing angles is adopted, filtering would be more demanding and adaptive/active filtering might be needed. The system already has a set of filters and therefore the results serve for relative comparison with conventional inverters. Note also that the DC voltage level follows the cos(α) relationship and therefore the active power reduces on either side of the 180deg operating point, as seen in Figure 8b). 4.2 Power [MW], [MVar] a) Harmonic level and inverter firing angle 400 200 0 -200 -400 -600 -800 -1000 Q-inv reactive power regulation, although this is not common in HVDC. The proposed inverter controller structure is shown in Figure 9, where the gains are obtained using model in [13] and they are given in the Appendix. The controller consists of two independent units: the low-gain AC voltage PI controller and the fast stabilizing feedback loop. The stabilizing feedback loop is based on the AC current angle feedback, since this signal was found to be most beneficial in improving stability of HVDC systems [14]. Assuming that the AC voltage is close to the nominal value such system will operate with the inverter firing angle around 165deg. During fast disturbance the stabilizing controller (which has high gain) will have dominant influence. If the AC voltage changes, the slowacting AC voltage PI controller will modify the firing angle thus changing the reactive power injection in order to return the voltage to nominal level. TABLE 2 LOCATION OF DOMINANT EIGENVALUES Conventional inverter -38.6±433.7j -190.6±633.4j -109.3±217.5j -19.6±9.5j -12.9 -8.1 With forced commutation -32±435.2j -184.4±632j -69.7±215.1j -3.96±5.18j -4.86±4.67j Vacinvref Vacinv P-inv 1.2 b) Inverter power 1.7 2.2 2.7 3.2 3.7 4.2 Time [s] Figure 8. Variation in harmonics level and power with the increase in inverter alpha 160-190deg. V. DYNAMIC STUDY The proposed inverter includes the resonant capacitors Cs, and also the commutating capacitors Cc, that influence dynamics at the system level. Also, there is no commutation overlap, implying very low commutating resistance Rc=6fLtr [1], which is assumed zero. A reduction in the commutating resistance has negative influence on the stability [1,14]. The inverter controller gain also changes because of the different operating point. On the positive side, the proposed converter has no commutation failure issues, therefore the inverter firing angle can be varied in a wide range, and this implies possibility for versatile large-gain inverter feedback control. The HVDC-HVAC, MATLAB-based, small-signal analytical model [13] is used to study stability of the proposed converter. A simplified model is developed assuming that only the DC side capacitance and the commutating reactance is changing. Table 1 shows the location of most dominant eigenvalues, assuming constant firing angle operation (no active control) at the inverter converter. It is seen that with forced commutation the eigenvalue real parts are smaller, and stability is slightly degraded as expected. The system stability can be improved if a feedback controller at the inverter side is used, like AC voltage or + 1/(Tis+1) Θaci - kv Kvi/s + + + 1/(Tis+1) Θaci - AC current angle ka 194 αinv 145 Stabilising feedback loop Figure 9. Inverter controller. VI. SIMULATION RESULTS This section presents the PSCAD/EMTDC simulation of HVDC with the proposed converter circuit. The extinction time for all thyristors is set to 200µs, and a low simulation step (10µs) is used to improve accuracy. Figure 10 shows the electrical and control variables following a 0.05s zero-impedance single phase fault at the inverter terminal. Phase A voltage reduces to zero during the fault, but as it is seen in Figure 10c) DC voltage remains positive and there is no commutation failure. For comparison, the conventional converter response is also shown, and it is evident that commutation failure is present because of the short circuit on the DC voltage. The extinction angle shows transient dip but it returns to the nominal value of around 5deg as seen in Figure 10b). Figure 10d) shows the power, where it is evident that the new converter shows much better power delivery during the fault. Figure 11 shows simulation of a 0.1s three-phase lowimpedance fault at the inverter terminal. It is evident that there is no commutation failure and that the responses are much better than with the conventional converter. The simulation with a weak AC system, in Figure 12, is also given since HVDC normally have difficulties when inverter AC system has low Short Circuit Ratio (SCR) (say 7 200 100 0 0.25 200 Inverter firing angle 5 190 Gamma Y 4 180 3 170 2 160 1 Alpha [deg] Gamma [deg] 6 0.30 -150 0 140 0.1 0.2 0.3 b) Inverter Gamma and Alpha 600 0.4 0.5 3.0 Vdc 500 2.5 400 2.0 Idc 300 1.5 200 1.0 100 0.5 Vdc - Conventional Inv. 0 0.0 0.0 0.100 0.1 0.2 0.3 c) DC voltage and DC current 300 100 -100 -300 -500 -700 -900 -1100 0.4 0.5 Q inv P - Inv Conventional Inv. 0.200 0.2 0.3 0.4 0.5 time [s] Figure 10. System response after a 0.05s zero impedance single-phase fault at inverter AC terminal. 0.300 Vdc 400 300 200 100 Vdc - Conventional Inv. b) DC voltage 300 100 -100 -300 Q inv P inv Conventional Inv. -500 -700 P inv -900 -1100 0.050 0.150 0.250 0.350 0.450 0.550 0.650 c) Power 300 280 260 240 220 200 180 160 140 120 0.05 Vacinv Vacinv Conventional Inv Alpha inv 0.15 d) Inverter AC voltage 0.1 0.250 500 P inv 0.0 0.150 0 0.050 0.150 0.250 0.350 0.450 0.550 0.650 150 Gamma D 0.0 DC Voltage [kV] 0.20 Power [MW, MVAr] 0.15 AC Voltage [kV] 0.10 a) AC voltages DC Voltage [kV] -50 600 -300 0.05 Power [MW, MVAr] 50 a) AC voltages -200 d) Power 150 -250 0.050 -100 DC current [kA] Voltage [kV] 300 Vinva Vinvb Vinvc 250 0.25 0.35 0.45 0.55 200 190 180 170 160 150 140 130 120 aplpha [deg] Vinva Vinvb Vinvc In this Figure the capability of fast regulation of AC voltage using HVDC converters is also demonstrated. In this aspect, the proposed concept can be compared with VSC based HVDC transmission. To enable full comparison with the conventional converters, the voltage across main thyristors during steady-state operation is analysed as shown in Figure 13. It is evident that there is only 30-40% increase in the peak forward blocking level. Contrasting further this converter against conventional inverters it is mentioned that reliability is degraded because of the increased number of components. Voltage [kV] SCR<2) [1]. The inverter AC impedance (zac in Figure 1) is modified to represent a circuit with SCR=1.2, at 75deg. The considered system is therefore extremely weak, at the margin of AC transfer capability, and an HVDC with conventional converters would not be able to maintain stable operation. At 0.1s an additional large load (400MW, 200MVAR) is connected to the inverter AC bus (as shown in Figure 1). Finally at 0.9s a low-impedance single phase fault is applied. The purpose of this test is to demonstrate that the AC circuit parameter changes can not affect the proposed converter to a degree that jeopardize stable operation. Note that minimal change in the resonant circuit frequency does occur but the normal operation is maintained. It is concluded that the proposed converter is suitable for very weak AC systems and that complete resilience to commutation failure is maintained. 0.65 time [s] Figure 11. System response after a 0.1s low impedance three-phase fault at inverter AC terminal. Power [MW, MVAr] 8 500 300 100 -100 -300 -500 -700 -900 -1100 significant cost savings are also introduced because of the elimination of reactive power support, downsizing of converter transformers and the much-improved performance. P load Q load Q inv VIII. REFERENCES [1] [2] P inv [3] 0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 280 260 240 220 200 180 160 140 200 190 180 170 160 150 140 130 Vacinv Alpha inv 0.0 0.2 0.4 b) AC voltage and Inverter alpha 0.6 0.8 1.0 1.2 [4] aplpha [deg] AC Voltage [kV] a) Inverter power and load power 1.4 [6] Time [s] Figure 12. Simulation results with very weak inverter AC system (SCR=1.2). At 0.1s, a 400MW, 200MVAr load, is connected, and at 0.9s there is a zero impedance single phase fault. Voltage [kV] [5] 500 Vt2 400 300 Vt2c - conventional 200 100 0 -100 -200 0.000 0.010 0.020 Switch on Vt2c [7] [8] [9] [10] [11] Switch on Vt2 0.030 0.040 [12] [13] Time [s] [14] Figure 13. Comparison of voltage stress across main thyristors. VII. CONCLUSIONS This paper proposes a converter for HVDC systems, which is based solely on conventional thyristors, and is capable of operating with firing angles that provide leading power factor. It enables HVDC to have wide range of reactive power exchange in exporting and importing region. For the minimal harmonic generation the operating point should be linked with the neutral reactive power exchange, which is close to 165deg in the proposed circuit. The HVDC system with such converters will have approximately 50% increased harmonic content and slightly increased thyristor voltage stress compared with conventional converters. The PSCAD/EMTDC simulation with 200µs thyristor extinction time is used to test the proposed converter. The results demonstrate that even for zero impedance single-phase faults at the inverter AC bus, commutation failure will not occur. The tests with very weak AC systems confirm good operation and unchanged resilience to communication failure. Considering the auxiliary thyristors and capacitors, the proposed converter will have higher costs and reduced reliability compared with conventional converters. However P. Kundur: “Power System Stability and Control” McGraw Hill. 1994. Kjell Ericsson "Operational Experience of HVDC Light" Seventh International Conference on AC-DC Power Transmission IEE. 2001, pp.119-24. London, UK J. Reeve, J.A. Baron, G.A. Hanley, “Technical assessment of Artificial Commutation of HVDC Converters With Series Capacitors” IEEE Transactions on Power Apparatus and Systems Vol 8 no 10 October 1968, pp 1830-1840 M.Meisingset, A.M. Gole, “A Comparison of Conventional and Capacitor Commutated Converters Based on Steady State and Dynamic Considerations” Proceedings, IEE 7th conference on AC-DC transmission, London November 2001, pp49-54 Sadek, K.; Pereira, M.; Brandt, D.P.; Gole, A.M.; Daneshpooy, A. “Capacitor commutated converter circuit configurations for DC transmission” IEEE Transactions on Power Delivery, Vol. 13 (4) Oct 1998 Pp: 1257-1264 Gomes, S., Jr.; Martins, N.; Jonsson, T.; Menzies, D.; Ljungqvist, R “Modeling capacitor commutated converters in power system stability studies” IEEE Transactions on Power Systems, Volume 17 (2) May 2002, Pp 371-377 D.A. Woodfford, “Solving the Feroresonnace problem When Compensating a DC converter Station with a Series capacitor” IEEE transactions on Power systems, Vol 11, no 3, pp 1325-1331. N Ottosson, L Kjellin, Modular back-to-back HVDC with capacitor Commutated converters (CCC) IEE 7th conference on AC-DC transmission, London November 2001, pp55-59 C. Lander “Power Electronics” McGraw Hill, 1987 N. Mohan, T. M. Undeland, W. P. Robbins “Power Electronics Converters, Applications and Design,” John Wiley & Sons, 1995 R.M.Davies, J.R.Melling, “Quantitative Comparison of Commutation circuits for bridge inverters” Proceedings of IEE, Vol 124 (3) 1977, pp 237-246. M. Szechman, T. Wess and C.V. Thio, April 1991, "First Benchmark model for HVDC control studies", CIGRE WG 14.02 Electra No. 135, pages: 54-73. D. Jovcic N. Pahalawaththa, M. Zavahir “Analytical Modelling of HVDC-HVAC Systems.” IEEE Trans. on PD, Vol. 14, No 2, pp. 506511, April 1999 D.Jovcic N.Pahalawaththa, M.Zavahir, “Inverter Controller for Very Weak Receiving AC Systems” IEE Proceeding – Gen., Transmission and Distribution, Vol. 146, no 3, May 1999, pp. 235-240. IX. APPENDIX INVERTER CONTROLLER GAINS Comment AC voltage control Stabilising control Filter Gain Kv Kvi Ka Ti value 0.3 [deg/kV] 5 [deg/kVs] -0.14 0.008 [s] X. BIOGRAPHY Dragan Jovcic (S’97, M’00) obtained a B.Sc. in Control Engineering from the University of Belgrade, Yugoslavia in 1993 and a Ph.D. degree in Electrical Engineering from the University of Auckland, New Zealand in 1999. He is currently a lecturer with the University of Aberdeen, Scotland where he has been since 2004. He also worked as a lecturer with University of Ulster, in period 2000-2004 and as a design Engineer in the New Zealand power industry in period 1999-2000. His research interests lie in the areas of FACTS, HVDC and control systems.