Sealed Enclosure Luminaires

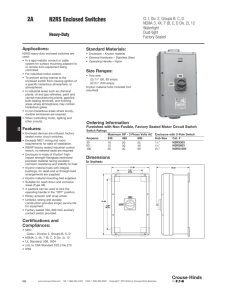

advertisement

Sealed Enclosure Luminaires Designed and sealed for critical environments Sealed Enclosure LED Luminaires SE Designed and manufactured in the USA LED SimpleSeal™ Overlapping and Inset Door Series Supporting stringent cleaning protocols From one-piece seam welded housings to IP ratings that ensure the integrity of pressurized plenums, Kenall offers LED overlapping and inset door luminaires ideal for environmentally critical applications. Designed to withstand the highest cleanliness standards and most stringent cleaning protocols, you can depend on Kenall for industry-leading expertise in sealed enclosure lighting. CSEDI Series CSEDO Series CSESO Series •Lumen packages: 4358 to 22426 •82 CRI •60,000-80,000 hr LED Lifetime (L70) •Universal recessed ceiling mount for grid or flange 1'×4', 2'×2', 2'×4' •Diffused high-efficiency lens •One piece inset doorframe, secured to housing with aircraft cables. •Lumen packages: 4358 to 22426 •82 CRI •60,000-80,000 hr LED Lifetime (L70) •Universal recessed ceiling mount for grid or flange 1'×4', 2'×2', 2'×4' •Diffused high-efficiency lens •One piece overlapping doorframe, secured to housing with aircraft cables. •Lumen packages ranging from 4258 to 20595 •82 CRI •60,000-80,000 hr LED Lifetime (L70) •Ceiling mount; surface – 1'× 4', 2'×2', 2'×4' •Diffused high-efficiency lens •One-piece doorframe provides air-tight integrity of luminaire C IP65 ISO 5 Class 100 CCEA Approved C www. kenall.com IP65 K230 P: 800-4-Kenall ISO 5 Class 100 CCEA Approved FN Email: info@kenall.com C IP65 ISO 5 Class 100 FN 10200 55th Street Kenosha, WI 53144 The Kenall product shown on this page is designed and manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA. Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof. SimpleSeal™ and Millenium™ Downlight Series LED Lighting designed with critical environments in mind Whether your lighting project involves an environmentally critical application where leakage, cleanability and electromagnetic interference are of primary importance, or a less critical area where aesthetics and other optical requirements are key, Kenall provides sealed LED downlights for your consideration. CDL Series HRDL Series •Lumen packages: 1001 to 1283 •Minimum 80 CRI •125,000 hr LED Lifetime (L70) •Recessed ceiling mount – 6" aperture LED downlight •Flush lens for easy cleanability •IP65 per IEC 60598 •Lumen packages: 1528 to 1916 •Minimum 70 CRI •100,000 hr LED Lifetime (L70) •Recessed ceiling mount – 6" aperture LED downlight •Sealed regressed lens and optical chamber •Tool-less design for easy installation and maintenance •Regressed Lens C K230 IP65 ISO 5 Class 100 CCEA Approved MIL STD 461F IP64 CCEA Approved EnviroSeal™ Linear Wraparound Series Delivering high levels of vertical illuminance Kenall offers a series of ceiling and wall mount linear wraparound luminaires designed to to provide higher levels of vertical illumination and superior environmental performance. ES Series •Lumen packages: 2236 to 8893 •82 CRI •80,000 hr LED Lifetime (L70) •Available in 3", 5", 8"and 12" widths •Lengths available in 2', 4' and 8' •One-piece, heavy gauge, seam-welded, cold-rolled steel or brushed 304 stainless steel housing •High impact extruded DR acrylic or polycarbonate lens •Optional EL pack available •UL/CUL Wet Location listed; optional UL Classified IP65- ceiling mount IP65 OPTION www. kenall.com P: 800-4-Kenall Email: info@kenall.com 10200 55th Street Kenosha, WI 53144 The Kenall product shown on this page is designed and manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA. Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof. LED T8 LED Retrofit Kit T8 Replacement Lamps •LumenPackages:5059-5820 •5-yearcombinedlampand driverwarranty •ApprovedfortheDesignLights Consortium®(DLC) QualifiedProductsList(QPL) •Ceramicmid-powerLEDarray maintainscolorstability,improves lumenmaintenanceovertime •100,000hrLEDLifetime(L70) •Extruded6063-T5aluminum heatsinkforeffectivethermal management;extendsluminairelife •Extruded,impact-resistantfrosted acryliclens •3000K,3500Kand4000KCCT; 80CRI •89-102lumensperwatt •120-277volts •24/7operation •MeetsorexceedsFCCCFRPart15 •Compatiblewithselectbattery backupsystems •>0.90PowerFactor •TestedinaccordancewithUL1598C byIntertek •RoHSCompliant •Designedandmanufactured intheUSA C Kenall’s T8 LED Retrofit Kit Theonlyretrofitoptionthatmaintainscriticallistingsof installedIPrated&Wetlistedsealedenclosures. Listings & Certifications NSF2—AnNSF2Listingdenotesthattheluminairehas beenevaluatedforcorrosionresistance,cleanabilityand theabilityofexposedmaterialtowithstandnormalwear. Thissupportstheinfectioncontrolstandardsestablished byhealthcarefacilitiesasitindicatesthattheluminaireis easytosanitize. ISO 5 Class 100 K230 IP64 IP65 OPTION MIL STD 461F ISO5—SuitableforISO5,Class100RatedRooms (FED-STD209E).Measuresthenumberofparticlesequal toorgreaterthan0.5mminonecubicfootofair.The measurementmustnotexceedspecifiedparticlelimitsin orderforthespacetobeconsideredacontrolled‘clean room’environment. CCEA Approved CCEAApproved—TheCityofChicagoEnvironmentalAir(CCEA) ratingensuresthattheluminaireisinherentlyairtight.Wiringand/ orbranchcircuitterminationsaresealedoffandgasketedfromthe plenumairspace.Thislistingensuresthattheluminaireissealedto limitairflowfromtheroomsidetotheplenum. UL/CULListed—TheULsymbolsignifiesthatUnderwriter’s Laboratory(UL)hasdeterminedthatamanufacturerhas demonstratedtheabilitytoproduceaproductcomplyingwith UL’srequirementswithrespecttospecificrisk,performanceunder specificconditions,compliancewithregulatorycodesandspecified standards,oranyotherconditionsasdeterminedbyUL. K230—TheK230performancestandarddeterminesa fixture’sabilitytorestrictthepassageorpenetrationof contaminantswhensubjectedtoaprescribedpressurelevel ineitherpositivelyornegativelypressurizedenvironments. IP64—ULCertifiedIP64perIEC60598ensuresthatthe enclosureisdust-tightandprotectedagainstsplashing waterwithoutanyharmfuleffects. MILSTD461F—MilitaryStandardstestingmeasurementscover bothradiatedandconductedelectromagneticemissionsinaddition tomaximumallowableamountsofemittedenergybasedonboth frequencyrangeandfieldstrength.LuminairesmeetingMILSTD 461FposethelowestpossiblelikelihoodofcausingEMI-related issues. C IP65—ULCertifiedIP65perIEC60598ensuresthatthe enclosureisdust-tightandprotectedagainstjetstreamsof waterfromanydirectionwithoutanyharmfuleffects. ETL—AproductbearingtheETLListedMarkisdeterminedto havemettheminimumrequirementsofprescribedproductsafety standardsascertifiedbyaNationallyRecognizedTestingLaboratory (NTL).Themarkalsoindicatesthatthemanufacturer'sproduction siteconformstoarangeofcompliancemeasuresandissubjectto periodicfollow-upinspectionstoverifycontinuedconformance. Kenallwillrepairorreplaceanyhighabuselightingfixturerendered inoperableduetointentionalabusebyvandalsoraccidentalimpact forthenormalservicelifeofthefixture. www. kenall.com P: 800-4-Kenall Email: info@kenall.com 10200 55th Street Kenosha, WI 53144 The Kenall product shown on this page is designed and manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA. Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof. What is a Sealed Lighting Enclosure? A sealed lighting enclosure is designed to separate its internal lighting components from the surrounding environment. One reason for this separation is to protect the fixture’s internal components from environmental dirt, dust, moisture and other performance-inhibiting elements. A second, and in some cases critical, reason is to protect the environment from heat, sparking, arcing, dirt, dust, contaminants, moisture, air pressure leakage, Electromagnetic Interference (EMI) and other conditions or events that could adversely affect the safety of the people or the integrity of the processes being performed. What are the Performance Requirements of a Sealed Lighting Enclosure? There are four major challenges to creating an effective sealed lighting enclosure: 1. A housing that does not leak. 2. A doorframe that does not leak. 3. A doorframe-to-ceiling /housing interface for fixtures that do not leak. 4. A housing-to-ceiling interface that does not leak. By reviewing the performance criteria, design, listings, and certifications of each of the luminaires in this brochure, you will see how Kenall has satisfied all of these mission critical performance requirements. Recommended Applications Cleanroom Containment Hazardous Location Environmental Locations Food Processing www. kenall.com P: 800-4-Kenall Email: info@kenall.com 10200 55th Street Kenosha, WI 53144 The Kenall product shown on this page is designed and manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA. Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof. 10200 55th Street Kenosha, WI 53144 262-891-9700 www.kenall.com ©2015 Kenall Mfg. Co. All rights reserved. L10068-042415 ¯¯