technical specifications of splice closure

advertisement

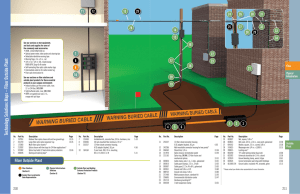

1. 2. 3. 4. 5. 6. 7. ISO Certificate Quality Manual HES Policy and Certificate Manufacturers Authorization Technical Data Sheet Compliance to Technical Specifications Testing Plans and Procedures All documents in French and English both Compulsory. TECHNICAL SPECIFICATIONS OF SPLICE CLOSURE The connection and junction boxes are intended are to: 17.1Ensure a perfect seal, with water and steam, the connections of the fiber optic cables 17.2 Establish the integrity of the casing and the carriers, including mechanical and electrical continuity 17.3 Protect fiber connectors against the elements in all types of installation. 17.4 Ensure the arrangement of fiber connections and storage of excess fiber. 2. Application Areas The installation and use of systems of splice protection must be possible in the following cases : 18.1 Cables buried optical fibers. 18.2 Optical fiber cables driving (rooms). 19.1 Splice enclosures will be installed in rooms provided for this purpose and 3. General will: description 1. Object Management of the arrival of the optical fiber cables and identification thereof, The mooring of fiber optic cables for interrelating the container, The organization, development of fiber and identification of these, Protection and coiling of the fibers on tray or cassette, Storage and protection of splice points suitable support, The labeling of the fiber optic cable at the splice boxes and adduction at the mask and out of rooms including rooms prints. 19.2 They will be designed to meet the fiber bend radius through guides, rings or organizers factory installed by the manufacturer. The opening of these containers must be maximum guarantee the physical safety of the fibers during handling as well as easy access to the splices. 19.3 Recommendation ITU-T 19.3.1 Splice protection systems must meet the requirements of the Manual of ITU-T "CIRP / FO" latest edition. 19.3.2 Nature of splice protection systems: Splice protection systems should preferably be made of fiberglass or other alloy which increases their mechanical strength according to the latest recommendations of the ITU-T and Series corresponding ISO 9000. 19.3.3 The Manufacturer will describe the mechanics and technical design of the proposed splice protection systems. 19.3.4 The connection methods of fiber optic cables described in Chapter III of the manual (CIRP / FO) of the ITU-T must be 19.4 considered. Capacity protection systems splices - The Manufacturer must comply with the following specifications: 19.4.1 Connecting the boxes must allow the junction of at least two independent optical fiber cables. 19.4.2 Junction boxes should allow the junction of four independent optical fiber cables. 19.4.3 Splice protection systems must be equipped with the arrangement of fiber optic systems. 19.4.5 Junction boxes must accommodate the total number of fibers with lengths between 1.5 and 2 meters for interventions. The curvature of the fibers inside the boxes must be greater than thirty (30) millimeters. 19.4.6 Cassettes must be equipped with appropriate housing for both types of splices (mechanical and bow). 4. Features environmental and mechanical 20.1 Factors to be considered for closure fittings are those described in the most recent manual "CIRP / FO" ITU-T (Chapter V, paragraph 2. Page 84). 20.2 The permissible limits of use of the proposed splice protection systems must be specified by the manufacturer. The testing method of these parameters must be specified and submitted for approval. 20.2 Splicing box Due to its location in drawing room, this box should have high protection features: shock resistance 20 joules (IK 10 according to EN 50102) protection against the effects of immersion (IP 68 to EN 60529) temperature range from - 30 ° to + 70 °, tensile strength of 100 daN by mechanical attachment of the cable to the box. These criteria will be achieved by: a pressurizing continuously to 100 mbar, a sealing body by elastomeric seal, a sealing entries by heat shrink and / or resin, or mechanical clamping on joint. Furthermore this box will have the following options: Opens and closes without removal, sufficient number of entries (minimum 4) for all architectures, inputs and fasteners allowing a cable to optical fibers of diameter 25 mm, inputs for reoperation or passage in cable to any input, inputs providing mechanical retention of the cable upstream and downstream of the stuffing box, versatile mooring systems for different types of cables, clamping sole plates for fixing all the mechanical elements of the fiber optic cable to the housing, elastomeric sealing gasket compressed between body and cover with stainless steel screws, pressurizing using the helium valve 0.5 bar (for maintenance and support for localization) fixing suspension of the box on the solder side panel road to pull chamber, placing the earth potential by terminals accessible from the outside. The inputs of fiber optic cables will be used interchangeably on arrival and departure of fiber optic cables to allow a reserve coiling without any constraint inside the drawing rooms. In case of mechanical failure, the entries, the body or the cover should be able to be replaced without a cut optical connections being necessary. These boxes will: the single junction or derivation, wiring passage (uncut coiled tubes and left waiting in each cassette respecting the color code of the ITU-T standard). 5. Technical characteristics of splicing systems 6. Implementation plan 7. Layout systems optical The interior of the box will include a storage space for the passage tubes. Management of bare fiber excess length and the protection and storage of splices will be provided by a cassette organizer, on a one cassette tube. These cassettes articulated on a chassis possess a translucent cover protecting and visualization of fibers. In addition, they may be returned (cover up or cover downwards) to allow work in any position (intervention flattening box or vertically). The tape will be a protection module and splice for a minimum capacity of 12 fibers. Studied the size of the tape will ensure the minimum bend radius of the fibers. Its interior will also lover of crossing fibers (uncut fibers). 21.1The splice protection system must be waterproof. 21.2 It should have a resistance against the atmospheric temperature variation from -20 ° C to 60 ° C for 8 hours and 100 cycles of the temperature variation. 21.3 It must withstand a compressive force of up to 300Kg. 21.4 In cases where the splice protection system is installed in the trench at a depth of 0.8 to 1 meter, it must withstand a crushing force to 30 tons per square meter. 21.5 The mechanical strength of the splice protection systems shall be secured without shells. 22.1 The Manufacturer must attach to their technical offer French language only detailed documentation on the implementation and installation procedures in different applications systems and ways and recommendations for the protection of personnel connections and installation. Comply with the manual "CIRP / FO" ITU-T. 12 FO CABLE HEAD Provision of cable heads 12 FO. These cable ends will be installed in a wall box. This item includes the supply of 12 and 12 crossings optic pigtails equipped with SC / APC or SC connectors / PC. The heat shrink sleeves for the protection of each splice optical fibers will be provided with each junction box in sufficient quantity (12 cable head). 72 FO CABLE HEAD Provision of cable heads 72 FO. The cable ends will be installed in wall boxes. This item includes the supply of 72 and 72 crossings optic pigtails equipped with SC / APC or SC connectors / PC. The heat shrink sleeves for protection of each splice optical fibers will be supplied with each box sufficient connection (cable head 90). 144 FO CABLE HEAD Headends supply 144 FO. These cables will be installed in a head wall box. This item includes the supply of 144 and 144 crossings optic pigtails equipped with SC / APC or SC connectors / PC. The heat shrink sleeves for the protection of each splice optical fibers will be provided with each junction box in sufficient quantity (170 cable head). NB: The supply of optical jumpers is not included in this item and will be a separate item in the bill of supplies of equipment. WALL BOX The wall box is provided for the protection of cable heads. It will be equipped with a front glass. It will be delivered with all mounting equipment.