SIMULATION OF PWM CONTROLLED CYCLOCONVERTER

advertisement

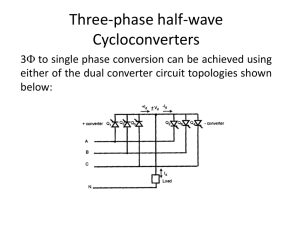

Progress In Science and Engineering Research Journal ISSN 2347-6680 (E) SIMULATION OF PWM CONTROLLED CYCLOCONVERTER Abhay Kumar Dubey1, Ramjee Prasad Gupta2 M.Tech. Scholar, 2Assistant Professor, Electrical Engineering Department BIT, Sindri, Dhanbad 1 Abstract: In this paper Simulink model of PWM supply frequency is converted directly to a variable controlled Cycloconverter with Thyristor and IGBT frequency without going through any intermediate dc switches has been analyzed. The dynamic performance of power conversion stage. In order to improve the Cycloconverter has been compared with Thyristor and performance and reliability of CCV-fed drives, two IGBT switches. In the Simulation, PWM control the output voltage with change in input voltage of Cycloconverter. The output frequency of Cyclocoverter has been taken as two times the input frequency to the Cycloconverter. The output current issues are being faced: network harmonic interaction and commutation failures [16]–[18]. To increase efficiency and quality of the grinding process, voltage and frequency of Cycloconverter can be adjusted it is usual to use power converters to control the energy without a DC link. delivered to the synchronous motor. Over the last few years, the Cycloconverter has been the selected Index Terms: Cycloconverter, PWM, Pulse generator, Thyristor, IGBT, Simulation performance [2], [3]. A commutation failure can produce a short circuit at the machine terminals I. INTRODUCTION through the CCV, as described in [19]. The use of The variable frequency has always been of great importance in the industrial world. The generating station generates electricity of the constant frequency (50 Hz) which is not always applicable for some electrical appliances. Some electrical devices need variable frequency. Therefore the variable frequency generation becomes necessary for meeting the ever growing demand alternative, mainly due to its high efficiency and global of industrial application. The Cycloconverter is such a device which generates variable frequency. Cycloconverter is essential for controlling a.c. motors at low speed drives especially in high power application. Cycloconverter (CCV), which is also known as direct converter [1], is basically ac to ac power converters where the alternating voltage at Cycloconverter also creates adverse effect on the input of the Cycloconverter system. Harmonics are produce in the input current, and the input power factor can be low depending on the load. These affects are consistent with rectifiers, though harmonics occur at different interval in Cycloconverter than occur in rectifiers [4]. The harmonic currents cause torque pulsations, as well as additional power losses in the motor [9]. Generation of harmonic currents, which cause harmonic voltages in the power supply network. Installation of filter circuits is often necessary. This has enabled the use of Cycloconverters (CCVs) for the development of high power drive systems for control in low-speed range and high torque applications, such as cement mills, ore grinding mills, ship propulsion, and mine winders [11], Corresponding Author : Mr. Abhay Kumar Dubey, PG. Scholar, Electrical Engineering Department, BIT, Sindri, Dhanbad Email Id: abhaydubeyece@gmail.com [12]. The mechanical limitations of girth gears have motivated the use of wraparound synchronous motors (SMs) for gearless motor drives (GMDs) fed by high- © 2014 PISER Journal http://.piserjournal.org/ PISER 13, Vol.02, Issue: 03/06 May- June; Bimonthly International Journal Page(s) 085-091 Progress In Science and Engineering Research Journal ISSN 2347-6680 (E) power CCVs operating with variable speed [13], [14], [15]. The CCV can also be found in hydropumped storage [7] applications. Power factor correction can be achieved by the proper design of the LC filters [10]. The power converters used constant-frequency (VSCF) for Variable-speed Aircraft. These new system of VSCF contains a lot of harmonics due to the existing of power converters. To meet the standards of harmonic contents passive filters and active power filters are used [5]. Analysis of induction motors controlled with Cycloconverter has been investigated extensively [6]. As mentioned before, the CCV is also Fig.2. Setup Cycloconverter with IGBT Switches used in ship propulsion [20]. Matrix converters also belong to this category and the power rating of these converters is only up to 150 kVA [8]. II. Simulation of Cycloconverter In this dissertation work Cycloconverter has been studied. The Cycloconverter model has been designed using Thyristor and IGBT switches. The Cycloconverter is to increase the efficiency & performance dissertation of is the to system. analysis The and objective design of of a Fig.3. Input-Output Voltage waveform of Setup Cycloconverter using Thyristor and IGBT switches. Cycloconverter with Thyristor Switches The step-up Cycloconverter model using Thyristor and IGBT as switches has been shown in figure-1 and 2 respectively. Fig.4. Input-Output Voltage waveform of Setup Fig.1. Setup Cycloconverter with Thyristor Switches Cycloconverter with IGBT Switches © 2014 PISER Journal http://.piserjournal.org/ PISER 13, Vol.02, Issue: 03/06 May- June; Bimonthly International Journal Page(s) 085-091 Progress In Science and Engineering Research Journal ISSN 2347-6680 (E) As shown in fig.3 that the shape of output voltage The PWM Generator model has been shown in figure- waveform is not identical in all the cycle when 5. The PWM waveform, triangular carrier waveform Thyristor is used as switches while in fig.4 that the and reference modulating signal of pulse width shape of output voltage waveform is identical in all the modulator (PWM) has been shown in figure-6. cycle when IGBT is used as switches. Hence it is clear that IGBT working as better switch than Thyristor. IGBT improves dynamic performance and efficiency and reduced the level of audible noise. IGBT has low driving power and a simple drive circuit due to the input MOS gate structure. IGBT can be easily controlled as compared to current controlled device Thyristor in high voltage and high current applications. IGBT have also the advantage for high speed, high power switching for building Pulse Generator controlled Cycloconverter. The Insulated Gate Bipolar Transistor (IGBT) is a minority-carrier device with Fig.6. PWM Waveform, Triangular Carrier Waveform and Reference Modeling Signal PWM Generator high input impedance and large bipolar current carrying capability. It is equally suitable in resonant- IV. Simulation of PWM Controlled mode converter circuits. Optimized IGBT is available Cycloconverter for both low conduction loss and low switching loss. The fundamental magnitude of the output voltage from III. Modeling of PWM Generator a Cycloconverter can be controlled to be constant by exercising control within the Cycloconverter itself that The pulses of pulse width modulator (PWM) are is no external control circuitry is required. The most generated by comparing a triangular carrier waveform efficient method of doing this is by Pulse Width to a reference modulating signal. Modulation (PWM) control used within the Cycloconverter. In this scheme the Cycloconverter is fed by a fixed input voltage and a controlled ac voltage is obtained by adjusting the on and the off periods of the Cycloconverter components. The PWM Controlled Cycloconverter model has been shown in figure-7. The output voltage and current waveform of PWM controlled Cycloconverter when R-load and RL-load is applied, has been shown in figure-8 and 9 respectively. IGBT voltage in positive and negative inverter switches with R-load and RL-load has been shown in figure-10 and 11 respectively. IGBT current in positive and negative inverter switches with R-load and RLFig.5. PWM Generator © 2014 PISER Journal http://.piserjournal.org/ PISER 13, Vol.02, Issue: 03/06 May- June; Bimonthly International Journal Page(s) 085-091 Progress In Science and Engineering Research Journal ISSN 2347-6680 (E) load has been shown in figure-12 and 13 respectively. The pulses G1, G2, G3 and G4, applied to IGTB gate has been shown in figure-14. Fig.8. (a) Source Voltage (b) Output Voltage Wave (c) Output Current waveform of Cycloconverter, when RL- Load applied Fig.7. PWM Controlled Cycloconverter Fig.10. IGBT Voltage in N and P switches with RLoad Fig.8. (a) Source Voltage (b) Output Voltage Wave (c) Output Current waveform of Cycloconverter, when R- Load applied Fig.11. IGBT Voltage in N and P switches with RLLoad © 2014 PISER Journal http://.piserjournal.org/ PISER 13, Vol.02, Issue: 03/06 May- June; Bimonthly International Journal Page(s) 085-091 Progress In Science and Engineering Research Journal ISSN 2347-6680 (E) V. CONCLUSION In manufacturing and process industries, the variable frequency is required for driving various electrical machineries. The Cycloconverter or variable frequency generator plays a significant role in driving those electrical machineries. In the present paper mainly focuses on the design and construction of the PWM controlled Cycloconverter. The PWM controlled Cycloconverter circuits has been designed and simulated and finally desired results has been obtained. In this study, the proposed design of PWM controlled Fig.12. IGBT Current waveform in N and P switches with R- Load Cycloconverter with both resistive and inductive loads, has been described in detail and got optimum result for input frequency of 50 Hz. REFERENCES [1]. Bin Wu, Jorge Pontt, José Rodríguez, Steffen Bernet, And Samir Kouro, “Current-Source Converter And Cycloconverter Topologies For Industrial Medium-Voltage Drives” IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS, VOL. 55, NO. 7, Pp. 2786-2707, JULY 2008 [2]. R.A. Errath, ”15000 -HP Gearless Ball Mill Drive In CementWhy Not!”, In IEEE Trans. OnIndustry Applications, Vol. 32, No 3, May/June 1996, Pp. 663 - 669. Fig.13. IGBT Current waveform in N and P switches with RL- Load [3]. J.Rodr´Iguez, J.Pontt, P.Newman, L.Mor´An, G.Alzamora, ”Technical Evaluation And Practical Experience Of High Power Grinding Mill Drives In Mining Applications”, Proceedings Of The IEEE Industry Applications Society 2003 Annual Meeting, 2003, CD-Rom. [4]. Y.Liu, G.Heydt, And R.Chu, “Power Quality Impact Of Cycloconverter Control Strategies”, IEEE Transactions On Power Delivery Vol.20, No.2, April 2005, Pp.1711-1718. [5]. A. Eid, H. El-Kishky, M. Abdel-Salam, And T. El-Mohandes “On Power Quality Of Variable Speed Constant Frequency Aircraft Electric Power Systems”, IEEE Trans. Power Delivery, Vol. 1, No. 25, Pp. 55-65, January (2010). [6]. Paul C. Krause, Oleg Wasynczuk, Scott D. Sudhoff, Analysis Of Electric Machinery And Drive Systems, 2nd Ed., ISBN: 978-0-471-14326-0, Wiley-IEEE Press, 2002. [7]. H. Akagi, “The State-Of-The-Art Of Power Electronics In Japan,” IEEE Trans. Power Electron., Vol. 13, No. 2, Pp. Fig.14. Gate Pulses G1, G2, G3, and G4 are Generated by PWM Generator 345–356, Mar. 1998. © 2014 PISER Journal http://.piserjournal.org/ PISER 13, Vol.02, Issue: 03/06 May- June; Bimonthly International Journal Page(s) 085-091 Progress In Science and Engineering Research Journal [8]. T. Podlesak, D. Katsis, P. Wheeler, J. Clare, L. Empringham, [16]. J. Pontt, J. Rodríguez, W. Valderrama, G. Sepúlveda, P. And M. Bland, “A 150-Kva Vector-Controlled Matrix Converter Induction Motor Drive,” IEEE Trans. Ind. Appl., ISSN 2347-6680 (E) Chavez, B. Cuitino, P. Gonzalez, And G. Alzamora, “Current Issues On High-Power CycloconverterFed Gearless Motor Drives For Grinding Mills,” In Proc. Vol. 41, No. 3, Pp. 841–847, May/Jun. 2005. IEEE ISIE, Jun. 9–11, 2003, Vol. 1, Pp. 369–374. [9]. R. Emery And J. Eugene, “Harmonic Losses In LCI-Fed [17]. J. Pontt, F. Rojas, J. Rodríguez, J. Rebolledo, J. San Martín, I. Synchronous Motors,” IEEE Trans. Ind. Appl., Vol. 38, No. Illanes, E. Cáceres, R. 4, Pp. 948–954, Jul./Aug. 2002. Valderrama, “Issues On Reliability Of Cycloconverter-Fed High- Power Gearless Mill Drives,” In Proc. Comminution, [10]. R. Bhatia, H. Krattiger, A. Bonanini, D. Schafer, J. T. Inge, And G. H. Sydnor, “Adjustable Speed Drive Using A Single 135 000 HP Synchronous Motor,” IEEE Trans. Energy Aguilera, P. Newman, And W. Perth, Australia, Mar. 14–18, 2006. [18]. L. Nieto And M. Ahrens, “Gearless Mill Drive Protection Convers., Vol. 14, No. 3, Pp. 571–576, Sep. 1999. Improvements And Its Behaviour At Minera Escondida [11]. H. Stemmler, “High-Power Industrial Drives,” Proc. IEEE, Ltda.,” In Conf. Rec. IEEE IAS Annu. Meeting, Sep. 23–27, Vol. 82, No. 8, Pp. 1266–1286, Aug. 1994. 2007, Pp. 1766–1772. [12]. H. Akagi, “Large Static Converters For Industry And Utility [19]. J. Pontt, J. Rodríguez, J. Rebolledo, K. Tischler, And N. Applications,” Proc. IEEE, Vol. 89, No. 6, Pp. 976–983, Jun. Becker, “Operation Of High Power Cycloconverter-Fed 2001. Gearless Drives Under Abnormal Conditions,” IEEE Trans. [13]. J. Rodríguez, J. Pontt, P. Newman, R. Musalem, L. Morán, Ind. Appl., Vol. 43, No. 3, Pp. 814–820, May/Jun. 2007. And G. Alzamora, “Technical Evaluation And Practical [20]. D. Gritter, S. Kalsi, And N. Henderson, “Variable Speed Experience Of High Power Grinding Mill Drives In Mining Drive Options For Electric Ships,” In Proc. IEEE Elect. Ship Applications,” IEEE Trans. Ind. Appl., Vol. 41, No. 3, Pp. Technol. Symp., 2005, Pp. 354–357. 866–874, May/Jun. 2005. [14]. S. A. Greer, “Selection Criteria For SAG Mill Drive Systems,” IEEE Trans. Ind. Appl., Vol. 26, No. 5, Pp. 901– 908, Sep./Oct. 1990. [15]. J. Regitz, “Evaluation Of Mill Drive Options,” IEEE Trans. Ind. Appl., Vol. 32, No. 3, Pp.653–662, May/Jun. 1996. Reference Figures © 2014 PISER Journal http://.piserjournal.org/ PISER 13, Vol.02, Issue: 03/06 May- June; Bimonthly International Journal Page(s) 085-091 Progress In Science and Engineering Research Journal ISSN 2347-6680 (E) FIG.7. PWM CONTROLLED CYCLOCONVERTER © 2014 PISER Journal http://.piserjournal.org/ PISER 13, Vol.02, Issue: 03/06 May- June; Bimonthly International Journal Page(s) 085-091