Wind Power Plant Collector System Design Considerations

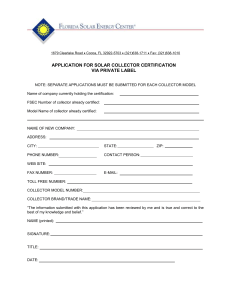

advertisement

1 Wind Power Plant Collector System Design Considerations IEEE PES Wind Plant Collector System Design Working Group Contributing Members: E.H. Camm, M. R. Behnke, O. Bolado, M. Bollen, M. Bradt, C. Brooks, W. Dilling, M. Edds, W. J. Hejdak, D. Houseman, S. Klein, F. Li, J. Li, P. Maibach, T. Nicolai, J. Patiño, S. V. Pasupulati, N. Samaan, S. Saylors, T. Siebert, T. Smith, M. Starke, R. Walling Abstract—This paper presents a summary of the most important design considerations for wind power plants. Various considerations, including feeder topology, collector design, interconnect and NESC/NEC requirements, and design engineering studies are discussed. Index Terms— Wind turbine generator, turbine layout, transient analysis, harmonics analysis, wind power plants. C I. INTRODUCTION onsiderations in Wind Power Plant (WPP) collector system design are driven by economics and reliability. While WPPs have many things in common with traditional utility electrical systems, they also have a number of unique characteristics that require special attention. This paper will discuss various important design considerations applicable to modern WPPs. The scope of the discussion includes design considerations associated with plant and equipment ranging from the point of interconnection (POI) to the switchgear or converter in the base of the wind turbine tower. II. FEEDER TOPOLOGY Feeder topology, also referred to as collection system layout, can range widely in function and features depending on several factors including, turbine placement, terrain, reliability, landowner requirements, economics, and expected climatic conditions for the location. After site selection for the WPP has been determined, the tower specific locations are defined, based on wind resource, soil conditions, FAA restrictions, land agreements, and constructability considerations. The turbine locations and the POI will be the primary factors in the design and layout of the WPP feeder topology. A POI located far from the wind power plant may require a transmission line and interconnect switchyard in addition to the collector substation; otherwise, the collector substation can be connected directly to the POI. To optimize loss efficiencies within the collector system, the ideal collector substation location is within a central area of the wind power plant to minimize collector conductor lengths. However, this is not always possible due to land constraints and the actual utility POI location itself. The majority of large wind power plants built in North America have a radial feeder configuration with a collection system voltage of 34.5 kV (Figure 1). In this configuration, turbines are connected together in a “daisy chain” style, moving outward from the project substation to the furthest located turbine. These feeder strings are commonly underground but may be of overhead construction as well. Each individual feeder string may also have branch strings, connected by sectionalizing cabinets that can make up several string paths within a feeder string. Sectionalizing cabinets, sometimes referred to as junction boxes, have separable connectors, or elbows, that can isolate a feeder string to allow the remaining connected turbines to operate while maintenance or repair work is being performed. The separable connectors can come in two forms: 200 A load-break or 600 A dead-break style. The load-break elbows allow removal and isolation of the feeder string while the connector is energized by use of a “hotstick” and properly trained electricians. For strings with full load current ratings above 200 A, 600 A dead-break elbows are required, which also requires the circuit to be deenergized before removing and isolating the connector, or a live-front cable termination (without use of elbows) which also must be de-energized for connection or disconnection. An alternative to the sectionalizing cabinet is padmounted switches, with or without interrupting devices, that can more easily isolate a feeder for maintenance or troubleshooting. However, the increased cost needs to be weighed against the expected frequency of operation. The number of winds turbine generators (WTGs) placed on a feeder string is limited by the conductor ampacity. In addition, the total number of collector circuits is driven by the size of the substation transformer (ST) located in the collector substation. System reliability is also a consideration since any given collector circuit cable fault will typically result in an outage to all WTGs connected to that particular circuit. Underground feeders are generally limited to roughly 25 to 30 MW per string due to soil thermal conditions and practical cable sizes, although parallel conductors may be combined at the collector substation circuit breaker to increase the number of WTGs on the feeder. 978-1-4244-4241-6/09/$25.00 ©2009 IEEE Authorized licensed use limited to: UNIVERSITY OF TENNESSEE. Downloaded on October 28, 2009 at 11:28 from IEEE Xplore. Restrictions apply. 2 Figure 1: Typical Collector Circuit Overhead conductors can carry more power for comparable or smaller size conductors, typically up to 40 to 50 MW per string, but will have higher losses associated with it. Overhead conductors typically have higher outage frequency rates than a comparable underground circuit, but because of its accessibility for locating and repairing failures, the outage duration will typically be less for repair. Reliability concerns should also be evaluated, which will influence the quantity of turbines on a single feeder string. If a feeder string experiences a failure, the entire WTG capacity on that string will be interrupted, resulting in revenue losses until the damage is repaired. Sectionalizing cabinets can help with isolating damaged sections to allow some portion of WTGs to be returned to service more quickly. For additional information refer to companion WG paper on Wind Power Plant Substation and Collector System Redundancy, Reliability, and Economics [10]. construction. However, high Rho values which translate to lower cable ampacities may warrant the implementation of an overhead collector system. Since collector systems typically spread throughout a vast area and land conditions vary, the collector system may consist of both overhead and underground portions. Many factors must be considered when deciding on overhead versus underground systems and in most cases cost is the biggest consideration. Total lifecycle costs, including losses should be evaluated, but often designs are optimized on a least first-cost basis. CTBs and their installation can be extremely expensive and have a significant impact on the overall project cost. Where portions or all of the collector system resides in extreme soil conditions, such as granite or perhaps lava-rock, not only must the CTB be considered but also the means for trench excavation. For example, in extreme conditions blasting or hydraulic hammers may be required to prepare the circuit trenches. After preparing the circuit trench and prior to backfill and cable installation an additional mesh or netting material is typically installed. The mesh is placed in between the excavated rock trench and CTB with the purpose of preventing the CTB from eroding through the permeable trench. Figure 2 shows the cross section of a typical trench with CTB and mesh. III. COLLECTOR DESIGN Many considerations apply to the overall design of the WPP collector system. The first is typically the soil’s thermal resistivity or Rho, which is measured in °C-cm/W. Thermal resistivity is basically the ability of the soil to dissipate heat generated by energized and loaded power cables. Proper methods must be utilized when testing soil to ensure correct values are available when sizing cables and designing the collector system layout. Improving thermal resistivity is commonly required due to the native soil conditions, which can have extremely high thermal resistivity. Common solutions to address high soil thermal resistivity include providing Corrective Thermal Backfills (CTB) or Fluidized Thermal Backfills (FTB) [11] within the trench and surrounding the circuit cables. These materials will improve the soil Rho condition, but project cost impacts must be considered and weighed against the disadvantages of utilizing an overhead collector system. Underground collector systems are the most commonly applied systems within WPPs because of their better acceptance from landowners and less restrictions on crane travel during Figure 2: Typical Circuit Trench Cross Section Where a total life-cycle cost evaluation is used, cable thermal ampacity tends to be a less limiting factor. This is because when the lost revenue from losses are considered, the optimized cable size is typically considerably larger than the size that approaches ampacity limits at peak loading. After considering the costs associated with the above example the decision to go with an overhead collector system could be justified on a portion or the entire collector system. An added benefit of the overhead system is the increase in collector circuit capacity as mentioned above, but this comes with an increase in system losses and decrease in reliability. Careful analysis is required when selecting an overhead versus underground system and in some cases even though the overhead system will realize cost savings it may be prohibited due Authorized licensed use limited to: UNIVERSITY OF TENNESSEE. Downloaded on October 28, 2009 at 11:28 from IEEE Xplore. Restrictions apply. 3 to land owner requirements. Conductor sizing starts with the soil Rho data and layout of the collector circuit trenches. In multiple circuit trenches derating factors must be applied due to mutual heating effects of close proximity circuits. Commercially available software is typically used to perform an analysis on various circuit trench layouts and many variables including trench dimensions, circuits per trench, trench spacing and soil Rho can be manipulated until the optimum trench layout is achieved. In some cases where specific circuit ampacities are required the cables may need to be oversized due to trench parameter limitations. IV. SUBSTATION DESIGN The planning of the substation and switchyard is not strictly focused on a single design but does have some flexibility. It is important, however, that the substation be planned for reliability, operability, as well as maintainability. Substation designs typically consist of both mediumvoltage (MV) and high-voltage (HV) bus configurations that are interconnected through wye-wye, delta-wye, or even wyedelta transformers. Wye-wye transformers with buried tertiary are often used. In wind plant substations, the medium- voltage buses are primarily of the single and sectionalized bus type while the high voltage buses could be composed of five different types: ring, single, sectionalized, main and transfer, breaker-and-a-half, double breaker double bus. The location of substation(s) will typically be at the wind plant site, but if the POI is several miles away there may be a need for switching station(s) for locating line breakers and associated equipment. There are many IEEE substation design standards and guidelines such as IEEE-605 for rigid bus structures and IEEE-80 for substation grounding. These are available as references in the planning and engineering of substation facilities. Also refer to a companion WG paper on Wind Power Plant Substation and Collector System Redundancy, Reliability, and Economics [10]. V. INTERCONNECTION REQUIREMENTS AND REGULATIONS In the United States, Federal requirements for certain aspects of WPP interconnection are contained in the provisions of FERC Order 661-A [13], which have been adopted as Appendix G to the Large Generator Interconnect Agreement (LGIA). This Appendix contains requirements for voltage ride-through (VRT), power factor design criteria (reactive power), and Supervisory Control and Data Acquisition (SCADA) capability. Other provisions contained in the LGIA for each project include metering and protection requirements. Note, for WPPs located within the Electric Reliability Council of Texas (ERCOT) region, similar interconnection requirements exist, but do not necessarily follow FERC guidelines. Refer to companion WG paper for additional details [4]. There are a large number of agencies that can impact the design and construction of the collector system. They range from local zoning agencies to international agencies. The final design of the collector system will be heavily dependent on the regulations and standards that you are required to follow. Some national standards, like the National Electric Code (NEC) may apply in some states and not in others. Other stan- dards may be purely local and in large WPP may vary from machine to machine as you cross local jurisdictions. Some of the key standards bodies and regulators that should always be reviewed include: 1. IEC and IEEE - both standards bodies have a large number of standards that can be applied to the collector design. These include standards like C37 (Circuit Breakers, Switchgear, Relays, Substations, and Fuses), C57 (Transformers), C62 (Surge Arresters), and other emerging standards. IEC standards include the IEC 61400 Series (Wind turbine generator systems). 2. ISO has a number of standards that apply to wiring and cables. 3. Many national organizations have taken ISO or IEC standards and renumbered them for local use. 4. State and provincial regulators. In many cases the regulators in a sub-jurisdiction (e.g. a state in the US or a province in Canada) have developed additional guidelines that need to be followed. 5. Local zoning. Most local zoning agencies have height, noise, setback, landscaping and road requirements that are not covered in any other standard. These can quickly impact collector and WPP design by restricting what can be done and how it can be done. In almost every case local zoning and regulation reduces the number of options that are available for designing and building the collector and placement of WTGs. 6. Utility requirements. In most utilities there are requirements that are set by the planning and standards groups. While many of these mirror the requirements of national and international standards, some do not, and for good reason in most cases. The design of the existing grid may not match the ideal that was used to create the international standards and to help maintain the function of the grid, each utility has developed standards that keep the grid functioning. 7. Manufacturer's requirements and standards. As transformers, wind turbines, and other equipment are selected they come with their own set of standards and restrictions. To keep warranties in force, these will have to be reviewed and accounted for in the collector design. In all there will be many documents that will have to be reviewed and it is not unusual for them to conflict with each other. In most cases, that conflict can be resolved most easily by starting with the most local requirements. They are typically the easiest ones to get changed when a higher authority conflicts with them. VI. NESC AND NEC CONSIDERATIONS FOR WIND POWER PLANTS The application of the National Electrical Code (NEC) and the National Electrical Safety Code (NESC) to wind power plants is in general a shared concern. Local jurisdictions also have rules, ordinances, and laws that may supersede both the NESC and NEC, so thorough advance research with local professional engineers, electricians, and inspectors is critical. Authorized licensed use limited to: UNIVERSITY OF TENNESSEE. Downloaded on October 28, 2009 at 11:28 from IEEE Xplore. Restrictions apply. 4 Any WPP with a medium-voltage (MV) collector system design and construction may be considered by some to be subject to the NESC rules, but inside the wind turbine tower the best approach is to assume that both codes may apply. The tower is both a “generation” plant, which is covered by the NESC, but it also has aspects of being an industrial site, which falls under the NEC. Regardless, each US state has the right to enforce whichever code or create new ones for its own purposes. It is also well known that there are now many states with permitting laws and regulations specifically for WPP which could impact the application of these safety rules. On the collector system NESC rules may apply because they involve grounding (sections in the 90’s), overhead conductor clearances and loadings (Part 2), and underground cable clearances and considerations (Part 3). A quick example of each would be: For grounding – collector cables or overhead must be grounded at least every quarter mile. As a special note - when grounding a collector cable special consideration must be taken to cross ground all sheaths and external grounds to reduce induced effects (see IEEE 575-1988). For overhead (sections in the 200’s) – overhead collector conductors must be designed for local temperature, ice and wind loading conditions and maintain minimum clearance distances from the ground surface and other objects and structures. For underground (sections in the 300’s) – cables must be set at proper burial depths and have certain underground clearances. NESC rules are generally self-regulated by the power and utility industry, but a few states have inspectors who will check new installations. In the tower the best approach is to assume both the NESC and NEC may apply. From the NESC it is mainly the grounding rules and the supply station rules in Part 1 (sections in the 100’s), which may apply and these would also include the rules for WTG unit transformers whether located inside or outside of the tower. From the NEC there are applicable rules for the LV cables and equipment that may apply. Such rules include cable ampacities, cable routing, small LV transformer use, LV circuit protection, and cabinets. There are also local (city, county, and/or state) inspectors who interpret the NEC in different ways, so advance meetings with the local authorities are important to determine what is most important to them. As to arc-flash considerations, the most basic approach would be to consider the NESC arc-flash rules from Section 410 to the collector system and the NFPA 70E rules to the inside of the tower. This would provide good coverage of the inside equipment and the proper approach to the power lines outside and will define the proper personal protective equipment (PPE) for both working situations. Lastly, there are rules for safe practices once the site is operational that must also be followed by workers. These include the rules in Part 4 (sections in the 400’s) of the NESC, in NFPA documents, and in federal (OSHA) and state occupational safety rules and regulations when working in a tower or on the power line. VII. TURBINE STEP-UP TRANSFORMER APPLICATION For wind turbines in the MW rating category, a dedicated step-up transformer is used for each turbine. A. Transformer Type Padmounted three-phase distribution transformers are used for WTG step-up transformers. These transformers are a commodity and meet the required function at minimum cost. WTGs with transformers in the nacelle or on platforms in the tower are outside the scope of this document since it is provided by the WTG manufacturer as part of the WTG installation. B. Winding Connection Many WTG manufacturers specify delta (MV) – groundedwye (LV) winding connections for wind turbine step-up transformers. The reasons for this connection are to provide isolation of the WTG from the zero-sequence behavior of the collector feeder; e.g., unfaulted phase voltage rise during ground faults, and to provide a solid ground source for the LV side connected to the WTG. Grounded wye-wye transformers are more commonly used for utility load-serving applications, and are thus more widely available. There is a common misconception that this connection provides a ground source to the collector feeder, in the case that that the feeder becomes isolated from the collection substation. This is only correct when the WTG is a grounded source, which is generally not the case. C. Transformer Protection and Switchgear Padmounted transformers are usually protected by internal fuses. Due to the short-circuit current available in most wind farm applications, current-limiting fuses are usually needed. These fuses are either coordinated with expulsion fuses, or full-range current-limiting fuses are applied. Since fusing options are limited for 34.5 kV delta configurations, careful consideration must be made when selecting coordinated fusing to ensure the fuse combination is matched for the application in which it will be applied. In some applications it can be difficult to ensure that primary (MV) fuses can adequately protect against faults at the point of secondary interconnection to the WTG equipment, particularly if a delta-wye transformer is used (in the case of single-phase faults, due to the lack of one-for-one correspondence between primary and secondary phases.) LV molded-case circuit breakers are sometimes installed inside the transformer secondary compartment to provide coordinated protection through to the end of the secondary cables and also may help in reducing arc-flash levels. Attention needs to be given to the ambient temperature for this mounting location, with respect to the molded case circuit breaker specifications. An internal primary MV oil switch, typically referred to as a LBOR (Load Break Oil Rotary) switch is commonly specified to allow isolation of the transformer and permit continued operation of other “downstream” WTGs. Authorized licensed use limited to: UNIVERSITY OF TENNESSEE. Downloaded on October 28, 2009 at 11:28 from IEEE Xplore. Restrictions apply. 5 E. Transformer Impedance IEEE Standard C57.12.24 specifies that three-phase transformers rated 750 kVA and larger have a minimum impedance of 5.75%. However, some manufacturers will supply transformers with smaller impedance on specification. F. Transformer Rating It is common practice to select transformers with a standard kVA rating, as listed in C57.12.24, which is at least as large as the kVA rating of the WTG. This is extremely conservative in most applications due to the cyclical loading of WTG step-up transformers. It is common practice in utility load-serving transformer applications to intentionally select a transformer rating less than the minimum load, thus subjecting the transformer to limited-duration overloads. The loss-of-life of a transformer due to loading is a cumulative function of the temperatures to which the windings are exposed, and the winding temperature is a function of loading history and the ambient temperature. IEEE C57.91 specifies transformer thermal modeling and aging functions that can be used to determine a transformer kVA rating that provides adequate service life for the particular WPP application; both loading cycles, and the contemporaneous ambient temperature conditions. Figure 3 shows the results of a transformer thermal aging analysis, using the algorithms in IEEE C57.91 with contemporaneous wind velocity and ambient data, for an actual WPP application. In this example, the WTG is rated 1.5 MW and is operated at a 0.95 power factor. Wind conditions at this site yield a 42% capacity factor. The typical transformer kVA rating used for this WTG turbine rating is 1750 kVA. The analysis shows that this rating yields a predicted transformer insulation life of 3,000 years, obviously much more than needed. And, there is no consideration of the forced cooling effect of the wind on the transformer; C57.91’s algorithms assume still air. For this wind plant, an under-sized transformer was successfully applied. Selection of transformer rating on a thermal basis must consider factors such as additional loading on transformers due to passage of harmonic currents. In one wind power plant application, WTG unit transformers failed from overloads caused by grid background harmonics resonating with WTG power factor correction capacitors. Harmonics can have a disproportionate impact on transformer heating. Refer to C57.110. 10000 Predicted Insulation Life (yrs) D. Transformer Primary Terminals Transformer primary terminals can either be live-front bushings, or separable connector (“elbow”) bushings. There are two different types of elbows in IEEE standards: loadbreak elbows which are rated up to 200 A load current, and dead-break elbows which are rated for up to 600 A. Loadbreak elbows allow the transformer connections to be opened “live” under load current conditions, using a hot-stick. The circuit must be de-energized to operate (make or break) the 600 A elbow connections. When elbows bushings are applied, it is common to specify a feed-through bushing configuration, which provides two bushings for each phase, and an internal connection between each pair of bushings. This allows both the substation-side and remote-end side cables in a daisy-chain radial configuration to be connected directly to the transformer without junction boxes. The 200 A capability of load-break elbows is a significant restriction in many applications, particularly where there are a number of wind turbines connected in a radial string. Also, many wind plant operators do not have hot-stick-trained technicians in their maintenance crews. 1000 100 10 1 1000 1100 1200 1300 1400 1500 1600 1700 1800 Rated kVA Figure 3 – Transformer predicted insulation life as a function of kVA rating for a 1.5 MW WTG application operating at 0.95 power factor in an actual wind and ambient temperature regime. VIII. DESIGN ENGINEERING STUDIES There are several important engineering studies to be performed during the various stages of the development of a new WPP. In each of these studies, it is important to model the WPP, and in particular, the WTG properly and to use the appropriate software package to perform the required analysis. In the following subsection, an overview of typical design engineering studies is given. It should be noted that preliminary interconnection studies performed by the transmission provider are outside of the scope of this paper. A. Load Flow Studies Load flow studies are performed to determine the final ratings of any required reactive power compensation system, and the steady-state performance of the wind farm under various operating conditions. The steady-state performance focuses on the determination of transformer no-load tap settings or the need for an on-load tap changer (OLTC). A model of the entire WPP, with detailed collector system is typically used in commercially-available software. Each WTG LV bus is represented as a PV (voltage controlled) or PQ (specified MW and MVAR) bus with certain MW and MVAR output based on specific conditions or based on voltage, power factor, or reactive power control at the WTG terminals. Load flow analysis should be performed for different active and reactive power output levels of the WTG while varying the Authorized licensed use limited to: UNIVERSITY OF TENNESSEE. Downloaded on October 28, 2009 at 11:28 from IEEE Xplore. Restrictions apply. 6 output of any substation-based reactive compensation system, to determine the WPP net active and reactive power flows and voltage profiles at the POI during different operating scenarios. B. Short Circuit Analysis This analysis, using a detailed model of the WPP as described for the load flow studies above, is performed to determine momentary and interrupting ratings of circuit breakers, cable ratings for proper short-circuit withstand capabilities, and momentary ratings of all equipment Special consideration must be given to the WTG short-circuit contributions[5], [12]. Both the maximum and minimum short circuit current contribution from the grid should be considered. It should also be noted that, the line-to-line or single-line-toground faults can result in higher short circuit currents than three-line-to-ground faults in some WPP configurations. C. Harmonics Analysis It is realized that due to the significant amount of capacitance in a typical WPP, there is a high potential for resonance problems to occur. That can result in unacceptable levels of harmonic current distortion at the substation capacitor banks, significant voltage distortion at the MV bus of the plant main substation, and unacceptable harmonic current injected from the plant at the POI. The first stage is to collect the data needed for harmonic analysis such as measuring background harmonic voltages at the POI and to obtain power quality test results for the WTG. Measurement of background harmonics may be useful even if switched capacitor banks are not used in the WPP. The second stage is to use the appropriate frequency dependent models for different types of WTG, padmount transformers, collector system cables and overhead lines, shunt capacitor and reactors, substation transformer and equivalent model for the transmission network. Appropriate frequency-dependent models should be used to represent the transmission system. This can be a complex task, which can be simplified by modeling the system for several buses after the POI. The third stage is to perform frequency scans and harmonics load flow. The frequency scans is used to identify series and parallel resonance problems while harmonics load flow is used to calculate harmonic distortion indices to determine if the relevant IEEE standards are satisfied in the WPP. Finally, solutions to overcome identified harmonic problems such as filter installation or changing the size of substation capacitor banks should be investigated [6]. D. Temporary Overvoltage and Insulation Coordination Studies There is a potential for severe temporary overvoltage to develop in WPP collector circuit when a single line to ground fault occurs on one of the plant feeders. Transient analysis is needed to determine the level of TOV and to assess the damage possibility of surge arresters in WPP collector circuit due to temporary overvoltages. A detailed transient simulation with accurate WTG model using an Electromagnetic Transient Program (EMTP) is needed in most cases to determine TOV levels and to choose the best method for the mitigation of TOV due to feeder isolation and to select arrester ratings [7]. The use of high-speed grounding switches or grounding transformer banks on each feeder will help in solving the TOV problem in most WPP collector circuits. The type of the WTG plays an important role in selecting which grounding method to be used. E. TRV Analysis for Circuit Breakers The Transient Recovery Voltage (TRV) analysis is needed in special cases where circuit breakers are used to switch capacitor banks with current-limiting reactors (CLRs) in series or where current-limiting reactors are used to limit feeder fault currents. The very high inherent frequencies of CLRs can challenge the ability of the circuit breaker to interrupt successively and may in some cases require TRV “taming” capacitors to be applied across the circuit breaker or connected phase-to-ground. F. Grounding Studies The overall grounding design of the WPP should begin in an early stage of the project and involves the substation, collector system, and tower grounding. Data must be acquired on soil resistivity, short-circuit duty at different locations in the collector circuit, and short-circuit duty at the POI. Soil resistivity can vary widely in the landscape of the project and should be measured in many locations. The collected data is applied in grounding software to obtain best design geometry, ground potential rise, and step and touch potentials [9]. G. Arc Flash Assessment Studies Arc-flash studies for the WPP will vary with the applicable code. For MV collector circuits under the NESC an assessment of the cal/cm2 levels throughout the system will be required. That assessment uses a short circuit evaluation and the knowledge of the length of time it takes to clear the fault at any given location. These two values are then used in a lookup table in the NESC to define the minimum level of PPE. For locations under the NEC the proper standard for an arcflash assessment is the NFPA 70E. This standard defines a detailed procedure that uses a series of lookup tables or an assessment study can be done that accomplishes the same goal. The basic results of an NFPA 70E assessment will be a set of information labels for various pieces of apparatus and switchgear that will inform the worker of the arc flash hazard level that must be prepared for in terms of cal/cm2 and the appropriate PPE level. The NESC assessment results must be communicated to the workers, but does not require posting any labels, and also does not exclude it. To best address these details, the WG is planning a future separate paper on arcflash assessment for WPPs. H. Other Special Studies These studies include protection and coordination studies for the WPP and reactive compensation system (if any), SCADA, communication, and control interaction studies, and voltage ride-through studies (in cases where alternative technologies from that used in the System Impact Study are consi- Authorized licensed use limited to: UNIVERSITY OF TENNESSEE. Downloaded on October 28, 2009 at 11:28 from IEEE Xplore. Restrictions apply. 7 [22] IEEE Std. C57.110-2008, IEEE Recommended Practice for Establishing Liquid-Filled and Dry-Type Power and Distribution Transformer Capability When Supplying Nonsinusoidal Load Currents. dered). IX. REFERENCES [1] Robert Zavadil, Nicholas Miller, Abraham Ellis, and Eduard Muljadi, “Making Connections [Wind Generation Facilities],” IEEE Power & Energy Magazine, vol. 3, no. 6, pp. 26-37, Nov.-Dec. 2005. [2] E. Muljadi, C. P. Butterfield, A. Ellis, J. Mechenbier, J. Hochheimer, R. Young, N. Miller, R. Delmerico, R. Zavadil, and J. C. Smith, “Equivalencing the collector system of a large wind power plant,” in Proc. 2006 IEEE Power Engineering Society General Meeting, Montreal, Canada, June 2006. [3] M. Behnke, A. Ellis, Y. Kazachkov, T. McCoy, E. Muljadi, W. Price, and J. Sanchez-Gasca, “Development and Validation of WECC Variable Speed Wind Turbine Dynamic Models for Grid Integration Studies,” in Proc. 2007 WindPower Conference, Los Angeles, USA, June 2007. [4] Wind Plant Collector Design WG, “Reactive Power Compensation for Wind Power Plants,” in Proc. 2009 IEEE Power and Energy Society General Meeting, Calgary, Canada, July 2009. [5] Nader Samaan, Robert Zavadil, J. Charles Smith and Jose Conto, “Modeling of Wind Power Plants for Short Circuit Analysis in the Transmission Network,” in Proc. of IEEE/PES Transmission and Distribution Conference and Exposition, Chicago, USA, April 2008. [6] Jun Li, Nader Samaan and Stephen Williams, “Modeling of Large Wind Farm Systems for Dynamic and Harmonics Analysis,” in Proc. of IEEE/PES Transmission and Distribution Conference and Exposition, Chicago, USA, April 2008. [7] R. A. Walling, “Overvoltage Protection and Arrester Selection for Large Wind Plants,” in Proc. IEEE/PES Transmission and Distribution Conference and Exposition, Chicago, USA, April 2008. [8] E. R. Detjen and K. R. Shah, “Grounding Transformer Applications and Associated Protection Schemes,” IEEE Trans. Industrial applications, vol. 28, no. 4, pp. 788-796, Jul.-Aug. 1992. [9] Steven. W. Saylors, “Wind Farm Collector System Grounding,” in Proc. of IEEE/PES Transmission and Distribution Conference and Exposition, Chicago, USA, April 2008. [10] Wind Plant Collector Design WG, “Wind Power Plant Substation and Collector System Redundancy, Reliability, and Economics” in Proc. 2009 IEEE Power and Energy Society General Meeting, Calgary, Canada, July 2009. [11] Deepak Parmar and Jan Steinmanis, “Underground Cables Need a Proper Burial,” Transmission & Distribution World, April 2003. [12] Wind Plant Collector Design WG, “Characteristics of Wind Turbine Generators for Wind Power Plants,” in Proc. 2009 IEEE Power and Energy Society General Meeting, Calgary, Canada, July 2009. [13] FERC Order No. 661-A, Interconnection for Wind Energy, Docket No. RM05-4-001, December 2005. [14] 2007 National Electrical Safety Code, C2 Standard, IEEE, 2006. [15] 2008 National Electrical Code, NFPA 70 Standard, National Fire Prevention Association, 2008. [16] 2009 NFPA 70E Standard, National Fire Prevention Association, 2009. [17] IEEE guide for the application of sheath-bonding methods for singleconductor cables and the calculation of induced voltages and currents in cable sheaths, IEEE Std. 575-1988, Nov. 25, 1987. [18] IEEE Std. 386-2006, IEEE Standard for Separable Insulated Connector Systems for Power Distribution Systems Above 600 V. [19] ANSI C57.12.10-1997, American National Standard Requirements for Transformers 230 kV and Below, 833/958 through 8333/10 417 kVA, Single Phase, and 750/862 through 60 000/80 000/100 000 kVA ThreePhase without Load Tap Changing; and 2750/4687 through 60 000/80 000/100 000 kVA with Load Tap Changing—Safety Requirements. [20] IEEE Std C57.12.00-2000, IEEE Standard General Requirements for Liquid-Immersed Distribution, Power, and Regulating Transformers [21] IEEE Std C57.91-1995(R2004), IEEE Guide for Loading Mineral-OilImmersed Transformers. Authorized licensed use limited to: UNIVERSITY OF TENNESSEE. Downloaded on October 28, 2009 at 11:28 from IEEE Xplore. Restrictions apply.