Clamp Levers with Push Button / with Pad / with SR Tip

advertisement

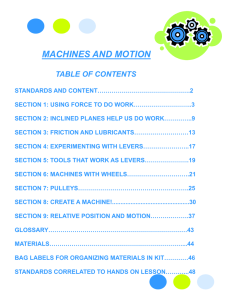

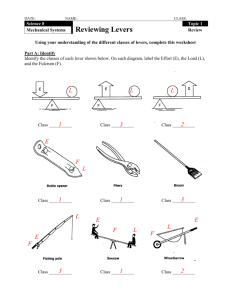

Clamp Levers with Push Button / with Pad / with SR Tip Resin Clamp Levers, Push Button Resin Clamp Levers CAD Data Folder Name: 43_Levers_and_Pulls When ordering, select Part Number and Values from Selection Steps 1~4. When ordering, select Part Number and Values from Selection Steps 1~3. - 4Lever Color CLDMP5 CLDFP4 CLWP8 CLRM10 - 12 7 20 20 - Male Thread B 63 44 Part Number 1Type 2M 4 Male Thread 5 CLDMP CLMSP 6 SCLMSP *1 8 35.5 S 30 49 40 4 (h) Number of Serrated Teeth 10 17.5 4Lever Color 3L Selectable for CLDMP and CLMSP only Selection 16 20 25 B(Black) 12 16 20 25 32 M(Orange) 12 16 20 25 32 S(Silver Gray) 16 20 25 32 40 S 3L 13 5.5 3L The projection at the head of the screw makes it easy to disengage the serrations. d 16 14 Max. Load Fmax. (N) Max. Tightening Force Pmax. (kN) Reference Mass (g) SUS303 S45C SUS303 S45C Threaded 48 80 1.8 3 40 65 108 2.9 4.8 40 110 184 4.1 6.8 41 189 316 7.5 12.5 70 B 1.3 20 1.3 Part Number Type M 4 5 Tapped CLDFP 6 8 Days to Ship 3 Days Stock L Lever Color Lever Color 7 B(Black) M(Orange) S(Silver Gray) B(Black) M(Orange) S(Silver Gray) Days to Ship 3 Days Part Number 1Type 2M CLNP CLSP 3L Selection 4 5 6 8 10 12 12 16 20 25 12 16 20 25 12 16 20 25 16 20 25 20 25 25 - Spring Lever MMaterial SSurface Treatment SUS304WPB Select from the followings. QResin Clamp Levers Type Male Thread Female Thread LNP LNF Zinc Die Casting 20° B Male Thread LNP Female Thread LNF H H1 H H1 3L S S (h) R CLRM CLRS 2M 2M d D d1 d D R H H1 (h) S D d d1 SR L 4 6.5 6.5 D d 13 10 18 21 25 14 16 19 16 B Max. Load Fmax. (N) 3 20 24 28 4 5 Days to Ship CLNP CLSP Max. Tightening Force Reference Mass Pmax. (kN) (g) 21 42 70 120 200 290 1.7 2.7 3.8 7 11 16 18 3 Days 20 40 80 120 Stock 3 Days 3 Days Stock 3 Days Lever MMaterial Nylon 6 (Mat Black) Screw MMaterial SSurface Treatment SUM22L Black Oxide Spring MMaterial SUS304-WPB Femal Thread R LNF 20° 2M 2M 4 5 6 8 10 12 3L Selection LNP 12 12 12 16 16 16 16 20 20 20 20 20 25 25 25 25 25 25 32 32 32 32 32 LNF 40 40 40 40 50 50 50 R EHex Socket B is created during a production of Levers. It is not a socket used during an installation of Levers. H H1 (h) S 8 45 35.5 39 24.5 4.2 10 14 17 63 46.3 50.3 31 78 55.4 59.4 36 92 66 70 43 D 13 6.5 17.5 8 21 11 25 Number of Max. Load Max. Tightening Force Reference Mass (g) d Serrated Teeth B Fmax. (N) Pmax. (kN) Threaded Tapped 21 1.7 18 16 42 2.7 10 18 3 70 3.8 20 14 13.5 24 120 7 40 30 4 16 26 200 11 80 50 19 28 5 290 16 120 70 Days to Ship LNP LNF 3 Days Stock 3 Days Stock EStock lineup may vary by country. EStock: Same day shipping available upon request. Order by THA: 16:00, SGP: 12:00, MYS: 15:00 D P.75 SR QPush Button Resin Clamp Levers EHex Socket B is created during a production of Levers. It is not a socket used during an installation of Levers. M 3 31 35 42 d D Part Number 1Type 2M (h) 20° 25.5 46.5 56 66 B QHow to Use Clamp Levers with SR Tip B l 3L CLWBP CLWP CLWBC CLWC 44.5 54 64 LNP Pad R 65 82 92 36 S EStock lineup may vary by country. EStock: Same day shipping available upon request. Order by THA: 16:00, SGP: 12:00, MYS: 15:00 D P.75 Stock EChrome over satin nickel is a non-gloss finish. Clamp Levers with Pad 34 (h) (h) Screw SUM24L Black Chromate Polyacetal (White) SUS303 SUM24L Black Chromate Free-Cutting Brass (C3604) SUS303 - 48 40 40 50 40 50 40 50 H1 S Shape CLWBP CLWP CLWBC CLWC H EHex Socket B is created during a production of Levers. It is not a socket used during an installation of Levers. Number of Serrated Teeth 3L Type 32 32 32 32 32 R Male Thread Clamp Levers with SR Tip Clamp Levers with Pad MMaterial SSurface Treatment (Clamp Levers with Pad only) CLRM CLRS 2M d D E *1. M8 is not available for SCLMSP. EStock lineup may vary by country. EStock: Same day shipping available upon request. Order by THA: 16:00, SGP: 12:00, MYS: 15:00 D P.75 QClamp Levers with Pad, Clamp Levers with SR Tip SUS304-WPB 20° B 2M 2M D Spring MMaterial Number of Serrated Teeth 5 3 5 45 35 38.5 25.8 4 13 10 1 16 6 4 6 8 63.5 45 48.5 32.3 7 17.5 14 6 8 20 2 10 78.5 54 58 37.6 8 21 16 8 10 24 E * Max. Load / Max. Tightening Force indicates axial force for screws (M). Pads may break if tightened with the max. clamping strength. E The Clamp Lever with SR Tip has less contact area with workpiece; therefore misalignment can be avoided when tightening the screws. * B 3 Lever MMaterial CLNPP CLSPP Nylon 6 (Mat Black) Screw Spring MMaterial SSurface Treatment MMaterial SUM22L Black Oxide SUS304-WPB SUS303 - Male Thread R QHow to Use 20° CLNPP CLSPP The projection at the head of the screw makes it easy to disengage the serrations. QHow to Use Serrations S 4 Max. Load * Max. Tightening Reference Mass Fmax. (N) Force Pmax. (kN) (g) 74 3.3 34 126 4.7 40 217 8.6 70 347 13.6 152 Type H H1 33 (h) CLNP CLSP B 45 H1 QHow to Use Screw MMaterial SSurface Treatment SUM22L Black Oxide SUS303 R (h) H Lever Type MMaterial CLNP Nylon 6 (Mat Black) CLSP Male Thread H H1 (h) S 3L 4 5 6 8 R 12 20 14 20 CLDFP 20° d D M 3L - Female Thread R (Stainless Steel) - CLNP4 LNP8 LNF10 CLNPP20 QPlastic Clamp Levers Type Lever Screw Spring Male Thread Female Thread MMaterial SSurface Treatment MMaterial SSurface Treatment MMaterial S45C Black Oxide CLDMP CLDFP Zinc Die Casting Electrostatic Coating SUS303 SUS304-WPB CLMSP SCLMSP SCS13 (Stainless Cast Steel) Buff Polished SUS303 CLDMP CLMSP SCLMSP Part Number (1Type·2M) B M M S 3L 3L H H1 - H H1 Part Number (1Type·2M) QClamp Levers with Push Button CAD Data Folder Name: 43_Levers_and_Pulls With Pad CLWBP CLWP CLWBC CLWC (Polyacetal) (Polyacetal) (Free-Cutting Brass) (Free-Cutting Brass) SR Tip CLRM CLRS 5 6 8 10 Days to Ship 3L Selection 2M 12 12 16 16 16 20 20 20 20 25 25 25 25 4Lever Color 32 32 32 32 CLWBP B(Black) M(Orange) S(Silver Gray) 40 C(Chrome Plating) 40 SC(Chrome over Satin Nickel) CLWP CLWBC CLWC CLRM 3L Part Number 1Type CLRS d D 5 Days 5 Days Stock 5 Days 5 Days 5 Days 5 Days 5 Days Part Number 1Type 2M Male Thread Order Standard Service Non-Standard Service Quantity Regular Quantity Large Quantity Quantity 1~50 51~ Days to ship Standard To be quoted EStock lineup may vary by country. EStock: Same day shipping available upon request. Order by THA: 16:00, SGP: 12:00, MYS: 15:00 D P.75 2113 QLoad Direction CLNPP CLSPP QHow to Use Rotating Radius R Serrations 4 5 6 8 10 12 3L Selection 20 12 16 20 12 16 20 16 20 20 25 25 25 25 25 32 32 40 32 40 50 32 40 50 40 1Pull up the lever to disengage the serrations, and the clamp is unlocked. 2M R H H1 (h) S D d Number of Serrated Teeth B 48 33.5 35.5 30 3 13 10 16 1.3 65 82 92 44.5 54 64 46.5 56 66 40.5 47 56 3.5 6.5 6.5 18 21 25 14 16 19 20 24 28 1.3 1.3 1.3 2Turn the unlocked lever to desired position. 3When the lever is released, the return spring automatically engages serrations and locks again. Days to Ship Max. Load Max. Tightening Force Reference Mass (g) Pmax. (kN) Fmax. (N) CLNPP CLSPP 21 42 70 120 200 290 1.7 2.7 3.8 7 11 16 18 20 40 80 120 3 Days Stock 3 Days 3 Days EStock lineup may vary by country. EStock: Same day shipping available upon request. Order by THA: 16:00, SGP: 12:00, MYS: 15:00 D P.75 Max. Load Fmax. Max. Tightening Force Pmax. 1Pull up the lever to disengage the serrations, and the clamp is unlocked. 2Turn the unlocked lever to desired position. 3When the lever is released, the return spring automatically engages serrations and locks again. Order Standard Service Non-Standard Service Quantity Regular Quantity Large Quantity Quantity 1~50 51~ Days to ship Standard To be quoted 2114