State of the art mechanical design requires state of the art

advertisement

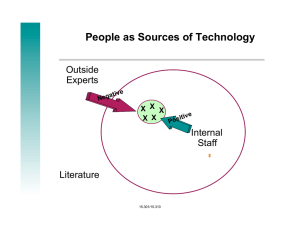

State of the art mechanical design requires state of the art solutions. P. Arras, D. Van Merode, C. Peeters Campus De Nayer, department of Engineering Technology, Lessius university college, Zandpoortvest 13, Mechelen, Belgium Email: peter.arras@lessius.eu Abstract This contribution presents the present state of design tools for mechanical engineering & design and reviews the results of the Tempus PROMENG‐project with respect to mechanical design tools. Keywords Design, engineering, CAD/CAM/CAE, Tempus PROMENG Introduction Time to market in industry has become an hot item to produce and sell new products in an economic beneficial manner. The 21st century economy moves faster than ever before, and product innovation and changes have become a daily routine in production and thus in design. Furthermore, globalization of the economy and the fierce competition on the market with other players puts pressure on all levels of production and product development in a nowadays company. The ultimate design aspect of a product isn’t changed yet: designs needs to result in a set of data for the production of the product. However, the tools for designing have changed dramatically over the last 20 years and are now readily available to any engineer. This article will discuss the design solutions for mechanical design which is promoted in the Tempus PROMENG project to renew and improve curricula for engineers in Russia, Ukraine and Uzbekistan. Results and discussion PTC’s Creo Elements as a design solution for complete mechanical design Design has shifted from drawing‐oriented design from the past to model‐oriented design nowadays. In drawing‐oriented design, the technical drawing was at the center of the design and contained a lot information. Besides the technical drawing, many other documents had to be included to contain all necessary information on a design, whether it was calculation reports, material properties or tolerance models of the design. In a model‐oriented approach, as is used in 21st century engineering design, the model itself is at the center of design. The idea is to make a virtual prototype of the design. A virtual prototype is the representation of the design on the computer with all properties of the real design. Virtual prototyping opens opportunities to virtually check the design, and analyze it for functionality, strength and other properties. Creo and Creo Elements, design solutions from PTC (Parametric Technology Corporation) (1) offer a solution for mechanical design without any compromises on functionality and tools. The aim of the software is to enable first time right design. In first time right design, we try to eliminate all errors preliminary to the first prototype or production. Therefore, a large amount of analysis tools are available in the design tool, to ensure solid and secure engineering. As we see in figure 1, the number of engineering tools available in the design solution is almost unlimited. At the heart of it, is the design database, the CAD‐model. These data are reused in all other applications to ensure data integrity and ease of use. visual represen ‐tation tolerance analysis production CAM documentation: drawings BOM virtual prototype= CAD model geometry checks numerical simulations: structural, thermal mechanism analysis Figure 1 model oriented design Applications in engineering range from making documentation, like making traditional technical drawings of the design, to numerical simulation for the calculation of forces, strength and dynamic behavior. All of this is done starting with the CAD‐model, without having to physically build the design for testing. This presents an enormous gain in time and costs ‐ since no (or not so many) physical prototypes have to be build ‐ and leads up to a first time design. In visual representation, it can be virtual pictures of the prototype or animations of a mechanism, to including light and appearance studies using rendering techniques. Here we present two examples of the flow of data through different applications to clarify the model oriented design. The first example is about a plastic ice‐cream spoon. At first the product will be designed (CAD‐model) with all of the properties of the real model. As we see in the diagram figure the terminology “properties” spans a wide range of different aspects. Geometry is the graphical representation on the computer (shape) of the design, but also contains vital information for production as there are dimensional and geometrical tolerances, and surface finish. appearance geometry physical and mechanical properties dynamic behavior virtual prototype: CAD Model Figure 2 CAD‐model is a real virtual object The physical and mechanical properties inform the system about the material of the design, but next to it, contain the structural and thermal properties, as there are Young’s modulus, yield stresses and thermal constants. For dynamic behavior properties include aspects like mechanical damping and fatigue behavior. Model containing the geometry of the plastic spoon with dimensions/tolerances and physical properties. Figure 3 model of the plastic spoon Technical drawing of the spoon for printed communication to production. Drawing containing section, dimensional information and other product specifications. Figure 4 CAD model of the spoon and technical drawing Figure 5 stress and strain calculation of the spoon Structural strength calculation of the spoon is done to verify strength and structural behaviour. If the spoon is not strong enough, design iterations can be considered. By changing dimension values, or by structural redesign of the product, an optimized shape can be found. In the CAM (Computer Aided Manufacturing) module, tool paths for the production of the mold are prepared and sent to the CNC milling machine. Figure 6 mold for plastic molding of the spoon The same association between model and application exists for complex designs build from some or many parts. The second example is the compressor head of on air compressor. Both examples are used in the curricula developed for Tempus P ROMENG. Figure 7 virtual model of an air compressor and compressor head The mechanism of the compressor can be analysed and calculated for mechanical stress. Figure 8 mechanical stresses in the crank of the compressor head. The examples show only some of the possibilities embedded in modern design software tools. Tempus PROMENG: PRactice Oriented Master Programmes in ENGineering in RU, UA, UZ. (2010­2013) The Tempus programs from the European commission supports the modernization of higher education and creates an area of co‐operation in countries surrounding the EU. Established in 1990, the scheme now covers 27 countries in the Western Balkans, Eastern Europe and Central Asia, North Africa and the Middle East. In the Joint Projects action, partnerships between higher education institutions in the EU and partner countries are promoted. They can develop, modernize and disseminate new curricula, teaching methods or materials, as well as boosting quality assurance and management of higher education institutions. (2) In this action the Tempus PROMENG project (3) was started to 1. Review / analyze / upgrade the current curricula in Electrical Engineering (MA) according to recent advances in the target field; 2. Therefore develop four new generic curricula concerning o Applied informatics and data transmission systems; CAD /CAM/CAE for Electrical Engineering; o Quality Engineering; o Environment management and Engineering. 3. Retrain academic staff in the new curricula methodologies / train of the non academic teachers / mentors from partner enterprises; 4. Pilot teaching / operation; 5. Establish ELM Offices (Engineers in Labor Market) with stakeholders support. The PROMENG project – a 3 year project ‐ has defined new curricula for engineering studies in electro‐technical engineering. Definition and development of the curricula was done in collaboration with the partner universities in the first year of the project. The second year of the project was used to install the laboratories at the partner universities and to distribute the curricula and courses amongst the partners. Also a summer school was organized to train teaching staff of the partners in the use of the design methods and materials provided. The Tempus PROMENG project promotes the use of ProEngineer/CREO (from PTC) as the state of the art design solution for mechanical CAD. Every partner university in the project is offered a CAD laboratory (existing of 12 computers) and the necessary licenses for the use of CREO‐ Elements/Pro with their students. Moreover partners at the same time get licenses for the ECAD (Electronic design) software, Altium Designer (4), for the electronic engineering students. As such, students can work with high‐end design software to complete their studies on mechanical (and electronic) design. At the same time, the project proposes curricula and provides course material with examples and tutorials to help the partner universities with at the start of the use of the new curricula. Students are motivated to start using the system, and are entitled to the free use a of school version of the design tool. Technical drawing Mechanism analysis Numerical simulation Finite element analysis design: CAD‐ model Tolerance analysis Geometrical checks Interference and clearance checking Machining: CAM CNC machining Figure 9 Creo/elements possibilities. Figure 9 represents the scheme on which the MCAD‐curricula is build. All engineering tools for designing and checking the design are available to students for use in their designs. As we can see, the construction of the CAD‐model, is only a small part of the design effort. In first time right design, the checks and calculations on the model are the most important tools. The so‐called “Aberdeen groups study” showed that companies leveraging three or more different types of simulation before actual production of parts are able to reduce the number of prototypes by 37%. (5) By providing simulation tools, as there are mechanism analysis tools and finite element analysis tools, the engineering design competences of the students can now be improved and raised to 21st century standards. Conclusions Mechanical design techniques switched from a drawing‐oriented to a model‐oriented approach. The design model in the CAD‐database serves as a virtual prototype, containing all properties of the real object. This approach enables engineers to virtually check their prototype to eliminate possible mistakes. These design techniques are part of everyday practice in the industrialized world. They lead to a shorter time on to market and as such to a more profitable way of doing business. To help partner universities in former USSR‐countries to restructure engineering studies towards a more nowadays approach, in the Tempus Promeng project western partners help out the partners in the east and in Central Asia to implement these techniques in their engineering degree studies. Curricula, course material and infrastructure is provided to give partner universities a head start in starting teaching state of the art designing techniques. References 1. PTC. [Online] [Cited: 09 10, 2012.] www.ptc.com. 2. European commission. [Online] [Cited: 01 20, 2012.] http://ec.europa.eu/education/external‐ relation‐programmes/tempus_en.htm. 3. TEMPUS PROMENG. [Online] [Cited: 09 20, 2012.] http://www.promeng.eu/index.php/about‐ promeng. 4. Altium. [Online] [Cited: 09 10, 2012.] www.altium.com. 5. group, Aberdeen. Engineering Evolved: Getting Mechatronics Performance Right the First Time. s.l. : Aberdeen group, 2008. Contact and links. Ing Peter Arras Lessius university college, Belgium Peter.arras@lessius.eu Ing Dirk Van Merode Dirk.vanmerode@lessius.eu Ing Chris Peeters Chris.Peeters@lessius.eu Uzbekistan partners: Fergana Polytechnic institute, contact Prof. Zair Usakov Karshi Engineering‐Economic Institute, contact ass. Prof. Ziyovuddin Nazarov Tashkent State Technical university, contact Prof. Zair Shamsiev