REGDOC-2.3.2, Accident Management, version 2

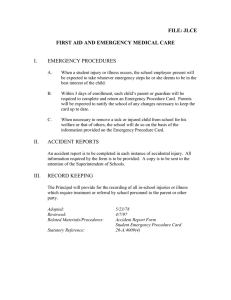

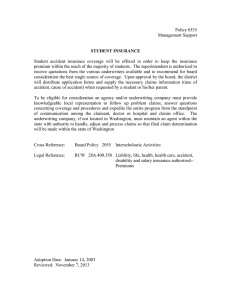

advertisement