Part 2: Good Operating Practice

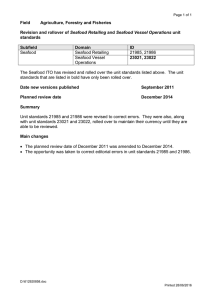

advertisement