family of six-axle locomotives

advertisement

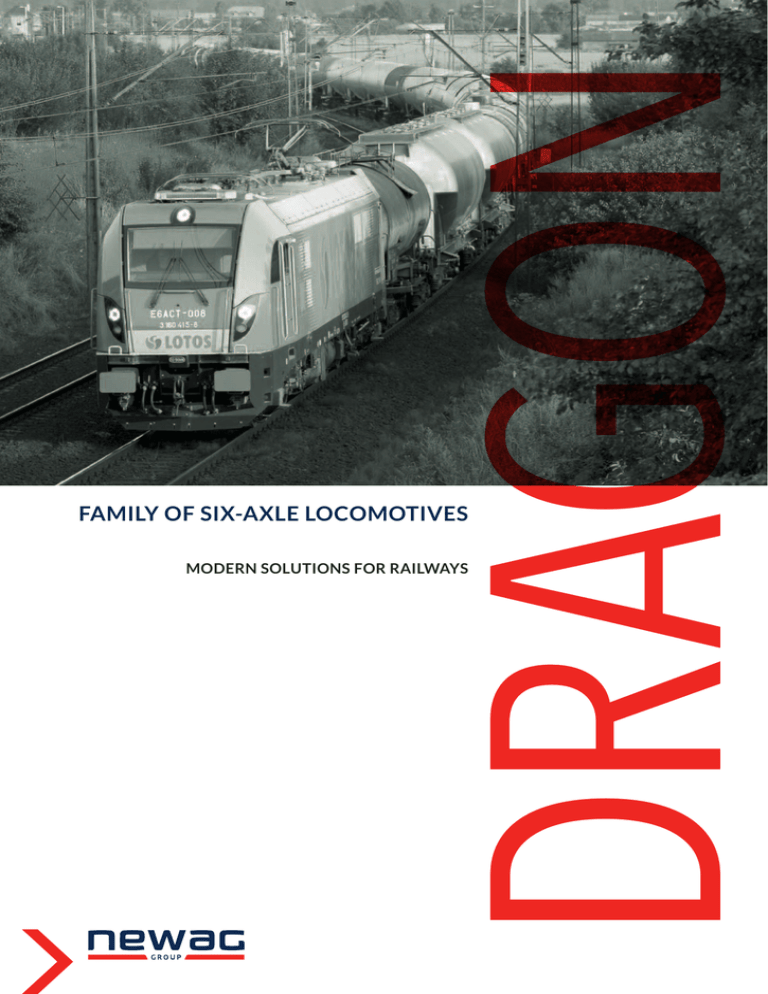

DRAGON FAMILY OF SIX-AXLE LOCOMOTIVES MODERN SOLUTIONS FOR RAILWAYS FAMILY OF SIX-AXLE LOCOMOTIVES DRAGON A modern six-axle locomotive, specially designed for heavy freight transport. E6ACT DRAGON is the first traction vehicle of our six-axle locomotive platform. The Dragon platform has been specially designed for heavy freight transport. Dragon locomotives are powerful, safe, attractively-priced, economical, and fullyequipped. These locos utilize the latest, reliable technological solutions and offer high comfort for the driver. DRAGON’s main advantage is a very high tractive power of 374 kN (or even up to 450 kN) which, together with a heavy locomotive weight, a performant anti-skid system and an individual drive of each axle, enables it to haul very freight trains. The mass of the locomotives and the axle load can be customized to customer requirements. Dragon locomotives can be supplied with an axle load of 20 t, 22.5 t or even 25 t / axle. OUR COMMITMENT: Safety, Reliability and Maintenability Our main commitment to our Customers is to deliver locomotives which are safe and reliable. Dragon locomotives are only built from components designed and delivered by world-class suppliers, whose quality and competency are unquestionably recognized. For this reason, Dragon locomotives are not only highly reliable, but also have a greatly optimized maintenance plan. This allows us to commit to a very high availability ratio, which will be completely satisfactory to every railway operator. The loco’s drive is made up of asynchronous traction motors driven by IGBT-based traction inverters. The locomotive has a modular construction which allows for tailoring technical parameters to individual clients’ needs e.g., increasing available tractive effort or implementing an additional Diesel engine to allow the loco to be run on non-electrified lines. Our designers also ensured driver’s safety and enhanced working conditions by providing an ergonomically-designed cab and driver’s desk, a double function air conditioning unit, as well as a system of cameras, a safety cage and an anti-climbing structure protecting the operators in case of collision. Dragon is equipped with microprocessor control systems adapting the operating mode to the changing conditions, allowing the operating mode to be adapted to the customer’s requirements, an on-board diagnostics system with full visual information and a data registration module which facilitates locating or predicting possible damages. Our company’s high quality standards confirmed by such certificates as e.g., International Railway Industry Standard IRIS (manufacturing, design, development and maintenance activity for the locomotives) and ISO 9001:2009 guarantee the highest level of quality. AVAILABLE OPTIONS: DUAL POWER AND MAX LOAD Depending on customers’ orders, Dragon locomotives can be equipped with an additional combustion module called “Dual Power”. This additional Diesel engine greatly increases the locomotive’s flexibility, allowing it to drive a complete train on non-electrified track sections. For customers who need a locomotive able to haul even higher loads, a Dragon locomotive can be equipped with the MAX LOAD” option, which enables an increase in maximum tractive effort from the existing 374 kN up to 450 kN. WHEELSETS monoblock wheels with a nominal diameter of 1250 mm braking discs fixed on both sides of the wheel asynchronous traction motors with power of 842 kW each axle bearing with conical roller bearings, temperature and speed sensors SUSPENSION primary level: two sets of coil springs mounted directly on both sides of the wheelset axle box secondary level: a set of large-scale, flexicoil spiral springs hydraulic shock absorbers for muffling vibrations LOCOMOTIVE BODY integral welded design safety cage in driver’s cab modular structure ergonomic, two-person loco cab modern fire detection and extinguishing system HIGH VOLTAGE ELECTRICAL CIRCUITS two or four single-arm pantographs with independent ADD system two traction converters, each equipped with 3 traction inverters and auxiliary converter module individual water cooling system for each of the supply blocks LOCOMOTIVE DIAGNOSTIC AND CONTROL microprocessor-based control system two independent panels to display drive parameters and diagnostics in each cab event recorder synchronized with the electronic speedometer LOW-VOLTAGE ELECTRICAL CIRCUITS 3x400V output voltage powering the auxiliary circuits 110V DC battery voltage top-class 100Ah FNC battery system FUNCTIONS overall control of locomotive operation fully automatic drive control with speed set by loco driver verification of loco driver’s orders entered by man-machine interface panel full locomotive diagnostics with the event recording TECHNICAL PARAMETERS AC DC DIESEL Co’ Co’ AXLE CONFIGURATION SUPPLY VOLTAGE MS DC 3 kV AC 15 kV 16 2/3 Hz AC 25 kV 50 Hz CONTINUOUS POWER 5 MW MAXIMUM SPEED 120 km/h STARTING TRACTIVE EFFORT 374 kN or TRACK WIDTH 1 435 mm SERVICE WEIGHT 119 t MAXIMUM AXLE LOAD from 20 t/axle to 25 t/axle NOMINAL WHEEL TREAD DIAMETER 1 250 mm LOCO LENGTH WITH BUFFERS 20 330 mm CLEARANCE GAUGE UIC 505-1 DC 3 kV AC 15 kV 16 2/3 Hz AC 25 kV 50 Hz 2,3 MW 450 kN (Max Load) 374 kN or 450 kN DRAGON www.newag.pl NEWAG S.A. was founded in 1876. It is one of the biggest and oldest rail industry companies in Poland, a leader in rolling stock manufacturing, modernisation and repairs. The company has extensive industry experience in manufacturing modern and fast passenger rolling stock, electric and diesel locomotives, trams and subway trains. Making customer satisfaction its priority, NEWAG S.A. places emphasis on the quality of the products and services it provides. The company was named “The company that transforms Polish industry” in recognition of its spectacular market success in competing with European rolling stock industry giants. NEWAG S.A. is the owner of NEWAG GLIWICE S.A. – a manufacturer of a family of electric and diesel locomotives: a six-axle Dragon and a four-axle Griffin. The company also specialises in repairs and modernisation of electric locomotives of all types, electric multiple units and subassemblies for rail vehicles. Both companies hold the PN-EN ISO 9001:2008 certificates, confirming that they introduced and have implemented the modern quality control system and the IRIS Rev. 02.1 certification which proves that they have implemented the international railway industry standard. NEWAG S.A. Zamiej­scowy Wydział Pro­duk­cji Loko­mo­tyw Elektrycznych ul. Chorzowska 58 | 44-100 Gliwice T. +48 32 235 82 01| F. +48 32 235 82 05 www.newag.pl ISO 9001:2008 KRS0000066315 | NIP: PL 734 00 09 400 | District Court for Kraków Śródmieście in Kraków, XII Economic Department. | Paid-up share capital of PLN 11.250.000,25