NHXMH-O/-Jhalogen-free plastic sheathed cable 300/500 V, VDE

advertisement

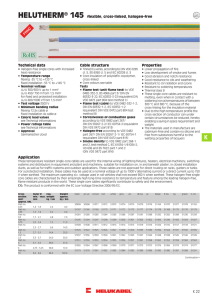

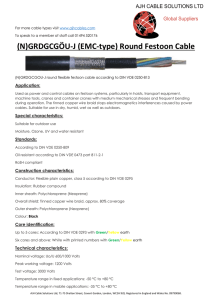

NHXMH-O/-J halogen-free plastic sheathed cable 300/500 V, VDE approved Technical data Cable structure Properties Ⴠ Halogen-free plastic-sheathed cable with enhanced characteristics in case of fire, according to DINVDE0250 part214 Ⴠ Conductor resistance (at 20 °C) according to DINVDE0295 and IEC60228 Ⴠ Max. temperature at the conductor during operation +70 °C in case of short circuit +250 °C Ⴠ Temperature range during installation -5 °C to +50 °C fixed installation -30 °C to +70 °C Ⴠ Nominal voltage U0/U 300/500 V Ⴠ Test voltage 2000 V Ⴠ Minimum bending radius single-core approx. 15x cable ø multi-core approx. 10x cable ø Ⴠ Caloric load values see Technical Informations Ⴠ Plain copper conductor, single core up to 10mm² multi-core from 16-35mm² according to DINVDE0295 cl.1 or 2, BS6360 cl.1 or 2 and IEC60228 cl.1 or 2 Ⴠ Core insulation of cross-linked polymer compound 2XI1 to DINVDE0207 part22 Ⴠ Colour code according to DINVDE0293-308 Ⴠ for 1 core cable core colour black or green-yellow Ⴠ Cores stranded in layer Ⴠ Overall core jacket of halogen-free filling compound (not for single-core cables) Ⴠ Outer jacket, flame-retardant polymer compound HM2 according to DINVDE0207 part24, halogen-free Ⴠ Jacket colour grey (RAL7035) Ⴠ LS0H = Low Smoke Zero Halogen-free. Ⴠ Flame-retardant Ⴠ Halogen-free, no liberation of corrosive or toxic gases Ⴠ Limited propagation of fire Ⴠ Low smoke development, Ozone resistant Tests Ⴠ Flame test to VDE0482-332-3, BS4066 part3/ DINEN60332-3/ IEC60332-3 (equivalent DINVDE0472 part804 test methodC) Ⴠ Corrosiveness of combustion gases according to VDE0482 part267/ DINEN50267-2-2/ IEC60754-2 (equivalent DINVDE0472 part813) Ⴠ Halogen-free according to VDE0482 part267/ DINEN50267-2-1/ IEC60754-1 (equivalent DINVDE0472 part815) Ⴠ Smoke density according to DINVDE0482 part268, HD606, EN50268-12/ IEC61034-12, BS7622 part12 (equivalent DINVDE0472 part816) Ⴠ Ozone resistance according to DINVDE0472 part805 Ⴠ Also deliverable in screened (St) version Note Ⴠ re = round conductor, single-wire; rm = round conductor, multiple-wire. Application Halogen-free plastic-sheathed cables with enhanced characteristics in case of fire are used for applications where harm to human life and damage to property must be prevented in the event of fire, e.g. in industrial installations, communal establishments, hotels, airports, underground stations, railway stations, hospitals, departmental stores, banks, schools, theatres, multi-storey buildings, process control centres etc. Suitable for installation in dry, damp or wet environments, for installation above, on, in and beneath plaster as well as in masonry walls and in concrete, not however for direct embedding in vibration, compacted or tamped concrete. These cables are also suitable for outdoor applications. = The product is conformed with the EC Low-Voltage Directive 2006/95/EG. NHXMH-O Part no. 53300 53306 53301 53307 53302 53308 53303 53304 53305 No.cores x cross-sec. mm² 1x1,5 re 2x1,5 re 1x2,5 re 2x2,5 re 1x4 re 2x4 re 1x6 re 1x10 re 1x16 rm Outer Ø min. - max. mm 5,0 - 8,4 7,6 - 9,2 5,4 - 8,8 8,4 - 10,1 6,0 - 9,5 9,6 - 11,6 6,4 - 10,0 7,4 - 11,3 8,5 - 12,4 Cop. weight kg/km 15,0 29,0 24,0 48,0 39,0 77,0 58,0 96,0 154,0 Weight approx. kg/km 49,0 110,0 60,0 136,0 80,0 202,0 111,0 160,0 232,0 AWG-No. Dimensions and specifications may be changed without prior notice. (RO01) O9 16 16 14 14 12 12 10 8 6 NHXMH-J Part no. 53350 53358 53366 53374 53351 53359 53367 53375 53352 53360 53368 53353 53361 53369 53354 53362 53370 53355 53363 53371 53356 53364 53372 53357 53365 53373 No.cores x cross-sec. mm² 3G1,5 re 4G1,5 re 5G1,5 re 7G1,5 re 3G2,5 re 4G2,5 re 5G2,5 re 7G2,5 re 3G4 re 4G4 re 5G4 re 3G6 re 4G6 re 5G6 re 3G10 re 4G10 re 5G10 re 3G16 rm 4G16 rm 5G16 rm 3G25 rm 4G25 rm 5G25 rm 3G35 rm 4G35 rm 5G35 rm Outer Ø min. - max. mm 8,0 - 9,6 8,5 - 10,3 9,1 - 11,0 9,9 - 11,9 8,7 - 10,6 9,5 - 11,5 10,4 - 12,3 11,4 - 13,8 10,1 - 12,2 11,3 - 13,7 12,5 - 15,1 11,5 - 13,9 12,7 - 15,3 13,7 - 16,6 13,8 - 16,7 15,1 - 18,2 16,3 - 19,7 16,5 - 20,0 18,0 - 21,8 19,7 - 23,8 20,4 - 24,6 22,6 - 27,3 24,7 - 29,8 22,7 - 27,4 24,9 - 30,0 27,5 - 33,2 Cop. weight kg/km 43,0 58,0 72,0 101,0 72,0 96,0 120,0 168,0 115,0 154,0 192,0 173,0 230,0 288,0 288,0 384,0 480,0 461,0 615,0 768,0 720,0 960,0 1200,0 1008,0 1344,0 1680,0 Weight approx. kg/km 130,0 151,0 177,0 209,0 163,0 200,0 238,0 300,0 235,0 300,0 345,0 323,0 400,0 475,0 485,0 603,0 720,0 850,0 940,0 1142,0 1152,0 1432,0 1800,0 1503,0 1930,0 2490,0 AWG-No. 16 16 16 16 14 14 14 14 12 12 12 10 10 10 8 8 8 6 6 6 4 4 4 2 2 2